A lot of owners want to place their life’s dream – a bathhouse – on their summer cottage plot. It needs to be located in a convenient place and equipped well. And the quality of relaxation depends on how the floor in the dressing room is arranged, since this is where people leave their clothes, relax after exposure to steam, water, and drink tea and other drinks.

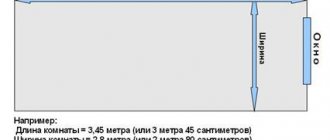

Diagram of a heated floor in the dressing room

Therefore, the floor equipment in this part of the bathhouse must be approached competently. Don’t forget about insulating the floor in the dressing room.

The waiting room is the beginning of everything

Professionals recommend installing the entrance doors to the bathhouse on the south side. This is done due to the rapid melting of snow in this place and less accumulation during snowfall. A visit to the bathhouse begins with entering the dressing room, which:

- perfectly retains cold air masses, it will be difficult for them to penetrate into the steam room;

- retains heat in the bathhouse.

According to ancient tradition, the doors and windows here are small.

When entering the steam room, it is advisable that the doors open into the dressing room to avoid excess moisture getting on the clothes left behind.

Insulating elements

The layered structure of the insulating floor coverings of the dressing room includes the following elements:

- Waterproofing. It is necessary for protection from groundwater and flood waters from the ground, i.e. from below, and to prevent the accumulation of moisture coming from the inside (steam condensation, from shoes in wet weather, from bare wet feet after washing procedures). Waterproofing layers are formed from moisture-proof roll materials (roofing felt, polyethylene film), in the form of a coating of bitumen or mastic. The second component of waterproofing protection is the impregnation of wooden parts, which eliminates the risk of rotting of the material. In addition, the so-called gluing method is used, when the joints of the elements are sealed with tape with an adhesive layer.

- Vapor barrier. When the doors to the steam room are opened, steam penetrates into the dressing room, affecting the material of the floor structure. Taking this into account, the “layer cake” includes a layer that is not permeable to steam. As such protection, films with aluminum foil are widely used. The base of the film can be polyethylene, PVC, polypropylene. In addition, in principle it is possible to use membrane materials that provide vapor tightness.

- Thermal insulation. Reliable thermal insulation of the dressing room floor is considered an urgent need. The thickness of this layer depends on the material used, but on average it is 10-15 cm. The most popular thermal insulation materials are: mineral wool, ecowool, expanded polystyrene, extruded polystyrene foam, expanded clay. One of the cheapest options is sawdust. It should be taken into account that the thermal insulation properties of mineral wool or expanded clay are significantly reduced when moisture penetrates, because It is due to the air gaps that they retain heat. Thus, when using them, the role of waterproofing increases.

Functions of the waiting room

At the request of the owner, the room preceding the steam room can be:

- an ordinary locker room with several benches and hangers;

- a fairly spacious lounge with suitable furniture and electronics;

- combination of a swimming pool with a shower in a bathhouse;

- such a wonderful device as a hydrobox.

The choice of material for insulation and flooring will entirely depend on the functions of the dressing room.

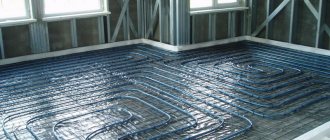

The process of installing heated floors in the dressing room

Whatever decision is made, we must not forget that the floor will always be exposed to strong moisture.

Requirements

Before building a dressing room, you need to study the requirements that the room must meet:

- There should be enough space in the room. One person needs 1.5 meters of free space.

- If the bathhouse will be used in winter, the rest room should be heated to make it comfortable to be inside.

- A high-quality ventilation system must be installed inside - natural or forced.

- The room should have furniture installed for a comfortable stay.

- The light in the recreation area should not be too dim or bright.

Often the furnace channel with the firebox is discharged into the dressing room. In this case, the area around the firebox door must be fenced off. This space should not be subtracted from the free space.

A little about finishing

The space and decoration of the room in front of the steam room are usually arranged at the request of the owners. The environment should be comfortable and relaxing. Many people prefer the Russian style.

It would be appropriate to use deciduous or coniferous wood. Using the latter, you can get an unsurpassed aroma that has a beneficial effect on the human body.

Having insulated the walls in the dressing room, you must not forget about the arrangement of the floor, especially its thermal insulation.

Subtleties of wall insulation

For internal insulation of the walls of a log dressing room, foil foam or mineral wool is used.

All work on internal wall insulation is carried out in the following sequence:

- Installation of membrane vapor barrier on wall structures.

- Installation of wooden sheathing from bars with a cross-section of 5 × 5 cm, observing a step of 55 cm. Before installation, all elements of the sheathing are carefully treated with antiseptic compounds.

- Mineral wool flooring between the sheathing elements.

- Laying polystyrene foam on a foil base and fixing it to the sheathing using staples and a construction stapler.

The next stage is connecting communications and laying electrical wiring in a plastic corrugation.

After completing the insulation work, you can begin interior decoration of the room. The traditional interior of the dressing room involves the use of natural materials - wooden lining or tongue and groove boards. Do not forget that the design of the dressing room should be combined with the general design style of other bath rooms.

What should the floors be like?

It’s unpleasant to step on cold floors after a steam room; you need to know what material is suitable for insulation and surface finishing. It should be moisture-resistant, warm, and the coating should be non-slip.

An example of wooden floors in a bathhouse

Drywall or concrete are not very good solutions. Although concrete floors are practiced, they will be most appropriate in solid brick baths. But the wood for a small, DIY bathhouse will be just right. You should think about insulating the floor in the dressing room already when laying the foundation for the bathhouse.

Design features

The dressing room is a special bath room where a person gets ready to receive the procedure and relaxes after washing. The entire design should create comfort and a good mood. The interior of the dressing room is selected taking into account the following main factors.

Furniture and equipment. In a small room, mandatory items are clothes hangers, shelves for shoes and hats, cabinets for small things and bath accessories, as well as a bench where you can sit for a while. In more “respectable” bathhouses in terms of volume, this room is combined with a relaxation room, and the corresponding pieces of furniture are located there: sofas, a table, a bar, a refrigerator, armchairs. The shape, material and color of the equipment makes it possible to give a certain gloss to the entire interior. You can make furniture yourself or pick it up in a store. Rest will become even more comfortable when there is a TV in the waiting room, where you can all watch a football match together. Don't forget about the opportunity to listen to music.

Style. Any room looks better when it is decorated in a certain style. Most often, traditional baths use the Russian approach to creating an interior. A fairy-tale plot is in demand when decorating a dressing room. Currently, modern design solutions are also highly rated.

Decor. Various fittings can give the dressing room a sophisticated appearance. A special role is given to decorative shelves, figurines, wood carvings, embossing, paintings, etc. All this makes a significant contribution to creating the original appearance of the room.

Lighting. In the waiting room, you should not rely on natural light through the window. Lamps can give the interior a cozy look and emphasize the chosen style. Of course, a chandelier, especially a large one, would be out of place in a bathhouse. Sconces and lamps in the form of candlesticks look good here.

The design decision largely depends on what type of room it is. Although it does not have the extreme conditions of a steam room, its specificity requires a special approach. You can build and decorate a dressing room yourself, but to do this you need to carefully plan all the work and choose the right material.

The dressing room is an important and obligatory room in the bathhouse. It can be very tiny (only for undressing) or larger, where you still need to make optimal use of the space, allocating a place for relaxation.

Types of wood

The wood chosen for the floor can be first or second grade. The necessary conditions are: thorough drying and the absence of fungi and mold. Coniferous boards and logs should have no more than 10% humidity. Logs or lag beams can even be made from third-grade wood. The construction of the floor, of course, can be entrusted to specialists. They know what to cover the floor with and how to carry out the insulation process. However, many can cope on their own and build a warm wooden floor for a bathhouse with their own hands.

What varnishes are available for coating in the bath?

There are types of varnish specifically designed for treating surfaces in a bathhouse. They are divided into the following types:

- for ceilings and saunas;

- to protect walls, floors and other structures in contact with the human body.

Diagram of the floor arrangement in the dressing room

Such varnishes are produced both in Russia and abroad.

Recommendations for arranging the floor

- It is necessary to try to divert the water further beyond the boundaries of the bathhouse; in this case, the floors can be concrete, tiles are laid on top, and wooden grates are placed on top of them, which can be easily dried.

- An option is possible when the boards are laid directly on gravel or sand; it is also good if there are logs raised by 10 cm. Before installation, it is important to know how to treat them in order to avoid the process of rotting.

- The subfloor does not have to be wood, as long as it is waterproof.

- When arranging the floor covering, it is not recommended to cover it with linoleum, it has a specific smell.

- The thermal conductivity of the material chosen as finishing flooring in the dressing room will no longer be so important, because the temperature above the floor level is unlikely to rise above 30 degrees.

Is it necessary to insulate the floor in the dressing room?

It is necessary to make the floor warm, first of all, so that it is not cold in the bathhouse, otherwise up to 20% of the heat will be lost. Thermal insulation will help:

Scheme of arrangement and insulation of floors in the dressing room

- quickly warming up the bath to the desired temperature;

- long-term heat retention in the room.

It is important to pay attention to the insulation of the bathhouse from the inside: walls, ceiling, and especially the floor. If there is none, then during operation, the next day the room will no longer be suitable for the next visit, which cannot be said about a bathhouse with insulated floors in the dressing room. After all, it is known that after a steam room it is very unpleasant to go into a cold room, and it is harmful to health. What materials can be used to insulate the floor in the dressing room and how to arrange everything correctly? In this video, watch the technology for making heated floors in the dressing room.

Foundation for frame construction

As a foundation for a frame dressing room, a lightweight foundation should be used: pile or shallow foundation.

Creating a shallow foundation is done as follows:

- The area is being planned and marked.

- In places where the walls of the building should be located, half-meter trenches with a width of 30 centimeters are dug.

- Sand is poured into the trench in layers and also compacted layer by layer with water wetting.

- Formwork is created along the perimeter of the trench.

- The base of the formwork is reinforced.

- The concrete solution is poured according to the level of the formwork.

- After the concrete hardens, waterproofing roofing felt is laid.

If a bathhouse with a large dressing room is being built, then you need to additionally insert reinforcement into the poured solution, which will increase the strength and reliability of the structure. In the same way, a bathhouse with a utility block can be built, which is quite practical.

Warm floor option

First, it’s worth considering the types of floor heating using the following systems:

- electrical;

- water;

- infrared.

Of course, this option is good for reputable baths, it is not cheap. At the request of the owner, it can be arranged in a small room. This requires knowledge of electrical engineering and some features:

- The use of laminate and other wooden coverings is unacceptable, since they have low thermal conductivity and cracks may appear.

- It is necessary to correctly determine the heat source.

- The work requires strict precision in compliance with the rules for electrical installations.

Insulation of concrete structures

There are many more varieties of materials designed for thermal insulation of the concrete floor in the room in front of the steam room.

An example of insulating a concrete floor in a dressing room

Their choice will depend on the financial capabilities of the owners. When choosing the necessary insulation, you must not forget that it must allow air to pass freely so that condensation does not accumulate in the dressing room. These properties have: perlite, polystyrene foam, polystyrene foam. They can be used to insulate floors inexpensively and effectively.

Perlite

This is material of volcanic origin:

- has excellent thermal insulation properties;

- does not react to substances and is fireproof.

You need to know that perlite itself is very light; when working with it, you should refrain from drafts. Perlite should be mixed with water in a 2:1 ratio, add cement to the mixture and stir constantly until water appears on the surface of the solution. It is then applied to the floor and allowed to dry for at least a week. Next, a layer of concrete is poured.

Thus, an insulated floor has a number of advantages:

- will serve for a long time;

- is reliable.

Expanded polystyrene as insulation

When using this material as insulation, you need to know that it is waste-free, this will reduce the cost of work. They insulate almost every room in the bathhouse. The level of the subfloor on which polystyrene foam is laid must be perfectly level.

Polystyrene foam is an excellent material for insulation

This method is very simple and cheap. The material itself is light in weight. Polystyrene foam tiles practically do not absorb water. They are laid in layers, the resulting spaces are sealed with polyurethane foam or the foam itself.

The process of floor insulation with foam plastic

What other materials exist for floor insulation?

Many builders who want to insulate the floors in the dressing room should know that there are other types of materials designed for this purpose. These are:

- glass wool or special felt for construction with bitumen impregnation;

- expanded clay sand;

- gravel;

- boiler slag.

Materials

When choosing cladding for a dressing room, a number of requirements must be taken into account. For example, she should:

- protect walls from moisture;

- mask heat and waterproofing;

- compensate for heating of surfaces, eliminate burns;

- provide therapeutic and prophylactic effects;

- decorate the space;

- be environmentally friendly, practical, heat-intensive;

- have fire-fighting qualities;

- be easy to clean, repair, and ventilate.

The finishing of the dressing room inside is best made from natural material. Wood is an ideal solution; it is not afraid of heat and has high thermal insulation properties.

At the time of purchase, finishing boards must be dried to a moisture content of 10%. In addition, you need to take material that is subject to heat treatment.

When choosing the best cladding option, you need to take a closer look at its characteristics. It must be safe, durable, inexpensive, and easy to process. At the same time, the material for finishing wall, floor, and ceiling surfaces may vary:

- oak is durable, has antiseptic properties, and has a beneficial effect on the cardiovascular system;

- linden promotes relaxation, provides a high level of moisture and noise absorption;

- larch is difficult to process, but durable, resistant to moisture, helps normalize blood pressure;

- pine has bactericidal, immunostimulating properties, is not afraid of moisture, mold, and does not deform;

- aspen has a calming effect, it is moisture resistant, but requires additional processing.

For walls and ceiling

It is better to sheathe the walls and ceiling inside the dressing room with natural wood. Suitable lining, tongue and groove boards made of larch, oak, linden, cedar, aspen. The lining can decorate a suspended or false ceiling. The material allows the installation of built-in lighting.

When covering wall surfaces from the inside, you can use coniferous wood. This will allow you to inhale an incomparable woody aroma. It will disinfect the air and have a beneficial effect on the health of users. However, preference is usually given to deciduous wood (linden, birch, alder).

If you want to recreate the Russian style in a bathhouse, you can use decorative panels to look like rounded logs. The cladding of a block house to look like a natural log house is distinguished by the originality of its relief. If you want a more modern solution, you can decorate the walls with plank.

Some people use OSB for cladding. Decorating the walls of the dressing room with plastic panels is done less frequently. Despite its availability, variety of colors, moisture resistance, PVC has a lot of disadvantages. In the humidity conditions typical of pre-bath rooms, the panels are deformed and subject to mechanical destruction, in addition, they do not provide a unique sauna aroma, as when paneled with natural wood. Covering wall and ceiling surfaces with panels is resorted to only in case of financial constraints. At the same time, mosaics and tiles are quite acceptable options for decorating the walls of the dressing room. They can accentuate the space of different functional areas of the room.

Stretch ceilings in the dressing room are rarely used. The PVC film used, impregnated with polyurethane, withstands temperature fluctuations and does not fade during use.

However, if ventilation is poor, it is not suitable for installation in a damp room. Otherwise, mold cannot be avoided.

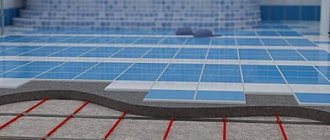

For floor

The floor finish must be moisture-resistant, wear-resistant, and comfortable to use. Preference is given to natural coatings with water drainage and waterproofing. In order to increase comfort, builders resort to a “warm floor” system and use insulation.

You can cover the floor of a frame dressing room with wood, using larch or oak boards, treating the floor material with an antiseptic. Someone covers the floor with wooden plastic.

Sometimes the floor is lined with stone, although in practice it is a cold sheathing material. However, it draws out the negative perception of wood when it is abundant in the cladding. The stone combines well with wood of different species. Its use for covering the wall adjacent to the steam room is quite justified. When heated, the stone accumulates heat in the dressing room, providing a comfortable microclimate inside the bath.

The floor can be covered with ceramic tiles. This is the optimal solution when installing a “warm floor” system, providing the required level of waterproofing.

The use of ceramic cladding reduces the formation of a source of condensation from the space under the floor.

Do not cover the base with rapidly heating materials. Others release toxic substances when the temperature rises. From this point of view, when decorating the floor, it is worth abandoning linoleum and some types of paint.

The ideal cladding option that creates the desired microclimate inside is a combination of wood (for walls) and tiles (for floors). Laminate is not the best cladding solution.

Exterior decoration

You can decorate the outside of the dressing room using decorative bricks, cover it with metal or vinyl siding, imitation wood, block house, wood paneling, plastic panels. Each type of raw material for exterior cladding of a building has its own characteristics.

- Siding is fireproof, resistant to fading and temperature changes. It has low moisture absorption, ease of installation, resistance to deformation and mechanical damage.

- Imitation timber is environmentally friendly, aesthetically pleasing, and durable. It is distinguished by a variety of standard sizes, a high level of thermal insulation, and resistance to chemicals and destruction.

- The block house is environmentally friendly and natural, and has an affordable price. It is considered a simple and convenient material to install, has a pleasant appearance, and convenient sizes. Installed on the frame.

- Lining is durable and is considered a traditional material for the outer cladding of bathhouses and dressing rooms. Board cladding is a traditional option for most buildings.

- Plastic panels are varied in the choice of color and are resistant to rust and rot. Frost-resistant, easy to maintain, but have low air permeability and are flammable.

We recommend: DIY toilet installation

Insulation of a wooden floor

The classic option is to insulate a wooden floor. You can do it yourself, the technology is quite simple.

Example of floor insulation with vapor barrier

Wooden blocks are nailed to the joists, which are the frame for the subfloor. An unedged board is also suitable for it. In order to protect the wood and insulation from moisture, a vapor barrier or roofing felt is laid. An excellent vapor barrier is foil material. The insulation is installed above the subfloor. You can use slag, mineral wool, sand here, and recently it has become popular to insulate the floor with penofol, polystyrene foam, polyurethane foam, and expanded polystyrene.

Then a layer of waterproofing is placed and a floorboard or lining is placed on top. Video on installing a heated floor in a bathhouse.

Frame construction: ease of work

Do not forget that first all wooden elements are treated with an antiseptic and fire retardant. The work is carried out as follows:

- the lower frame is attached to the foundation with pins, and there is a beam on it, the cross-section of which is 10x10 cm;

- first, corner support bars are installed, their verticality is checked with a level, then intermediate ones are fixed, their pitch is 80 cm;

- the top trim is attached;

- external corners are additionally fixed with braces;

- floor logs are made from unedged boards;

- elements for door and window openings are installed;

- the frame is upholstered with waterproofing and windproof membrane material;

- The frame work ends with the outer cladding.

After building the frame, they move on to building the roof.

Some important points

Many owners are concerned with the question: is it necessary to treat the wooden structures of the building and with what? Either it will be an antiseptic solution or a special varnish that will extend the life of the products. It is not advisable to do this in a steam room, because at high temperatures the chemical components will evaporate. But the wooden floors in the dressing room must be impregnated, protecting them from rotting processes, the formation of mold and fungi.

Products for coating wooden structures, in particular floors, are as follows:

- Varnishes - they contain antiseptics that prevent the spread of putrefactive bacteria. But they are also suitable for decorative finishing;

Example of a varnished floor in a waiting room - Colorless impregnations contain phytoncides that protect wood from mold, rot, etc.;

- Antiseptic solutions contain toxic fungicides. After their application, further painting of the material is expected.

A qualified approach to equipping the floor in the bathhouse and dressing room is one of the important components that can influence the amount of heat in the bathhouse and its long-term preservation.

Acrylic-based antiseptics

Acrylic products not only protect wood, but also give different shades

Acrylic-based antiseptics help prevent the development of almost all types of pathogens. Before application, they are diluted with water, after which they are applied to walls, joists and floor boards. The distinctive features of such antiseptics include:

- Resistance to temperature fluctuations, which allows surface treatment not only in the rest room, but also in the washing room or steam room;

- Resistance to moisture, which helps prevent wood swelling, which subsequently leads to warping;

- High vapor permeability, thanks to which the wood can “breathe”.

If desired, this impregnation can be applied with your own hands. But before breeding and processing wooden surfaces, it is recommended to use protective glasses and gloves that will protect the skin and eyes from contact with the synthetic product.

Drying oil for processing and floors

As a result of polymerization, drying oil forms a very durable protective film

Drying oil is a film-forming composition that is made on a plant basis. Drying oil can be used to treat wooden coverings in the following rooms:

- washing;

- steam room;

- rest room;

- dressing room

As a result of polymerization, the liquid composition forms a very durable protective film that prevents moisture from entering the wood. Drying oil is used to treat coatings not only for disinfection, but also to prevent the appearance of splinters.