Purifying water with homemade filters is a standard activity for camping and field conditions. After all, it is unwise to carry huge bottles on yourself due to the incredible physical costs. In addition, this is irrational due to the almost ubiquitous presence of the liquid component of the earth’s shell necessary for the body.

The liquid people need is indeed available everywhere, but its sanitary condition is not always compatible with consumption. But you can make a very effective water filter with your own hands even on a multi-day route, being far from populated areas, with a minimum of available tools.

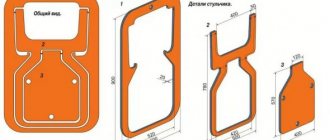

We will introduce you to the most effective and easy-to-implement devices for purifying dirty water. Here you will find diagrams, recommendations and a detailed description of manufacturing technology. The material offered for review is systematized, supplemented with visual illustrations and video instructions.

How to make a water filter

The easiest way to purify water is to pass it through a layer of charcoal.

Most of the impurities remain in the filter, and the water is safe to drink. Many jug filters operate on the principle of carbon purification. However, coal cannot rid water of chemical elements. Another inconvenience is the need to regularly change the layer of coal through which the water passes. Changing the filter is necessary every three days, just enough to solve the problem of water filtration in the house.

How to make a carbon filter?

- It is necessary to burn a sufficient amount of birch firewood in a metal container, such as a tank.

- The coals formed after combustion, after they have cooled, are placed in a funnel.

- The funnel is placed in a container to collect filtered water, and water is poured into the funnel itself from above.

Remember that such a filter cannot be used on an ongoing basis; the carbon layer quickly becomes clogged and requires replacement.

You can improve the carbon filter and make it more efficient by making a multilayer filter. In this case, a layer of sand is added to the coal layer. You will also need a piece of gauze or loose fabric.

- You need to make coal, as in the first case.

- Several layers of fabric or gauze are placed in the neck of the funnel.

- A sufficient layer of charcoal is poured onto the fabric, and a layer of river sand is poured onto the charcoal.

- It is better to pour a layer of gravel onto the sand, which, in turn, is covered with a layer of gauze.

The further operation of the filter is the same as in the first case. True, here the cleansing will be much more effective. The only negative is the length of time it takes to manufacture such a filter. The filter agents themselves also need to be changed frequently.

The third version of the carbon filter was most common among Soviet tourists and even soldiers during the war. Today, an activated carbon tablet is included in any kit for a foot soldier; it allows you to purify water for drinking in field conditions.

As you may have guessed, you can make such a filter from activated carbon. So, let's make a water filter with our own hands.

- A layer of gauze or cloth is placed in a funnel or an inverted plastic bottle without a bottom and with a hole in the lid.

- Activated carbon tablets are poured onto it.

- Water is poured onto the coal, which, passing through a layer of agents, is purified.

One standard tablet of activated carbon can purify a liter of water, take this into account when calculating. In any case, there should be several tablets in the filter for the cleaning to be most effective.

Troubleshooting methods

Black or yellow water in the wells on the site is not a reason to refuse a free source of liquid. Complete purification of well water at your dacha with your own hands is possible. Some expenses and good preparation will help you complete it in a short time.

A set of well cleaning works

The first way to purify water is to use a bottom filter in a well. It also requires attention when cleaning.

A shield made of aspen, oak or larch is placed at the bottom. River sand, crushed stone and coarse gravel are poured on top. Everything is laid in layers of 20-30 cm. They filter the inflow and need periodic cleaning or complete replacement. Often, summer residents try to install a filter cartridge when thoroughly cleaning their wells.

If you select a FP of the required diameter, it requires installation on a support ring, which means almost complete dismantling of the well. But FP is used in wastewater treatment. These are flows in a different direction. To use it, you need to make something like a water jacket in a well. Collect filtered water from the resulting layer. This requires a lot of expense.

Why and how to make a bottom filter for a well:

What is a clay castle

What to do so that after digging and building the trunk, water from the top layer of soil does not penetrate into it. After the upper part of the rings is installed in place, we develop the soil around it. We remove the soil to a depth of 2 m and a width of at least 1 m. You will get a funnel with a slight slope from the head.

We fill the resulting opening with clay, kneaded to a dough consistency. Sprinkle the upper part with crushed stone. We compact the crushed stone in a layer of 25-30 cm, with a slight overlap along the entire diameter. After constructing the formwork, we pour concrete onto the prepared site. Such a clay castle creates an obstacle to drainage runoff and protects the upper rings from soil shifts.

How to make a clay castle for a well:

We disinfect the well

It is mandatory to disinfect the structure. There are three main types:

- preventive;

- periodic;

- emergency.

Periodic disinfection is carried out taking into account seasonal fluctuations in the composition of the liquid and the nature of the structure’s contamination.

Emergency cleaning allows you to clean up the source if the color or odor of the water changes. And also in the presence of impurities of iron, salt in the source water and other harmful chemical elements.

UV treatment

Equipment for water purification, using the ultraviolet part of the light spectrum, is located near the surface of the water. This process is suitable for gravity drainage and kills a wide range of bacteria. But it cannot change the chemical composition of the liquid.

It is an additional method of disinfecting wells. It cannot be used as an independent method in our case.

Step-by-step cleaning with active chlorine

It is best to purify water from wells in dachas using chlorination methods. Let's divide them into two stages:

- Primary (pre-chlorination).

- Finish (post-chlorination).

Prechlorination involves adding large amounts of chlorine directly to the source. At this stage, the entire structure is processed.

We treat the walls of the well with the resulting solution, using for this purpose a long pole with a brush at the end. Pour into the water, stirring, a chlorine solution of high concentration - 350-400 mg/m3 of water. We calculate the volume of the water column using the formula: Vcolumn = 3.14R2H, where:

- R – radius of the well, (m);

- H – height of the water column, (m).

Close the well head tightly for a day. During this time, chlorine will enter into an oxidation reaction. Absorbs harmful impurities into flakes and sediment, performing the process of coagulation and deferrization. Pathogenic bacteria will die. The chlorine smell will disappear. If it does not disappear, we repeat the procedure.

After the first stage, the walls are mechanically cleaned, water is completely removed and the bottom is cleaned.

The second stage, final chlorination, is the use of chlorine only for water purification. The residual concentration of the substance in water should be 0.3-0.5 mg/l, when chlorine interacts with water for 30 minutes.

The dose is determined experimentally, depending on the composition of the water. It’s easier to take samples and take them to the laboratory, where they will select an individual dosage. A week after post-chlorination, boil water before use.

We talk in more detail about the ways in which you can clean a well with your own hands in this material.

The main condition for high-quality cleaning is filter media

The working container is selected so that all the necessary filling fits into it. A variety of components are used for absorption: artificial and natural. The latter have higher filtration capabilities. These include:

- sand from a river or quarry;

- gravel;

- zeolite;

- Activated carbon.

For initial rough cleaning, cotton fabric materials or even paper are usually used. According to hygienic requirements, they are very impractical: they are constantly in a humid environment, subject to rotting, and an unpleasant odor appears. The very structure of such filters contributes to almost instant contamination, which requires frequent replacement.

The best material for filtration is activated carbon

Artificial materials have the best performance in this regard. One of the most preferred is lutrasil. It is not afraid of moisture, dirt accumulates to a lesser extent than on cotton. Of the other fabric filters, the synthetic one used in coffee machines is the cheapest.

Zeolite is also a mineral, but has a disproportionately greater filtration effect. It cuts off metal and salt impurities - everything that comes into the water from the agricultural industry: pesticides, herbicides, mineral fertilizers.

Zeolite used in homemade structures

Activated carbon has found the most widespread use in homemade devices. It retains mineral formations and toxic substances with equal quality. Another advantage is that water after passing through it becomes transparent, unpleasant odors and microorganisms are eliminated.

Cooking charcoal yourself is not particularly difficult. Wood of any species is used, except coniferous. Birch has the best qualities. Firewood is loaded into a metal container, which is placed on the fire, ideally in a stove. When they are red hot, stop heating and allow to cool. If you overdo it, valuable filtration properties are lost.

How to make a filter for a well with your own hands

Well filters are installed on the bottom pipe and lowered into the source along with the casing; making them yourself is pointless if you are not involved in downhole drilling. The problem is relevant for drilling organizations and individual drillers who want to make an inexpensive, high-quality filter with high characteristics and parameters that are most suitable for a specific well (depth, soil composition).

Gravel

To install a gravel filter with your own hands, proceed as follows:

- First, the size of the gravel backfill is selected taking into account the granulometric composition of the aquifer sand. To do this, contaminated water is removed to the surface, and after it is filtered, the size of the sand particles is determined.

- The gravel fill should have a granule size approximately 8 times the minimum diameter of the sand particles or 5 times their maximum diameter. For example, if the dimensional parameters of aquifer sand are 0.5 - 1 mm, the backfill should have dimensions of 4 - 5 mm, with sand grains 0.25 - 0.5 mm. gravel sizes are 2 - 2.5 mm.

- The gravel fraction selected by size is immersed in the well bottom using the free-fall method in a water flow; its minimum thickness is 50 mm.

- Multi-layer backfilling is allowed, starting with larger fractions and moving on to small particles.

Rice. 11 Sprinkling the casing

Hole filter for perforated well

You can make a perforated filter yourself without much effort if you have a simple tool (a drill with a suitable drill bit). When installing a perforated filter from 125 HDPE casing pipe, proceed as follows:

- Markings are made, noting the distance from the bottom plug to the end of the sump about 50 cm, the length of the filter part with perforation is 110 cm.

- Draw 4 equally spaced lines along the pipe, drill 4 rows of holes with a diameter of 20 - 22 mm. feather drill for wood - they need to be done in a checkerboard pattern. The distance between them should be about 10 cm.

- The burrs formed during the drilling process are cleaned with sandpaper, or they can be scorched with a gas torch.

If the depth of the source is small, the number of holes can be increased to 8 rows, and also holes can be made for almost the entire length of a 3-meter pipe, their number will be about 20 - 25 pieces in a row.

Rice. 12 DIY holey filter

Slotted

The manufacture of a slot filter is rarely carried out independently - the process is labor-intensive and time-consuming. When installing it, proceed as follows:

- Make markings along the pipe surface, dividing it into 8 equal-sized sectors, drawing 8 lines and retreating 50 cm from the ends.

- To cut slots, take a grinder with a disc for metal or concrete, but it should be taken into account that the slots from the disc for metal will have a smaller width.

- Cutting is done in increments of 10 mm. by the width of the sector between two lines, alternating free longitudinal sections with cut ones. In this case, stiffening ribs 20 mm wide are left between the slots. through 10 – 20 lines.

- After cutting out 4 longitudinal segments with slotted areas, their surface is cleaned of burrs with sandpaper.

Rice. 13 Plastic pipe with slots

Wire mesh filter systems

Making a wire filter at home is not possible - to ensure a gap between the turns of the V-shaped wire is about 0.5 mm. it requires welding to a rigid frame from the inside at thousands of points.

At home, mesh filters are most often made by proceeding as follows:

- They take as a basis a casing pipe with round holes made using the technology described above. A nylon cord or stainless steel wire with a circumference of about 2–5 mm is wound onto its surface. with a distance between turns of 50 - 100 mm. The ends of the winding are secured with brackets, screws or screwed with adhesive tape.

- A metal or synthetic mesh is placed over the winding; to fix it, a second outer winding of wire or synthetic cord is used.

Rice. 14 Making a strainer

Design features of industrial and home-made installations

Purified from harmful chemical and bacteriological impurities, life-giving moisture is considered accessible to people only after filtration. In cities, due to the wear and tear of communications, it reaches consumers with rust, lime deposits and other additives. In such conditions, even an aquarium needs to purify the water, otherwise the fish will not survive.

If the house is connected to water supply, the owners use washing machines and dishwashers, which react even more sensitively to water quality. Manufacturers equip their products with mesh filters, which provide rough cleaning, but allow small particles up to 5 microns to pass through. This is harmful for many household devices; they require additional fine filtration.

Simple household filters for the home

Industrial units are produced separately for cold and hot water; it is unacceptable to use them for purposes other than their intended purpose. In addition, a pressure regulator is required if pressure drops are observed in the pipes. All such installations have one or more cartridges plus a settling tank in the form of a flask or glass. The quality of water depends on the material used and the cell sizes of the working elements.

All of them require periodic replacement, because harmful impurities accumulate.

The cost, depending on the design, is sometimes very impressive. A DIY water filter allows you to get rid of unnecessary financial expenses, and the quality of cleaning can exceed some industrial designs.

A simple homemade device

Sand traps

In this facility, wastewater is purified from large particles, the size of which is at least 250 microns. In fact, these are primary settling tanks, because if sand is not first removed from any wastewater, then further cleaning will be difficult due to the fact that sand will begin to clog treatment facilities. The operating principle of the sand trap is based on influencing the speed of movement of large particles in the general flow.

Sand traps use several cleaning methods:

- Horizontal flow movement with a rectilinear direction.

- Horizontal flow movement in a circular direction.

- Vertical flow movement.

- Translational-rotational flow.

Materials for filtration equipment

The efficiency of cleaning depends on the quality of the filtration material; a limited number of them are used in wells, the main ones being:

Stainless steel. In addition to strength, the material has flexibility and excellent corrosion resistance; the durability of stainless steel is tens of years. It is used to make strong meshes and wires that are mounted on top of the pipes. The disadvantages include the high cost of stainless steel products.

Plastic. Plastic is another common material for the manufacture of filters in water sources; meshes and cords are made from it, which are cheaper than stainless steel. Plastic is corrosion-resistant and inert to most chemicals, easy to install and has a long service life. The disadvantages of plastics include low physical strength, which does not allow them to withstand heavy loads at significant depths.

Non-ferrous metals. Copper, brass, and bronze can be used in the manufacture of water filters without any restrictions; they have high corrosion resistance and a long service life. Soft alloys with a high copper content are recommended for use at shallow depths to avoid deformation from strong water pressure. In the manufacture of filter elements, brass mesh and thick wire made of brass or copper are used.

Rice. 4 Filter for casing pipe - installation in the well

Steel. Steel filters are susceptible to corrosion and can be used as a budget option in water intake sources intended for technical needs. Increased content of iron oxide in water as a result of iron corrosion of more than 0.3 mg. per liter leaves a yellow residue on water main equipment and plumbing fixtures. Galvanized steel also rusts over time to form zinc oxides, which are harmful to human health - this material is not recommended for use in water filter elements.

Thin-layer sedimentation tanks

With a large depth of water in the settling tank, it takes more time for a particle to float to the surface . Therefore, it is difficult to improve efficiency in conventional oil traps.

Increasing the size of settling tanks worsens hydrodynamic characteristics. In a thin layer, the process of floating or settling of particles is much faster at the same water speed. This conclusion led to the construction of sedimentation tanks with a thin layer of water. Such devices are divided into two types:

- tubular settling tanks;

- plate sedimentation tanks.

Pool water purification

Do-it-yourself sand filters allow you to filter a fairly large tank. They are easy to set up, and their cost is half that of store-bought ones. The structure consists of the following parts:

- container with a wide neck;

- pipes for water supply and intake;

- quartz or glass sand as a filter.

It requires a plastic reservoir, usually a barrel, at the bottom of which there is a fine mesh with cells smaller than sand. Its fraction is from 0.4 to 0.8 mm.

The first one changes after 2 or 3 years. The second one will last 5 years, but its cost is higher. Multilayer media is also used when the filter elements alternate from larger to smaller sizes or gravel is included.

Dirty water is supplied into a sealed container from above, suspended mineral and organic particles remain in the filter, and clean water flows into the pool from below. To operate the device, a pump with a power of 150–300 W is required, which is usually installed in front of the tank. Then he pushes the liquid out. If you place a pump after a container, a vacuum is created in it and water is sucked in. There is no fundamental difference in the two schemes; the procedure is ensured in any case.

For the first option, you need a container with reliable tightness that will withstand the pressure created in it. An expansion tank with a membrane is often used. This is removed and the inside of the body is painted to protect the iron from rust.

Using a plastic barrel with a volume of at least 60 liters for such purposes is also possible. But not every container of this type can withstand pressure: the lid often breaks off or the sides split apart at the joints. In this case, it is advisable to use a pump connection diagram after the filter. The lid is additionally sealed to prevent the slightest air leakage. The master class will show you the details in more detail.

To allow water to flow in and out, fittings are cut into the housing and the connection points are carefully sealed. A coarse filter is installed at the feed: an inexpensive cartridge or bottle neck with a mesh. A plastic pipe with holes is mounted on the back side of the filter tank, covered with non-woven material, through which even fine sand does not penetrate, and clean water flows into the pool.

If a pressure circuit is implemented, be sure to install a pressure gauge on the fitting in the tank lid or between the pump and the filter. It is more reliable to use a manifold that has a pressure sensor, air vent and safety valves. If the suction principle is used, a tap is cut into the lid. When the system becomes airy, just open it and bleed the air.

A filter with top water intake is placed below the level of the pool mirror. Taps are installed on both pipes to regulate the operation. The discharge and collection sites are located as far away as possible. Before turning on the pump, the tank is filled with liquid manually.

Type

Static settling tanks

Static settling tanks are used to separate various oil product contaminants from water. This is a long process, up to two days . And the flow of wastewater is very uneven.

Therefore, for such wastewater treatment, large-volume buffer reservoirs are built. Since it is difficult to separate floating impurities without pumping, a scheme with at least two buffer reservoirs is used.

The operating algorithm is as follows:

- filling;

- sucks;

- pumping out.

Buffer tanks level out the unevenness of the volume of wastewater entering treatment plants and make it possible to significantly reduce the concentration of oil.

The main advantage of such tanks is their tightness. They are built using the industrial method, which dramatically reduces construction time.

Why do you need a well filter?

The need for filtration inside the well is caused by the following circumstances:

- Purified well water, in contrast to contaminated water, increases the service life of submersible and surface well pumps - impellers, membranes and other moving parts wear out less.

- Filtered water, when further passing through the pipeline, pollutes less filters in water purification systems located in the water supply system - this allows you to save money on the purchase of new cartridges and increases their durability.

- Filtration increases the service life of automatic control systems for pumping equipment - pressure and idle speed switches, hydraulic accumulator.

- Purified water contributes to better permeability of the water main and increases the service life of plumbing units (check valves, ball valves, mixers).

- Additional well treatment contributes to better quality of drinking water used in households.

Rice. 3 Filter element design

Assembly technology

The peculiarity of such a filter (unlike a pool filter) is that it is not a separate structural part, but is manufactured directly at the end of the last bend of the pipe assembly installed in the barrel. The specific model is selected mainly based on the characteristics of the soil and the depth of the well.

In some cases, to increase the performance of the filter, you can use a piece of pipe with a larger cross-section than the main line, which connects to the last elbow. Or increase the number of perforations and the sizes of holes (slots).

Simple hiking water filter

In order to design a water filter with your own hands, we will need:

- two identical plastic bottles with caps;

- plastic tube with a diameter of the neck of a bottle;

- glue gun;

- a drill with a feather drill, or a strong, sharp knife.

Now let’s find out how to make a water filter:

- Unscrew both caps from the bottles and glue them together along the front side using hot glue from a gun.

- Screw a pen drill with a diameter of 20 mm into the drill, and drill a through hole in the glued covers. In extreme conditions, you can cut through it with a camp knife, but you will have to tinker a little longer and be precise.

- Insert a plastic tube into the resulting hole. Its length should be slightly shorter than the height of the plastic bottle.

- Take your bottles and screw them into the caps on both sides. One of the bottles will then be placed on a plastic tube.

Your DIY water filter is ready! But how to purify water with it? Let's check:

- Unscrew the empty bottle from this device and fill it with water that needs to be purified. Take any cloudy water with mud to better notice the difference.

- Place the bottle on the table and screw the second part of the structure into it through the cap.

- Leave the bottle somewhere in the sun or, if possible, cover it with a black cloth to enhance heat absorption. Or you can immediately use a black plastic bottle.

- After a few hours, check how our filter is doing. You will find that the liquid evaporates from the first container and passes through the tube into the drainage container, settling on its walls and flowing down. And the condensed water looks absolutely pure, just like bottled water from the store!

- When a sufficient amount of water has collected, unscrew the water collection bottle, turn it over and unscrew the cap with the tube - that’s it, you can enjoy clean water! It’s true that it’s better to boil it before using it if you have heat-resistant dishes and the ability to make a fire.

If you try to make this filter yourself at home, then no problems should arise. In extreme conditions, you will, of course, have to use a knife instead of a drill, and think about where to get a plastic tube, or what can replace it. But water bottles and superglue are usually carried by any travelers.

We make a water filter with our own hands to purify well and borehole water

The problem of drinking water purification is becoming relevant not only for city residents, but also for residents of rural areas. To make water from a well or borehole suitable for drinking, you can make a water filter with your own hands.

Why filter well water?

It would seem that what could be purer than well water, sung in ancient Russian epics? Alas, modern reality is not at all like a fairy tale. Water in private wells can be contaminated with a variety of substances, such as:

- nitrates;

- bacteria and pathogens;

- impurities that impair the taste and quality of drinking water.

For the excess of nitrates, i.e. salts of nitric acid, in drinking water, we should “thank” farmers who widely use fertilizers and pesticides when growing agricultural products. Some of these substances inevitably seep into the aquifer.

The simplest filter can be made from a plastic bottle with filler

Poor quality and damage to equipment lead to the fact that the water contains an admixture of rust, sand, etc. Drinking such water is simply unpleasant. Therefore, it is recommended to buy or make at least a simple water filter for your dacha.

Review of filtration materials

The principle of operation of the filter is simple and well known to everyone. It is necessary to pass water through a layer of filtration material. The filler can be different:

- textile;

- cotton wool;

- paper napkins;

- gauze;

- sand;

- grass;

- coal;

- Lutraxil.

You can buy charcoal in a store or make it yourself

For regular use, other materials are used, mainly charcoal. It is laid in layers, alternating with sand, gravel, grass, etc. Lutraxil is a synthetic material made from polypropylene fibers.

The simplest filter from a plastic bottle

The use of ordinary household filters for a small garden is rarely convenient. Such devices require the supply of water from a water supply system under a certain pressure, and not every dacha has a water supply system with suitable characteristics. Pitcher filters purify water too slowly.

In addition, you will have to constantly change cartridges. Therefore, a homemade water filter made from a plastic bottle and a bucket with a plastic lid may be the most acceptable option.

A homemade water filter can be made from a regular plastic bottle.

This filter uses carbon and ordinary fabric napkins as a filler.

The simplest filter for a summer house is made as follows:

1. The bottom of a plastic bottle needs to be cut off.

2. Cut a suitable hole in the plastic lid of the bucket.

3. Insert the bottle into the hole with the neck down.

4. Fill the filter with filler.

On top of the receiving container you need to place a 10-liter plastic bottle with a filler hole in the bottom. To make a filter, you can use a 40 mm piece of polypropylene pipe. The top and bottom of the pipe are covered with pieces of perforated plastic, which is recommended to be fixed with hot glue. The pipe is filled with charcoal.

Such a homemade filter should fit tightly into the neck of a standard ten-liter bottle. All that remains is to connect the receiving tank with the filter and the bottle. You can immediately fill the installation with a full bucket of well water, which will be filtered after a few hours. This way there will always be a supply of clean drinking water in the house.

Three-flask design for full-fledged water supply

Happy owners of a full-fledged water supply in a private house can make a three-flask homemade filter for water purification. To do this you need:

- Buy three identical flasks.

- Connect the flasks in series with two quarter-inch nipple adapters. In this case, it is necessary to strictly adhere to the in/out designations in order to maintain the direction of water movement. Nipple threads should be sealed with FUM tape.

- The outermost holes of the flasks are connected to the quarter-inch tube using straight adapters.

- Connect the filtration system to the water supply with a tee, which is cut into the water supply using a 1/2” connector.

- At the outlet, a standard drinking water tap is connected to the filter system.

- Fill the flasks with filter material. You can use a polypropylene cartridge, carbon filter and anti-scale filler.

This is interesting: Walls in the corridor - finishing options

Operating principle of solenoid valve

The operating principle of such fittings is quite simple, it is as follows. When the valve is closed and the coil is de-energized, the piston and valve diaphragm are in close contact with the valve seat due to the mechanical action of the spring. In the process of applying electrical voltage to the coil, the valve with an electromagnetic drive begins to gradually open. This occurs through the influence of a magnetic field that is created in the valve coil.

When selecting a solenoid valve, it is recommended to take into account its design features and technical characteristics

It is important to remember that not all designs allow the movement of the working environment in any direction. Some models are designed to work in one direction only

If this condition is not met, the valves lose their functionality partially, and in some cases, completely.

Home water filter

The most basic household water filter, which you can make from scrap materials at home, is a filter made from cotton wool and paper napkins.

Please note that such filtration can only free water from dirt and debris, but not from chemical impurities, which, in some cases, can be hazardous to health.

- You need to prepare a bottle or funnel, as we did in previous cases.

- The bottle is filled with several layers of cotton wool and paper napkins in random order.

- The dirtier the water, the more filter material you need to put in the funnel.

- The filter is ready, all you have to do is pour water on top and place a container under the funnel to collect clean water.

These methods of making a household water filter are taught in school. If you know how to purify drinking water, you can put your knowledge into practice in difficult situations. In any case, this is only a temporary filter replacement; it will be difficult to use such a filter on a permanent basis.

Anastasia Sergeeva

What is a well filter and its structure

Water purification from a well occurs in two stages - with a well filter and surface filtration systems built into the water main. In this case, the well filter has a structure consisting of three main elements:

- Above-filter area. The part that plays the role of fittings when mounted on a column.

- Filter elements. Includes the holes in the pipe of the correct size and the external materials that are attached to it.

- Sump. The space for placing soil particles that have fallen inside the source or are screened out by filter elements is the lower part of the filter without perforation. The sump for water from the well is about 0.5 m long.

Rice. 2 Filter design

What height should I choose?

The height of the filter directly depends on the throughput of the soil and the diameter of the service pipe. The lower the throughput of the aquifer, the higher the filter should be.

To accurately calculate the height of the filter, an analysis of the components of the aquifer is required, which will be quite expensive when drilling an individual well.

The following indicators are used as a basis:

- The height of the filter must be at least 1 meter;

- Sandy soil has poor throughput, so the height of the filter should be at least 2 meters with a pipe diameter of 10-15 cm;

- Fine sandy soil will require a pipe height of about 4 meters, a dusty structure will require a height of 5-6 meters.

Stationary filter device consisting of three flasks

Now let's figure out how to make an effective filter yourself to connect it directly to the system. For these purposes, we will need three flasks with the same geometric parameters into which we need to place the filler.

From containers prepared in this way, we will make a productive stationary filter for purifying tap water, guided by the following diagram:

- Take two 1/4 inch adapter nipples. Use them to connect all three flasks into one structure.

- Seal the joints of the nipples (their threads) with fluoroplastic sealing tape (the so-called FUM material).

- Using straight adapters, connect the 1/4-inch holes of the two outer flasks to the tube.

- Cut the prepared filter into the pipeline (you will need a half-inch connector and a tee).

- Connect a regular water tap to the filter outlet tube.

High-quality water in modern conditions, especially drinking water, is a very rare occurrence. If several decades ago there were still clean springs and wells, now they are very rare even in rural areas. Agricultural companies pollute the soil no less than industry and herbicides. Mineral fertilizers inevitably penetrate into the sources. Water filtration has become a necessity.

Jug-type installations have become frequent guests in kitchens in the city and in the country. They are effective for small volumes of liquid. But if you need to clean tens or hundreds of liters, such devices are unsuitable. When there is a well, borehole, or swimming pool on the property, water filters are necessary. You can buy ones designed for these purposes, but those made by yourself are always cheaper.

Caring for comfort

Of course, the beautiful facade of the building is the pride of the homeowners.

But there are also more prosaic things that you should always remember.

Cottage and holiday villages are rarely connected to the central highway.

As a rule, each owner of a private building has to overcome the current situation individually.

Remember! Such an important matter as installing a sewer system must be approached seriously and with full awareness of what you are going to do.

When building an autonomously operating sewer system, it is necessary to think through to the smallest detail how to install the equipment in which wastewater will accumulate and settle.

Both options have a similar feature of operation, which is based on the laws of gravity.

The drainage system (read how to calculate local treatment facilities in this article) provides special storage tanks in which wastewater is divided into fractions by weight.

The liquid substance, flowing from one container to another, will leave heavy inclusions at the bottom. Therefore, it will be necessary to periodically clean the settling chambers from accumulated dirt.

Do you know how to connect PVC pipes? Read this useful article about current docking solutions and different types of installation.

The cost of a heat pump for heating a house is written on this page.

For optimal operation of the sump, it is necessary to ensure that the liquid flows from one chamber to another as slowly as possible.

The low speed of movement of wastewater is a guarantee that a significant part of the pollution will settle (watch a video about cleaning sewer pipes with your own hands here).

A certain part of bottom sediments is processed by anaerobic bacteria, and a certain percentage is mineralized.

Water preparation devices for food

You can clean dirty liquid at home with homemade filters. The resulting product does not always satisfy all requirements. Only the use of high-quality elements allows you to achieve the expected results. They retain mechanical, chemical and bacteriological impurities.

At the dacha they use several types of homemade filters:

- flow-through coal;

- submersible for technical water in an aquarium, swimming pool;

- external, allowing you to get rid of mechanical contamination.

A homemade system is used when it is necessary to coarsely filter water from a well, well, or rainwater. Fine cleaning is used to eliminate odors caused by the presence of bacteria.

Simple filters for home made from plastic containers

There is no better absorbent for a homemade device than activated carbon. It does not allow mechanical impurities to pass through, as well as many toxins and bacteriological harmful substances. For production, dishes with a sealed lid and plastic pipes are used. For a small aquarium, disposable syringes are suitable.

The main thing is that the volume allows you to accommodate the required amount of filter material in several layers. The manufacturing process of the simplest device occurs in the following sequence:

- 1. Take a plastic bottle or other similar container, in which the bottom is cut off. Below, at a distance of about 2 cm, 2 holes are made with an awl.

- 2. One 10mm hole is also drilled into the lid. Alternatively, many small ones are pierced.

- 3. Screw onto the bottle and begin laying the cleaning material. Natural fabric or ready-made filters, lutrasil, are used on the bottom and walls.

- 4. Next comes activated carbon. On top there is clean sand, then gravel, which alternate in several layers. The total volume should not exceed 2/3 of the container's capacity.

- 5. Cover everything with a cloth that will not allow large particles to pass through. They hang it up and fill it with water, wait for it to be cleaned and poured into a clean container.

The system has a disadvantage: filtering takes a long time.

It is more convenient to use 2 pieces of pipe, one of which is 4 times longer than the other. The short one is used for rough cleaning. Place the lid tightly on the plastic container in which the hole is made. A mesh is placed on it and the space is filled with pharmaceutical cotton wool or padding polyester. On the other side, the pipe is also covered with a lid and mesh.

One end of the long piece, which serves as a fine filter, is prepared in the same way: a tight lid with a mesh. On the other side is the neck of a plastic container. The filter material is filled in, each layer in turn. Both parts of the structure are connected.

It’s also easy to do water purification for your home aquarium yourself. Requires 2 disposable 10 ml syringes with cut off tips. They are connected to each other, holes are made along the entire length. A tube with a spray at the end is placed inside, and if you add zeolite, the quality of the water will increase - nitrites will be removed. The outside of the device is wrapped with a sponge.

Selection rules

Decisive criteria when purchasing a cleaning system:

- Iron concentration. Each filter is designed for a specific load. If there is a high concentration of ferrous iron, take a closer look at aeration filters.

- Additional impurities. If the water contains hydrogen sulfide, manganese, calcium and magnesium salts, you need to look for a filter that will retain these substances.

- Water consumption. The more liquid is needed, the greater the productivity of the installation should be. Focus on the number of people and bathrooms. A filter with a capacity of 0.6-0.8 m3/hour satisfies the needs of 1-2 people. For a family of 4-5 people, a system with a throughput capacity of 2.5-3 m3/hour is needed.

- Features of plumbing. This item determines what operating pressure and its differences the installation will withstand.

- System autonomy. If you periodically live in a country house, or your water consumption is low, you can choose budget options for cylinders with manual cleaning (it takes 30-50 minutes). There are installations with automatic control of filter cleaning and washing. They don't need supervision.

To select an effective filter, submit well water for laboratory analysis. Experts will determine how much iron is in the liquid and in what form it is (divalent, trivalent, in the composition of oxides).

- To remove soluble iron (Fe2+), ion exchange resins, reagent and non-reagent filters can be used.

- If the sample contains a lot of trivalent ferrum (Fe3+), fine and coarse disc/mesh/cartridge filters are suitable.

Important. It is easiest to work with reagent-free filters with automatic control

They do not require additional materials for maintenance and do not require human control.

Features of selection for a country house

When selecting a cleaning system for a cottage or summer house, water analysis is required. In addition to the iron remover, coarse mesh filters may be needed to remove sand and silt.

Next, the water passes through fine filters, which:

- reduce acidity,

- get rid of chemical impurities,

- microorganisms.

Only after these stages does the liquid enter the deferr filters.

Complex cleaning is provided by a multi-stage main system, which is selected individually.