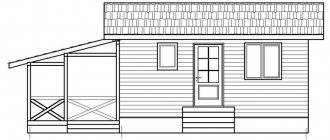

Having been engaged in the creation and implementation of inexpensive housing projects for the population of the central and northwestern regions of the Russian Federation for more than 9 years, “Russian Construction” has studied their needs and material capabilities. The company successfully sells dozens of turnkey frame houses.

The site presents 20 projects of 8x8 frame houses for seasonal and year-round use. These are one- and two-story buildings with balconies, attics, terraces, made in various architectural styles. For each option, the equipment, prices, drawings and floor plans are indicated.

Features of frame house construction

The main advantage of frame construction is the speed of construction and its low cost. Since the house is light in weight, it does not require a complex and expensive foundation. The construction of a frame house can be carried out independently, without the involvement of professional builders. Thanks to this, such buildings are often erected on summer cottages; in addition, garages, bathhouses, and outbuildings are often built using frame technology.

A frame house measuring 8 by 8 can be either one-story or 2 levels. In this case, it is important to erect a building with an attic. This layout allows you to get a larger living space without significantly increasing the construction budget. The only negative is the inconvenience caused by the sloping roof.

The main arguments for building a frame house:

- Speed of construction, even with the condition of completely independently performing all the work;

- High heat capacity of frame houses due to the use of modern building materials;

- There is no need to wait for shrinkage, unlike houses made of wood or stone; after building the walls and roof, you can proceed directly to finishing work;

- It is worth noting that 8 by 8 frame houses are a budget construction option that does not entail significant costs.

We have figured out the advantages of frame construction. Now let's look at how you can build such a frame house with your own hands: step-by-step instructions for building an 8x8 house are presented below.

Projects of possible structures

The design drawing of a 6x8 panel structure is determined according to the following criteria: the construction method is determined, after which it is clarified whether it is possible to build using one or another method. It is imperative to calculate the rigidity of all structural elements; this will require the following diagrams:

- Foundation diagram;

- Measurement of required work;

- Wall box calculation;

- Drawing of the roof and interfloor covering;

- Scheme of types of structures;

- And also a drawing of the beam structure.

In order to determine what kind of foundation is required, it will be necessary to base it on the horizontal and vertical section drawing. It is also necessary to take into account the climatic conditions of the region in which construction will be carried out, in addition, you will need to know the composition of the soil and general geological analysis. On diagrams with a horizontal section, we identify the number of main supports on the beam flooring and their location, types of crossbars and stops for beams.

The documents for wall frames specify all the necessary dimensions, the required number of supports for each wall, as well as for each opening and at the ends of the beams. It is necessary to indicate each wall on the diagram and, if necessary, give the structure additional rigidity. It is necessary to mark those beams that will interact with the overall frame of the house.

The frame connection is shown in a section of the construction drawings. The joining is carried out in this way: the building slab is attached directly to the frame, then the frames are joined together, the shape of the shoes and their installation locations are determined, to the point where the required number of nails for installation is indicated.

All work should be measured, this is necessary in order to purchase everything you need at a building materials store, which is why all calculations must be made before starting work.

All important points during construction should be noted on the diagram, and a clear order of work should also be indicated, this will subsequently protect you from unexpected unpleasant surprises.

Start of construction

The construction of any building begins with a project. Even taking into account the simplicity of an 8 by 8 frame house, it is better to make a calculation and draw up a plan. A detailed estimate will make further work easier and cheaper.

Next you need to choose a place for construction and clear the area. To do this, it is necessary to remove the top fertile layer of soil. After this, you can proceed to the construction of the foundation. The choice of its type should be based on data on the type of soil, freezing depth, and landscape of the site. If necessary, it is necessary to carry out or order a geological survey.

Most often, frame houses are built on piles or strip foundations. The solution is poured as for ordinary houses - there are no special features. In the case of a strip base, a bundle of reinforcement is required, which requires wire. Concrete can be purchased mixed and ready for pouring, or you can mix it yourself using a concrete mixer on site.

If you are building an 8 by 8 frame house with your own hands, then the easiest way will be to build a shallow strip foundation. For this foundation, it is necessary that the depth of soil freezing in your region is no more than 50 centimeters. Otherwise, it is recommended to install a slab base, which, although not cheap, is the only way out in the presence of groundwater. In controversial situations, it is recommended to seek help from professionals.

Sketch design of the building

When drawing up a sketch of a house, both the architect and the owner of the future building must be present, since it takes into account all the nuances, such as: the number of storeys of the house, the layout of the rooms, the decoration of the building outside and inside, and other individual preferences of the owner. By the way, at this stage you can make approximate calculations on the material that will be required to build the house.

Only after the drawings have been drawn up can you begin to obtain a building permit. These documents must be presented to the supervisory authorities for urban planning control. The document allowing construction to begin contains information that the future structure is safe for use and does not deviate from the norms and requirements for this type of construction.

This document also includes drawings: facade, composition, as well as sectional drawings, both vertical and horizontal.

Different regions of the country may require different permits; you can check the list of all required papers with the relevant supervisory authorities for urban planning in your district.

House frame

After erecting the foundation (in the case of a strip foundation), you need to wait until the concrete mixture dries completely. After this, you can proceed to assembling the frame. The main structural element of a frame house itself can be made of metal or wood.

Metal frames are rare due to their high cost. If you are building an 8x8 frame house with an attic floor, then you should use a metal frame, although this does not matter much. If the wood option is chosen, then the surface must first be treated with antiseptic substances.

When building walls, you need to pay attention to the openings for windows and doors. First, vertical posts are installed. The distance between them is selected based on the type of insulation planned for use and, as a rule, is 60 centimeters.

Horizontal elements are mounted under the openings, strengthening the structure and secured with self-tapping screws.

Working drawings

The working drawings include such indicators as the location of windows and doors, in addition, other details and features of the building are marked. These drawings are necessary not only in order to refer to them during construction, but also according to these drawings, as a rule, construction materials are purchased.

The working diagrams indicate all the subtleties and details of the structure, such as: types and materials of finishing, communications and other equipment required for a comfortable and cozy stay.

Required types of documents:

- Drawings of window and door openings;

- Location of utility rooms and kitchen;

- Planting and landscape design scheme;

- Description of the structure, as well as room-by-room drawings;

- Structural and architectural properties of the attic and domestic buildings, as well as the fence and roof overhang.

Working drawings of the panel structure with dimensions 6x8 are carried out at the stage of forming all other documentation.

Ceilings and roof

Before starting this stage, it is necessary to install floor supports. If a two-story frame house 8 by 8 is being built, then for the second level the role of these supports will be performed directly by the walls themselves.

To install the roof, you need to install a frame. The rafter system is most often assembled on the ground and then raised to the top. For rafters, a beam with a cross-section of 50 by 150 millimeters is usually used and is fixed at an angle of 50 degrees.

To cover the roof of an 8x8 frame house, you can use soft tiles, ondullin or metal tiles. The roof structure must be stable enough to withstand the weight of the snow cover, as well as the negative external influences of the environment.

Construction of a panel structure

A frame house with dimensions of 6 m by 8 m with an attic itself implies the presence of a second floor. The second floor is designed to accommodate an attic; the lower tier is designed as a residential one. Here are the generally accepted design solutions:

- The room is insulated using mineral wool or penoplex;

- The average thickness of walls and ceilings is 150 mm;

- The rafters are 200 mm thick.

Foundation installation

Reliability, long service life and stability directly depend on a well-made foundation. A building with dimensions of 6x8 with an attic will not put a serious load on the foundation and, if the soil is not heaving, then it is permissible to use a monolithic strip foundation with dimensions: the depth and height of the plinth is at least 500 mm, with a strip width of 400 mm.

For a high-quality foundation, you will need reinforcement with a cross-section of 12 mm; it is necessary to reinforce the mortar; you need to create two armored belts of three rods. Using knitting wire, we make a bunch of rods. For formwork it is necessary to use timber with a cross-section of 50x50 mm and plywood 10 mm thick; for a building with our dimensions, the consumption of concrete solution will be, on average, 18 m3.

At the place where the top layer of earth is removed, geotextiles are laid, after which expanded clay is poured. Next, the solution is poured, and the process stops until the concrete dries completely. In no case should you skip the point regarding waterproofing the base; for this you can use bitumen mastic.

We build walls

To strap along the bottom and arrange the floor joists, you must have a beam with a cross-section of 150x150 mm; the strapping will be done along the spacer flooring. The laying is carried out using polyethylene foam. For better fixation and connection of lumber, it is necessary to use hardened self-tapping screws measuring 100x5 mm.

To complete the bottom trim, it is necessary to fasten two boards parallel to each other at a distance of 100 mm. We connect the boards in increments of 1000-1500 mm. All gaps formed during the work are tightly filled with insulation.

Both a frame house and a structure made of timber are in no way inferior to each other in terms of strength. We build the first wall of the frame using boards with a section of 150x50 mm and a distance between the posts of 600 mm. In order for the structure to be more rigid and strong, it is necessary to install jibs. It is also necessary to carry out work on soundproofing the walls. The remaining walls are mounted in a similar way. Only after all the walls have been installed can you begin to install partitions on the lower floor and install the stairs to the second floor.

A 6x8 frame house with an attic initially implies the use of a soft roof. At the first stage of installing the pediment, we attach the ridge beam. Lumber with a cross-section of 150x50 mm is used for installing interfloor structures. The cells resulting from the work are densely filled with mineral wool.

To install the roof, you must purchase the following materials:

- Roofing soft tiles;

- Beam with a section of 50x50 mm;

- Lathing;

- As additional protection from wind, the use of polyethylene film with a density of 140 g is allowed. per 1 m2.

Windows, doors and insulation

After the roof is installed, you can begin installing windows and doors. First of all, windows are installed in the attic of a frame building and only after that - in the rest of the house. The installation of doors always begins with installation in the farthest room; this will significantly reduce the risk of damage to already installed panels.

The building is insulated after the house has been sheathed. Warming occurs as follows:

- Standard sizes of mineral wool are 800x600x50 mm;

- Sheets of insulation are inserted between the main posts at random;

- If the size of the insulation does not correspond to the gaps between the posts, then adjustments can be made using a construction knife.

The floor is insulated in a similar way, but an additional layer of vapor barrier is required, after which a rough version of the floor is installed.

Necessary communications

For such a house, a wood-burning fireplace-stove is used for heating, under which it is also necessary to install a small foundation. Natural ventilation is not provided in such a building, and only windows and doors perform this function. A recuperator will help you create a comfortable indoor microclimate.

To avoid electrical hazards, materials and devices may be required such as:

- Cable 5x6 for supply;

- Automatic machines 16-40 amperes, at least 10 pcs.;

- Distribution boxes and panels;

- Automatic two-pole input.

An excellent sewerage solution for such a building would be an autonomous septic tank, although its installation and arrangement will cost a tidy sum, but the comfort and convenience will more than pay for the costs.

Finishing of the building

Everyone chooses the material for interior decoration for themselves, but, as a rule, wooden lining is used for this. All finishing work should begin from the attic level.

Recommendation! Craftsmen strongly recommend using “A” or “Extra” class lining for interior decoration, since the material of this quality is practically free of knots and looks quite beautiful.

Before starting the exterior finishing, it is necessary to lay a layer of windproofing; this is easier to do using a stapler. You can also use lining for finishing, having previously treated it with the necessary impregnations. It is better to sheathe the pediment and overhangs with plastic.

Thermal insulation of a frame house

Nowadays, the building materials market offers a huge number of insulation materials of various characteristics. The most commonly used materials are mineral wool, ecowool, and polystyrene foam.

When building an 8 by 8 frame house, it is necessary to insulate the walls, floors and ceilings. Thermal insulation material is laid before the walls are faced.

The insulation is installed in the space between the racks. The material serves to protect the interior from the cold outside the house. Mineral wool is supplied in rolls and placed in the “honeycomb” of the building frame, fixed using a construction stapler.

In this case, one important rule must be taken into account: an 8x8 frame house should turn out to be a kind of “thermos”, so the walls need waterproofing both outside and inside. For this, polyethylene film or a special membrane is used. The second is a more reliable option with a long service life. After installing the insulation, the walls are sheathed and finished, and you can move into the house.

Stage-by-stage design

Before starting work, you need to decide on the material from which your structure will be built. And also know exactly how the walls and attic will be finished, what your house will look like externally, as well as the number of floors in the proposed building. You can add uniqueness to your home; for example, windows with an original shape will look very unusual.

Even a simple, standard house can be made original and exclusive; if the ideas are really good, then when you contact an architect, he most likely will not refuse and will make changes to the project. When deciding on the finishing material, it is worth considering the ease of maintenance and practicality, as well as the durability of the decorative coating.

Recommendation! Only after you have decided on the internal layout of the premises and rooms can you begin to select the location of window and door openings.

In addition to the plan of the house itself, you should stock up on projects:

- Electricity supply;

- Estimates;

- Constructions;

- Heating systems;

- Ventilation;

- Water supply and sanitation;

- Foundation.

To build a 6x8 frame house with an attic, you will need not only an architectural design, but also several more documents, without which you will not be able to start construction. First of all, the construction permit itself, working drawings and, of course, the outline plan.

Roofing device

The construction of the roof of the house begins when work on the installation of the ceiling, which is also the floor of the 2nd floor, is completed. According to the project, a place for the staircase is determined - it is better to leave its choice to specialists in order to accurately calculate the number of steps, load-bearing capacity and material.

You can use both wooden and combined structures with metal elements. A spiral staircase with a load-bearing steel frame and wooden steps looks good and is quite reliable; another point in favor of this solution is its compactness.

Traditional climbing ladders with steel or wooden strings are also found in standard solutions, but take up more space. The use of exotic systems (elevator, lift) is unlikely to be advisable and will lead to an increase in the cost of the project as a whole. It is better to spend this money on finishing the interior or facade. When constructing frame buildings, the following types of roofing are used:

- Gable;

- Hip;

- Tent

- Combined.

The simplest design is a gable one: the surfaces of the covering converge at the ridge that crowns the roof. The most complex design is the combined roof - it requires the installation of multi-level transitions and skylights. It looks much better than other types, but requires a serious investment of time and money. To reduce the cost, the design of a standard 8 8 frame house with an attic often includes an easy-to-manufacture and reliable pitched roof. To install it, you will need to mount racks that are located along an axis running in the middle of the house: the purlin will rest on them.

In the case of a metal supporting frame, the structure can be visually lightened by using trusses mounted in the transverse direction. In this case, the coating is laid over beams laid on the upper chord of load-bearing structures (trusses).

Wooden frame elements look different: pieces of boards of a certain length (rafters) rest on the ridge, forming the load-bearing frame of the roof. The pitch of the rafters is calculated depending on the size of the building and its cross-section. Additional rigidity of the structure is provided by purlins laid perpendicular to the inclined rafter legs; their number and pitch are also determined in advance, and not chosen arbitrarily.

During the installation of roofing elements, communication outlets (chimney or ventilation intake pipe), locations of skylights, and window openings are taken into account.

Where exactly to install windows - in the end walls or in the inclined planes of the roof - is up to the customer to decide. The designer’s task is to select the option that best suits his needs. The number and area of openings must take into account the requirements of natural light; this is determined by appropriate calculations.

The roofing work is completed with a covering device, for which it is permissible to use any materials suitable for the purpose: bitumen or metal tiles, reinforced plastic, artificial stone.

Facade finishing

The choice of color and material for facade cladding can be entrusted to a designer or done independently. The range should be unobtrusive, resistant to fading and exposure to the external environment, the same applies to the finishing material. Plastic lining (siding) has proven itself well: it is relatively cheap, comes in a wide range, imitates wood species, stone cuts, and perfectly protects internal structures from snow, rain and wind, as well as temperature changes.

Depending on their wishes and their financial capabilities, customers order both simple painting of OSB panels and wall cladding with natural stone.

Selecting a frame type

For a structure in which the main load is carried by load-bearing posts that form the frame, the choice of their design and type is very important. For the manufacture of frame parts, 2 main materials are used:

- Wood;

- Metal.

Each type has both its advantages and disadvantages.

Wooden frame structures of houses are easier to install, lighter (weigh less) and cheaper compared to metal ones. But they urgently need special treatment against pests, as well as chamber drying to achieve optimal humidity (no more than 15%). Otherwise, the racks and beams will quickly become unusable under the influence of the external environment.

Another serious disadvantage of wood products is their easy flammability and flammability. Impregnation with a fire retardant compound, which prevents the effects of fire and high temperature, will help save from such a defect.

The metal frame is distinguished by higher durability and strength, and due to the use of a special thin-walled profile it is possible to reduce its weight. Such structures can withstand heavy loads and can be used for the construction of 1 and 2 storey buildings. They are non-flammable, with appropriate treatment they are not affected by a humid environment and corrosion, and are excellent for the design and construction of frame-panel houses.

The disadvantage of steel structures is the need to use special equipment for installation; without its help, it is unlikely that it will be possible to carry out work on installing racks and laying beams.