A modern country house is equipped with many technological benefits that were unavailable even a couple of decades ago and the functioning of which requires water. In addition to cooking and washing hands, there is at least a shower, a washing machine, and maybe also a dishwasher. For all these devices, it is necessary to establish not only the supply of clean water, but also the drainage of the resulting wastewater. This means that the usual level of convenience cannot be imagined without a modern device for treating household wastewater. When it is impossible to connect a house to a central collector, a septic tank made of reinforced concrete rings can be one of the few ways that allows you to properly process waste and prevent soil contamination.

View of a septic tank made of concrete rings in the courtyard of a private house Source mirhat.ru

How does a septic tank work?

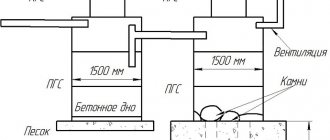

For a small private house, a septic tank made of concrete rings is installed according to the classic scheme, including two tanks. If a significant volume of wastewater is expected, three tanks (wells) are installed, different in design and functionality. The first two wells are made hermetically sealed; in the third, a crushed stone filter is installed, through which the water flows into the soil.

The principle of constructing a septic tank made of concrete rings Source admiral-oz.ru

Purpose and design of cameras

- The first septic well serves to receive and settle wastewater. Here, thanks to the work of anaerobic bacteria, sedimentation occurs and partial treatment of wastewater occurs (Anaerobic bacteria are able to decompose complex organic matter into simple substances without access to oxygen). The initially clarified water flows into the second section. The volume of the chamber should be equal to half of the total planned volume of the system; its base is concreted.

- In the second well (drainage) with sealed walls and bottom, additional filtration occurs. Additional filters made of gravel can be installed here.

- In the third well, final filtration occurs. The bottom here is not concreted; a sand-crushed stone (or sand) mixture is poured in for final filtration.

Types of wells depending on functions

Where can concrete rings be used? When it comes to sewer wells, you need to understand that there are also, for example, inspection (or inspection) wells. They are located at the turning points of the pipeline through which wastewater is discharged from the house (read: “Sewer inspection well - design and installation options”). In addition, if such a pipeline is too long, then it also makes sense to install inspection wells every 10-15 meters.

This is done so that in the event of a blockage or stagnation in the pipe, it is possible to determine in which part of it it occurred. And as a result, quickly eliminate the problem. Types of sewer wells:

- Inspection

well (discussed a little higher). - Control

. In terms of its tasks, this well is very similar to the previous one. The difference is that it is built where pipes are combined into one, or there is a transition from a pipe with a larger diameter to a pipe with a smaller one. - Flushing

. Its function is to help clean the pipeline. It is placed at the highest section of the pipeline. - Rain

. They help collect water from heavy rains from roofs and the surface of the ground. - Sucks

. These wells are used where wastewater needs to be cleaned of solid sediments, where the wastewater is highly contaminated (for example, after production or the presence of a large amount of household waste in the wastewater). - Special

. They are installed in places where the sewer pipeline is connected to other main networks. - Drops

. These wells help dampen the flow of wastewater. This happens in those sections of the pipeline where there is a sharp downward slope (for example, due to landscape features).

Advantages and disadvantages of a septic tank made of concrete rings

Due to the features of use, design and installation, such a system is the optimal solution in many cases.

Let's consider all the pros and cons of septic tanks made of concrete rings:

Its advantages include:

- simple installation and use technology. There is no need to supply electrical power, arrange additional drainage, or install a pump;

- reliable autonomous design with high mechanical strength;

- complete freedom in choosing the dimensions of the structure;

- long service life;

- large useful volume and easy maintenance;

- resistance to aggressive wastewater environment;

- the weight of the rings is a guarantee that groundwater will not displace the septic tank from the soil;

- available materials and reasonable price for building a septic tank.

Components of a concrete sewer well

Of course, you can do without concrete rings when constructing a sewer well. You can dig a pit and make concrete walls and bottom yourself. True, it will take a lot of time and effort. In this case, you will need: reinforcement, formwork, as well as time for the concrete to harden properly.

The construction process is simplified if you use ready-made concrete rings. In addition, today they produce completely different sizes and diameters of rings, which allows you to choose a model exclusively for your site. All concrete rings have the same set of components:

- Bottom plate

- Neck

- Floor slab inside the ring (if a multi-stage wastewater treatment system is required)

- The rings themselves

- A plate that acts as a cover (usually available with a hatch for pumping out the contents of a sewer well). Read also: “Lids for sewer wells, types and advantages.”

Concrete rings are often used to create sewerage tanks. However, in northern latitudes their use can be problematic. There, the soil freezes to a very great depth, so the functioning of the well may not be entirely ideal. In general, concrete rings are an unpretentious material, and there are practically no restrictions on their use.

Making the right calculations: capacity and design

At the design stage, a septic tank diagram is created from concrete rings, then the volume of the future device is determined:

Number of cameras

The number of cameras depends on the number of people using the sewer system. If a family actively uses the shower, bathtub, and appliances, the drain down the drain will be significant. The drains will require thorough cleaning, for which you will need a septic tank of three wells, two of which will be settling chambers.

Diagram of a septic tank made of concrete rings Source tolkobeton.ru

Capacity

To determine the volume of wastewater entering the septic tank from the kitchen, bathhouse and toilet, you need to calculate the daily water consumption. Knowing that the daily rate of domestic water consumption for one resident is equal to 200 liters, it is easy to calculate that a family of 4 people will fill the septic tank at a rate of 800 liters per day.

The quality of the septic tank improves if wastewater lingers in the chambers for a long enough time. By increasing the volume, you can improve the quality of the wastewater and protect the system from clogging with difficult-to-decompose fat.

According to building codes, the installation must accommodate wastewater that is generated over three days (the daily flow rate must be multiplied by 3). This number determines the volume of the septic tank and the number of chambers:

- a single-chamber septic tank is installed if daily waste does not exceed 1 cubic meter;

- two-chamber – up to 5 cubic meters;

- three-chamber – 8 or more cubic meters.

In a septic tank with two chambers, the first sump occupies the volume of 2/3 of the entire septic tank, in a three-chamber septic tank - half.

Frequently asked questions

During the construction of a septic tank, the same type of questions often arise, which are easier to answer in advance:

How to protect a septic tank from seasonal soil movements?

No one can give a 100% guarantee here. If the composition of the soil layers is replete with clay layers, it is necessary to take any measures to prevent frost heaving - make drainage, increase the backfill layer, insulate the bottom of the pit.

Will the septic tank freeze in winter?

Fermentation processes taking place in the chambers produce heat. In addition, the temperature of the wastewater, as a rule, is high enough to maintain the thermal regime in the chambers. Even in the northern regions, septic tanks are capable of supporting the vital activity of bacteria that cannot withstand negative water temperatures.

There is often advice online to locate overflows below the ground freezing level. How critical is this?

This rule applies only to regions with shallow freezing depth. In most regions with harsh climates, pipes are insulated by installing a foam shell, or by filling them with polystyrene foam granules.

If the rings are not equipped with a bottom, is it possible to install them on a concrete screed?

Can. This will require additional effort and time of pouring until structural strength is achieved. However, if there is no alternative, you have to fill the bottom yourself.

What reserve volume of a septic tank is best to set when performing calculations?

As a rule, they expect 2 more users to appear.

Which sewer pipes are best to use for overflows?

The best option is red PVC pipes. However, you can install asbestos-cement or cast iron pipes.

Video description

About septic tanks on high groundwater in the video:

See also: Catalog of companies that specialize in utilities: water supply, sewerage, heating.

Increased structural strength:

- To protect the building from possible ground movements and shifting of the rings, they are additionally secured with metal ties.

- To reduce the subsidence of the septic tank and improve its thermal insulation and drainage, during installation a cushion of sand, crushed stone or gravel is placed around it.

How to save on construction?

If it is not possible to use special equipment during installation and finances do not allow you to attract a team of workers, try using these methods.

Instead of traditionally digging a pit and then immersing rings in them, use a technology in which the soil is removed gradually as the ring is deepened. It is built on the fact that the ring falls down under the influence of its weight. The master’s task is to dig up the soil inside the ring and under its wall.

The technology of “undermining” rings laid on the ground is used only when installing products without a bottom

In this case, the concrete bottom will have to be poured later. And it will be located exclusively inside the ring.

A significant drawback of the described method is the inability to perform thermal and waterproofing on the outer walls of the structure. In addition, due to the fact that the bottom is located inside the ring, the reliability of the structure is reduced.

In an effort to reduce the cost of the structure itself, craftsmen offer an option for constructing a structure that looks like a triangle.

Storage tanks act as the basis of an isosceles triangle, and their common neck is its vertex

By choosing this arrangement option, you will save space for placing rings and can significantly reduce the amount of land work.

But during installation, take into account the peculiarity that the inspection entrance in such a design will be one per three rings. Therefore, all overflows should be placed outside its accessibility.

How much will the rings cost?

Concrete rings are selected based on calculations of the volume of the septic tank. The dimensions of concrete rings for a septic tank are indicated on the marking. They are characterized by the height, diameter and thickness of the walls of the structure, as well as the type of product:

- KS – wall ring, suitable for erecting walls;

- PP – floor slabs;

- PD – road slabs, installed at the bottom of the pit.

The cost of concrete rings is affected by their size and location of production. Reinforced concrete rings with low surface permeability, resistant to aggressive environments, are suitable for sewerage.

The height can be 290, 590, 800, 900 mm. A typical product with a height of 900 mm can have a diameter of 700, 800, 1000, 1500 and 2000 mm. The average price for it varies from 1200 to 1800 rubles. Rings with other parameters can cost from 680-1050 to 1500-2400 rubles.

Rings for septic tank Source humphrey.alpvd.ru

It should be remembered that some rings are marked with an internal (useful) diameter, while others have an external diameter, which is important for selecting caps. The average cost of a reinforced concrete cover or polymer hatch ranges from 1,700 to 2,000 rubles.

When drawing up an estimate for a septic tank made of concrete rings, the price takes into account additional materials: pipes, cement, sealant, as well as the cost of work (digging, installation of rings). The final average price of a turnkey septic tank is in the range from 38,000 to 69,000 rubles.

Which rings to choose - with or without a lock?

Concrete rings with a lock (tongue-and-ridge connection) and without it are available on the market. There is an opinion that the former provide higher water resistance and better protect the septic tank structure from lateral movement.

However, according to experts, this is not true. In practice, there is no big difference between both types of rings in terms of water permeability. If there are such significant shifts in the soil during frost heaving that, in principle, they can displace one ring relative to another (the weight of one ring with a diameter of 1 m is 600 kg), then the lock will not save. As for the convenience of centering rings with a lock during installation, this is only true for a structure of two rings. In the case of a septic tank with three or more rings, the difference is unlikely to be noticeable.

Video description

The work procedure and installation of a septic tank made of concrete rings in the video:

How to choose the optimal location for a septic tank

The structure is mounted above the groundwater level. The best location is at the maximum distance from the house (at least 7 meters, but no more than 20, so as not to increase the cost of pipeline construction). It is logical to place the septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving a sewage tank is affected by access to the system and the length of the hose. In addition, with the correct location, the sewage disposal truck does not need to enter the yard, and the hoses will not lie on the beds or paths (otherwise, when the hose is rolled up, waste may end up in the garden).

The distance to the nearest source of drinking water (well, borehole) is at least 30 (and if possible more) meters.

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of the rings and their waterproofing. The bottom is covered with crushed stone and concreted.

Preparing a pit for a septic tank made of concrete rings Source rostovgruz.ru

Location of the structure

When designing a septic tank, the sanitary zone is placed in such a way that organic waste cannot penetrate into drinking water and fertile soil. To do this, when choosing a location, you should be guided by sanitary and building codes and regulations.

The correct location of the cleaning system on the site is regulated by:

- SNiP 2.04.03.85. It sets out the rules for the construction of external sewerage structures.

- SanPiN 2.2.1/2.1.1.1200-03. It lists the requirements for creating zones that are environmentally hazardous.

According to the standards, in order to avoid the foundation getting wet in the event of emergency leaks, the septic tank must be placed lower than the house is located.

Failure to comply with these requirements may result in a risk of untreated wastewater penetrating into aquifers (+)

When choosing a location, you should definitely take into account the presence of bodies of water with running water, maintaining a distance of 5 m to them. The distance from trees should be 3 m, from bushes - reduced to one meter.

It is also necessary to know where the underground gas pipe is laid. The distance to it should be at least 5 m.

Since the construction of purifier chambers from rings involves the construction of a pit and the use of special equipment, when choosing a location it is worth providing free space for its access and maneuvering

But keep in mind that the machine cannot be placed directly above the deepening site of the treatment plant. With their weight they can destroy the entire structure.

How to put a septic tank into operation

In order for the system to begin to function effectively, the constructed septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- The new septic tank is filled with wastewater and left for 10-14 days. Then sludge sludge from an existing anaerobic septic tank is loaded into it (2 buckets per cubic meter).

- You can purchase ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes, which are intended for other treatment systems).

Ready-to-start septic tank made from rings Source remont-book.com

Volume of septic tank for home

According to the standards, the minimum capacity should be equal to the three-day volume of sewage from the house. At the same time, each family member accounts for about 200 liters/day (0.2 cubic meters/day). That is, we multiply the number of people living in the cottage by 3 and by 0.2 - we get the calculated cubic capacity of wastewater. This volume must be completely contained in the first two chambers, which have a sealed bottom.

Calculate the volume correctly

The drainage tank is not included in these calculations. It infiltrates water into the ground. If the project is done correctly in accordance with all building codes, then it is necessary to take into account the ability of the soil under the gravel-sand filter to accept moisture. And for this you will have to carry out geological surveys on the plot where the septic tank will be installed. However, private owners usually do not have extra money, so the third chamber is most often built with the same capacity as the first.

Knowing the cubic capacity of the expected wastewater from the house, it is not difficult to calculate the required number of products to build a septic tank with your own hands. Their height ranges from 0.5–1 meter, and their internal diameter ranges from 80 to 250 cm. These parameters are always indicated in the labeling for each reinforced concrete product sold.

And then the formula for calculating the volume of the cylinder is used. You need to multiply 3.14 (Pi), height (H) and diameter squared (D * D), and then divide all this by 4. The result is the cubic capacity of one ring of concrete. And then divide the total volume by the capacity of one round reinforced concrete product.

Table of sizes of reinforced concrete rings

| Name | Height | Diameter (internal) | Volume of concrete |

| KS 7-3 | 290 mm | 700 mm | 0.05 cubic meters |

| KS 7-6 | 590 mm | 700 mm | 0.1 cubic meters |

| KS 7-9 | 890 mm | 700 mm | 0.15 cubic meters |

| KS 10-3 | 290 mm | 1000 mm | 0.1 cubic meters |

| KS 10-6 | 590 mm | 1000 mm | 0.16 cubic meters |

| KS 10-9 | 890 mm | 1000 mm | 0.23 cubic meters |

| KS 15-3 | 290 mm | 1500 mm | 0.14 cubic meters |

| KS 15-6 | 590 mm | 1500 mm | 0.26 cubic meters |

| KS 15-9 | 890 mm | 1500 mm | 0.4 cubic meters |

| KS 20-6 | 590 mm | 2000 mm | 0.39 cubic meters |

| KS 20-9 | 890 mm | 2000 mm | 0.59 cubic meters |

What rules must be followed when servicing a septic tank?

There are simple rules that support the high-quality operation of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (or better yet, every 2-3 years) the bottom heavy fats are removed. The volume of sludge should not exceed 25% of the tank volume. When cleaning, part of the sludge is left to restore the microflora.

- Quality of work. The wastewater leaving the system must be 70% purified. Analysis of wastewater in the laboratory will determine the acidity indicator, which will allow you to find out the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after intensive ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (humid environments).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

Septic tank installation technology

There is nothing difficult in making a reliable and durable septic tank from rings. When designing several compartments, a linear construction principle is used, in which all concrete columns from rings are lined up along one line.

The receiving compartment and the following tanks are placed in close proximity to each other, and the filter column is located at a slight distance from them.

Step #1 - measurements and design

One of the prerequisites for effective wastewater treatment is to create conditions for it to remain inside the walls of the septic tank for at least three days. Therefore, the dimensions of the chambers are determined using the total three-day volume of wastewater as a basis.

According to standards, the daily volume of water consumption per household, subject to the use of household appliances, is about 200 liters.

So for a family of two or three people, the minimum volume of a treatment plant should be about two cubic meters. A family of 5-6 households will require a more spacious structure with a volume of 3-4 cubic meters.

When calculating, only the volume of the septic tank compartments is taken into account; since the filter well is not one of these, it is not taken into account (+)

But when determining the volume of the structure, it is worth making a small reserve. After all, if guests arrive, there is a risk of “overfilling” the norm. And eliminating the consequences is a rather complex and at the same time expensive procedure.

The table below will help you determine what size rings you will need and in what quantity.

Marking and dimensions of manufactured reinforced concrete rings indicating the outer/inner diameter, weight and volume

When choosing rings, keep in mind that the actual volume of the column must be clearly higher than the calculated one. This is due to the fact that as the drains fill, they rise only to the level of the overflow holes and never reach the top edge. Therefore, the calculated volume of liquid must be placed up to the level of these pipes.

Step #2 - preparing the necessary materials

When choosing rings for a septic tank, it is advisable to buy products with locks. The presence of locks not only simplifies the installation process, but also prevents their displacement under the influence of frost heaving. When purchasing products, you need to pay attention to the evenness of the seats and carefully inspect the integrity of the locks.

In addition to the rings themselves, materials and construction tools will also be required:

- sewer pipes;

- fine crushed stone;

- river sand;

- polyurethane foam;

- cement mortar;

- waterproofing compounds;

- rolled thermal insulation materials;

- building level;

- ladder;

- perforator;

- wide brush;

- container for mixing the solution.

To create overflows between wells, you will need asbestos-cement or polypropylene pipes marked “for external sewerage.”

Polypropylene pipes are famous for their strength and elasticity; their operating temperature is about 65°C

The diameter of asbestos-cement or polymer pipes used for overflow should be 110-120 mm.

Step #3 - digging a pit and arranging the bottom

It is better to carry out excavation work after the onset of the first frost or in the hottest months. During this period, the lowest groundwater level is observed.

The pit can be dug manually, by hiring a team of “diggers”, or by using the services of an excavator. If we take into account the costs of carrying out excavation work, then the costs of a team of diggers will be comparable to the amounts that will be spent on calling out special equipment.

The dimensions of the finished pit should exceed the dimensions of the installed rings by 50-80 cm. This will simplify the installation process and allow for external waterproofing of the joints of the structure.

When calculating the pit depth, three values are summed up: the height of the monolithic or filtration bed (20-30 cm) + the height of the rings (indicated in the table) + the height of the slab (15 cm).

It is better to immediately remove a large amount of soil removed from the pit from the site, using the same machine that delivered the rings

The pit for installing the treatment plant should be two-tiered: its second tank should be buried 50 cm lower than the first. Alternatively, dig your own hole for each tank.

To connect sewer pipes, trenches are dug, laying them below the freezing depth of the soil. The width and depth of the trenches are selected based on the dimensions of the rings used for the construction of the tanks. Most often they are made 50 cm wide with a depth of 1.2-1.5 m.

The bottom of the dug trenches should be located at a slope of 2-3 cm, distributed per linear meter. It is better to calculate in advance the difference between the extreme points, multiplying the distance between them by the slope value stated by the standards.

Compliance with this condition will ensure gravity flow of the liquid. The leveled and compacted bottom of the trenches is covered with sand, forming a layer 10 cm thick.

The bottom of the pit is carefully compacted again. For concreting, standard cement mortar prepared in a 3:1 ratio is used.

If you plan to install a lower ring equipped with a bottom, you don’t have to construct a concrete screed. In this case, you can limit yourself to crushed stone filling, forming a layer 20 cm thick.

The bedding created after compaction must have a flat horizontal surface, free of differences

It is necessary to achieve an effect in which the pillow sags as much as possible. To thoroughly compact the embankment and achieve maximum density, tamping is alternated with filling the fill with water.

Step #4 - installing rings and sealing seams

The construction of a septic tank begins with the installation of its closed part - the lower ring, equipped with a bottom. It is set exactly so that the walls are positioned strictly vertically. Compliance with this condition will ensure the strength and stability of the structure.

When using a ring without a bottom as a base, the bottom of the pit must first be concreted. To do this, pour a concrete screed 30 cm thick. The dimensions of the created concrete screed should be 20 cm larger than the diameter of the immersed ring.

An option for pouring the base for a three-chamber septic tank, the tanks of which are arranged not in a straight line, but in the form of a triangle

It can take up to two weeks for the concrete to harden. As soon as it acquires the necessary strength, install the first ring. Laying the rings without outside help is almost impossible. This work is performed with two or three assistants.

To protect the structure from leakage and reduce the harmful effects of groundwater on concrete, the joints between the base and the lower edge of the ring are thoroughly coated with waterproof cement mortar.

Ideal for waterproofing materials:

- bitumen mastic;

- deep penetration impregnation.

As an impregnation for treating concrete rings, it is good to use cement-based compositions such as “Penetron” or “Aquacement”.

When sealing joints, liquid glass is often added to cement mixtures, which increases the resistance of the joints to excess moisture.

Toxic compounds must not be used for internal processing. During operation, they can destroy bacteria that are responsible for the decomposition of bio-inclusions.

All subsequent ones are installed on the first ring one by one. To create a more durable fixation, metal brackets are installed on the outside of the structure. The “entry” points of the staples are concreted and covered with a layer of insulation.

Immerse the rings into the tank using a tap. The resulting joints between the elements are also carefully sealed. The voids between the outer walls of the tank and the pit are filled with a mixture of soil removed when digging the pit and sand.

The “pockets” should be filled evenly, alternating compacting the soil composition with filling with water.

Such a layer will perform a dual function: drain rain and groundwater, and also serve as a shock absorber

The upper part of the structure, located above the soil freezing level, should be insulated. In severe frosts, there is a high probability that an ice plug will form inside the tank. And this significantly reduces the speed and efficiency of cleaning.

It is convenient to use as a heat insulator:

- pieces of expanded polystyrene;

- finished shell products.

At the top of the columns, necks with holes for sewer hatches are installed. They are equipped with concrete or cast iron covers.

The second compartment of the purifier is equipped with a ventilation pipe. It should rise 70-80 cm above the ground surface.

Image gallery

Photo from

Finishing concrete ring

Method for narrowing the neck of a septic tank

Sealing the butt seams of the well

Installation of ventilation pipes

Step #5 - installation of overflow pipes

The location of the overflow pipes is determined by the level of the pipe leading from the house. Since the overflow septic tank device is designed to ensure the movement of liquid by gravity, the highest point of the sewer pipe must be located below the freezing level of the soil.

The overflow on the opposite wall of the tank should be approximately 15-20 cm below the supply point.

The overflow between the second tank and the filtration column can be done at the same level, or the same 5 cm can be maintained

To connect the sewer pipe, a hole of the appropriate size is made in the wall of the ring using a perforator. The easiest way to fix the pipe in concrete is with polyurethane foam. It will retain moisture and act as a damper pad.

The entrance of the pipe to the tank wall is carefully sealed. The inlet pipes coming from the house, as well as the overflow pipes between the chambers, are equipped with tees.

The main purpose of the tee is to direct wastewater downward in order to improve its processing and prevent crust erosion

Tees at the ends of the outlet and inlet pipelines will provide unobstructed access for clearing blockages.

To increase the resistance of pipes to the most severe frosts, it is advisable to apply a layer of insulation to them and cover the top with a protective casing.

Principle of operation

Let's start with the fact that there are two types of septic tanks: two-chamber and multi-chamber. The two-chamber one is the simplest in design. Its components: a settling tank, where a three-day process of separating wastewater into liquid and solid waste takes place; a filter well without a sealed bottom, into which purified water flows from the sump and goes into the ground. In order for the filter well to be less polluted and the quality of water purification to be better, several settling tanks can be combined into a sequential chain.

A multi-chamber septic tank is different in that when used, the degree of wastewater purification is much higher, and removing sediment from it is faster and more convenient. But it is important to know that even a ten-day septic tank will not completely clean the wastewater, since the bulk of the sediment is in the 1st section, without re-contaminating the water with waste products.

How to prepare a pit?

When starting to prepare a pit, you should take into account the maximum permissible groundwater level. When installing filter wells, it must be at least 3 meters from the ground surface, when installing underground filtration fields and clay soils - 1.5 m.

When digging a hole for a future well, adhere to the principle: the soil moisture has increased at a decent depth - it’s time to finish. If the depth of the dug hole is less than 1 meter, then nothing will come of it and you will have to bury it.

In order to have good stability and prevent drainage of wastewater into the ground, the installation of a multi-chamber septic tank requires the fulfillment of the following conditions: all chambers, except the final one, must be installed on a concrete base.

How to install overflows?

The tray must be placed 100 mm higher than the filter. It supplies wastewater to the entire water supply system. Its open end should be in the center of the well.

The overflow should be laid with a slope of 2 cm per linear meter, which will reduce blockages.

The distance between the inlet and outlet pipes must be at least 50 mm. The first one will be located above. Please note that the use of plastic pipes for the external main leads to premature wear of the entire system.

To ensure that the water flow is directed downwards, the sewer tee must be installed in a vertical position.

Tees for overflows

In addition to the overflow holes, it is important to take care of the hole for the ventilation pipe.

How to install a filter well?

An iron barrel is suitable as a filter well, which will save your budget.

The location of the filter base should be at a level exceeding 1 meter of groundwater level. Otherwise, the load goes up to 20%.

1 — water barrier; 2 — neck rings; 3 — hatch cover; 4 — insulating cover; 5 — hatch body; 6 - floor slab; 7 - ventilation riser; 8 — blind rings; 9 — perforated rings; 10 - filter media; 11 — holes in the rings; 12 — concrete base; 13 - supply pipeline

To increase the absorbent surface area, holes with a diameter of 60 mm and a total area of 10% need to be made on the walls of the well.

At the bottom you should lay out a layer (200-300 mm) of expanded clay, crushed stone and other small stones, which will serve as a filter.

We recommend reading the instructions for building a drainage well.

How to install a sump tank?

Consider the installation of a two-chamber septic tank. In the pit, the bottom is filled with sand to a depth of 100-150 mm and watered for the best shrinkage.

The next concrete ring is installed on a solution in proportions - 1 cement: 3 sand: 0.1 liquid glass. It is necessary to prepare the solution in small portions, since it must be used within half an hour.

1 — rings of the working part; 2 — insulating cover; 3 — neck rings; 4 — hatch body; 5 — hatch cover; 6 — ventilation riser; 7 - floor slab; 8 — bottom plate; 9 — crushed stone cushion; 10 - waterproofing; 11—sediment zone; 12 — running brackets

The cover with the hatch is installed on a bed of sand-cement mortar.

The sump requires waterproofing with two layers of hot bitumen or coating with a water-repellent composition.