Designers and builders have several options for roofing designs at their disposal. Choosing the optimal option is a responsible matter, because... The reliability and durability of the entire structure depends on it.

It is quite logical to ask questions about how to properly make a hip roof of a house with your own hands, what distinguishes it and when is it most suitable? To answer them, you should consider the structural and technological features of such a roof.

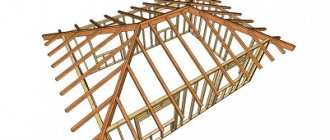

Photo of a hipped roof

Types (tent, hip, half-hip)

Main types of hipped roofs:

- Tent type . The roof has 4 triangular slopes, the tops of which converge at one point. Usually its base has the shape of a square, and all slopes are equal in area. This design is suitable for a house in which the lengths of all walls are equal. Typically these are small buildings. The roof is particularly attractive.

- The classic option is the Dutch hip roof . A rectangle is formed at its base. The roof resembles a gable structure, because the slopes, supported by long walls, converge at the top along a line, forming a ridge run. However, in a hip roof, it is not the pediment that is erected above the short walls, but slopes in the shape of a triangle. As a result, the roof is made up of 2 trapezoids and 2 triangles, on opposite sides of the house. This roof has versatility. It is suitable for any structures, especially when erected in regions where significant winds can blow from all directions.

- Half hip type . Instead of triangular slopes, more complex structures are provided in it, which accordingly changes the side edges of the trapezoidal slopes. There are 2 main varieties - Dutch and Danish half-hip roof. In the first case, the triangular slope is located at the top, but does not descend to the entire height of the roof. The lower part ends with a vertical wall in the shape of a trapezoid. This design allows you to equip a convenient entrance to the attic or attic window. In the second option, the vertical element has the shape of a triangle and is located in the upper part. The bottom is made in the form of a trapezoidal slope. The upper gable provides the possibility of installing an attic window.

All types of hipped roofs have an attractive appearance and have long been popular abroad. Recently, they are finding more and more admirers in Russia.

Flaws

- Technical difficulty. Without practical skills, it is difficult to cope with work. It is better to entrust the construction to specialists.

- A roof will require more materials than a gable roof. Since four slopes imply the same number of connections, and they will have to be trimmed. Roofing material will cost more according to the estimate.

- The attic is small, since rafters, supports, and braces take up a lot of space. Hip structures are not used for attic construction.

Advantages and disadvantages

The following advantages of a hipped roof are noted:

- The absence of a pediment makes it possible to increase the resistance of the structure to wind loads from all sides, which is important for regions with variable wind roses.

- Effective drainage of precipitation and melt water around the entire perimeter of the house.

- Possibility of arranging a comfortable attic of considerable size.

- Attractive appearance.

Disadvantages include more complex design and construction and increased costs. This design is more often used in luxury homes, where special attention is paid to design.

Attracting specialists

Each residential building differs in dimensions, which directly affect the design of the roof truss system of this type, as well as the number of struts, racks and other related elements.

If you have to build a dacha-type house with your own hands, then it is better to entrust all the calculated measurements of the rafter system to specialists, as well as the installation of such a complex type of roof. Professionals will be able to “in reserve” increase the standard parameters of the roof’s strength, which will definitely not fail for many years. This service is not cheap, so we do not recommend saving on it. Please note, when starting to work on installing a hipped roof yourself, that the internal rafter system is more difficult to install than the calculation, assembly, and installation of a gable roofing system.

It is the specialists involved in the construction of a hip roof who will have the entire necessary arsenal of tools, and most importantly, the experience that allows them to competently and quickly carry out all the work on installing a roof of this type.

Design (drawings) and necessary calculations

In order to make a hipped roof, it is necessary to correctly make calculations and establish the basic parameters of the roof . It is most important to determine its area, because it determines the operating loads, the size and number of rafters, the angle of inclination of the slopes, on which the height of the roof depends.

For the construction of a hipped roof, detailed drawings must be developed. Without knowing the exact dimensions of all roof elements, it is impossible to reduce them into a single whole. It is best to create a 3D model using a special computer program. With its help, the exact dimensions of all parts will be determined.

Area calculation

The total roof area consists of the areas of 4 slopes. The calculations use formulas for isosceles triangles and rectangles.

In a hip roof, the total roof area will be S=4Sc=4(aha/2cosA)/2 =aha/cosA, where:

- a is the length of the house wall,

- A is the angle of inclination of the slopes.

In a hip roof, the total area consists of 2 triangles and 2 trapezoids: S=2(b+c)h/2 +2ah/2sinA = h(b+c)+ah/sinA, where:

- a is the width of the house,

- b – length of the house,

- с – length of the ridge purlin (ridge),

- h – roof height above the ceiling,

- A – angle of inclination of the triangular slope.

When calculating, it is necessary to take into account the length of the overhang, which is formed on all sides of the roof. To do this, add 3-5% to the calculated area, depending on the length of the overhang.

Calculation of rafter cross-section

The complete calculation of the rafter system is quite complex . It takes into account all operational loads, rafter length, slope angle, installation pitch, support reactions and other factors.

It is not always possible to carry it out on your own, and therefore it is recommended to use building codes.

The choice of rafter cross-section is based on the strength properties of the material, taking into account a safety factor of about 0.8 . In general, the calculation of a hip roof is in many ways similar to the calculation of a gable roof.

Recommendations for choosing a rafter section, taking into account some factors, are summarized in Table 1.

Table 1. Section of the rafters of a hip hip roof:

| Rafter length, m | Rafter dimensions, mm | Rafter installation pitch, m | |

| beam (paired board) | Log, diameter | ||

| Until 3 | 80x100 90x100 90x160 | 100 150 160 | 1,1 – 1,4 1,4 – 1,7 1,7 — 2,2 |

| 3- 4 | 80x160 80x180 90x180 | 160 180 190 | 1,1 – 1,4 1,4 – 1,7 1,7 — 2,2 |

| 4- 5 | 80x200 100x200 | 200 200 | 1,1 – 1,4 1,4 – 1,8 |

| 5- 5,8 | 100x200 | 200 | 1,1 – 1,5 |

| Up to 6.5 | 120x220 | 240 | 1,1 – 1,4 |

The length of the rafters does not exceed 6.5 m. If it is necessary to obtain a longer length, it is necessary to make splices and introduce additional reinforcing elements.

Selecting the angle of inclination

The angle of inclination of the slopes is selected based on the snow and wind load, the roofing materials used and the size of the attic space. It can vary widely - from 5 to 65°.

For regions with significant snow load, an angle of 45-65° is required. Moreover, with a slope of 60%, the load from snow can not be taken into account at all, because it does not accumulate on the roof.

However, as the slope increases, the windage of the structure increases, which reduces wind resistance. This load can be ignored at an angle of less than 25°E. For regions where strong winds are possible, the inclination should not exceed 45-48°.

Taking into account the properties of various roofing materials and the characteristics of their application, the following angles of inclination are recommended:

- soft, rolled materials – from 5 to 20°;

- slate, metal, asbestos-cement sheets – 12-65°;

- ceramic tiles – 22-60°.

It is also important to take into account that with an increase in the angle of inclination of the slope, the height of the roof increases, and therefore the consumption of materials. In each specific case, you should look for the optimal ratio between the size of the attic space and the cost of materials.

Rafter pitch

The distance between the rafters or the pitch of their installation depends on the operational loads, as well as the size of the structure and the rafters themselves. The weight of the roofing material is important. In addition, the dimensions of the roofing elements or the width of the rolls of soft materials are taken into account.

Minimal steps required for slate, metal, tiles. They are installed within 0.6-0.8 m. When laying a soft roof, the pitch increases to 1.4-1.6 m.

Another important factor is rafter length . So, with a length of more than 4 m, the optimal pitch for a soft roof is 1-1.2 m.

Average prices for turnkey work

Typically, specialized companies offer their services for the construction of 4-pitch roofs based on the installation cost of 1 sq.m. roof area. By analyzing advertisements of this nature on the Internet, you can present the average price with an element-by-element installation layout in the following table.

| Type of work | Price, rub./sq.m. |

| Rafter system | 350 |

| Insulation | 150 |

| Waterproofing | 100 |

| Countergrid | 100 |

| Lathing | 150 |

| Seam roofing | 300 |

| Additional elements | 350 |

| Total | 1500 |

Preparatory stage

After developing the project and drawing up drawings (models) of the hipped roof, preparations for the construction of the roof begin. At this stage, it is important to choose the right material, control its quality and prepare the necessary tools.

Before purchasing basic and consumable materials, it is necessary to calculate their need , because... they must be purchased immediately for the entire volume of construction, but without excessive reserves.

Particular attention is paid to wooden elements for the rafter system. A board, timber or log of coniferous species is most suitable for it. Larch stands out especially for its strength and resistance to decay. If you have financial resources, you can use oak.

The calculation of the need for rafters is made taking into account the installation pitch and the height of the roof (the angle of inclination of the slope). The length of each rafter is determined as L=h/sinA. The lumber of the ale rafter system must be of high quality and have a residual moisture content of no more than 20%.

Roofing material is selected based on financial capabilities, size of the house and overall design. It could be:

- rolled material (including ondulin),

- slate,

- tiles,

- corrugated sheets,

- metal tiles,

- asbestos-cement or metal sheets.

For waterproofing, bitumen mastic, roofing felt or polymer films are usually chosen . Mineral wool and expanded polystyrene (foam plastic) are most often used as insulation.

The need for these materials is selected based on the roof area, taking into account the overlap of elements or strips, as well as inevitable waste.

Required Tools

Before starting the main work, you need to prepare the following tool:

- Bulgarian,

- hacksaw,

- electric drill,

- screwdriver,

- plane,

- axe,

- hammer,

- pliers,

- screwdriver,

- chisel,

- construction knife,

- scissors,

- construction or furniture stapler,

- paint brush and roller,

- building level,

- plumb line,

- roulette,

- metal ruler,

- square

For large amounts of work, it is advisable to have a circular saw.

How to assemble: construction methods

Hip roofs are erected in two ways. The fastest and most expensive construction method is to assemble a support frame from pre-fabricated wooden rafter sections.

A specialized enterprise, under an agreement with the developer, takes measurements on site, then, based on them, prepares sections of the frame in its workshop.

The company delivers structures to the construction site and assembles the roof as a constructor .

This installation method is certainly effective and time-saving. Its only drawback is its high cost. For a construction site owner who has experience in construction and owns tools, it will be much more profitable to do this work with his own hands.

Practice shows that self-assembly of the rafter frame allows you to save significant financial resources , although it will take much longer than with the first installation method.

For small buildings, for example garden gazebos with a square plan, the rafter frame is assembled on the ground. Then, using a simple winch (pulley hoist) and a leash, the roof is lifted and pushed onto the top of the building.

Construction of the rafter system

The basis of a hipped roof is a rafter system with reinforcing elements. However, other design details that provide the necessary strength and reliability are no less important.

Support beam

To ensure a reliable connection of the rafters with the load-bearing walls and uniform distribution of loads, a Mauerlat is mounted. This is a beam or beam attached to the top of the walls around the entire perimeter of the house .

Typically, a wooden beam measuring 10x10, 10x15 or 15x15 cm is used. It must be positioned strictly horizontally and form a continuous support frame.

Sloping legs

At the junction of the long and short slopes of the hipped roof, on both sides of the house, inclined rafter pairs - slanted legs - are installed. The length of the rafters in them exceeds the length of other rafters that form the slopes.

In addition, the load on this element is increased. Taking this into account, paired boards are usually used to make legs . Their total size reaches 10x15 or 10x20 cm.

Ridge beam

In hip roofs, the rafter legs in the upper part are connected by a beam, called a ridge purlin or ridge. It provides rigidity to the entire rafter system and serves as an upper support for the racks.

There is no such element in a tent structure. For the ridge, a 10x10 cm beam is most often used .

Scheme of arrangement of the supporting structure

The basis of the supporting structure of the roof is made up of rafters, which, in fact, form its load-bearing frame. In hip roofs, in addition to slanted legs, two types of rafters are used - main rafter legs (pairs) and outer (shortened) rafters.

The rafter pairs form long slopes, rest on the Mauerlat below, and on the ridge beam at the top. Their design is similar to the rafters of a gable roof.

External rafters connect the slanted legs to the mauerlat. The choice of rafter section is given above.

Strengthening elements

The rafter system must be strong and rigid. The following elements are used to strengthen the rafters:

- Racks are vertical beams that support the rafter system and hold it at the desired height.

- Sprengels are inclined elements supporting the rafters of a short slope.

- A bench is a beam that serves as a support for the racks. It is laid on internal walls or ceilings.

- The crossbar and tie are horizontal beams that fasten the rafter pairs in the upper and lower parts, respectively.

- Struts are inclined supports that strengthen the racks. They serve to increase the strength of the entire structure.

- Fills are boards that form an overhang.

The need for additional reinforcing elements determines the size of the span to be covered and the length of the rafters.

Material selection

The roof structure is made of larch or pine. For residential buildings, it is preferable to purchase first-grade wood, for outbuildings - second or third. It is undesirable to use timber with knots and cracks for the frame. All workpieces should be treated with antiseptics. Board section sizes:

- Mauerlat, ridge, racks, truss – 100x100, 100x150, 150x150;

- Puffs, fillies – 50x100, 50x150;

- Sheathing and wind beam – 20x100, 25x150.

The amount of material is calculated using formulas. Having received the calculation results, it is worth purchasing a board with a small margin. For continuous sheathing, use plywood or OSB with a thickness of 12–15 mm. Most types of roofing materials are attached to it: ondulin, metal tiles, corrugated sheets.

Step-by-step instructions for constructing a 4-pitched roof for a private house

Step-by-step instructions for constructing a hipped roof for a house or gazebo include several characteristic steps. They should be carried out in a given sequence, taking into account technological nuances.

Mauerlat installation

When constructing load-bearing walls made of bricks or aerated blocks, an armored belt is formed on their upper part - a concrete pour with a reinforcement frame. When pouring, vertical rods made of steel reinforcement with a diameter of 10-14 mm with an outward projection of up to 10 cm are installed into it. They serve to secure the Mauerlat.

Before installing the mauerat on the beam, the locations of the rods are carefully marked. Holes are drilled according to the markings. The Mauerlat should form a continuous rectangular frame around the entire perimeter of the house.

To do this, the ends of the beams are securely joined by joining according to the “half-tree” principle. At the ends, a sample is made to the middle of the beam at a length of 25-30 cm .

The elements are superimposed on each other and securely fastened with nails, self-tapping screws and additional staples and overlays. The frame is pressed tightly onto the rods using a hammer.

Horizontality is controlled by the building level. For greater reliability, anchor bolts are sometimes used instead of rods .

Laying the beds

The next step is to create support for the racks of the rafter system. The beds are made from horizontal beams measuring 10x10 cm or paired boards.

They can be installed on load-bearing internal walls . If these are not provided for in the project, then you will have to mount a floor beam, and install a bench on it.

Mounting racks and ridge

Racks are mounted on the bench. First, supports are installed under the top of the mowing legs, and then, between them, racks for rafter pairs are fixed. The installation pitch must correspond to the pitch of the rafter system. The racks are attached to the bench using angles and steel plates.

To fix them until construction is completed, temporary reinforcement is used in the form of slopes (supports) made of boards.

It is important to ensure a clear line for the entire row of posts in the center of the house, as well as absolutely the same height, which sets the height of the roof. The verticality of the racks is controlled by a plumb line.

Next, a ridge beam is attached to the top of the posts . It is fastened with nails, and the joint is reinforced with metal corners and plates. If the roof span is significant, struts are installed. They are located on both sides of the post, and at an angle connect the place where the post is attached to the bed with the ridge beam.

When erecting a hip roof, the racks are installed diagonally. The external rafters are directly attached to them, and therefore the length of the racks must correspond to the angle of inclination of the slope.

Installation of rafters

Installation of rafters begins with the main pairs with a given pitch . The upper end of the beam is cut at the desired angle and attached to the ridge.

The lower end forms an overhang, and the rafters are attached to the mauerlat “on the passage”. To do this, a corresponding cutout is made in it according to the size of the rafters.

Next, the external rafters are installed . They are cut to the required length. The upper end is fixed to the slanting leg, and the lower end to the mauerlat in the same way as the main rafters.

If the rafters are long, a crossbar is installed between them in the upper part. It rigidly connects the bars into a pair with a certain angle.

To secure large external rafters, a sprengel is installed on a triangular slope. It connects the rafters to the floor (ceiling) at an angle, which strengthens the structure. Truss posts are most often used in a tent system.

The rafters can be fastened rigidly or hingedly (sliding fastening) . The first option is used for houses with walls that are not subject to shrinkage (brick, blocks). Sliding fastening is necessary for wooden structures. For this purpose, special corners and strips are used, as well as adjustable anchors.

Lathing

To give final rigidity to the rafter system and create a base for attaching the roofing, lathing is made. It is performed by installing edged boards 2-2.5 cm thick and at least 10 cm wide between the rafters. The joint of the boards should be in the middle of the beam.

The following lathing design is possible:

- Solid. The boards are fitted close to each other. It is used for soft roofing and tiles.

- Discharged. The gap between the boards is 20-25 cm. This is a common option for laying slate and corrugated sheets.

- Rare. The gap can exceed 50 cm. This lathing is only suitable for large and solid roofing sheets.

The sheathing boards are attached directly to the rafter beams using nails or self-tapping screws.

Insulation

A thermal insulation layer is installed on top of the sheathing . For these purposes, mineral wool mats or foam plastic (expanded polystyrene) boards are most often used.

They are installed without gaps. The joint should be filled with foam and sealed with tape. Fastening is carried out with nails or self-tapping screws with a large head.

After insulating the roof, it is necessary to ensure reliable waterproofing. For this, roofing felt or thick polyethylene film is used. The strips of material are laid with an overlap of at least 15 cm. The joint is sealed with tape.

Roof covering

Each roofing material requires an individual approach to installation . All steps for its implementation are specified in the product instructions, and they must be strictly followed. The coating is laid in the direction from bottom to top.

It is important to use the fasteners that are designed for this material. When fastening with other elements, you can cause the appearance of microcracks, which will lead to rapid destruction of the coating.

How to build an overhang?

The eaves and gable overhang of the roof are needed to remove flowing moisture away from the wall of the house . This is the final element of the roof and forms the final appearance. It must have a length of at least 25-30 cm. Most often, the length is increased to 45-70 cm.

To make it attractive, this element should be specially finished. Its aesthetic appearance is given by lining, block house, plastic panels, wooden products, and metal strips. A special design style is provided by ready-made elements for the overhang - soffits.

Supports used

The choice of shape may depend on the materials used during the construction of the building. In different types of buildings, the design of the hip roof rafter system may focus on different planes, for example:

- In wooden houses - on the top crowns;

- In frame houses - on a wooden frame formed on top of the house;

- Stone houses - on the lower support beams.

Diagonal sloping rafters usually have a greater linear length than conventional beams. In order to achieve the required length, the bars will have to be spliced. All resulting joints during merging must be reinforced with supports for struts or racks. The process of merging the beams should take place so that the joint along the length is obtained at the point 0.15xh, in which the designation h means the height of the rafters, namely the distance between the 2 supports.

It is necessary to carry out calculations of the linear length of the beams taking into account the total number of supporting structures. Typically, the merging of elements is carried out using an oblique cutting technique. After this, the joining place of the rafters is tightened with 12-14 mm bolts.

Roof covering

The range of roofing materials consists of piece, sheet and roll materials. These are different types of tiles, ondulin and corrugated sheeting, seam and roofing felt, its modifications, etc. Pitched roofs are covered with the following materials:

- Bitumen rolls and tiles .

Roll material is regular or modified roofing felt. The rolls are rolled out in horizontal rows from bottom to top, overlapping the slope. The strips are laid on hot bitumen or cold mastic with a solvent. Shingles are bituminous tiles in the form of curly petals, made of fiberglass impregnated with bituminous compounds. The shingles are nailed or stapled to the boardwalk, overlapping from the bottom to the top of the roof slope. - Metal tiles . The material consists of metal profiled plates, painted in different colors. Installation is carried out using self-tapping screws or special clamps, overlapping from bottom to top.

- Ondulin . One of the best roofing sheet materials. Ondulin replaced harmful asbestos slate. It is a product of pressed cellulose impregnated with a bitumen composition. Ondulin is easy to process and install. It can be easily painted in different colors.

- Corrugated sheeting . Corrugated metal sheets are gaining more and more popularity every year. Waves look like rectangular protrusions and depressions. The corrugated sheets are painted with durable multi-colored enamel compounds. They are attached with an overlap from the bottom up to the boardwalk with self-tapping screws and rubber washers.

- Seam roofing . Thin metal sheets are connected to each other with a special lock using special crimping pliers. This is one of the most expensive roofing coverings. Roofs with such roofing are absolutely waterproof and beautiful in appearance.

Pie composition

The culinary term for a pitched roof refers to everything that is between the rafters, sheathing and roofing. This includes thermal insulation mats, vapor barriers and waterproofing.

It is used for arranging warm roofs to create comfortable living conditions in attics. In some cases, this also includes the mandatory elements of a cold roof - sheathing, counter-lattice and roofing.

In a flat roof, the pie has a more complex structure:

- The sequence of layers of an insulated unused roof : base → slope-forming layer (if necessary) → vapor barrier → insulation → waterproofing (roof covering).

- The sequence of layers of an insulated exploitable roof : base → slope-forming layer (if necessary) → vapor barrier → insulation → waterproofing → separating and filtering layer (geotextile) → paving slabs for preparation.

- The sequence of layers of an inversion (reverse) roof : base → slope-forming layer (if necessary) → waterproofing → insulation → drainage layer → geotextile → protective finishing layer - crushed stone or gravel ballast, tiles, decking boards, etc.

Why is a hipped roof more popular than a gable roof?

“Why the extra headache and complexity?” you ask: “After all, you can build a simple gable roof much faster and cheaper.” Here the craftsmen emphasize some important points in favor of choosing exactly four slopes for the roof:

- High wind resistance.

The hipped roof has no gables; all its planes are inclined towards the ridge. This structure minimizes the impact of strong winds and reduces possible destructive consequences to “0”. - The most successful load distribution.

A multi-pitched roof can withstand the maximum amount of precipitation, since the gentle slopes take part of the main load. Therefore, sagging, deformation and destruction of the rafter system, in this case, have a minimal probability. - Availability of choice of any method of roof insulation.

Straight gables require a special approach when choosing the type of roof insulation, since they are located vertically and are subject to wind blowing. The gentle slopes of hip and hip systems make it possible to evenly insulate the roof with any available material.

In addition to the listed “advantages”, a roof with four slopes perfectly conserves heat, can be covered with any roofing material and always has a neat appearance.