Stairs to the second floor on a metal frame are an optimal option for arranging the interior space of a two-story private house, both in terms of practical and aesthetic properties. Let's consider their main pros and cons, the variety of standard structures and railings for them, what rules to follow, calculations to carry out and installation features to take into account, as well as what main stages the DIY installation procedure consists of.

Staircase on a steel frame Source gidlestnic.ru

Pros and cons of metal stairs

A staircase to the second floor in a private house on a metal frame has the following advantages:

- Large margin of safety.

- Variability in design.

- Inertness towards other materials.

- Possibility of completing with voluminous and heavy steps and railings.

- Less absorption of space, formation of lightness and airiness in the design style - compared to analogues made of wood, stone, concrete.

- Maintaining performance characteristics throughout the entire service life.

- High resistance to aggressive environmental factors with proper surface treatment.

- Possibility of using any available installation technologies - assembly with bolts, welding, concreting in the surface.

- A wide selection of rolled metal used to create the frame - pipes, channels, angles, etc.

- A combination of different decor styles.

Despite the huge list of advantages, the iron staircase has several disadvantages:

- Complex material processing - requires specific experience and skills.

- If not designed correctly, reconstruction will require significant effort and investment.

- The need for welding work.

Frame of a metal staircase to the 2nd floor Source zonaremonta-ufa.ru

However, with an initially competent approach and thoughtfulness of all stages, the shortcomings are easily leveled out, and the money, labor and time spent are fully justified in the long term of the product’s operation.

Note! A staircase from a channel and a corner to the second floor is often built on the outside of the wall. In this case, when manufacturing it, the climatic features of the region should be taken into account. Most often, builders forget to make technological gaps at fastening points. With large differences in winter and summer temperatures, significant deformation of the metal occurs - compression and expansion. As a result, the structure may bend and crack in places.

Noisiness

Some metal stairs provide increased noise levels when moving. This especially applies to models with low weight, which are characterized by strong noise when using the finishing. If the structure does not have sufficient mass, additional load can be used. For example, cover it with bitumen as a finishing material. This will also protect against moisture.

A staircase using rolled metal as a base is a good choice for quick and budget-friendly construction. The diagram can be drawn up independently using existing drawings. You can make both straight and angular marches. In addition, there is the possibility of decorating in any way.

Calculations should be carried out only after the project has been fully drawn up. Consider typical climate conditions, maximum load levels and other stair parameters. If all the necessary parameters are taken into account, the structure will last quite a long time.

Voted over 366 times, average rating 5

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Stairs Do-it-yourself installation of a spiral staircase: 15 photos with examples and stages of work Staircases with straight flights of flights have long been used by some...

Stairs Technology for installing handrails for stairs in a private house: choosing a model A staircase inside a private house is not only a way to climb...

Stairs Step-by-step instructions for building a goose step staircase with your own hands A staircase in a house with several floors is always needed, but not necessarily ...

Stairs Options for stairs on one stringer - design, types, differences from analogues Stairs are necessary structures in multi-storey construction. They …

Types of designs

Depending on the principle of fastening the steps and the structure, the frame of a metal staircase to the second floor has the following modifications:

- With stringers.

One or two special stands on which the steps rest. The number of supports, type and thickness of material used depend on the width, weight and total load. It is characterized by reliability, durability, minimal footprint and ease of installation.

Curved staircase on stringers Source region-master116.ru

- With bowstrings.

The structure has two stair supports. Compared to the above-presented option, the design is more durable, but also has maximum massiveness and occupied volume.

- Console.

Frames for steps are fixed directly to the wall surface using fasteners. Thanks to this, the visual effect of a floating staircase is created. It takes a minimum of materials to make and it takes up very little space. However, the natural price for this is low load-bearing capacity.

- Screw.

A wooden staircase on a metal frame is mounted around a powerful central support, such as a pipe. The version is distinguished by high strength indicators and reliability. Despite the fact that it is characterized by elegance and grace in the interior, in terms of operating comfort and practicality it is inferior to all the modifications considered.

- Combined.

The combination of several construction principles increases reliability and ease of use. Thus, the design often uses a stringer for external support of steps and a console for fixation on the side adjacent to the wall.

Combined staircase to the 2nd floor Source gidlestnic.ru

See also: Catalog of companies that specialize in the design and installation of metal structures

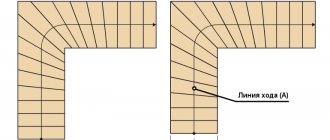

In addition to this classification, there are others, for example, by the number of spans, type and size of bends - trapezoidal, rounded, L-, U-shaped, etc. At the same time, it is initially better to take on the production of a simplified version on your own. An example is a straight staircase from a 50x50 corner into one flight. It is better to entrust the creation of a more complex modification to professionals.

Advice! Attaching wooden steps to a metal frame must be carried out in full accordance with their length and area. If the opening is less than 80-90 cm, then it is allowed to use one stringer, and if it is larger than this value, then you need to use a structure with two similar supports.

Channel in production

If it was decided to use a channel for the base of the frame, then it is necessary to correctly calculate the load weights. The strength and durability of this type of metal profile have made it popular, but even it has load limits. There is also no vibration or resonance during movement.

And its simple appearance also makes it competitive with other types of profiles. Rolled metal sheets are usually used to make bowstrings or stringers, which are the components that form the load-bearing base.

Stringers can be single or paired. In this case, the steps are placed strictly in the middle.

Railing Modifications

A metal staircase to the second floor in a private house must be equipped with railings. This is required by safety regulations. In addition, they can be used to improve the interior and structural strength. There are several options:

- Steel.

- Stainless.

- Forged.

- Homemade (welded or prefabricated).

Staircase with railings with elements of artistic forging Source olestnicah.ru

Railings should emphasize, improve or simply match the design style of both the staircase itself and the entire room. Therefore, if you have the wrong approach, lack of skill or lack of vision for artistic design, it is better to order these design elements or buy them ready-made from specialized companies.

Recommendation! An iron staircase to the second floor with wooden steps, complete from an aesthetic point of view, should also have handrails for the railings, similar in type, texture and color of wood.

Classification

Metal stairs are used permanently or temporarily. According to their purpose they are classified:

- to the main ones, serving for general use;

- auxiliary - service, spare, roofing;

- intra-apartment - for moving people within the boundaries of a private house or apartment;

- front doors;

- firefighters;

- garden

Stairs for permanent use are stationary, for temporary use - folding, sliding, attached.

The configuration of the spans is varied:

- single-march straight line;

- double-flight rotary;

- L-, P-, T-shaped;

- screw;

- spiral;

- S-shaped;

- pyramidal.

Between the flights there are landings or winder steps. Structures with risers are called closed, while structures without them are called open.

For straight spans, the treads have a rectangular shape; for curved or helical spans, they are wedge-shaped or angular. An interesting march layout is like a “goose step” or “samba”. Each step is divided into two halves, designed for stepping with a specific foot.

Design Rules

In order for the iron staircase to the second floor to comply with building safety standards and to be simply convenient in everyday use, the work on its construction must meet the following series of requirements:

- The optimal span width is 0.9-1 m.

- The step height in steps is from 14 to 19 cm.

- The depth of the steps is from 27 cm (so that an adult’s foot can fit).

- The march inclination angle range is 30-45 degrees.

- The minimum load capacity of the railing is 100 kg.

- The gaps between the fence posts are no more than 12-15 cm.

Important! A self-made metal staircase to the 2nd floor from reliable steel assortment (pipes, angles, channels) is strong enough in itself. If all the above standards are observed, all elements are properly fastened and connected, there is no need to worry about the magnitude of its load resistance. The only important indicator that should be calculated before all work is the angle of inclination. The rise should not be excessively steep (from 50 degrees and above), nor too gentle (less than 20 degrees). Since this will add inconvenience in the first case and waste of money, materials and space in the second.

Reliable ladder on a metal base Source proffi-grup.ru

Which channel to use

Which channel is best to use for stairs? To choose the right product, you need to calculate the load. The manufacturer's marking on the product makes it possible to obtain information about the parameters. Typically, numbers are important when calculating height. For stairs, it will be convenient to choose rolled metal with indexes from 8 to 18.

Moreover, the calculation part of the work is carried out based on the following data:

- tilt angle;

- maximum loads on it;

- mass of steps;

- dimensions of steps;

- number of bases for fastening;

- march height.

If you plan to make a march wider than 100cm, you need to use 3 or more load-bearing bases.

Typical types of channel

Basic calculations

The design of a staircase on a metal frame requires the following series of calculations and measurements:

- The distance between the finished floor surface of the 1st and 2nd floors.

- The length of the span from the first step to the last in projection onto the horizontal plane.

- Calculation of march length. To do this, you need to add the sums of squares above certain values in meters, and then extract the square root from the resulting value.

- Decide on the number of steps for each flight, based on their height and width.

Rules for choosing the angle of a staircase Source 7lestnic.com

It is better to place all calculated data, as well as a schematically depicted frame for a metal staircase, on a spacious sheet of paper in advance and indicate their number and sizes next to specific elements. The plan will significantly save time, nerves and money in the future when performing preparatory and installation work.

Plastic covers

What types of stairs are there and which one is better?

PVC overlays are used mainly for landscaping and protecting the edges of steps from damage in interior spaces. PVC overlays are available for sale, both flat and typical - in the shape of corners for steps. An additional property of PVC linings is the improvement of visual aesthetic perception and decoration of the entire interior. They are made of elastic PVC material, which, when heated to 80 degrees, easily takes a given shape, including curved ones.

Corner and flat PVC overlays are very popular in everyday use, as they are wear-resistant, durable and relatively low in price, like aluminum materials.

There may be simple plastic covers, or there may be such beautiful LED panels

Installation Features

During installation work, special attention is paid to the accuracy of installation of support beams (stringers), which are often played by channels. To prevent distortion, small metal plates are screwed onto dowels, bolts or screws at the point of contact between the supports. Next, the supports are welded or screwed to them.

After this, the steps are attached to the metal frame. They are pre-assembled using welded or prefabricated technologies in the form of separate structures - corners with shelves. Then they are mounted one by one by welding with the corners down or up - depending on the type of material of the steps. This method is suitable for finishing wood, porcelain stoneware, concrete, corrugated metal and tiles.

DIY installation steps

The instructions on how to install a channel ladder with your own hands are as follows:

- Stringers are installed. Their role is played by a pair of channels. Their minimum cross-sectional size is 8 by 10 cm. In this case, the contact points must ideally correspond and be adjusted to the surfaces on which they are attached. The fit must be absolutely tight, the welds must be free of gaps, and the bolted connections must be free of distortions.

- Installation of steps. They are made in the form of separate structures - corners with shelves. If the finishing will be done with boards or sheet metal, they are fixed with shelves downwards, and if it is planned to be poured with concrete, vice versa. In any case, the steps are attached to the metal stringer by means of a welded joint.

Homemade staircase to the second floor Source stroy-podskazka.ru

- A staircase made from a corner, channel, pipe or other type of rolled metal product requires finishing. All sharp corners and protruding seams from welding are ground smooth.

- Treated with an anti-corrosion compound and painted.

- Finishing. Step platforms are installed, railings and handrails are mounted, and decorated with decorative elements.

Knowledge alone of how to weld a metal staircase, even if you have some experience working with metal structures, is often not enough. Only a team of professional craftsmen from a specialized company can produce it quickly, profitably and safely.

Briefly about the main thing

The staircase to the second floor made of metal can have 5 main modifications:

- On the stringers.

- On the bowstrings.

- On consoles.

- Screw type.

- Combined.

The main advantages of a metal frame in them are greater strength, durability, reliability, aesthetics, availability of materials and preservation of performance qualities for the entire service life. During installation, correct preliminary calculations and measurements, mandatory construction requirements, type of railings and technical nuances of assembly are of great importance. You can make a simple metal staircase yourself, but it is better to entrust this task to professionals.