December 17, 2015

Gas burners are an indispensable assistant in the household, workshops and production shops, on a picnic and on hikes. Ease and ease of use have long given the primacy to gas appliances over other types. When choosing a burner, you should take into account the scope of application, the required power, as well as the maximum flame temperature. The last factor is especially important when performing more delicate types of work. Therefore, it is necessary to know the basic parameters directly related to the temperature distribution of the gas burner flame.

What determines the temperature of a gas burner flame?

A gas burner in a can and the flame temperature in it directly depends on the composition of the gas fuel, the ambient combustion conditions and the power of the equipment used. In this case, a direct relationship is observed between the calorific value of the gas and the temperature of the flame torch - an increase in the first indicator leads to an increase in the second.

When the process of mixing the fuel used with air occurs, the gas is completely consumed, which in turn increases the burning rate and increases the flame temperature. This indicator can be improved through additional use of air blast. For example, without the use of blowing, the maximum temperature regime is 1500 °C, but when using it, results up to 2200 °C are possible.

The temperature is also affected by the flame pattern. It is not homogeneous and is divided into three zones:

- internal - is the shortest and has the lowest temperature indicators. It is in it that the gas mixture is heated, but without combustion;

- The average reduction zone is the so-called light fire zone, in which the highest temperature is reached. Combustion already occurs here, but not at full power, due to the lack of oxygen and the presence of carbonaceous gas decomposition products;

- bordering - characterized by the lightest flame, is oxidizing. The temperature of this zone is also high and due to excess air, complete combustion of the gas occurs.

All about the temperature of gas burners

- What does it depend on?

- What temperatures do different types produce?

- How to adjust?

Despite the great popularity of electric stoves and other similar electric heating devices, the use of simple gas burners still remains relevant both in everyday life and in production.

When using burners, few people seriously think about the flame temperature. However, it is precisely this factor that determines the scope of application of the burner. Read below for all about what the temperature of a gas burner depends on and how to regulate it, as well as many other interesting facts.

Precautions for use

A hot water burner, like any tool that produces a flame during operation, is a high-risk tool.

Therefore, when using it, you must follow a number of rules that will help protect yourself and others, as well as carry out the planned processes efficiently:

- regularly carry out a preliminary inspection of the structure, make sure that the equipment is in good condition and that there is no risk of gas leakage due to a damaged hose or connections;

- when igniting gas, do not stand in front of the nozzle, do not direct the fire towards the gas cylinder, hoses, or people;

- in the process of fusing various materials, carefully control the flame, avoid excessive heating and accidental fires;

- do not go beyond the working area with the device;

- Do not work near gas cylinders or gas pipelines - the safe distance is at least 10 meters.

Fire extinguishers and sandboxes should be present at the workplace to help suppress a fire in the event of a fire. If the connecting hose or glass is clogged, the device cannot be used. This may be indicated by popping noises, kickbacks, or overheating of the equipment.

Having identified such problems, you should turn off the device by shutting off the fuel supply. Do not use wire or other sharp objects to clean the mouthpiece.

To protect your eyes from the harmful effects of infrared and ultraviolet radiation, it is advisable to use special glasses with light filters. You need to work in clean, oil-free workwear and non-slip shoes

In addition, the device must be extinguished correctly. First of all, the fuel supply is shut off, and then the lever is released.

It is not recommended to leave the tool turned on during breaks in work: it is better to extinguish the flame. If a significant break is planned, you need to shut off the gas supply to the cylinder by tightening the reducer valve.

How to choose a torch for connecting copper pipes is described in detail in the following article. We recommend that you read the useful information material. The torch soldering technology is given here, the process is outlined in great detail.

Burner parameters

Gas burners for a cartridge with a collet connection represent a separate class of tools. They are used in conditions of high fire safety where serious construction equipment is involved, and the risk of damage to the apparatus is minimized.

The main parameters are temperature and flame shape. In the simplest devices, the combustion temperature is close to the minimum - 700−1000°C. Air comes naturally and there is never enough of it. More expensive products have a special shape of air supply channels, which increases air flow and the flame temperature increases to 1200°C.

The flame has an even higher temperature in ejector burners, in which air is supplied to the hearth due to rarefaction, and the flow force is directly proportional to the operating gas pressure. Thanks to this, the temperature can be increased to 1500−1600°C and relatively smoothly adjusted with the flame length just by turning the tap. There may be several sources of combustion in the apparatus. This tool does not perform delicate work, but it successfully heats large areas.

The threshold temperature of the burners is 2000−2400°C, and it is achieved by concentrating the injected air into the combustion chamber, as well as using methyl acetylene propadiene gas (MAPP). A high-temperature cone is formed in the flame, whose power and temperature can be compared with oxy-fuel welding.

In addition, any type of product can be equipped with a flexible or rotary tube, piezo ignition and a highly sensitive control valve. There is a wide selection of devices based on power and gas consumption .

Adjustment

The cleanliness of the cut depends on the correct flame setting . Oxygen treatment is carried out with a slightly oxidized or normal torch. The carefully adjusted flame of cutters with concentric nozzles is surrounded by a cutting stream of oxygen. The core of the torch in each section should be symmetrical and not differ in brightness.

Cutting with a torch with the mouthpiece moved cannot be carried out, as this will lead to heating of the edge, which will negatively affect the quality of the cut. The use of self-centering mouthpieces increases the ease of use of such equipment, because the device makes the flame symmetrical.

Sometimes the movement of the gas mixture is hampered due to clogging of the channel, which divides the torch into streams and leads to loss of stability. Such a product not only reduces the quality of processing, but also reduces productivity. Flame adjustment is based on creating a symmetrical flame of the required power in relation to the oxygen cutting jet.

Important! The installed combustion power is determined by the thickness of the material.

A normal flame is ensured with the valves slightly open, which makes it possible to make adjustments during operation. When acetylene and oxygen are fully open, an excessive amount of the former is observed. Smooth closing of the acetylene valve leads to stabilization of the process.

Rexant GT-19

- Fuel type – propane-butane mixture.

- The connection is collet.

- Flame temperature – 1400 ºС.

- Gas consumption – 80 g/hour.

- Overall dimensions – 153x40x57 mm.

- Weight – 135 g.

Rexant GT-19 is a compact and convenient burner designed for connection to standard gas cylinders using a collet connection. The model can be used for a variety of jobs involving flame processing, including removing old paint, lighting fires, barbecues and stoves, soldering pipe connections, and insulating wires using heat-shrinkable materials. Thanks to the built-in piezoelectric element, ignition is carried out with one touch.

After two minutes of warming up, the burner can be held at any angle, based on the characteristics of the work being performed. The design provides the ability to adjust the flame, which ensures economical fuel consumption. Recommended continuous operation time is no more than 30 minutes. It should be remembered that the burner is a subject of increased fire hazard. It is prohibited to be transported on public transport or left unattended while working. During operation, the device requires minimal human intervention. Maintenance comes down to periodically cleaning the burner from contaminants that could lead to clogging of the nozzle.

If you liked the article, please share it

Previously on the topic:

Share

Temperature conditions of different types of burners per cylinder

You can purchase a burner online or at a hardware store. It is better to give preference to the second option, since the buyer can consult with an experienced seller, he will select the appropriate option depending on the tasks set by the user. The product range includes models that differ in temperature conditions:

- Refillable. They are characterized by small dimensions and thoughtful shape, as well as ease of use and a piezoelectric element. This type does not apply to the cylinder variety of gas burners.

- On a collet can. They are a source of powerful flame with an average outlet temperature of 1500 degrees.

- Threaded. Propane accounts for the lion's share of the fuel, due to which the temperature in the combustion zone is 1800 degrees. Advanced models are equipped with systems for mixing air with a propane mixture.

What does it depend on?

The burner temperature is determined by the chemical composition of the gas and the power of the product. During the research, it was possible to establish that the temperature parameters of the torch depend on the calorific properties of the gas mixture.

After combining the fuel with air, the gas is consumed critically, so the combustion intensity increases. By using an additional air source, you can increase the temperature you get at the burner. Without blowing, the value reaches 1500 degrees; access to auxiliary air flow gives an increase of up to 2200 degrees. The temperature differs in different parts of the torch :

- Internal . This is a short zone with little heating.

- Average . In this area, the temperature of the flame from the gas burner reaches its limit, but the fire does not open completely, which is due to a lack of oxygen and the release of decay products.

- Bordering . Visually characterized by a bright fire with high efficiency.

Cheap burner models are structurally the same. Expensive ones are equipped with additional elements that increase technical characteristics and ease of use.

To perform welding and cutting, special requirements are placed on the composition of the gas mixture, since the temperature regime of the product depends on it.

Schematic representation of a gas burner flame

The first step is to figure out what parts the burner flame consists of. This can be done using the simple diagram below.

In this schematic diagram, the following flame areas are indicated by letters:

- O – area of oxidizing flame; here the air-gas mixture burns completely, and an increased oxygen content is observed.

- B – recovery area. Here the gas does not burn completely, since it does not have enough oxygen for this. As a result, it breaks down into molecules that are combustion products. It is they who burn out completely in the oxidizing flame.

- A is the area in which the formation of the air-gas mixture occurs. Here the combustion process does not occur at all.

The numbers on the diagram are intended to indicate areas with different flame temperatures. The latter increases in regions, starting from region A and ending with the reducing part of the flame. In the process of complete combustion of gas, it decreases slightly:

- Areas 1-4. At the very bottom the temperature is 300 degrees and rises first to 320 and then to 520 degrees. In the area indicated by the number 4, it reaches a value of 1540 degrees.

- Areas 5-8. Here the temperature is 1550-1560 degrees in the center and 450 degrees at the edges. The maximum value of 1570 degrees can be observed at the very tip of the reducing part of the flame.

- 9 is an oxidizing flame, the temperature of which reaches 1540 degrees.

Gas combustion air

If you take air from the common ventilation duct, this will have a bad effect on the operation of the system. This is due to the fact that the ventilation duct has common walls with the bathroom, kitchen or toilet. If the temperature outside is negative, then after a while the temperature in the ventilation duct will be 1 degree, and in the room adjacent to the duct there will be an uncomfortable atmosphere. Agree, it is unpleasant to be in a cold bathroom or cook in a cool kitchen. Therefore, it is not advisable to take air from the general ventilation duct.

Connection standards

There are quite a few different replacement cartridges on the market. It is customary to distinguish the following connection types:

Such cartridges comply with European standards. The thread of such products is 7/16. Most often you can find products with a volume of 110, 230 and 450 grams. There are several types of threaded cylinders of this standard, the first produce a temperature of about 1300 degrees, and the second, which uses copper soldering, produces a temperature from 1500 to 2500 degrees. The level of combustion temperature directly depends on the characteristics of the gas mixture. The burner is attached to such a product using screw-on methods.

These cartridges comply with American MAPP standards. Mostly they are filled with a special mixture intended for soldering copper. Its combustion temperature varies from 1500 to 2500 thousand degrees. The burner is also attached by screwing.

Products of this standard are among the most widespread and inexpensive. The cylinder is fixed using a special fastener. Additionally, the product is equipped with a safety valve.

This type of product is used primarily for refilling various products.

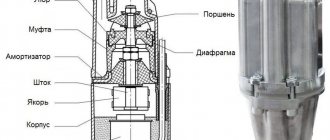

Design features and operating principle

Burners vary in design - from basic devices with a nozzle to more complex mechanisms equipped with an air supply device and piezo ignition.

Let's consider the design of a torch designed for welding metal.

The design with an injector and check valve increases work productivity and reduces fuel consumption.

Almost all portable household appliances belong to the so-called injection burners, when air is naturally sucked into the burner to support the flame.

Inside, in a special chamber, fuel is mixed with air, as a result of which the fuel ignites after a spark is given.

From the mixing chamber, the mixture of gases enters the nozzle-nozzle, where it is distributed through the channels. At the end of the structure, at the point where the torch is formed, there are fire holes - the ends of the channels.

Rating of gas burners for soldering and repair

1st place – mini gas burner with soldering attachment

Designed for both heating medium-sized parts and for contact soldering due to the heating of the tip from the flame. A kind of soldering iron without wires. The gas tank capacity is 8ml. The flame temperature when filling with butane reaches 1300 degrees Celsius, and the tip temperature – 450 degrees. The flame length is adjustable from 4 to 6 cm. The burner length is 13 cm and the diameter is 1.5 cm.

small and inexpensive, the refill is enough to solder several medium-sized parts, there is a nozzle for contact soldering, it is easy to refill.

2nd place – gas micro burner

There is nothing in it except a tank with a filling valve and a nozzle with a gas supply regulator. The ZC57100 does not have piezo ignition and it is supplied unfilled, so you will also have to buy a gas cartridge - it will be suitable for lighters. In general, to solder two wires or heat heat shrink without a soldering iron, such a torch is enough. The burner is also about 20 cm long and weighs 43 g.

This is the cheapest burner that can be found and the price of such a micro burner is 200 rubles.

the cheapest, easy to refill.

small flame, the filling runs out quickly, there is no piezo ignition.

3rd place – mini gas soldering iron KVT XZ-1

This remarkable soldering iron from the gas powered brand features piezo ignition and comes in a case with a set of 4 soldering tips, a spool of solder, and a tip cleaning sponge. Thus, the declared power of the soldering iron for contact soldering is 137 W - this is a lot for a soldering iron with a length of 21 cm and a weight of 120 g. Electric soldering irons have never dreamed of such weight and size characteristics. This soldering iron is not positioned as a torch, but it can be used as a torch - the flame is pencil-type.

This soldering iron is good for everyone, except for the price of 2300 rubles, which is why it landed in 3rd place.

burner from a famous brand, easy to solder, set of components, good case, high heat output.

4th place – gas burner IRIS BARCELONA

This torch is not only designed for soldering, welding, repairing electronic devices and jewelry. The flame of this burner is of course adjustable. Can be charged with a standard lighter gas cylinder. The flame length reaches 3 cm. The operating time is about 20 minutes. The flame temperature reaches 1300 degrees Celsius. The length of the burner itself is exactly 20 cm.

small size, piezo ignition, brand.

The length of the flame does not allow heating medium and large parts.

5th place – butane burner KVT X-220

It is positioned as a burner for construction and repair work. She looks very stylish. The knurled handle fits nicely in the hand. Has a piezoelectric flame ignition system. The capacity of the cylinder for highly purified butane is 22 ml. This amount of gas is enough for 110 minutes of continuous operation. The flame length is adjustable from 30 to 80 mm from a sharp wedge-shaped flame to a soft flame with yellow tongues. The weight was only 226 grams with a length of 14 cm.

a good option for desktop work, there is a stand, piezo ignition, and a comfortable handle.

It's bulky, you can't put it in your pocket, you can't fit it into a narrow place.