The operation of water heating networks is characterized by two main parameters - temperature and coolant flow. But there is a third value that often attracts the attention of residents of apartment buildings and private buildings - the pressure in the heating system. The main question is what it should be like for the normal functioning of all heating devices - radiators, heated floors, and so on. Since there is no clear answer, we decided to explain the essence of the problem within the framework of this publication.

Introductory information on the topic

First of all, we propose to consider why excess pressure (above atmospheric pressure) is created in pipelines and how it is measured. Let's start from the end: the amount of water pressure in a closed heating system is usually displayed in the following units:

- 1 Bar = 10 m water column;

- 1 MPa equals 10 Bar or 100 m of water. Art.;

- 1 kgf/cm² – the same as 1 technical atmosphere (Atm.) = 0.98 Bar.

For reference. Kilogram-force per cm² is a measurement often used during Soviet times. At the moment, pressure is usually measured in more convenient metric units - MPa or Bar.

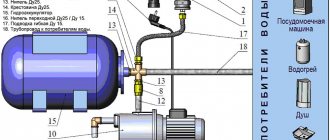

Simplified heating scheme for a 3-story mansion

Next, imagine a three-story cottage with a ceiling height of 3 m, which needs to be heated in winter. To do this, batteries are installed on both floors, connected to a common riser coming from the boiler, as shown in the diagram. The actual pressure in the resulting closed heating system will consist of three components:

- A column of water in a pipeline presses with a force equal to its height. In our example, this is 6 m or 0.6 Bar (0.06 MPa).

- The pressure created by the circulation pump. It forces the coolant to move at the required speed and overcome the resistance of three forces: gravity, friction of the liquid against the walls of the pipes and obstacles in the form of reinforcement and fittings (restrictions, tees, turns, etc.).

- Additional pressure arising from thermal expansion of the liquid. Practice shows that cold water with a temperature of 10 °C after heating to 100 °C adds about 5% of its original volume.

Note. The static pressure of the liquid column varies depending on the measurement location. When the pump is turned off, the pressure gauge at the bottom point of the system will show the maximum value - 0.6 Bar, and at the top - zero.

Thermal expansion of liquid

A very important point. In order to supply the required amount of heat to the premises, it is necessary to ensure the required water temperature and its flow rate - two main parameters for the operation of water heating. The resulting pressure is only a consequence of the system’s operation, and not the cause. Theoretically, it can be anything as long as the radiators and boiler installation can withstand it.

This gives rise to the concept of what operating pressure is in a heating system: this is the maximum permissible value specified in the technical documentation of the equipment - boiler or batteries. Regulatory documents require that in private homes it should not exceed 0.3 MPa, although some cheap units are not able to withstand even 0.2 MPa.

Hard water is the enemy of the system

The condition of the inner surface of all elements of the heating circuit is affected by the quality of the water used as a coolant. If it is hard, rich in salts and minerals, then when heated it will form scale and sediment, which over time will damage the equipment and cause blockages in the system. And those, in turn, will affect the pressure in pipes and radiators.

As a preventative measure, it is better to fill the circuit with specially prepared, demineralized water. If this is not possible, the boiler must be cleaned regularly. It is better to entrust this work to an experienced professional who is well acquainted with the construction of expensive equipment. He will disconnect the heat exchanger and wash it with special reagents.

In the case of large amounts of deposits, the entire system can be subjected to a similar treatment. But only real professionals in their field can cope with this task.

Why raise the pressure?

The pressure in the supply line is higher than in the return line. This difference characterizes the heating efficiency as follows:

- A small difference between the supply and return makes it clear that the coolant successfully overcomes all resistance and transfers the calculated amount of energy to the premises.

- An increased pressure drop indicates increased section resistance, decreased flow velocity and excessive cooling. That is, there is insufficient water flow and heat transfer to the rooms.

For reference. According to the standards, the optimal pressure difference in the supply and return pipelines should be in the range of 0.05–0.1 Bar, maximum 0.2 Bar. If the readings of 2 pressure gauges installed on the line differ more, then the system is not designed correctly or needs repair (flushing).

To avoid high drops on long heat supply branches with a large number of batteries equipped with thermostatic valves, an automatic flow regulator is installed at the beginning of the line, as shown in the diagram.

So, excess pressure in a closed heating network is created for the following reasons:

- to ensure forced movement of the coolant at the required speed and flow rate;

- to monitor the condition of the system using a pressure gauge and recharge or repair it in time;

- Coolant under pressure heats up faster, and in the event of emergency overheating, it boils at a higher temperature.

We are interested in the second item on the list - the pressure gauge readings as a characteristic of the serviceability and performance of the heating system. They are of interest to homeowners and apartment owners who independently maintain home communications and equipment.

Reasons for deviation from the norm

The heating system must operate uninterruptedly during the heating season, which is almost six months. At this time, each owner wants heat to be supplied in the required quantity, that is, the pressure in the heating boiler must be constantly within normal limits.

Practice shows that not everything is always as smooth as you want it to be. Under the influence of certain factors, malfunctions in the operation of the heating system or equipment occur. What affects the efficiency of an autonomous heating structure?

Pressure in pipes of apartment buildings

From the contents of the previous sections, it becomes clear that the amount of heating in the central heating pipelines of high-rise buildings depends on the floor on which the apartment is located. The situation is as follows: if residents of the first two floors can roughly navigate using a pressure gauge installed in the basement heating unit, then the real pressure in the remaining dwellings remains unknown, since it drops with every meter of water rise.

Note. In new buildings with apartment-by-apartment heating distribution from a common riser, where floor-to-floor heating units are equipped, it is possible to control the coolant pressure at the entrance to each apartment.

Moreover, knowing the amount of pressure in a centralized network is of no practical use, since the owner cannot influence it. Although some people argue this way: if the pressure in the line has dropped, it means that less heat is supplied, which is a mistake. A simple example: turn off the return tap in the basement and you will see a jump in the pressure gauge needle, but the movement of water will stop and the supply of thermal energy will stop.

This is what the heating point looks like at the entrance

Now specifically about the numbers. The diameters of the heating supply networks and the power of the supply pumps from the boiler room are calculated so as to ensure the rise of the required amount of coolant up to the top floor. This means that at the entrance to a multi-storey building the working pressure in the heating system will be:

- in old five-story buildings, where cast iron radiators are still found to this day, no more than 7 bar;

- in nine-story Soviet-built buildings, the minimum value is 5 Bar, and the maximum depends on the proximity of the boiler room to the pumps, but not higher than 10 Bar;

- in high-rise buildings - no more than 15 bar.

For reference. At least once a year, pipelines and heating devices must be tested under pressure, 25% more than the working one. But in real life, utility companies do not risk checking house systems and limit themselves to testing external heating networks.

The information presented is only useful in terms of choosing new radiators and polymer pipes. It is clear that in high-rise buildings you should not install cast iron and steel panel batteries rated for a maximum of 1 MPa, which is described in detail in our selection guide and in the video from the expert:

Pressure indicators in a private home and the reasons for its drop

In closed heating systems of country houses and cottages, it is customary to withstand the following pressure values:

- immediately after filling the heating network with water and releasing air, the pressure gauge should show 1 Bar;

- after warming up to operating temperature, the minimum pressure in the pipes is 1.5 Bar;

- during operation in different modes, indicators can vary within 1.5-2 Bar.

Important point. It is not for nothing that we indicated what pressure should be provided with a cold heating system. The fact is that the vast majority of imported gas boilers equipped with modern automation are designed to start at a minimum pressure of 0.8-1 Bar and in its absence simply will not turn on.

How to properly remove air from heating lines and create the required pressure is described in a separate instruction. Here we will list the reasons why, after successful commissioning, pressure indicators may decrease, even to the point of automatic shutdown of the wall-mounted boiler:

- Residual air escapes from the pipeline network, heated floors and heating equipment ducts. Its place is taken by water, which is recorded by the pressure gauge falling to 1-1.3 Bar.

- Due to a leak in the spool, the air chamber of the expansion tank was emptied. The membrane is pulled in the opposite direction and the container is filled with water. After heating, the pressure in the system rises to a critical level, causing the coolant to be discharged through the safety valve and the pressure again drops to a minimum.

- The same thing, only after the expansion tank membrane breaks.

- Minor leaks at the joints of pipeline fittings, fittings or pipes themselves as a result of damage. An example is the heating circuits of underfloor heating, where leaks can remain unnoticed for a long time.

- The coil of the indirect heating boiler or buffer tank is leaking. Then pressure surges are observed depending on the operation of the water supply: the taps are open - the pressure gauge readings fall, closed - they rise (the water supply is pressed through a crack in the heat exchanger).

The master will tell you more about the causes of pressure drops and how to eliminate them in his video:

Briefly about the main thing

Normal pressure in the heating system contributes to comfortable living. Ensuring that the pressure gauge needle shows the normal pressure value in the gas boiler is the responsibility of every owner of a house with a heating boiler.

Of course, how much pressure should be in a gas boiler is different for specific systems, since the type of system, equipment features, number of floors of the room - all this affects the value of the normal operating pressure in the heating design.