Gas equipment of the boiler + water heater type is a suitable solution for owners of apartments and private houses: heat is provided, hot water is available, and it is economical. And connecting a double-circuit gas boiler to the heating system is not as complicated as it seems. But before embarking on the implementation of such a project, it would be a good idea to familiarize yourself with the theory, don’t you agree?

In this publication, we will talk about the features of the connection process: what requirements of service organizations need to be taken into account and what technical nuances of installing wall and floor models should be paid special attention to. We will supplement the presented material with visual photos and videos, which will help you complete all the work as quickly as possible and without errors.

Equipment installation rules

Installation and connection of the boiler to the system should begin after passing the design stage, when a place in the house has been prepared for the unit. If you install it in violation of the requirements, the specialists of the gas distribution company will not connect the equipment to the gas main.

General requirements at the design stage

The basic standards for installing gas equipment are prescribed in SNiP 42-01-2002. Supporting information is also contained in the already invalid, but useful SNiP 2.04.08-87 .

Usually all the rules are taken into account by the design engineer, but it is also useful to know them for yourself. The room for the boiler can be a kitchen if the power of the device ranges up to 60 kW. A separate or attached combustion chamber is relevant for units with a power rating of up to 150 kW.

Additional standards for the installation of gas equipment are given in SNiP on boiler installations, as well as on heating, ventilation, and air conditioning

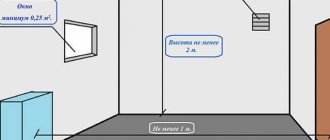

The premises requirements are as follows:

- The minimum room height is 2 m, volume is 7.5 m3. If there are two or more gas appliances, the parameters change to 2.5 m3 and 13.5 m3, respectively.

- Not suitable for installation: basements, balconies, bathrooms, corridors, rooms without windows.

- The walls of the room must be covered with non-flammable materials or protected with special panels.

- Lighting: per 10 m3 of room there is at least 0.3 m2 of window. In the event of a gas explosion, the windows are an easily removable structure, which increases the safety of equipment operation.

- It is necessary to have grounding and a cold water pipeline.

- The cross-section of the chimney corresponds to the power of the installed equipment.

- The space left around the device is: in front - from 1.25 m, on the sides (if maintenance is necessary) - from 0.7 m.

- The distance from the vertical chimney to the unit is maintained - no more than 3 m.

Ventilation must also be provided. Natural is calculated at the rate of 3 room volumes per hour. When organizing a supply air system, combustion air is added to this value (the parameter is indicated in the boiler passport).

The requirements apply not only to premises. The distance from the attachment to the nearest structures is also regulated. This information is indicated by the manufacturer in the equipment instructions.

If a double-circuit boiler is installed on a wooden wall, a sheet of roofing steel (0.8 - 1 mm) or a mineralite slab is attached to it. If the equipment is not located in the kitchen, asbestos is also possible

Floor-standing boiler models are installed on non-combustible bases. If the surface is wooden, a metal backing is required.

It is recommended to place the device as close to the gas pipe as possible. The use of special hoses is acceptable, but they should not be very long. Bellows hoses up to 5 m are available on sale; they are allowed for installation, but according to European standards, the length is limited to two meters.

Documentation preparation process

After a general familiarization with how to technically correctly connect double-circuit gas boilers, you can begin preparing documentation. The first stage is obtaining technical specifications . It is necessary to contact the regional gas service with a statement indicating the expected volume of blue fuel consumption per hour.

Technical specifications are issued in 1-2 weeks. The document is a permit to connect housing to the gas main.

The second stage - according to the technical specifications, an equipment installation project . The third is approval of the prepared documentation by engineers of the gas distribution company.

The project includes both the installation diagram of the boiler itself and the laying of a gas pipeline from the connection point to the main line. If we are talking about a private house, a drawing of communications on the site is added

The boiler technical passport, operating instructions, certificates, and an expert opinion on the compliance of the device with all standards are submitted to the regulatory organization. The necessary papers are provided by the manufacturer of the double-circuit boiler.

Coordination of documentation can happen in a week or last up to 3 months, it all depends on the complexity of the project. In case of refusal, the inspection is obliged to provide a list of edits to eliminate the deficiencies. If all requirements are met, stamps are affixed and you can begin connecting the equipment.

Premises requirements

There are several rules that must be followed when choosing a room to install the unit:

- The presence of a window that can open at any time.

- Functional ventilation.

- The room must have outlets for all necessary pipelines to which the home boiler will be connected. Particular attention should be paid to the gas pipe. It must have a counter.

Usually the connection of similar devices is the same. The only thing that may differ is the location of the pipes. But this does not happen often.

Features of the wall-mounted model

First you need to make connections to the heating system, water supply and electrical network, if the device has control and regulation elements. Connection to the gas main is carried out by an employee of the relevant service or a licensed company. The home owner only needs to buy a meter and a gas filter.

The device has 5 connection pipes: heating system supply and return, cold water inlet and hot water outlet plus gas supply. It is convenient to screw all the fittings before hanging the device on the wall. The handles that interfere with rotation can be removed by unscrewing the nut on the rod. Installation of a gas valve cannot be done without a dielectric gasket

What products and materials will be needed during the work process:

- 3 ball valves with American sizes 1/2″ and 4 of the same size 3/4″;

- 2 mud traps (mechanical or self-flushing) - installed on the cold water supply and return of the heating pipe;

- gas filter;

- expansion tank (if its volume is not enough for a large pipeline network, a membrane tank is also needed);

- fittings for pipelines - elbows, tees;

- three-core cable (brand VVG, cross-section 2.5 mm2);

- automatic two-pole switch 20 A.

This list is suitable for heat generators of simple design with an open combustion chamber. Expensive models are equipped with an expansion tank and a gas filter.

If the water pressure is less than 1 atm, it is worth installing a pressure booster station. It is useless if the water pressure is constant within 2-3 atm.

Additionally, the system may include: a third fine cartridge filter, pressure gauges for monitoring pressure in different places of the circuit, an automatic air vent, a circulation pump, a voltage stabilizer

In the case of a separate boiler room, you will need a heating radiator, which will ensure normal temperature conditions for the boiler to operate and protect it from the formation of condensation

Next, we hang the boiler on the wall, determining the optimal height. You shouldn’t hang it from the ceiling - ease of use is important. The minimum distance from the ceiling to the outlet pipe is 15 cm, from the floor - 80 cm, from the wall - 20 cm.

To mount the device you will need two special brackets, which are supplied in the kit. They are attached to the wall with plastic dowels and screws. To set them correctly, it is recommended to use a level and plumb line.

Stage #1 - connection to the heating system

All ball valves for shutting off the pipeline are installed more for servicing the system than taking into account its possible cutting and dismantling during operation. Heating equipment is characterized by reliability. Example: a shut-off valve on the heating return is designed to clean the filter without draining the coolant.

The standard connection diagram is in the passport of any double-circuit boiler. This is what you should use to navigate when tying up the device.

Recommendations for connection:

- Half-inch taps are installed on water fittings and gas supply. And DN20 are mounted on pipes with coolant.

- The fittings must be screwed with the pipes down.

- The filters are attached horizontally, with the “spouts” facing the floor. In this position it is convenient to clean them.

- The external expansion tank is connected to the return line using additional fittings.

- The drain pipe is installed at the lowest point of the system.

If you plan to fill the system with non-freezing antifreeze as a coolant, to be on the safe side, additional valves for supply and return should be added to the circuit. This makes it possible to dismantle the boiler without draining the antifreeze.

Stage #2 - connecting the boiler to the electrical network

There are usually no difficulties with supplying electricity - just plug the device into an outlet. But there are also rules and safety requirements.

If the boiler is heavily dependent on electricity and its supply is often turned off in the region of installation, the circuit is supplemented with an uninterruptible power supply

The main requirement when connecting the device to the network is grounding and the presence of a circuit breaker. The latter is located so that in case of an emergency water does not get on it.

Primary requirements:

- You need a wire connected to the ground loop. If such a cord is not included in the kit, the conductor is connected to the body of the device itself.

- It is prohibited to use steel pipes of the hot water supply system as grounding conductors.

- The cable is laid in a protective “corrugation”.

When connecting turbocharged boilers from European manufacturers, it is important not to confuse phase with zero . Otherwise, the electronic unit will not start the system.

Stage #3 - connecting the unit to the chimney

In 95% of modern houses, wall-mounted boilers with closed combustion chambers and a coaxial chimney are installed. It is discharged horizontally through the wall with a slope of 3-5% towards the street to allow condensation to escape.

Pipe sections of several elements are mounted inside each other in the direction of the flow of combustion products. In a vertical channel, joints must be sealed

For a high-power floor-mounted unit, only a vertical design is suitable, which can cope with a large volume of combustion products. It should have as few turns as possible and protrude beyond the boundaries of the roof at a distance of 0.5 m.

Connectivity

To connect the heating boiler to the main line, the following conditions must be met:

- The gas appliance must have a fitting with an external thread, which the rubber sleeve can reach.

- For ease of installation, an adapter in the form of a brass corner is installed.

- Gaskets must be present to prevent gas leakage.

- The end of the hose attached to the boiler is equipped with a mesh that prevents microparticles from penetrating into the device.

At the end of the installation procedure, you can cover the butt joints with a soap solution. The appearance of air bubbles will indicate a gas leak. The connection method is simple, but requires correct adherence to technology.

Installation of a floor-standing device

If a double-circuit heat generator requires power supply, then it is connected in the same way as a wall-mounted “colleague”. The energy-independent device has a built-in copper or stainless steel coil for heating water. Apart from the burner, automation and heat exchanger, nothing is supplied with this equipment.

To install a non-volatile unit, you will need a set from the previous list plus the following system elements:

- safety group, the safety valve of which is designed for the operating pressure of the boiler (data is in the passport);

- expansion tank with a volume of 10% of the total amount of coolant;

- circulation pump.

A safety group is always installed on the supply pipe next to the heating device to protect the most expensive part of the system from destruction during a sudden pressure surge.

The distance from the boiler to the device should be no more than 50 cm. Taps and tees must not be installed on the pipe section between the heater and the element; the line must be left clean

If the floor-standing device is connected to a gravity system, only an open-type expansion tank with overflow is installed. The pump and safety group are excluded from the diagram.

In this situation, pipes with a diameter of 40 mm or more are needed, which are laid at a slope of 5 mm for each linear meter of the main line. The heat generator remains at the lowest point, the tank is located at the highest.

If electricity is connected, it is permissible to organize forced circulation using a pump. In this case, its installation is carried out through a bypass

Most modern systems include a circulation pump , which is efficient but dependent on electricity. When the lights are turned off, heating and water heating are turned off. It is wise to organize an alternative natural circulation method for force majeure.

What is a bellows eyeliner and what are its advantages?

A bellows gas hose is a corrugated pipe made of stainless steel. Special fittings are installed at the ends of the hose to create a strong and safe connection. The connection to the pipes and equipment is secured using union nuts made of the same material. To increase the level of tightness, metal or plastic sealing rings are installed at the joint.

As a rule, sealing gaskets are included in the flexible hose kit.

Eyeliner kit

The advantages of a bellows hose over other types of flexible hoses designed for connecting gas equipment are:

- strength and rigidity. According to manufacturers' requests, the service life of the bellows is up to 25 years;

- possibility of correct operation at different temperatures;

- not exposed to direct sunlight;

- ability to withstand high pressure;

- possibility of stretching, and when the length increases to 50%, the strength of the liner does not decrease.

The disadvantages include the cost of the equipment, which is 2–3 times higher than the price of rubber analogues.

Options for schemes with a boiler

When the standard power of the device of 9-13 liters is not enough to meet the needs of the residents (example: there is a bath in the bathroom), the system is supplemented with a boiler. If an indirect heating boiler is selected, then it is impossible to simulate the flow with an additional circulation pump, which is turned on and stopped by a thermostat signal.

An incorrect circuit leads to a problem in the form of prolonged heating of the boiler. During this time (up to 2 hours), the house is not heated and the rooms cool down. Plus, the boiler life is reduced due to the “clocking” effect and hot water entering the second circuit rather than cold. Bacteria multiply in the boiler itself.

The correct scheme is to connect an indirect boiler to the heating circuit. The thermostat is connected to the boiler automation. The DHW outlet pipes are simply plugged

In this scheme, heating between the circuits is provided by a three-way valve. The boiler loads in 20-25 minutes. The plugs do not affect the life of the heat generator.

More practical options are installing a layer-by-layer heating boiler (there are models for dual-circuit systems) or an electric storage tank. The first does not have a heat exchanger, which reduces the cost of the system. The second significantly improves the comfort of using hot water.

In a circuit with an electric boiler, check valves and safety valves are mounted on the supply pipe. The latter sometimes leaks water that needs to be disposed of. The safety valve requires manual inspection 2 times a month

In the case of an electric boiler, it is recommended to additionally install an expansion tank. And if the pressure in the system is more than 6-8 bar, you will need a pressure relief valve to reduce it.

Launch

The installation of a double-circuit boiler has been carried out, after checking its condition, the system is filled, there is no need to rush, if you open the liquid supply minimally, then the accumulation of air masses will be insignificant, which will facilitate further adjustment.

Before starting up gas equipment, you need to look at the pressure in the system; individual indicators are provided for each model. Experts advise draining some of the water from the pump; to do this, you will need to remove the front panel; if you are not confident in your own abilities, it is better to turn to professionals. After which you can ignite and monitor performance by setting special programs for the user.

Additional installation recommendations

strictly forbidden to reduce the diameter of the internal cross-section of the connected pipes . The optimal value for a boiler up to 28 kW is at least 20 mm for heating and at least 15 mm for water supply.

If the boiler is not included in the circuit, it is wiser to install the device closer to the hot water tap, which is often used.

In the case of connecting underfloor heating, the system is complemented by a separate branch with a collector and a circulation pump.

Double-circuit heating system

This layout method is the most popular way to efficiently heat a private home. It is much more efficient in comparison with a single-circuit one, since the coolant is distributed more rationally, which ensures better return of thermal energy.

In double-circuit heating systems, there are 2 pipes connected to the radiator, which serve a different purpose. One transfers the coolant heated to a given temperature, the second removes the cooled liquid and transfers it to the boiler for subsequent heating. This ensures that the cooled water no longer enters the battery installed next (in the branch). In most cases, the coolant circulates in one direction. There are also heating systems in which the coolant is transferred towards each other. But they are not as common as one-sided ones.

Important! Installation of a double-circuit heating system is considered labor-intensive and requires greater pipe consumption compared to a single-circuit one. However, these costs are reflected in better efficiency and practicality in subsequent operation.

What is the difference between double-circuit heating and single-circuit heating Source cheremo.ru

The two-pipe heating system of a cottage makes it possible to maintain a comfortable temperature in specific rooms separately. In addition, it can be automated in such a way that it will turn off when the set temperature is reached. After cooling, it starts again, reducing energy consumption. This also optimizes the indoor microclimate; a certain regime is constantly maintained (there are no sudden changes: hot or cold).

Healthy! A distinctive feature of two-pipe heating systems is the presence of a separate line for supplying coolant to each battery. In such schemes, each radiator is equipped with two pipes: inlet and outlet.

What to do if the diameter of the gas pipeline does not match the boiler pipe

Sometimes the inlet on the boiler may not match the diameter of the gas pipeline. For example, the gas pipe of a Navien floor-standing boiler is 1/2″, and the gas pipeline is 3/4″. Is it possible to connect the device using a DU-15 1/2″ bellows connection instead of 3/4″? Such a transition is permissible, since it is local and does not provide significant resistance.

It is impossible to imagine a modern private house, and especially an apartment in an apartment building, without gas equipment. This could be a stove, a heating boiler, a heating boiler, or other household appliances.

Gas is supplied to a house or apartment through a pipeline system, and from it to each individual consumer via flexible connections. Flexible gas supply can be made in several versions at once.

Types of gas taps

In old buildings, two types of cranes were usually installed on vacation:

- petal;

- suberic.

The differences between the designs of these products can be seen in the figure.

When the slab is replaced or the valve fails, it is best to install a new ball valve.

This device is much better, but more expensive. Installation of an Italian faucet will cost $10. You can also install a cheaper domestic faucet, costing $5. They are no worse than their foreign counterparts, but sometimes have defects. Therefore, do not forget to take a receipt with you when purchasing so that you can exchange the defective product for a good one.

This is a must know valuable advice

Before purchasing a flexible hose, it is necessary to check the size of the thread at the outlet of the plate, its classification and whether it is straight or angular. If the outlet is of a direct type (directed into the wall), you must purchase a sleeve with a square at the end.

The gas hose should not be painted - this will accelerate its cracking. A more attractive look can be created by covering it with special paper or oilcloth.

It is also strictly forbidden to tightly seal gas communications with false plasterboard panels and other structures - this will make it difficult to carry out service work on individual elements.

To camouflage the gas supply system, a collapsible box is used, which can be easily dismantled if necessary. In this case, there will be constant access to all structural elements of the gas system.

It is forbidden to use unnecessary connections. Independent complication of a gas structure, according to technical regulations, may entail a fine or disconnection from gas supply

If a technician was called to connect the gas stove, it is necessary to check that the work was performed correctly: the excess tap from the tap at the lower end should be unscrewed, the flexible line should be directly connected exclusively to the tap located on the branch pipe, and its other end - only to the outlet of the gas stove.

It is also possible to use an adapter. Any additional installations are prohibited.

Types of gas flexible hoses

The current market offers a fairly extensive list of gas hoses. In addition to the material, you will also need to choose a manufacturer. And in this case it is better not to save. The item is bought once and for a long time. Having saved 500 rubles, you can then spend a lot on health and repairs if the pipe starts leaking gas. Therefore, let’s first look at the varieties.

Rubber-fabric

It has many advantages that allow it to be used in a gas system:

- easy installation;

- good flexibility;

- low cost;

- various sizes;

- excellent electrical insulation.

The disadvantage of such rubber parts is poor rigidity. Today, the industry produces hoses from a special material of high elasticity. Therefore, their service life can reach 10 years.

The cost of such hoses usually does not exceed $7.

Bellows metal

Professional gas fitters consider it the most suitable for gas systems. The service life of such hoses can be more than 25 years. It connects to a gas stove without any difficulty. Bellows systems can be connected to boilers and water heaters, and they are completely safe.

If you have a gas stove equipped with electric ignition in your kitchen, in order to connect the bellows device, a special insulating connection is created between it and the tap.

This type of hose bends freely and can withstand high pressure, reaching 6 atmospheres. It can withstand significant temperature changes ranging from -50 degrees to heating up to 200 degrees. The main disadvantage of a bellows hose is its cost. It is many times higher than similar gas connections.

The advantages of such bellows metal systems include:

- made of stainless steel;

- complies with GOST;

- meets all technical requirements;

- protected from any mechanical influences by a special polymer coating;

- able to withstand any mechanical impact;

- the warranty period exceeds 30 years;

- withstands voltage of 1500 Volts.

Oxygen

It can also be connected to gas stoves, but you need to take into account several very important points:

- The internal diameter must exceed 16 millimeters;

- The surface in contact with oxygen must be well cleaned of oil. Otherwise, the hose will overheat and material damage will occur.

The advantages of oxygen hoses include the following characteristics:

- withstands high pressure. It can reach 20 atmospheres;

- very simple installation;

- low cost;

- rich assortment;

- does not conduct electric current.