Gas equipment is the most common option in organizing autonomous heating. It is characterized by reasonable cost, economical fuel consumption and high efficiency. However, any equipment has its own service life and requires restoration over time.

The simplest repair of a gas boiler can be carried out yourself. And any owner simply must cope with the implementation of regular preventive measures on his own. We will tell you how to return the equipment to serviceability and how to extend its service life.

Causes of boiler breakdowns

First of all, it is necessary to establish why any malfunctions may occur in the operation of gas heating boilers. A number of different factors can lead to problems.

Electricity

Modern gas boilers are equipped with various automation equipment. These products, in turn, are powered by electricity. And, despite the fact that it is already the 21st century and systems for the use of alternative energy sources are being actively developed all over the world, the problem of the stability of power grids remains relevant for many regions, especially for remote villages and all kinds of holiday villages.

To avoid all the associated troubles, buy a high-quality stabilizer in advance. Do not spare money to purchase this device - cheap models are of little use, so it is better to immediately allocate funds to purchase a good stabilizer from a well-known manufacturer. Rest assured, if the automation breaks down, you will spend much more money on its repair and replacement.

Voltage regulator

Water

At home, wall-mounted models of gas boilers are often used. Such devices are simultaneously responsible for heating the premises and preparing hot water.

The design of wall-mounted boilers includes a flow-through heat exchanger. Low-quality hard water with various inclusions is the main enemy of the gas boiler heat exchanger. Moreover, under the influence of low-quality water, the heat exchanger can fail in just one season.

To prevent such damage, install special filters. The best option is a complete water purification system. With it, your boiler will work for as long as possible, and using purified water is much safer for your health.

Water purification systems

Installation errors

Any knowledgeable person will tell you: the installation and piping of gas heating equipment should be carried out exclusively by qualified specialists.

Even the slightest errors at the stages of installation and connection of equipment can lead to irreversible consequences. For example, incorrectly performed piping in the case of a cast-iron gas boiler with a power of more than 50 kW will lead to the fact that the unit will simply crack at low temperatures.

If you are not an experienced gas installer, have the boiler installed by professionals.

Weather

Adverse atmospheric conditions can also lead to many different problems. During frosty winters, people turn on the heating at almost full power. This leads to a significant decrease in pressure in the gas pipeline system. As a result, boilers cannot reach their full potential.

You won’t be able to solve this problem on your own - you still won’t be able to explain to your neighbors that their actions are only aggravating the situation. As a solution to the problem, you can install an additional boiler that runs on a different fuel.

Automatic solid fuel coal boiler with bunker

Using a chemical solution through a booster

To perform this cleaning method, it is necessary to use special equipment - a booster, with which an acidic washing solution is pumped into the heat exchanger.

Then, over a long period of time, it is necessary to drive the solution through the pipes several times. The result will be that the deposit will dissolve and will be removed from the equipment along with the liquid used for flushing.

After flushing, the throughput and thermal conductivity of the gas boiler will increase. An acidic solution can dissolve any stubborn contaminant, which can be carbonate salt deposits or ferric iron deposits. A small amount of acid remains in the pipes, which is neutralized. To do this, use a special solution, which is launched into the heat exchanger after the washing is completed.

Why do you need regular gas boiler cleaning?

For most of the year, water constantly circulates in the heating system. Over time, a coating of salts, lime, and impurities that enter the coolant settles on equipment parts. The harder the water, the more mineral deposits appear on the system elements. They remain in the heat exchanger for the gas boiler, which negatively affects its operation.

Heating equipment in the house

The operating principle of heating equipment is based on the fact that the coolant is heated as it passes through the curved channels of the coil. To raise the temperature of the liquid, special plates are used. Thanks to these additional elements, the coil itself and the water entering it are heated more evenly. When assembled, the system looks similar to a car radiator.

The operating efficiency of equipment largely depends on the thermal conductivity of the materials from which it is assembled. Usually copper or alloys with this metal are used. Any growths or deposits on the internal surfaces of the coil tubes lead to a decrease in thermal conductivity and deterioration of the system.

Deposits in the heat exchanger for the boiler

Preventive measures are beneficial

If equipment is not cleaned promptly, problems may arise:

- The heat exchanger of a gas boiler constantly overheats and fails faster. It can be replaced, but such repairs are very expensive. To this amount should also be added the inconvenience and cost of heating the house during the period when the equipment is being repaired. Electric heaters are usually turned on, and this significantly increases the cost of repairs.

- Limescale greatly impedes the passage of coolant through the system. The more scale there is, the higher the load on the circulation pump. The equipment has to constantly work in emergency mode, which leads to natural wear of spare parts and negatively affects its service life.

- A clogged boiler heat exchanger works less efficiently. It takes more energy to heat it. Accordingly, gas consumption increases (on average by 10-15%). This means that the owner will overpay for heating, and the house will not warm up as well. Simple calculations show that for the season the amount will be close to that paid on bills for a whole month.

Do-it-yourself device for washing heat exchangers

Do-it-yourself repair of double-circuit boilers

Double-circuit boilers should be repaired especially often, since they work in intensive mode, heating rooms and storing hot water for domestic needs.

NOTE

During the repair of gas boilers, structures will almost always need to be dismantled. You need to carry it out carefully, remembering the connection sequence, so that later you can correctly assemble all the elements of the system.

Repair of a wall-mounted gas boiler (cleaning and flushing the heat exchanger with special means) is clearly shown here:

Methods for self-diagnosis of faults

Often the user is in a situation where he is not sure what exactly is broken in the gas boiler. In such cases, there is no need to rush to remove and repair anything. It's risky and dangerous. Before work, you should diagnose the equipment and identify the exact causes of malfunctions.

If the boiler smokes, this phenomenon is usually caused by the consumption of low-quality gas or lack of air. You can check the cause of the problem yourself

Modern gas boilers are equipped with various sensors that reflect a number of important functional indicators of the unit. They monitor changes in temperature, pressure and other parameters. In the event of a malfunction, modern boiler models provide automatic shutdown of the device.

The source of the breakdown is identified by the consequences it causes. For example, you can visually see fumes, leaks, and sparks. You can smell a gas leak or short circuit by smell. From the changed sound of the gas boiler, it becomes clear that the unit has malfunctioned.

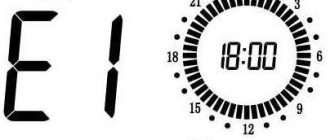

The instructions included with the purchase of the device describe the most common faults in the boiler model being purchased and how to detect, diagnose, and eliminate them. It also indicates what a specific error code and blinking lights on the dashboard mean.

So the light can blink in different modes: fast or slow. Or burn constantly. The color of the light bulb can be red, green or yellow.

The manufacturer's instructions indicate all possible error codes that may appear on the display. It also explains how to troubleshoot the problem.

You should not throw away the instructions from the device, as they may be useful to the gas technician you called to fix the problem. It indicates the characteristic features of the gas boiler model, the dimensions and location of components and parts.

Diagnostic nuances

Modern gas fuel heaters are complex technical objects. They are a source of increased danger due to the potential for fire or even gas explosion. This outcome can be caused by neglecting the rules for using the heating system and untimely troubleshooting.

An automatic control system maintains the operation of the boiler in a given mode and ensures the safety of its operation. An inexperienced user will not be able to determine a malfunction in the electronic unit; in this case, you should immediately contact professionals who have sufficient qualifications and the necessary diagnostic equipment.

It is best to entrust the diagnosis of a gas boiler to specialists

With your own hands, it makes sense to eliminate simple faults associated with contamination of individual parts and assemblies, sealing of connections, and poor contacts.

Models

Let's look at the most popular models of Vulcan gas boilers.

Volcano AOGV 10 E

This unit has one circuit and, accordingly, is intended exclusively for heating; the chimney here is traditional. The boiler is used in heating systems with forced or natural circulation of water and other types of coolant.

As already mentioned, there is no second circuit; small-volume “indirect” boilers are used to prepare hot water.

The Vulcan AOGV 10 E boiler is connected to the gas mains, but it can also operate from liquefied gas. The control system here is mechanical, with a similar protection system. The heat exchanger is made of steel with additional corrosion protection.

Vulcan AOGV 12 VE

This model is the best option for supplying heat to houses and other premises with an area of up to 120 m². The power of the device is 12 kW. The boiler is a double-circuit boiler, and the package includes Italian automatic equipment, as is common in similar units from alternative brands. A traditional chimney is used to remove combustion products.

The operating temperature of the coolant varies from +50 to +90 degrees, the volume of boiler water is 19.3 liters.

Volcano AOGV 9 VPE

This model is parapet. Vulcan differs from traditional boilers in that for their operation there is no need for traditional chimneys. Instead, double chimneys of the “pipe-in-pipe” (coaxial) system are used, exiting from the rear and extending behind the wall.

The gas boiler Vulcan AOGV 9 VPE is double-circuit and non-volatile. It can be installed in new households, where conventional chimneys are rarely built.

Externally, the unit looks exactly the same as its counterparts with open combustion chambers. The heat exchanger of the device is made of durable steel, which is protected from corrosion by means of a special coating. Italian mechanical automation is responsible for controlling the temperature in the pipes and the second circuit.

Vulcan AOGV 16 PE

This model is considered one of the most powerful parapet-type units. The device includes a closed combustion chamber; combustion products are discharged through a coaxial chimney. Air is also taken in through it for the burner to operate.

The power of the device is 16 kW, which is enough to supply heat to rooms with an area of up to 160 m². As in all other models, the heat exchanger here is made of steel and has a special coating that protects against corrosion.

The control system is mechanical, it ensures switching between circuits and maintaining a given temperature regime in the heating system.

Ignition is carried out by a piezoelectric igniter. The device does not need to be connected to the electrical network, so the Vulcan AOGV 16 PE boiler can be used in buildings not connected to electrical mains.

Parapet gas boiler Vulcan AOGV-16PE

Summarizing all of the above, it is worth saying once again that the Vulcan gas boiler deserves attention. This is a high-quality heating device with good technical characteristics. This is confirmed by many positive user reviews.

What causes blood pressure to drop?

A drop in pressure (the boiler goes out) indicates the appearance of leaks. It is necessary to check the condition of pipelines, threaded connections, gaskets and other external elements of the heating system . If there is no visible damage, you should look for problems with the boiler.

The main problem element may be the heat exchanger. Welded joints sometimes crack or break due to frequent temperature changes. Sectional cast iron heat exchangers used on powerful floor-standing models are risk factors at section connections.

In addition, the pressure relief valve may be triggered or jammed open..

Threaded connections of pipes can also lose their tightness due to drying out or destruction of gaskets, non-threaded connections, etc. All detected problems are eliminated in accordance with their specifics.

Specifications

Signal gas boilers are used to supply heat and hot water to industrial premises and private homes. The devices are characterized by: high performance, safety, as well as ease of use and efficiency.

Other advantages include:

- Very attractive pricing policy. When compared with other domestic manufacturers producing similar products, Signal equipment is cheaper.

- Thanks to the automation included with the Signal gas boiler, it is absolutely safe to operate.

- Its operation is stable and reliable.

- Thanks to the modern design, the boilers look attractive in appearance.

- The Signal gas boiler has a piezo ignition, which allows you to start the unit without using matches.

- High efficiency is due to the use of two operating modes of the gas burner. The analogue mode is intended for the normal operation of a gas boiler. In this mode, the burner does not go out and outputs the boiler to 100% of the rated power. In relay mode, gas is saved due to the frequency of burner operation (on-off cycle). In this mode, the unit can produce from 25 to 50% of the rated power.

Why is blood pressure rising?

If the pressure in the system increases, this usually indicates that the water level has increased. This problem can lead to serious emergencies and even an explosion of a cast iron radiator. To reduce risks, the installation included an expansion tank that collects excess water.

An increase in pressure indicates problems with the tank. Problems can occur in the membrane, which sag in order to make room for an increased volume of water. Sometimes it breaks, and can also be loosely fixed to the walls. As the volume of fluid increases, there will be nowhere for it to go, which will cause an increase in pressure.

The situation can be corrected by replacing the membrane or the expansion tank itself (if that is the problem).

Plasterboard construction

In this case, only moisture-resistant drywall is used. Due to the material availability, simplicity and speed of installation, this method of masking communications is quite popular.

The basis of such a box will be a metal or wooden frame covered with plasterboard. You can decorate the top to your liking.

At the end of the installation, windows are cut into the drywall to access the valves and closed with decorative doors.

How to turn on (light)

The Lemax boiler is started after filling the system with the required volume of water (12-14 liters for each kW of power) and connecting the gas pipeline.

Procedure:

- Open the lid, providing yourself with access to the regulator and the piezo ignition button.

- Turn the regulator counterclockwise, which will move the boiler to the “on” position.

- Push the regulator all the way in and hold it in this position while simultaneously pressing the piezo ignition button.

- After a flame appears on the pilot burner, the button can be released, but the regulator must be held for about another minute.

IMPORTANT!

If an attempt to ignite the boiler was unsuccessful, it can be repeated only after 1 minute, not earlier.

What can be repaired without gas workers?

There are several main causes of malfunctions. This is the incorrect operation of gas equipment, the presence of an unacceptable microclimate in the boiler room, untimely maintenance of all systems or low-quality components.

When making repairs yourself, be sure to observe safety precautions and strictly follow the instructions. First of all, the user should decide which parts of the gas boiler can and cannot be repaired on their own.

When repairing gas equipment, the main danger is a possible gas leak.

Therefore, it is necessary to carry out all manipulations for installation and dismantling of units and parts of the device with caution.

Particular attention should be paid to replacing components related to the fuel supply system.

Knowledge of typical malfunctions of gas boilers and methods for eliminating them allows you to make simple repairs yourself. It is worth remembering that serious repairs can only be carried out by gas workers, but there are procedures available to independent home craftsmen

Boiler manufacturers strongly recommend calling gas service employees to correct problems associated with breakdowns of the gas supply system and built-in electronic devices. An inexperienced person will not be able to independently configure, repair and restore the functions of specific automation in a gas boiler.

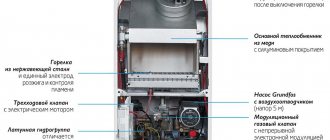

There are three main elements in the design of a typical gas boiler:

- Gas burner closed/open type;

- Specific security blocks;

- A heat exchange system consisting of one or two internal devices, the number of which is determined by the number of circuits served.

If all the components involved in the operation of the boiler are classified according to their functional purpose, then they can be divided into the following groups: control system devices, hydraulic system devices, burner and gas supply unit, smoke exhaust, boiler operation control devices, multi-level safety systems.

Most often, users have the following problems: the boiler emits an unpleasant odor of gas, does not turn on, turns off during operation, does not heat the pipes or smokes

Most of the listed elements cannot be changed or repaired yourself. In case of tampering with the boiler design, its owner loses the right to restore operability at the expense of the manufacturer during the warranty period. But you definitely need to know what and how the craftsmen from the organization with which the contract for servicing the unit and supplying gas are repaired.

However, the owner of gas equipment, seeking to extend its service life, can independently produce:

- Chimney cleaning. It is performed in cases where traction is weakened by mechanical manipulation or using chemicals.

- Checking the tightness of water supply connections, gas supply lines, and heating circuit branches.

- Installation of a voltage stabilizer.

We warn you once again that all actions that require removing the casing from the boiler must be performed by a gas service representative.

However, if the guarantee is not important to you, then you can do it yourself:

- Manual external cleaning and internal flushing of the heat exchanger/heat exchangers. They are easy to dismantle, carry out the necessary procedures, and then install them back. In this case, it is effective to use homemade water solutions of citric acid (100g/1l) or suitable household chemicals that can dissolve calcium deposits.

- Supercharger fan maintenance. Replace the fuse or the fan itself, check the electrical circuit connected to it, and lubricate the bearings with technical fluid.

- Cleaning the injectors. Clogged nozzles cause a weak burner flame. They need to be periodically cleaned to remove any deposits with fine sandpaper and dirt removed with a rag containing household chemicals.

- Adjusting the pressure in the system.

- Finding a problem due to which the boiler does not turn on.

In order to decide how and how to repair a gas boiler, you need to visually inspect it and, if necessary, carry out a series of diagnostic procedures. Self-repair is possible in cases where the manufacturer’s warranty has already expired.

If you smell gas, you should immediately forget about manual intervention. It is necessary to turn off the gas supply, immediately carry out burst ventilation and call an emergency. The rules for operating gas equipment are described in detail in the following article, the contents of which we strongly recommend that you familiarize yourself with.

Basic malfunctions and their elimination

After carrying out diagnostic procedures and identifying a specific problem, you need to begin solving it. To do this, you will need some tools and components depending on the situation. Most problems can be easily fixed with a tool that is always at hand.

Before starting work, it is important to disconnect the gas boiler from the electrical network. You also need to shut off the gas supply by turning off the gas tap. Even in cases where repair procedures do not affect parts in contact with gas, the fuel supply must be turned off in accordance with safety regulations.

Volatile boilers quite often break down due to voltage surges. As a result, not only the settings are reset, but also sensitive sensors become unusable

In some cases, it is not possible to estimate approximately the duration of the required repair work. If in such a situation the temperature outside is below zero, then a significant decrease in the temperature in the room is possible. And therefore, the water in the system will freeze.

To prevent ice plugs from forming in the boiler coils, the anti-icing system is never turned off for long periods of time. For example, if the boiler is not used for one or two days, all volatile devices are turned off, except for this function. It is possible to completely disconnect it from the power supply only if the unit is preserved for a long period.

Also, before you begin repairing the boiler and dismantling its internal components, you need to make sure that the working surface of the device has an acceptable temperature. During operation, the casing and appliances of the boiler heat up significantly, and contact with some parts can lead to burns.

Gas boiler does not turn on

Sometimes, when you try to turn on the boiler, you discover that the device simply refuses to work. First of all, you should make sure that the device is connected to the electrical network. Then you need to check whether the switch in the distribution machine is turned on.

If, after inserting the boiler plug into the socket and turning it on, the machine knocks out, then you should remove the plug from the socket. Then you need to inspect the wiring for faults

If it turns out that the device is connected to a working outlet, but still does not start, then you need to disconnect the boiler from the network and carefully remove its protective casing. It is necessary to carefully inspect the internal elements of the boiler for signs of a short circuit. Such signs include the presence of a burning smell and soot on the internal elements.

If there are no signs of a short circuit, then you need to inspect the fuse and the electronic board. If a blown fuse is detected, you need to install a new one, turn on the boiler and check its functionality. Sometimes after replacement the new fuse immediately burns out. This usually indicates that there is a serious problem inside the boiler or a problem with the wiring.

A common problem with electronic boards is that they get wet. It is better to dry it with a regular home hairdryer, then leave it for a couple of days until the moisture has completely evaporated.

Electrical wiring must be checked for correct connection and wiring. You need to make sure there are no exposed wires or short circuits.

If it is found that the fuse is OK, then you need to inspect the varistor. This device protects the boiler from voltage surges. Perhaps there was a serious voltage surge earlier and the varistor exploded. Only a small part of it may remain. To solve this problem, you will need to resolder the varistor using a blowtorch and the required material.

A varistor is a semiconductor resistor. If the voltage rises to too high a level, it redirects it through itself, thereby protecting the device

In cases where the boiler is accurately connected to the electrical network, and the fuse and varistor are in perfect order and after inspection it was not possible to find any visible causes of starting problems, you should call a gas boiler repair specialist. Most likely there is a serious internal problem that will be difficult to fix at home.

A number of models of gas boilers, which are designed to display an error code on the dashboard, do not turn on and do not display an error code at the same time. This problem often manifests itself when the circuit of a temperature sensor installed in a room or outside is broken.

It is necessary to inspect the room sensor; perhaps it is unplugged or its batteries are dead. Then you need to replace the batteries or plug the plug into the socket. If the boiler panel does not show the temperature, then most likely there is a problem with the thermostat and it is advisable to start looking for the problem with it.

Problems with filter and pump

The boiler may not operate properly due to a clogged cold water filter. To clean it, you need to turn off the water supply and remove the filter mesh. Rinse it under running water or replace it with a new one.

The coarse filter of the water supply system provides reliable protection of the boiler system from large foreign particles. If contaminated water flows through the water supply, the filter often becomes clogged.

Boiler users may also encounter problems with the pump. The pump stops pumping water when the rotor is broken or air accumulates inside it. First of all, the serviceability of the rotor is checked. To do this, unscrew the nut from the pump and drain the water. Then you need to insert a flat-head screwdriver into the slot and force the axle to rotate. Sometimes the pump jams or sticks.

If it turns out that the pump is broken, you will need to disassemble it yourself and find out the cause of the failure. Having determined which part has broken, you need to order it from a gas equipment store or from a boiler seller. Pump parts are changed at home or in a workshop.

If air has accumulated in the pump, then it is necessary to open the air vent slightly and wait until the excess air comes out. The air vent is closed with a tight-fitting cap. The process of releasing air is accompanied by a characteristic sound.

The pump is often installed when installing a heating system in private homes. It allows warm water to circulate through a closed circuit and ensures equal heating of all radiators

If the pressure gauge needle is in close proximity to the red zone, then you need to turn on the boiler and heat the water in the system. If, with low heating, the pressure rises strongly in the range from 0.7 to 1.5 bar, then you need to carry out a procedure to add air to the expansion tank.

Air is added after the pressure in the system has been reduced to zero. This is done by opening the tap and draining the water. Then, using a pump or compressor, the pressure in the tank is pumped up to 1.3 bar. After this, you need to bring the pressure in the system to 1.5 bar.

Heat exchanger cleaning procedure

The cause of boiler overheating is often faulty automation or a clogged heat exchanger. If the automation of a gas boiler will most likely have to be repaired by a service center, then the heat exchanger can be cleared of blockages at home. To do this, you need to turn off the boiler and wait until it cools down. Turn off all taps and remove the cover of the device.

All electrical components and parts, the pump and control devices must be tightly covered with plastic film so that water does not accidentally get on them. By opening the tap or valve of the gas boiler, you need to drain the remaining water from it.

Next, you need to dismantle the burner block with the manifold, remove the fan from its seat, disconnecting the fasteners securing it to the combustion chamber. After which the return pipe is disconnected from the heat exchanger.

Water heats up unevenly due to impaired thermal conductivity. This occurs due to the accumulation of a large layer of scale on the walls of the heat exchanger. Uneven heating causes alternating water supply at different temperatures

To remove the heat exchanger, you must first disconnect the overheating sensor, then remove the combustion chamber. To do this, first unscrew three self-tapping screws, after which the camera along with the cap is pulled towards itself. After which the cap is detached from the chamber and the heat exchanger is disconnected.

The heat exchanger itself is first mechanically cleaned using a brush and emery cloth. Then you need to hold the part in a 10% solution of citric acid or household chemicals that dissolves mineral deposits. Soaking in the solution should run for about 10-15 minutes.

Next, the solution is poured into the internal pipeline and kept there for a period of similar length. Afterwards everything is drained and washed thoroughly with running water. Reassembly is carried out in the exact reverse order. In order not to forget the sequence, it is recommended to take a photo of each step on your phone during dismantling.

If you first read the recommendations for cleaning the heat exchanger and the instructions for disassembling the gas boiler, the preventive cleaning process will not take much time

It is recommended to clean the heat exchanger every one and a half to two years.

Solving the problem of poor traction

Boilers with an open combustion chamber sometimes lose draft power. To determine the cause of this malfunction, it is worth looking directly into the combustion chamber. Perhaps it is clogged with soot, soot or decay products. You need to brush and vacuum this part.

Models with a closed combustion chamber are equipped with coaxial chimneys, which have the following disadvantages. In the cold winter, drops of water fall from the outer pipe into the inner one, and there the water freezes and turns into an icicle.

Ice in the space between the pipes blocks air access to the gas boiler and, therefore, reduces the supply of fresh air required for combustion. To solve this problem, the street part of the chimney is insulated or holes are drilled in the outer pipe to drain condensate.

There are situations when foreign objects and waste get into the chimney. In such cases, you need to carefully dismantle the pipe and clean it of excess contents. Problems with a gas boiler occur when the coaxial chimney becomes excessively clogged. Soot needs to be cleaned out at certain intervals. Then the boiler will work long and efficiently.

It is worth noting that the accumulation of soot in a gas boiler is a rather rare occurrence. Gas does not emit too much soot when burned. Therefore, the manufacturer usually recommends chimney cleaning every two or three years.

A pipe cleaner is quite easy to make yourself. However, it can also be purchased in stores at a reasonable price.

Cleaning the chimney is carried out as follows. It is necessary to turn off the boiler, turn off the gas and water supplies and wait until it cools down. Remove the external protection of the boiler and disconnect the chimney pipe from it. Cleaning can be done mechanically or chemically.

It is convenient to clean the lower part of the chimney pipe directly adjacent to the boiler with a long-handled metal brush and then use a brush. After this, you can use chemical solutions. After cleaning the inside, you need to start cleaning the outer outlet of the pipe.

There are several ways to clean the chimney with your own hands while on the roof. Most often, a special metal brush is used on a rope with a weight attached to it. In this case, the circumference of the cleaning tool must correspond to the circumference of the chimney.

Alternately lowering and raising the mechanism, the pipe walls are cleaned. The soot falls down and needs to be shaken out, removed or vacuumed from the inside of the chimney.

You can also clean the chimney using a powerful vacuum cleaner specially designed for similar procedures. This device has pockets for drawing in waste. And the hose is long enough to clean the entire chimney.

In special cases, it is worth calling a chimney sweep who has a vacuum unit designed for cleaning chimneys. This expensive device will completely clean the chimney of contaminants without damaging the system.

When cleaning the chimney and other elements of the boiler, be sure to wear a mask on your face. It will protect the owner from inhaling soot and getting harmful microelements into the lungs

If you do not solve the problem of weak traction in a timely manner, you may encounter a number of negative consequences:

- Carbon monoxide entering the premises and causing harm to the health of residents;

- Soot accumulations increase the risk of fire;

- Due to carbon deposits on the boiler walls, heat loss and gas consumption increase.

Possible problems indicate that it is necessary to regularly carry out preventive cleaning of the gas device.

Replacing components and eliminating leaks

If leaks and water leaks are detected at the gas boiler connection points, the water supply should be shut off. Then, using a wrench, you need to unscrew the connection, remove the remaining tow and check the threads for damage. After which you need to apply a new layer of tow or FUM tape and screw the pipes tightly.

If, as a result of the inspection, it is discovered that the water pipe is damaged, then you need to replace it yourself or call a plumber.

The use of FUM tape, plumbing thread, liquid or anaerobic sealant protects pipe connections from leaks. Before re-screwing the pipes, you must thoroughly clean the threads from foreign elements.

If you detect the smell of gas in the air, turn off the lights and all sources of fire. Open the window and ventilate the room. You can check the location of the leak using a soap solution. After applying it, a soap bubble appears on the pipe. Gas leaks are eliminated in the same way as on a water pipe.

Sometimes after diagnostics it turns out that it is necessary to replace the burner in a gas boiler. You can replace the burner yourself, but you should install exactly the same burner model. It is necessary to disconnect all communications, and when dismantling, be sure to remember the correct location of all elements connected to the burner.

If the boiler refuses to maintain the set temperature, then a broken sensor is usually to blame. Temperature sensors can be surface-mounted or submersible. Overlays are easily mounted on pipes and replaced without difficulty. When installing an immersion sensor, you need to drain the water from the boiler and, after installing the sensor, seal the thread.

In order to maximize the safety of your own space and eliminate the possibility of excess toxins due to the operation of gas equipment, it is recommended to use a carbon monoxide detector at home. The principle of its operation, selection and installation rules are described in the article we recommend.

Design Features

The main elements of the Zhitomir boiler are:

- a housing in which the main components and equipment are installed;

- gas burner unit located in the firebox. Here gas combustion occurs and heat flow is released;

- recuperative heat exchanger, in which heat exchange occurs between combustion products and coolant;

- gas exhaust system, its responsibilities include removing combustion products outside the boiler and releasing them into the chimney.

In order to increase the efficiency of heat transfer, the gas boiler Atem Zhytomyr 3 has the following design features.

- The heat exchanger pipes made of heat-resistant steel have a rectangular cross-section; this device allows you to increase the contact area of the flue gas and the coolant.

- The counter movement of coolants was organized, this solution made it possible to increase the efficiency of the heat exchange device to 92%;

- To increase the area of interaction between combustion products and the coolant, as well as to prevent the accumulation of soot on the surface of the steel pipes of the ATEM boiler heat exchanger, turbulators are installed. Soot accumulates on the lower surface of the turbolizers, while the pipe walls remain clean. To remove soot, you need to periodically remove the turbolizers and clean them of soot.

- Gas double-circuit turbocharged boilers in Zhitomir have a coil of copper pipelines around the heat exchange heating pipes.

To organize a stable gas combustion process, a POLIDORO gas burner device is used. Its distinctive feature is a single-stage atmospheric burner. The edges of the burners themselves are made of heat-resistant steel, which allows you to maintain the combustion mode at different gas supplies to the firebox. Even at low gas consumption, the heating of the edges is sufficient to maintain stable combustion.

The gas supply mode is regulated by the EUROSIT gas valve. This device automatically switches the gas supply to the burners depending on the temperature of the coolant. The user independently sets the temperature of the coolant, focusing on the temperature in the open air. As the ambient temperature decreases, the temperature of the coolant increases.

Sources

- https://www.stroy-podskazka.ru/otoplenie/kotly/zhitomir/

- https://ProfiTeplo.com/gazovye/56-kotly-zhitomir.html

- https://SpetsOtoplenie.ru/gazovoe-otoplenie/gazovye-kotly-evropejskogo-proizvodstva/chto-nado-znat-pro-gazovyj-kotel-zhitomir.html

- https://teplospec.com/gazovoe-otoplenie/kak-zapustit-gazovyy-kotel-vpervye.html

- https://microklimat.pro/otopitelnoe-oborudovanie/kotly/kak-vklyuchit.html

Doesn't start (ignite)

The unit is ignited according to a certain pattern. It does not always start the first time, and this is quite normal. But, if after repeated attempts the boiler does not ignite, it is necessary to check the condition of the components responsible for ignition.

Possible reasons could be:

- Failure of the electronic or mechanical ignition system. It is necessary to replace the system, or clean the thermocouple contacts.

- There is no voltage in the power supply network (for volatile units).

- The valve on the gas supply pipe is closed.

- The gas pressure in the system does not correspond to the nominal values.

- The main burner nozzles are clogged. It is necessary to clean them and start the boiler.

All these reasons are the most common, but far from the only possible ones. Any malfunction in the system can negatively affect the ignition of the boiler .

NOTE!

If you have tried all the options, but the problem is not solved, you need to call a technician from a service organization.

Types of homemade stoves in development

Engine oil contaminated with impurities will not ignite itself. Therefore, the operating principle of any oil stove is based on the thermal decomposition of fuel - pyrolysis. Simply put, to obtain heat, the waste must be heated, evaporated and burned in the furnace firebox, supplying air in excess. There are 3 types of devices where this principle is implemented in different ways:

- The simplest and most popular direct combustion design with afterburning of oil vapors in an open perforated pipe (the so-called miracle stove).

- Drip furnace using waste oil with a closed afterburner;

- Babington burner. How it works and how to make it yourself is described in detail in our other publication.

The efficiency of heating potbelly stoves is low and amounts to a maximum of 70%. Note that the heating costs indicated at the beginning of the article are calculated based on the indicators of factory heat generators with an efficiency of 85% (to get acquainted with the full picture and compare oil with firewood, you can go here). Accordingly, fuel consumption in home-made heaters is much higher - from 0.8 to 1.5 liters per hour versus 0.7 liters for diesel boilers per 100 m² of area. Take this fact into account when starting to manufacture a furnace for testing.

Design and disadvantages of an open-type potbelly stove

The pyrolysis stove shown in the photo is a cylindrical or square container, one-quarter filled with used oil or diesel fuel and equipped with an air damper. A pipe with holes is welded on top, through which secondary air is sucked in due to the chimney draft. Even higher is an afterburning chamber with a partition for collecting heat from combustion products.

The principle of operation is as follows: the fuel must be ignited using a flammable liquid, after which the evaporation of the waste and its primary combustion will begin, causing pyrolysis. Combustible gases entering the perforated pipe flare up upon contact with the oxygen flow and are completely burned. The intensity of the flame in the firebox is controlled by an air damper.

This stove has only two advantages during testing: simplicity and low cost and independence from electricity. The rest is all downsides:

- stable natural draft is required for operation; without it, the unit begins to smoke into the room and die out;

- water or antifreeze that gets into the oil causes mini-explosions in the firebox, causing fiery drops to splash from the afterburner in all directions and the owner has to put out the fire;

- high fuel consumption - up to 2 l/hour with low heat transfer (the lion's share of the energy flies into the chimney);

- The one-piece housing is difficult to clean from soot.

Although the potbelly stoves look different, they operate on the same principle; in the right photo, fuel vapors burn out inside the wood stove

Some of these shortcomings can be leveled out with the help of successful technical solutions, which will be discussed below. During operation, you should adhere to fire safety rules and prepare used oil - settle and filter.

Pros and cons of IV drips

The cardinal difference of this furnace is the following:

- a perforated pipe is placed inside a steel casing made from a gas cylinder or pipe;

- fuel enters the combustion zone in the form of drops falling to the bottom of a bowl located under the afterburner;

- To increase efficiency, the unit is equipped with air pressurization using a fan, as shown in the diagram.

Diagram of a dropper with bottom supply of fuel from the fuel tank by gravity

The real drawback of the drip stove is the difficulty of execution for a beginner. The fact is that you cannot rely entirely on other people’s drawings and calculations; the heater must be manufactured and configured to suit your operating conditions and the fuel supply must be properly organized. That is, repeated improvements will be required.

The flame heats the body of the heating unit in one zone around the burner

The second negative point is typical for supercharged stoves. In them, a jet of flame constantly hits one place in the body, which is why the latter will burn out quite quickly if it is not made of thick metal or stainless steel. But the listed disadvantages are more than offset by the advantages:

- The unit is safe to use because the combustion zone is completely enclosed by an iron casing.

- Acceptable waste oil consumption. In practice, a well-tuned potbelly stove with a water circuit burns up to 1.5 liters in 1 hour to heat 100 m² of area.

- It is possible to wrap the body with a water jacket and convert the exhaust furnace into a boiler.

- The fuel supply and power of the unit can be adjusted.

- Undemanding to the height of the chimney and ease of cleaning.

Boiler with pressurized air, burning waste engine oil and diesel fuel

Varieties and advantages

Owner reviews indicate that Mimax gas boilers are distinguished by high performance indicators, despite the fact that they are not bulky in size.

The equipment can operate not only on natural gas. If you replace the jets (injectors), you can switch the device to operate on liquefied gas.

According to their purpose, the described heating devices are divided into:

- single-circuit;

- double-circuit.

Single-circuit boilers are used exclusively for heating premises. Their marking is SSG (Steel Gas Boiler). Following the letters is a number that indicates the thermal power of the unit. KSG-7 has a minimum heating capacity of 7 kW, while KSG-40 has a maximum heat output of 40 kW.

Double-circuit units not only supply the room with heat, they also provide hot water. The two circuits are equipped with separate heat exchangers. Water and coolant do not mix. Their designation is KSGV. The power of such devices varies from 12.5 to 40 kW.

Among the advantages of Mimax gas heaters, we note the following:

- acceptable price;

- a wide selection of power models; finding the best option for a particular case is not difficult;

- heating equipment has a quality certificate and meets all sanitary standards and fire safety requirements;

- the devices are very reliable, perfectly adapted to domestic operating conditions;

- high performance, efficiency reaches 90% and above.

How to repair a boiler yourself: step-by-step instructions

Once a specific breakdown has been accurately diagnosed, you can begin to fix it. Of course, if you are sure that this is a feasible task that does not require special skills and equipment.

Preparatory stage

- First of all, you need to disconnect the device from the power supply and also turn off the gas valve tightly. Even if the repair is not related to elements in direct contact with fuel, this condition is mandatory.

- If it is difficult to estimate the time of restoration work, and it could theoretically take several hours, you should completely drain the water from the heating system or pour in an antifreeze solution (if it is not there). The fact is that during the repair the air temperature in the room may drop to negative values, and the water will freeze.

- Safety precautions: along with turning off the gas valve and de-energizing the system, you should also remember that before repairs, the working surface must cool to an acceptable level. Otherwise, touching it may cause burns.

Cleaning the heat exchanger

If the boiler overheats, this may indicate 2 reasons:

- The automation that controls the operation of the device is faulty.

- The heat exchanger is clogged (soot deposits).

Automation can be repaired only with the help of special equipment, which in most cases is not available in the house. But it is quite possible to clean the heat exchanger yourself.

The sequence of actions is as follows:

- Turn off the boiler and allow it to cool.

- The taps are turned off.

- Remove the front cover.

- Dump the remaining water (open a hot water tap or a valve inside the mechanism to drain water from the heating system).

- Remove the heat exchanger.

- The heat exchanger is cleaned first mechanically, then in a solution of vinegar and citric acid, taken in equal quantities (you can use a tablespoon per liter of water). Instead of a solution, you can also use special formulations purchased in the store.

- The heat exchanger is kept in this mixture for 1-2 hours until completely cleaned.

- Then rinse with running water and wipe dry.

- Put the heat exchanger back, close the lid, and fasten all the parts.

Chimney cleaning

Reduced draft and overheating of a gas boiler can certainly be associated with a clogged chimney. It is in this part of the system that the largest amount of soot accumulates. However, dirt accumulation is quite rare since the gas does not produce a large amount of waste.

Technical characteristics and device

Keber boilers are distinguished by their reliable assembly and long service life. The manufacturer provides a 15-year warranty. Also, units of this brand are characterized by high efficiency.

Keber gas boilers are equipped with gas burners, which ensure:

- stable heating of the coolant;

- maximum complete combustion of fuel.

In addition, these elements are distinguished by high anti-corrosion properties.

Due to the fact that Keber boilers have gas burners, the size of their fuel chambers is smaller than that of similar heating devices produced by other manufacturers. Thanks to the special design of the Danko automation, fuel burns as efficiently as possible, even if the flame height reaches 7 cm.

Also included in the package is the Arbat automatic system, which is responsible for regulating the operation of heating equipment and its safety. There are five levels of protection. If the pressure in the water or gas supply system decreases, the unit will turn off automatically. The design of the automation is simple, which has a positive effect on its reliability, and in case of problems, repairs will be simple.

It is worth saying that, if desired, users can order from the boiler manufacturer Keber a model with a more expensive, but at the same time more reliable and high-quality Italian Eurosit automation. Such units can operate practically without third-party intervention.

You can read about the types of automation for gas boilers here.

The assortment of the company that produces Keber boilers includes a wide selection of models of different powers: 10, 12.5, 16, 20 kW, etc.

Let's look at the technical characteristics of the device using the example of the Keber 12.5 floor-standing model:

- type of execution - floor-standing;

- combustion chamber - open;

- power - 12.5 kW;

- Efficiency - from 85%;

- mechanical control;

- gas consumption - 1.62 m³;

- weight - 39 kg;

- heated area - 125²;

- The maximum water pressure in the heating system is 3 bar.

Gas non-volatile boiler KS-G Keber 12.5 with EUROSIT automation

Is it worth taking on the repairs yourself?

In a typical gas boiler, all structural elements are conventionally combined into three groups:

- burner;

- blocks that are responsible for safety;

- a heat exchange unit equipped with a fan, circulation pump, and many other elements.

During repairs, the main safety risk arises from possible gas leaks. The reason for this may be improper repair, dismantling or installation of equipment with fuel supply functions.

Because of this, it is better to have these structural parts repaired by a specialist. In addition, it is not allowed to independently troubleshoot faults in the electronic equipment of a gas boiler. The automatic system is quite specific, and unless you have the appropriate qualifications, it is impossible to correctly restore this type of equipment in practice.

And yet, if you do not have enough experience, it is better to entrust the maintenance of heating boilers and the repair of geysers to professionals.

What can you repair yourself?

All other elements can be repaired yourself, for example:

- The heat exchanger is washed manually (to do this, the unit is dismantled, after which it must be correctly put back in place). You can perform this work without dismantling - using pumps.

- Chimney cleaning will be needed in cases where there is a problem with draft (mechanical or chemical removal of blockages is carried out).

- Repair of the boost fan by lubricating its bearings with technical oil.

In fact, you can repair a gas boiler yourself only in cases where there are mechanical damages or blockages that can be easily identified visually (or by smell).

Other breakdowns are considered more serious, so they are repaired with the help of a specialist, and not with your own hands.