Recently, Russian craftsmen began to use flexible tiles to decorate the facades of houses. Some people prefer to focus on finishing the pediment. Others cover the entire facade of the building. The polymer base, bitumen impregnation, and basalt coating make the tiles airtight.

Facade tiling

This finish is attractive due to its similarity to facing bricks. Only upon closer inspection can one realize that this is not brickwork. More information about soft roofing, its characteristics, and installation rules is described in this article.

Installation

Any decoration of the walls occurs according to a certain scheme.

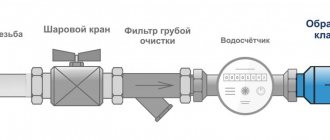

It does not matter whether the interior decoration is planned or the exterior - everything must be done in compliance with the technology. For bitumen or flexible tiles it will be something like this:

- It is necessary to create a ventilation gap between the wall and the finishing material - the sheathing is installed. If you plan to insulate the facade, then the insulation is placed in the resulting cells, and a counter-lattice is placed on top.

- The resulting sheathing is sheathed with sheet material - plywood (waterproof), OSB boards or other similar ones.

- Horizontal lines are drawn on the assembled plane, which will serve as a guide for laying the slabs.

- The starting strip is being installed. The first row is special - you need to cut off the figured part from the bottom side of the tiles. It is worth starting installation by retreating 5 - 10 millimeters from the corner of the house. On the reverse side of each part there is a film covering the bitumen layer. It needs to be removed.

- The remaining parts of the covering are mounted - they will all overlap, and each element is attached not only with an adhesive layer, but also with seven to eight nails.

Door and window openings are decorated with trimmed parts. To secure their edges, special metal corners are used, decorated on the outside with basalt chips. You can choose the desired color. In the same way, the outer corners of the building are decorated with corners. At the top of window and door openings, tiles are laid overlapping metal corners to prevent water from flowing inside.

Peculiarities

The covering is assembled from small rectangular fragments with shaped cutouts in the lower part. The slabs have a complex multi-layer structure - the base is fiberglass coated with a bitumen composition, covered on one side with basalt chips. Fiberglass provides strength to the parts. Bitumen serves, on the one hand, as the basis for basalt granules, and on the other, provides the material with all its basic properties - flexibility, resistance to moisture, and so on.

It is worth noting that finishing the facade of a house with flexible tiles is possible only on a pre-assembled plane. That is, to install the coating you will have to assemble a structure from sheet materials. This increases the cost of finishing, but provides the opportunity to install additional insulation and eliminates the need to level the walls.

Features of installing a soft roof on the facade of a house

Odes User FORUMHOUSE

I built a frame house. The outside is covered with OSB. The roof is flexible tiles. I’m also thinking of mounting a warhead on the walls. Because Few people here do this; they have thought about the correct design and service life of such a façade.

The topic aroused great interest on the portal, and the opinions of participants were divided. Someone is in favor with both hands, considering such a facade to be original. Some are against it, believing that it is expensive and impractical, and most importantly, the tiles will soon fall off, because... “works” on the wrong vertical plane from the point of view of its installation.

An interesting experience is that of jovik2003, who was attracted by the idea of a MS on the facade due to its unusual nature. A member of the portal was not lazy and wrote a request to several manufacturers of flexible tiles, where he asked them the question: is laying soft roofing on a vertical plane allowed according to the technical regulations.

Here are the manufacturers' responses:

First company

Laying the shingles at an angle of 90 degrees is possible if you follow a number of our recommendations, namely: each shingle is nailed with at least six rough nails (in places as prescribed in the installation instructions). The petals of the shingles must be glued to the base (regardless of the ambient temperature) using a hair dryer. The thickness of the OSB board is at least 12 mm.

At the same time, the heat resistance of the heating element is up to +110 C°, so the facade will not “float” in the summer. The facade will not smell of bitumen, because... tiles contain virtually no volatile compounds or solvents.

Second company

Flexible tiles can be used to decorate the facade. The shingles are fastened with six nails per sheet, four of which are standard nails, and the other two are driven in the upper corners, at a distance of at least 2.5 cm from the edge.

So, manufacturers confirm that HF on the facade is a normal solution. You just need to install the tiles in accordance with the instructions, and if you have any questions, do not hesitate to call the company and ask for advice from specialists.

Now let's move from theory to practice.

nikitin_ilya

I am well versed in the nuances of laying flexible tiles and, based on this experience, I can give advice on their installation on the facade.

High-quality MS is sintered in the summer sun into a continuous carpet within 1 week after installation. It is important to pay attention to the modifier used in the bitumen - SBS or APP, and choose a quality product. At the initial stage, the petals of the shingles can be additionally secured with small nails or using a construction stapler.. nikitin_ilya. nikitin_ilya

nikitin_ilya

The studs or staples will eventually rust and disappear. There will not even be a trace left of them and no micro-holes either. We did this even with a negative surface slope.

- The ventilation duct in the house that Ilya built goes from the very bottom to the ridge.

Flexible tiles on the facade + lining carpet = vapor-proof finish, therefore, to remove water vapor flowing out of the house, a ventilation gap about 4 cm wide is necessary.

- The junction areas are decorated with aprons made of galvanized steel, with a pural coating in the color of the roof.

- Frame wall pie (from inside to outside):

- drywall;

- OSB;

- frame posts – board with a section of 5x15 cm + insulation – stone wool;

- counter-lattice for cross-insulation, for cutting off cold bridges - 5x5 cm block + insulation - mini-slab;

- moisture-and-windproof superdiffusion membrane;

- ventilation duct – block 5x5 cm;

- OSB;

- waterproofing in especially critical places (waterproofing carpet under the head);

- flexible tiles.

Vzik FORUMHOUSE user

I decorated the guest house GC. The “pie” is ordinary, as when installing a roof on a roof: OSB, frame with insulation, ventilation gap along the sheathing, OSB, flexible tiles. I don’t see any shortcomings in such a façade. The house is warm, dry and quiet.

A member of the portal with the nickname PETR2222 also finished his frame house with GC, because... believes that it is fast, practical and beautiful

The user advises to make sure to make a ventilation gap, pay special attention to the junction points of the main parts - windows, corners, at least hammer in as many nails as the manufacturers advise, and heat the petals with a hair dryer

PETR2222

In my opinion, the facade made of flexible tiles looks very good and original, especially when viewed from the side. I consider a ventilated façade to be the optimal solution for a frame structure.

On average, each PETR2222 shingle was secured with 10 nails.

Andrey_Tulkin FORUMHOUSE user

I looked at the photo of the MS on the facade and decided to do the same for myself. Everyone I know who has seen the finish “live” likes it.

Review of manufacturers: quality from all over the world

Bituminous shingles from different manufacturers only look similar in appearance, but in fact their quality, raw materials used and technologies are as different as day and night. And what is often good for warm Europe is not always suitable for the cold northern climate. Therefore, let's look at what the modern market offers and what can please you.

Italian design: environmental friendliness is a priority

Tegola is a well-known Italian company that produces excellent soft tiles for the Russian winter. It has been known to the domestic market for more than 10 years, and even one of its factories has been built in Russia itself. This company is the European leader in the production of soft tiles, accounting for 49%!

The Italian company Tegola has its own branch in the Moscow region. It is famous for the fact that its range includes more than 100 colors, and is good for structures of complex shape.

Such flexible tiles can withstand sudden changes in temperature remarkably well, because they are made from improved bitumen with higher frost resistance. Therefore, Tegola is suitable for different climatic regions.

American Made: Style and Layering

CertainTeed tiles are an American company, and America is deservedly considered the world leader in the production of soft tiles. The Italians use natural bitumen as a raw material, which is specially imported from South America.

CertainTeed itself is part of the International Construction Concern Saint Global, and supplies two-layer and three-layer tiles in more than a hundred colors to the Russian market! Impressive, isn't it?

Finnish technology: weather resistance

You will also probably like the beautiful Finnish tiles, especially Katepal, because its designers were inspired by such harsh nature. The famous Katepal is a company that has been producing flexible shingles since the late 40s.

Its products are especially popular in Scandinavia, and if you happen to admire neat houses among the hills, these were the tiles on the roofs.

In addition, Katepal roofing is considered one of the most convenient materials. Which is not surprising, since Finns are famous as born builders. And when working with such tiles, you don’t need any special skills or special tools.

In addition, Katepal is simply an ideal coating for architecturally complex roofs that usually have to be tinkered with. Here are the technical characteristics of this tile:

In all Katepal collections, shades were specially selected that harmonize with the landscape at absolutely any time of the year. In addition, the roof itself was designed to withstand all weather conditions, especially changing climates. That is why they say about her that she has a “truly Finnish character”.

Let us also note such an exclusive new product from Katepal as the two-layer “Mansion” tiles made of modified bitumen, which are distinguished by particularly high waterproofing properties.

The basis of these tiles is SBS modified bitumen. The secret of Katepal is in innovative technologies that allow bitumen to maintain its properties in almost any weather conditions. That's why Katepal has been particularly popular on the Russian market for more than 20 years.

Another popular Finnish brand is Kerabit. It has been known on the Russian market since 2003 and before that it was called “Pikipoyka”. Also known in Europe for its good qualities, durability and affordable price. Different types of flexible tiles differ from other types in that the inside of the shingles is protected with a silicone film:

Danish experience in production: a century-long history

Icopal is one of the oldest companies, having its origins over 160 years ago. It would be more correct to say that this is a whole group of companies that are leaders in the roofing and waterproofing materials market today:

The tiles, which are produced under the Icopal brand, are of good quality and thoughtful design.

German quality: value lies in cooperation

Now let's move on to the German manufacturer Docke. This is a large enterprise that specializes in the production of flexible tiles. Docke products are the result of German-Russian cooperation. Moreover, it is successful, since the produced tiles have a number of advantages and advantages: ease of installation, enhanced tightness, lightness, excellent design and resistance to temperature changes.

The tiles themselves are suitable for all climatic regions of our country, because special elements are added to the bitumen base even under production conditions, which increase the melting point and make it difficult to ignite.

Docke flexible tiles have one unusual feature - vapor permeability. It perfectly allows steam to pass through from the inside, but at the same time protects the roof from external moisture. Thanks to all this, the under-roof space with such a coating always remains clean and dry, without any condensation or dampness. Another important point: Docke flexible tiles are not blown by the wind at all.

By the way, the manufacturer himself initially expected that the flexible tiles would fit perfectly with the siding on the facade, so if you have this type of home decoration, Docke will fit perfectly into the overall exterior:

Typically, Docke tiles are dark in color and heat up in the sun, but retain all their properties without losing durability. And fiberglass mesh with a special filler is not at all sensitive to frost. In addition, here bitumen has a low density, which plays the role of additional insulation.

You will remember the Docke collection by its unusual collection names, which are dedicated to different countries and famous cities. Moreover, Docke produces two types of tiles: with oxidized bitumen and SBS-modified. Therefore, be careful: the products here are really different. And when there is a narrow specialization, enough time and effort is devoted to quality and technology.

Types of shingles

Modern manufacturers offer various options for cutting sheets, which allows you to give the roof an original look. According to modification, the following types of flexible tiles are distinguished:

- The row type is used to form rows.

- Ridge elements are necessary for laying at joints.

- The cornice option is used for arranging roof areas that experience the greatest load during operation.

- The ridge-cornice modification is a universal type.

Red-brown, dark green, blue colors are the most popular. The buyer can choose another shade that is ideal for his structure.

Today, not only single-color options are produced, but also shingles with a transition of colors. Modern technologies make it possible to paint products in any shade. To achieve interesting effects, different colors of sprinkles, shapes of elements and patterns on them are used.

- Balusters - definition, installation, design and creation with your own hands (70 photos)

- Window shutters - main types and DIY options (65 photos)

- One-story houses are beautiful, functional designs. 65 photos of finished and standard drawings

Voting by our readers

Which of the proposed models of flexible tiles would you choose or recommend?

CertainTeed Landmark

0.00 % ( 0 )

GAF Timberline Ultra

0.00 % ( 0 )

Icopal Plano Natur

0.00 % ( 0 )

Katepal Katrilli Dune

40.00 % ( 2 )

TechnoNIKOL Shinglas

20.00 % ( 1 )

Onduvilla

20.00 % ( 1 )

Ruflex Runa

0.00 % ( 0 )

Dock Europa

0.00 % ( 0 )

Kerabit L+Cedar

0.00 % ( 0 )

Types of decorative panels

Since Technonikol uses the same materials in the manufacture of its products, the panels are classified by color and scope of application:

- Burnt brick is used to emphasize one or another architectural element, as well as for the exterior decoration of door and window openings.

- Beige brick emphasizes the regular rhythm of life of the home owners.

- Marble brick is used to decorate flower beds, platforms for benches, gables of office premises and respectable leisure facilities.

- Antique brick - for finishing museums and private houses designed in the appropriate style.

- Terracotta brick – adds a touch of mystery and severity. Can be used for both full and partial finishing of buildings or fences, arch bases. Finishing the foundation of a small country house will look great.

- Sand brick for finishing openings if the building is surrounded by greenery.

- Dark tones harmonize perfectly with flower beds and giant trees.

- Clinker brick is suitable for cladding houses designed in the Gothic style, and also visually increases the volume of small buildings.

Where can I buy

Different types of goods can be purchased in construction supermarkets or in markets where a large range of products is presented. In addition, budget new items can be easily ordered online using the Yandex.Market aggregator, which demonstrates products with descriptions, photos and a direct link to the manufacturer’s online store. Tips and recommendations on what to look for, what the best models are and how to choose the right shingles will be helpful.

Rules for installing TechnoNIKOL decorative panels

You need to start decorating the outside of the house with TechnoNIKOL facade panels from the corner of the building, retreating 5-6 mm from the edge of the wall. If the length of the wall exceeds 6 m, the manufacturer recommends starting cladding from the middle of the wall. Installation is carried out from bottom to top.

The first row is the so-called starting tile. Essentially, this is a regular panel with the petals cut off. They are laid parallel to the foundation base and secured to the wall with galvanized nails 30 mm long. Eleven nails are used per panel, three of them are driven into the top edge, eight into the bottom.

Then the row panels are installed. They are laid so that their petals completely cover the starting panels. That is, the installation is carried out along the base of the foundation. The starting elements cover the gaps between the petals. This is their main purpose. Ordinary façade panels are secured with eight nails, two for each petal.

All subsequent rows of facing material are laid in relation to each bottom row with an offset of half the width of the petal. In this way, the adhesive strips located on the main plane of the façade panels are closed.

Specifications

Appearance of packaging

Appearance of tiles

| Height, mm | 250±3,0 |

| Width, mm | 1000±3,0 |

| Thickness, mm | 3,0±0,2 |

| Fiberglass base, g/m² | 100 |

| Type of bitumen binder | Improved |

| Loss of granules of mineral powder, no more, g | 1,2 |

| Top coating | Granules from natural basalt (gabbro-diabase) |

| Bottom cover | Quartz sand |

| Heat resistance, °C, | not lower than 110 |

| Number of facade tiles per package, pcs. | 20 |

| Quantity of cladding per package, m² | 2 |

| Approximate weight of facade tile packaging, kg | 23,8 |

| Approximate weight of 1 m² of facing coating, kg | 11,9 |

| Number of packages on a pallet, pcs. | 40 |

Advantages and disadvantages

Roofing tiles have a fairly impressive list of advantages. The choice in favor of this material is determined by the following characteristics:

Economical. It is expressed not only in cost, but also in the small amount of waste during the installation process.

Virtually no operating costs. The roof does not require periodic painting; repairs are necessary only in exceptional cases.

Fire safety. The roofing carpet will not catch fire even when in contact with an open flame.

Tightness. Thanks to the technology of manufacturing roofing tiles, when arranging the roof, a continuous carpet is formed that is practically waterproof.

Protective properties. This material is a good heat insulator and sound insulator. Does not accumulate static electricity, which virtually eliminates lightning from entering the house. There is no need to erect a lightning rod on a building with a roof made of flexible tiles.

Durability. Bituminous shingles are not susceptible to rust, rotting and fungus. The service life of this coating is 30 years and above.

Resistance to temperature changes. Tolerates frost and heat equally well

This quality is especially important in the Russian climate.

Resistance to mechanical loads. Withstands the weight of a person and large wind loads, even withstands hurricane winds.

Aesthetics

Retains the original color for many years: it practically does not fade and does not lose color under other atmospheric influences.

Maintainability. Flexible roofing very well withstands various types of deformations caused by shrinkage processes of the building and other reasons. If damaged, bitumen tiles can be easily replaced in the damaged area due to their small size. There is no need to replace the entire roofing carpet. The color of the tiles is also easy to choose. Small differences in shades are smoothed out over time under the influence of sunlight.

Light weight bitumen shingles. The roof does not exert additional significant loads on the supporting structures of the structure (foundation and walls).

Environmental friendliness. Achieved by using natural bitumen in the production of the material. Ease of installation.

Roofing made from flexible tiles has absorbed almost all the best that is available on the building materials market in this sector. All shortcomings can be attributed to compliance with certain conditions when constructing this type of roofing.

In addition, it is necessary to provide ventilation in the space under the roof structure to avoid condensation. In hot weather, you should not be on a bitumen roof, as this can easily damage or deform the heated coating.

Positive traits

Many people believe that finishing the facade with soft tiles has no practical meaning. It is expensive, you have to spend quite a lot of time on installation, and at the same time, the coating looks alien on these surfaces. However, if you take into account the advantages of such a design, you can consider this decoration option from another point of view - practicality. The advantages of the solution will be:

- Strength. Many people claim that the material invented for roofing will not withstand the loads experienced by the walls. This is not so - the strength of the basalt layer is very high and it withstands standard impacts perfectly.

- The coating can be of different colors and, if desired, you can choose an option that imitates stone or brickwork.

- Neither bitumen nor basalt interact with aggressive substances and withstand their effects. In addition, they are not subject to rotting, mold will not grow on the coating and no pockets of corrosion will appear.

- If installed correctly, the surface will be waterproof and will not allow water to pass through.

- There will be no need to worry about the safety of load-bearing structures for about forty years - this is the service life of the tiles.

- The multilayer structure of the coating creates additional insulation and sound insulation.

As for the appearance, which many opponents of this method of decoration consider not suitable for walls, you can decide for yourself whether this option suits you or not - the photo below shows what finishing the facade of a house with flexible tiles looks like.

Installation technology

To perform the installation correctly, you need to carry out a number of actions:

- Prepare the surface of the walls.

- Glue stone wallpaper.

- Treat the surface with special means.

Installation

When checking the wall, you need to make sure that it meets the requirements. Namely: cleanliness and adhesion of the wall. In order for the material to adhere reliably, there should be no oily, greasy stains or old paint residues on the surface.

If the wall surface is not level, it needs to be leveled with plaster or putty (depending on the damage). When finished, apply primer.

Before installation, you need to prepare the glue. If you don't want to make it yourself, buy a ready-made mixture at the store.

What does it consist of?

The multicomponent structure consists of several layers.

- Easy-to-remove siliconized film to prevent sheets from sticking together during storage and transportation. Removed immediately before installation.

- Self-adhesive layer on the inside, treated with bitumen glue to facilitate work.

- Non-woven fiberglass (molten glass with additives of reinforcing resins) as the base of the roof.

- Layers of bitumen applied to fiberglass on both sides, providing elasticity and durability, and also creating a reliable frame for other layers. Several varieties are used, including those with SBS polymers or atactic polypropylene (APP), as well as oxidized ones.

- Mineral or stone coating with additives for decoration and protection from damage. It is made from natural materials with the appropriate palette: anthracite, basalt or slate. Such granules look good and do not lose brightness with prolonged exposure to the Sun.

What is façade cladding?

The Technonikol facade panel for exterior decoration of a house is a multilayer material similar to bitumen shingles, which the corporation produces in huge quantities. It consists of several materials laid in a certain sequence on top of each other.

- Fiberglass

, which forms the basis of the façade cladding. It is this that determines the strength and reliability of the material.

- Bitumen

, with which fiberglass is impregnated. Its task is to create a waterproofing layer. As the operating temperature increases, bitumen additionally performs the functions of an antiseptic.

- Basalt granulate

. These are small pebbles that give the finishing material a decorative effect. It is applied to the front surface of the product. In this case, the granulate covers the outer surface, protecting it from the negative effects of sunlight. That is, facade cladding from TechnoNIKOL does not lose its original presentable appearance for many years of service.

- sand layer

, which covers the back side of facade panels. This layer has its own functions: to increase the adhesive qualities of the skin and increase the fire resistance of the material.

Facade panel "TechnoNIKOL" Source wilisbel.by

Specifications

In principle, in all their characteristics, facade panels from TechnoNIKOL are standard soft tiles. Therefore, it has the same dimensions:

- length 1 m;

- width 25 cm;

- thickness 3 mm.

The same applies to other technical characteristics:

- temperature range from -50C to +110C;

- number of freezing cycles – 100;

- weight 1 m² – 12.4 kg;

- service life – 30 years.

The manufacturer packs the panels in bundles containing 2 m² of material, which is 20 panels.

Advantages and disadvantages

Soft roofing for the TechnoNIKOL facade has the following advantages that were not mentioned above:

- ease of installation on house facades;

- high versatility, which allows you to install panels not only on flat surfaces, but also on curved planes; they can cover the joints of walls and their parts, creating a sealed plane;

- this is a flexible material, which is already good;

- it is easy to trim without using complex tools or equipment;

- 100% tightness of the walls of the facade of the house;

- you can get creative and create decorative panels using panels of different colors;

- reasonable price, even with installation service;

- possibility of installation at low temperatures.

Easy installation of the TechnoNIKOL facadeSource taraz-stroi.kz

Unfortunately, there are some drawbacks:

- the main thing is that bitumen material does not tolerate chemical influences well, under the influence of which it simply melts;

- sudden temperature changes also negatively affect the quality of the panels;

- if the air temperature is below -50C, then installation is carried out using special equipment, with the help of which the facade material is heated.

Let us add that TechnoNIKOL panels for finishing facades are not used for all houses. They can only be installed on:

- wooden surfaces of timber houses;

- frame houses;

- frame-panel;

- constructed from foam gas blocks.

Fences and other types of fencing structures are lined with this material. As for brick, stone or concrete structures, including houses, they can also be faced with this material only under one condition - to assemble a continuous sheathing of moisture-resistant plywood, OSB-3 boards (also moisture-resistant) or boards on the facade. The thickness of the wooden flooring should not be less than 9 mm.

Fence lined with facade bitumen tilesSource kupitk.ru

Bitumen tiles: a new word in the decorative finishing of facades

In conditions of limited budgets, the most easy-to-install materials are popular among buyers: anyone who has ever held a screwdriver or hammer can handle these. At the same time, everyone understands that it is better to show “independent activity” in those areas where we are not talking about the load-bearing capacity of the house or about additional loads not provided for in the project. It is better to entrust the work on the construction of buildings to professionals, but some operations on exterior or interior decoration can indeed be done by yourself. Today we will look at just such a case - HAUBERK facade tiles, new on the market and easy to install.

Today there are many different solutions for finishing facades, but most of them require complex installation operations. We have previously described the most common errors in their design. Therefore, it is in the interests of the future owner to choose an easy-to-install facade material. One of these is a relatively new material for Belarus - facade bitumen tiles. In fact, this is an analogue of roofing bitumen shingles, but it is used on facades and vertical planes. Some architects had previously used ordinary bitumen shingles to decorate walls - interesting architectural solutions were obtained, the facade smoothly flowed into the roof. Therefore, it can be argued that the need to create a facing material based on bitumen arose a long time ago; the only question was the time and method of implementing such a solution.

Description of material

Bituminous tiles for facades imitate brickwork due to the offset of the shingles. To give a similar effect, a sheet of material 1000 mm wide is divided into 4 petals of 250 mm each, which corresponds to the size of the brick. The tiles are made on a base of fiberglass impregnated with bitumen, and on the front surface they are covered with a protective layer of basalt of various colors. Currently, the line of shades includes 6 different coating colors, which can even be combined with each other.

This material is suitable for solving any architectural problems. First of all, it is ideal for frame-panel houses: in this case, the owner of the house immediately has a ready-made base for laying facade bitumen tiles. If it is necessary to renovate an existing block structure, an additional foundation will be required, which will increase the overall cost of construction work. Therefore, this work is usually carried out together with additional insulation of the walls, trying to kill two birds with one stone. In such a case, wooden guides are mounted along the existing wall, which are filled with a 50-100 mm layer of insulation. After thermal insulation, a special super-diffusion membrane is covered to remove excess moisture from the wall, a ventilation gap is installed, a base is made of OSB, and only then the finishing is done. In addition to permanent buildings, bitumen tiles are also suitable for small architectural forms: fences or gazebos. Moreover, all work can be completed on your own in just a few days.

Installation

The basis for bitumen facade tiles are OSB boards, plywood with increased moisture resistance, tongue-and-groove or edged boards with a thickness of at least 20 mm. In practice, OSB boards have become the most common solution due to their combination of lightness, strength and low cost.

Since bitumen tiles excellently protect the facade from moisture and after installation create an almost sealed surface (vapor-tight), for free diffusion of steam from inside the room through the wall structure, a ventilation gap of at least 50 mm thick is provided in front of the base. This gap is usually formed using a wooden beam, to which the OSB is fixed with self-tapping screws. As with the installation of any slab material, in this case it is necessary to provide small gaps between the slabs to compensate for possible temperature deformations.

There is a self-adhesive bitumen layer on the bottom surface of the tiles. The shingles in the pack do not stick together thanks to the anti-adhesive film, which will have to be removed before installation. When installing in winter at temperatures below +10°C, the material will have to be additionally heated with a hairdryer - at low temperatures, bitumen tends to “tan.” It is advisable to mix packs of purchased material with each other before installation to prevent possible differences in shades.

The installation of the coating itself begins from the base to the cornice in order to comply with the principle of cascading - to protect against moisture getting into the structure. After installing the base drip, the installation of the main covering begins. Each shingle is nailed onto 8 nails located directly above the petals, thereby additionally fixing the lower shingle, which means there will be 16 nails per element. This expense is dictated by the fact that when fixing facade tiles, a larger amount of fasteners is required than for a roof: the tiles actually “hang” on nails, rather than lying on the base.

In some places it will be necessary to use a fixing adhesive compound. In this case, using ordinary bitumen mastic (or, for example, mastic for flexible tiles) will not work - such a composition takes a long time to dry and can flow down vertical surfaces. Therefore, a new two-component composition was developed for fastening bitumen tiles, which completely hardens in 1 hour. Lubricating complex junctions with it should be done in 1 pass, completely consuming the mixed components.

By the way, if the usual mastic for bitumen shingles cannot be used on the facade, then the opposite situation is quite possible: the adhesive will help solve complex problems on roofs, so it is better to have a jar of this material “for every firefighter.”

All corners and junctions are made using decorative metal strips. Their special feature is a factory-made basalt coating in the color of the purchased tiles, so they do not stand out on the facade and do not shine in the sun. Even the fastener screws can be covered with mastic and covered with sprinkles to preserve decorative expressiveness.

You can learn more about installing bitumen facade tiles in the video here.

Advantages and disadvantages of flexible tiles

To choose a roofing material, you need to compare its advantages and disadvantages. Thus, you can get an idea of upcoming repair work, costs, and additional materials.

Advantages of flexible tiles:

- Relatively low price.

- You can do the installation yourself. Installation does not require special skills. The work uses simple tools that anyone can easily master. The self-adhesive bottom layer allows you to easily glue the shingles to the roof. However, if in doubt, you should still seek help from specialists.

- Lightness of the material. This helps save on both the roof and the supporting structure. When using lightweight material, the requirements for the foundation are lower.

- Thermal conductivity is low. This factor determines that the material must be attached to a solid flooring made of wood or plywood.

- Electrical conductivity is low. No grounding required.

- Corrosion resistance. This also includes durability. The period during which the material can be used is 60 years. In practice, flexible tiles can last longer. Some foreign companies even give a lifetime warranty on their products.

- Of all roofing materials, shingles have the highest impact resistance. This effect is achieved due to the presence of continuous sheathing and shock-absorbing properties.

- Excellent sound insulation, which is achieved due to the softness of the material.

- There is no windage because the coating is formed on one base and cannot be torn into pieces.

- Small amount of waste during installation.

- Easy installation.

- Variety of colors. Flexible tiles can include shades of the same color or a variety of colors.

As for appearance, here flexible tiles outperform all other materials. It comes in various patterns on the outside. The most popular types of designs are rectangle, oval, hexagon. More complex types are also found.

Disadvantages of flexible tiles:

- Low resistance to ultraviolet rays and aggressive environmental conditions.

- Low resistance to flowering. To prevent the appearance of mold, you need to treat the surface with a special compound.

- Low resistance to frost and temperature changes. Over time, cracks and tears may form. The material may become deformed.

- High water absorption. You will have to take care of a moisture-resistant base. Because of this, costs will increase.

- Thermal resistance is low. The material is flammable.

Repairs cannot be carried out in hot weather. Human movements can cause damage.

Note! The warranty on shingles is most often provided for several years longer than on other types of tiles.

Features of laying flexible tiles

When laying the material you need to pay attention to some factors. The roof slope should be from 10 to 90 degrees

Installation can be carried out using either adhesive or non-adhesive methods. In most cases, flexible tiles have a self-adhesive layer. This greatly simplifies installation.

Interesting moment! Flexible tiles are the only material capable of covering complex surfaces. These can be various curved shapes or protruding bricks. Flexible tiles can cope with unevenness of any complexity. Flexibility and plasticity allows the material to be mounted even on circular roofs.

Useful video about the characteristics, advantages and disadvantages of flexible tiles:

Post Views: 828

Dispelling myths: color, weight and moisture capacity

There are many myths surrounding natural tiles, and if you listen to them, you may get the impression that they are the worst material in the world. In fact, all these myths and speculations are nothing more than marketing wars. Let's figure it out?

Myth No. 1. Moss grows on a natural roof

For all other purposes, natural roofing simply needs to be maintained. It's all about moisture capacity: for cement-sand tiles it is 3%, for ceramic tiles it is 5 and 8%.

Myth No. 2. Natural tiles weigh a lot

Perhaps the weight of the tiles is the biggest stumbling block for those who have taken a closer look at such a roofing covering. The tiles alone in your hands feel no less than 2 kg, so what about the load on the entire roof?

By the way, cement-sand tiles weigh about a third less than ceramic tiles, since that matters.

Myth No. 3. The roof fades in the sun

Myth No. 4. The shards crack and splinter

All characteristics of cement-sand tiles depend on the exact dosage of those components that are used in the raw materials, and ceramic tiles - on the quality of the clay and its firing in special ovens.

This is why high-quality tiles cannot be cheap. But both of them are fragile, although any roof covering can be broken by physical force.

And in general, when a new house is built, the only roofing covering that is gladly removed and taken from the old one is natural tiles. You can't do this with anything else.

Myth No. 5. Natural tiles absorb water

Colors

Despite the variety of color options, bitumen shingles can be made in one of 2 colors:

- monochrome (combines several shades within the same range);

- multichrome (tiles include different shades and their derivatives).

Finnish and American brands of tiles presented on the domestic market mainly use monochrome coloring. The leader in the field of stylish and diverse tile design is the Tegola brand. A two-color new product is popular - a two-layer panel with a 3D effect. This is how shingle tiles are usually designed. Monochrome tiles are cheaper than multichrome tiles.

The installation of grayish-brown tiles interspersed with green and reddish colors will add Mediterranean notes to the exterior. Indigo-colored tiles look expensive and unusual, as if enveloping the structure in a lilac-violet haze. It is best used on low houses with a complex roof shape in the shape of many triangles.

Lovers of rustic styles should take a closer look at materials in gray shades that imitate stone surfaces, as well as wood-colored shingle coverings. The first will help you move to a European “village”, the second will help you recreate the atmosphere of a traditional Russian house or an Alpine chalet.

For buildings in a classic style, it is recommended to purchase red-brown tiles, as well as grayish shades characteristic of the mountain range.

Examples

You can talk a lot about the coating, but it is much more important to understand how bitumen tiles will fit into the decor of your home. To make this task easier, below are several photo examples of how finishing a façade with bituminous shingles can look like in different designs.

Types and forms of shingles: classics and modern trends

All types of bitumen shingles are classified according to a number of criteria. The very first of them is the number of layers: there are single-layer, two-layer and three-layer tiles. Two-layer and three-layer tiles are also called “laminated”, and this coating is more resistant to wind and moisture, although they weigh a little more.

The main advantage of multi-layer shingles is that they are thicker and stronger than a single sheet. This type is difficult to pierce or damage during operation and installation of the roof. Multilayer tiles successfully withstand even hurricane winds of up to 150 km/h, which easily tears off euro-slate and metal tiles.

The most common types of tiles in cut shape are beaver tail, brick, dragon teeth, rectangle and hexagon. In addition, manufacturers come up with their own names for their own collections and forms.

And finally, mineral chips bring the greatest variety to the world of roofing design. There are plain shingles, and those that seem to play with color, and those that are sold with a silver, golden tint, and even coated with copper.

Here is a rather interesting interview with a professional roofer on this topic:

Pros and cons of using the material

Soft roofing, like any other building material, has its pros and cons, which can affect the purchasing decision.

Among the advantages are:

- high aesthetics;

- quick installation;

- large selection of colors and tile options;

- no extra garbage;

- not afraid of wind, showers;

- easy transportation;

- can be used for roofs with complex architecture;

- does not break or crack compared to conventional tiles;

- seamless finish.

- price;

- If installation technology is not followed, moisture may enter.

This can lead to rotting of the OSB sheets; in winter, accumulated moisture under pressure can break the tightness of the coating and squeeze out the bitumen shingles.

Please also ensure that branches of trees adjacent to the building do not touch the tiles if possible. Pets can also ruin the seal of the masonry.

Instructions for decorating a house with your own hands using flexible tiles

Working with flexible roofing requires certain knowledge and conditions. This will preserve the performance characteristics of the material.

- The optimal installation time is the off-season at a temperature of 15-20 ° C. There shouldn't be any wind.

- Roofing material should be stored in a warm room, without sudden changes in temperature, and avoid direct exposure to sunlight.

- The protective layer of shingles is removed only before installation. Otherwise, it will dry out quickly, lose its adhesive properties, and the tightness of the nodes will decrease.

- You cannot rely on freshly laid material due to its deformation.

Laying the material is not particularly difficult. However, first a number of preparatory works are carried out.

- A vapor-waterproofing film is mounted on the sheathing to protect against condensation and prevent the insulation from getting wet.

- A ventilated layer is made on top of the vapor barrier.

- The soft facade is laid on a continuous flooring made of boards, OSB boards, and plywood. There should be no gaps or changes in level. The maximum height difference should not exceed 1-2 mm. Using boards may warp the base when dry.

After laying the solid base, begin laying out the shingles.

- Marking the base will make the installation process easier. It is worth drawing vertical and horizontal stripes with vertical pitches of about 1 m, horizontal ones - 0.8 m. Specific values are adjusted to the size of the shingles and can fluctuate in one direction or another.

- We need to prepare the basis for the start. It is made from shingles without tabs. They must be removed on a flat wooden surface with a sharpened knife. Instead of a ruler, it is allowed to use a straight wooden block, a long level or other available material.

- After removing the protective film, the base is coated with a special mastic. The width of the coating is about 10 cm, leaving 1 cm from the edge. It is recommended to use only bitumen-based adhesives. They are best combined with soft bitumen roofing material. The thickness of the composition should not exceed 1 mm. After mixing, the two-component adhesive should be left for 15 minutes. for settling. It is necessary to use the prepared mastic within 40 minutes while the polymerization process is underway. Further adhesion decreases.

- First, the base frame is laid. The first element is attached at the very corner of the house with an indentation of 0.5 cm. For fastening, special non-corrosive nails are used with a length of at least 25 mm, a diameter of 3 mm with a head of 9 mm. The fastening step is 20-25 cm, with a distance from the edge of 2-3 cm. For three-layer tiles, the length of the nail must be at least 45 mm.

- Regular shingles are attached with tabs. For example, brick material. The size of its shingles is 100*25 cm. Each element will require 8 hardware near the cuts of the petals, 2 on each side. This is done on purpose - the next rows will lie on top of the nails. The manufacturer's pattern of hammering in hardware must be carried out flawlessly. Due to its thoughtfulness, the penetration of precipitation into the coating is completely eliminated.

- Each row is shifted by half a petal. This action closes the fastenings with hardware, the facade wall imitates natural material. Due to the notches made in advance by the manufacturer at the ends of the shingles, it is easy to align the position. Serifs can cling to vertical surfaces, making it easier to install the roof alone. This is how all flat façade surfaces are laid.

Decoration of corners

It is much more difficult to install tiles around openings and protruding elements. These works require precise cutting and measurements. Laying shingles above the windows is done according to the same principle as above the base. The main thing is not to forget about shifting the petals and trimming excess length. It is recommended to first lay shingles around the opening on the right and left, and only then below and above.

Correct design of door and window openings:

- The side metal trims are attached to match the color of the material. If the width is small, the direction of precipitation flow is taken into account.

- The upper casing is installed with the condition of further covering with shingles.

- The tide is fixed. The fastening method is different, depending on the material of manufacture.

- Additional elements are adjusted to size using metal scissors.

External and internal corners are decorated with special additional metal elements. They are fastened with metal screws with enlarged heads. The planks are overlapped by 5 cm. The fastening step of the hardware is 30 cm. The screws can be coated with glue and covered with crumbs from the cut elements - this makes the wall look better.

How to install it yourself

Preparatory work

1. At home, a standard set of materials and tools is selected.

2. Using plywood, OSB boards or wide boards, the base is strengthened.

3. Rafters are treated with antiseptic and fire-resistant agents.

4. A ventilation system is being installed.

For a slope greater than 25 degrees, the ventilation outlet area is 8 square meters. cm, with a smaller slope - 16 square meters. cm.

5. A bitumen cushioning layer is laid around the perimeter of the roof.

With a slope of less than 18 degrees, the gasket can only be placed in certain areas:

- in the pipe area;

- at the junction with the wall;

- on a skate;

- on eaves overhangs.

6. Cornice and pediment strips are installed.

7. The chimney outlet is marked.

8. The valley lining carpet is laid in the color of the roof.

Step-by-step instructions on how to lay it yourself

- Eaves shingles are laid on strips fixed to the eaves and nailed with galvanized nails. To save money, instead of cornice tiles, you can take ordinary tiles and cut off the petals. Then the installation is done end-to-end two centimeters from the overhang.

- Ordinary shingles are laid on both sides of the middle of the roof overhang and nailed with four nails. With a large slope, the number of nails driven can be increased to six.

- The first row should retreat from the eaves overhang by one to one and a half cm, and the petals should cover the joints of the eaves sheets.

- The second row is placed in a similar way, overlapping the cutouts of the previous row with petals.

- The edges are cut and glued, leaving a layer of up to 10 cm.

- The final rows are laid in exactly the same way - the shingles are cut to form a strip of 15 centimeters and coated with seven to eight centimeters of glue.

- Before working on the skate, the scaffolding is first prepared.

- The sheets are laid with an overlap of five centimeters and nailed with four nails. Ridge shingles are obtained by cutting the eaves along the perforations, then bending them and laying the short part along the ridge.

- Passages through the roof are made using rubber seals or special technologies: a triangular strip is installed at the junction of the roof and pipe; - lay the gasket with overlaps coated with glue; — the surface of the pipe is insulated with the calculation of covering 35 cm of the pipe and 25 cm of the slope; — a bar is installed around the perimeter; — the iron apron is fixed: — the seams are sealed with silicone sealant.

- The connection to a vertical wall is done in the same way. Only the rail is fixed along the wall, and not along the perimeter.

A properly installed roof will serve for many years, protecting the building from cold and moisture. In the absence of sufficient experience in laying soft tiles, it is better to entrust the arrangement of such an important element for a house, garage or gazebo to trained specialists. At the same time, knowledge of the instructions will allow you to control the entire process.

Installation video tutorial:

Important factors when choosing roofing tiles

Before choosing tiles for your roof, it is important to consider:

- Material service life and warranty period.

The longer the better. - Installation features.

To install some types of tiles, you will need the help of specialists. And these are additional costs. - The weight of the tiles and the technical characteristics of the building.

It should be remembered that the roofing is an additional load on the floors and foundation. And some types of tiles are quite heavy and the load is significant. Therefore, ceramic tiles, for example, should not be used when arranging the roof of a relatively light wooden house. - Climate.

The shingles must be designed for use in your climate region. - Price.

When calculating the cost of roofing, you need to take into account not only the cost of the tiles, but also the installation devices, as well as the installation work itself.

Centuries-old history: what has changed since then?

In addition, the amount of impurities must also be minimal, so the artisanal production of ceramic tiles cannot be called effective. And he makes this only from clean, oily and plastic clay.

Today, natural tiles are far from the same rustic, crooked shards that were hung on strings, but a much more complex structure:

What is on the back side of the tiles is extremely important, because the entire installation process and the wind resistance of the roof will depend on it.

The tiled roof itself ultimately consists of the following elements and looks like this:

Today in Europe, about 90% of private houses are built using just such roofing material, and for good reason.

Performance characteristics of flexible roofing

The parameters are:

- Bitumen begins to melt at a temperature of 300 degrees.

- A bitumen carpet in one layer does not exceed a load of 5–8 kg per square meter. m, laminated multilayer - 13 kg per sq. m, so it is not necessary to build a reinforced rafter system, unlike metal tiles.

- Soft tiles are environmentally friendly and safe for health.

- The bituminous surface does not store electrostatics.

- Low electrical conductivity minimizes the risk of lightning strikes.

- Bitumen has a hydrophobic property - it repels moisture.

- Tight fastening to the roof makes the material resistant to any wind loads.

- Flexible roofing is plastic and protects from ultraviolet radiation.

Care procedure

A long service life will be ensured by simple recommendations:

- Clean the roof of leaves, branches or other debris twice a year. Carefully collect large residues by hand, and sweep away small debris with a soft brush without damaging the outer layer;

- control the functionality and, if necessary, clean the drainage system (funnels, gutters) mounted on the roof;

- when large amounts of snow accumulate, clean the surface, leaving a small snow cover, using tools that will not damage the outer layer;

- Regularly inspect the roof to identify defects, damage, leaks, and then repair the damaged area. If you delay replacing damaged shingles, the defective area will increase due to constant exposure to adverse weather conditions.

Enjoy the shopping! Take care of yourself and your loved ones!