Daewoo gas boilers are made in Korea. They are inexpensive, but there are many complaints about their quality. Thus, you can find reviews that the boiler has a weak pump and there is no possibility of simultaneous operation of heating and hot water. Despite the manufacturer's claims that all models operate silently, this is actually not the case - there is noise and quite a lot. The boiler itself is inexpensive, but the price of components is very high. In addition, spare parts still need to be found. In general, there are more dissatisfied owners.

Combination boiler

Combined installation

In places where the gas supply may be temporarily interrupted or in the presence, for example, of a solid fuel heating boiler, a combined heating installation shows good results. It consists of two circuits:

- a direct heating gas boiler, the task of which is to ensure the temperature of the water during its intensive selection;

- an indirect heating boiler, the heat source of which is the liquid supplied by the main heating boiler or the exhaust gases generated during its operation.

Combined heating systems show significant cost savings. It is rational to use them if there is a sufficient supply of boiler power in the heating system. With a significant capacity, they are able to meet the hot water needs of a large family even without starting a direct heating circuit. Also, if the gas supply is interrupted, the combined boiler will perform its functions using the energy of the heating system.

Daewoo turbocharged boilers

Daewoo household turbocharged wall-mounted double-circuit gas heating boilers have a closed combustion chamber. Requires connection to a coaxial chimney. Air supply is forced.

The design of Daewoo DGB mounted turbocharged heating boilers involves the use of a system for forced removal of combustion products. Electricity is required to operate.

The Daewoo Gasboiler double-circuit turbocharged wall-mounted gas boiler has high efficiency and cost-effectiveness. The closed combustion chamber allows installation of equipment even in small rooms that have not been converted into a boiler room.

Installation and connection basics

Although installing the Daewoo Gasboiler boiler is not difficult in itself, self-installation has several disadvantages.

- As practice shows, problems with Daewoo boilers are primarily related to mistakes made during installation.

Representatives of the company selling heating equipment have the right to refuse warranty service. An employee with the appropriate license must set up the boiler and perform its first startup.

Piping the boiler may involve connecting to the electrical network and installing thermostats in the apartment. This will require permission to work with electrical equipment and an understanding of the rules of the Electrical Regulations.

Download: Daewoo Altoen – installation, operation and maintenance instructions.pdf

The basic installation rule remains the need to strictly adhere to the manufacturer’s recommendations regarding the installation of equipment. The operating instructions provide a schematic diagram of the piping and requirements.

Which boiler to choose - turbocharged or atmospheric

For an apartment, it is better to choose a turbocharged model. It connects to a coaxial chimney. PPB rules and requirements for the installation of turbocharged gas equipment are lower than for atmospheric equipment.

The disadvantage of turbocharged boilers is their dependence on electricity. Atmospheric models are non-volatile and continue to work even when there is no voltage in the network.

Atmospheric and turbocharged boilers from Daewoo are easy-to-use and reliable models, attractive for their cost and useful functions. A good alternative to European equipment in the mid-price category.

Other faults

During operation of a Daewoo boiler, error codes cannot always help with malfunctions.

The following problems may occur:

- The room remote control power buttons do not work when the power cord is connected. You should measure the voltage at the signal end of the remote control and at the blue CN terminals. It should be equal to 12 volts. The solution is to replace the defective controls and configure the terminal unit.

- If overheating is detected, check whether the circulation pump is working correctly, check the pressure in the heating pipe and the cleanliness of the distribution pipe.

- If a pump failure occurs during testing, the mains voltage is measured between the two black-and-white and white-black terminals on the CN pump

- When ignition does not occur, the locking condition and operation of the control panel are inspected. The operation of the main board is also checked. Diagnostic points for this are indicated in a special table in the operating instructions.

Atmospheric boilers Daewoo

Atmospheric wall-mounted gas heating boilers Daewoo Gasboiler have an open combustion chamber. Air is supplied to the burner naturally. Combustion products exit through a traditional chimney. The models are designed for autonomous heating of small residential premises, up to 200 m².

The design of the Daewoo mounted atmospheric boiler allows you to achieve the following advantages:

- Low noise level during burner operation.

High level of security.

Long service life.

Absence of complex parts and assemblies.

When installing double-circuit mounted gas atmospheric heating boilers Daewoo DGB, you must follow the general rules for connecting equipment running on natural gas. During operation, the burner consumes oxygen from the room, which is used as a boiler room. As a result, the premises are subject to high standards related to the minimum area, ceiling height, the presence of forced ventilation systems, etc.

How to properly set up a daewoo gasboiler 100 boiler?

Which mode is the most effective for an apartment in winter? From the air temperature or from the temperature in the pipes?

How to properly heat a solid fuel boiler?

You can melt equipment that runs on solid fuel in two different ways: burning and layers. Each option allows you to increase the burning time of one load. Firewood is placed in the firebox. For faster ignition, you need to add paper or wood chips. After the flame appears, the loading door closes and the heater control unit turns on.

The process then proceeds as follows. Firewood, coal or briquettes burn from top to bottom, giving off the maximum possible amount of heat. Combustion in a firebox in this way can continue for a long time.

After switching on, the unit must be brought to optimal operating mode by setting a deliberately high heating temperature. After the equipment reaches the optimal temperature regime, you can reduce the boiler power by setting the necessary temperature parameters.

For some models, one download is enough for 24 hours (in standby mode up to 48 hours).

source

Stages of building a warm chicken coop

If we consider the construction of a poultry house, it consists of the following stages:

- Design is the creation of a detailed drawing of the future structure with all the features of the internal layout.

- Selecting a suitable location on the site and marking the construction site.

- Pouring the foundation - it can be a strip or column base.

- Construction of floors in two stages (rough and finishing with insulation).

- Construction of walls and partitions.

- Roof installation.

- Insulation around the entire perimeter.

- Installation of frames in window openings and doors.

- Making perches and nests for chickens.

- Creation of a high-quality ventilation system.

- Heating installation or installation of heating devices.

With the right approach, building an insulated chicken coop with your own hands for ten birds, even a beginner will not have problems with the construction of the structure. Only under comfortable conditions will laying hens delight their owner with delicious, healthy eggs every day.

Advantages and disadvantages

The advantages of boilers include:

- High efficiency of units.

- Reliability, durability of boilers.

- Resistance to external influences.

- The ability to independently identify problems and notify the owner about them.

- Together with space heating, hot water is supplied.

- Low fuel consumption, which does not affect the performance of the units.

The disadvantages of Daewoo boilers are considered to be:

- Energy dependence. If there is a power failure, the system will stop operating.

- Sensitivity to water quality, stable supply voltage, requiring the use of additional equipment.

- Some users report increased noise levels when heating water.

Most of the disadvantages can be attributed to the general features of gas boilers.

Atmospheric boilers Daewoo

The line is represented by four positions, with a power from 12.8 to 23.3 kW. In terms of technical characteristics, atmospheric DEU boilers do not differ from turbocharged ones. The only exception is the electricity consumption - there is no fan for a coaxial chimney. However, their operating principle is somewhat different. Mainly due to the design of the combustion chamber. For atmospheric boilers it is not airtight. Accordingly, the air to maintain the flame comes directly from the room where the heater is installed.

To ensure safe operation of the equipment, it is necessary to provide a constant flow of fresh air into the room. This can be done the old fashioned way by ventilating the room, or you can install an air recuperator.

Remember, the chimney is one of the key elements in the heating system (see Design and connection of a chimney for a gas boiler). Improper installation or insufficient insulation can lead to such undesirable consequences as:

- lack of traction;

- the appearance of reverse draft - the entry of carbon monoxide into the room is deadly;

- the appearance of condensation, which corrodes the chimney.

In atmospheric Daewoo boilers, malfunctions occur less frequently than in turbocharged ones. The principle works here: the fewer structural elements, the lower the likelihood of failure. In this regard, the absence of a fan for circulation can be regarded as an advantage.

Heating boiler error codes

| Fault code | Type of failure | Possible reason | Control point | Required Corrective Actions |

| E0 | The room temperature sensor does not function | Sensor malfunction or broken contact | Temperature sensor in the control panel, temperature sensor | Restore contact or replace sensor |

| Error E1 | A sharp drop in pressure in the heating system | Mains water leak or low coolant pressure | Checking the pipe part of the firebox, heater, and in-house heating circuit for possible leaks | Eliminate leaks and fill the system with make-up water to operating pressure |

| E2 | Incomplete combustion of gas occurs in the boiler due to a violation of the regimes in the gas-air path | Soot deposits in smoke ducts or air ducts, fan does not work | Monitoring the condition of the gas-air path of the boiler, chimney and fan | Clean up soot |

| E3 | Overheating of the supply coolant | The circulation of the heating circuit is disrupted | Check whether the supply and return valves are open, the condition of the sump tank and the circulation pump | Open the shut-off valve, clear the mud trap of debris, start the pump |

| E4 | No traction | The chimney is clogged | Check the condition of the gas-air path | Clean up soot |

| E5 | IR torch sensor does not work | Sensor, board or software failure | Check the serviceability of the sensor, board and software | Replace faulty elements |

| E6 | Gas leak sensor triggered | Gas leak, sensor malfunction | Gas path connections, gas sensor | Check connections along the gas path for leaks in accordance with the rules for operating gas equipment, eliminate identified leaks, or replace a faulty sensor |

| E7 | Communication failure with the operating control panel | The integrity of the communication line is broken, the control unit is faulty | Communication lines | Check the integrity of the electrical circuit and the operability of the control unit |

| E8 | The coolant temperature sensor does not work | Line power failure, temperature sensor failure | Coolant temperature sensor circuit | Checking the network voltage, sensor functionality, eliminating identified causes |

| E.E. | Fan stop | Failure in the working network, non-working fan, capacitor or speed sensor | Fan circuit | Checking the presence of voltages, operability of the electric motor, board, capacitor and speed sensor |

| The temperature indicator and the LED on the remote control flash simultaneously | It is not possible to ignite the gas in the burner | There is no pressure in the gas line | Gas pipeline in front of the boiler | Check the condition of the gas tap and gas pressure in the line, restore the gas supply |

Daewoo gas boilers are rightly recognized by users as highly reliable and ready for use in Russian municipal conditions.

In order for the service life to be as long as possible, the owner will be required to strictly follow production instructions and routine maintenance. Maintenance work should be carried out in the summer, long before the start of the heating season, so that there is enough time to correct any identified faults.

source

Price range

The cost of Daewoo gas boilers is in the conventional range of 34-59 thousand rubles. The price difference depends on the model, power and other factors.

If the region is located far from large populated areas, the price of the boiler will increase due to logistics costs. Before purchasing, you should find out in what configuration the equipment is supplied and what needs to be purchased in addition for optimal and safe operation of the boiler.

In addition, you need to take care of concluding a warranty agreement, which will also cost a certain amount.

IMPORTANT!

Some users do without warranty service, but this approach is only possible for specialists who can independently repair and configure the boiler. For mass users, it is strongly recommended to use the services of warranty workshops.

Maintenance instructions

Once again, the user will be required to carefully configure automatic functions. For example, most Korean gas boilers support options for air removal, tank disinfection, fault detection, etc.

As for physical maintenance, it is important to prepare for some repair operations, which a Daewoo gas boiler can undergo at home. Spare parts are supplied separately - a typical list of main components includes heat exchangers, expansion tanks, fans, pipes, pipes and accessories for loop infrastructure

It is important to note that regular maintenance can significantly increase the cost of maintaining equipment. This depends on the gas consumed and on the use of new consumables with components

For example, a gas boiler, the price of which is no more than 20 thousand, on average every six months requires an investment of up to 2-3 thousand to update pipes and fittings.

Daewoo DGB – 300 MSC

Gas wall-mounted boilers with an open chimney system and a closed chimney will easily provide

your living space will be warm and cozy and hot water will be provided. Daewoo Gasboiler DGB MSC is a turbocharged double-circuit boiler that can provide an area of up to 450 square meters with heating and hot water supply. Works with various smoke removal systems: internal, attached, coaxial. Has proven itself quite reliably when working with voltage generators

What is also important is application in dachas, apartments and in places with frequent power outages. In heating mode, the boiler operates with a power (from 4 to 46 kW) of 46 kW, when DHW is operating (the boiler operates with a power from 11 to 46 kW) it boosts the power to 46 kW, which is necessary to meet the requirements for SNIP to obtain hot water. water and saves energy resources

Advantages of the Daewoo MSC boiler: The advantage of this boiler is its simplicity, operational reliability and good maintainability. The boiler will fit perfectly into the interior of any room, for example a kitchen, and its small overall dimensions will save space and money; you will not need to organize a special room for the boiler room. Operation control - thermostat functions The Daewoo boiler is equipped with an external room thermostat (Control panel) with which you can set and control various parameters: Boiler on and off timer, unmanned mode Digital pressure value Degree temperature adjustment Indication of temperature set Set of error codes ok, with help which can determine malfunctions or lack of necessary operating conditions for the boiler. For example: Lack of gas, coolant, coolant circulation, chimney blockage, unstable power supply, boiler overheating. Reliability during operation Operates at low gas pressure Patented technology of adapted ignition Patented technology of automatic combustion control Automatic detection of problems - errors are displayed on the control panel and the boiler automatically stops Prevents freezing of pipes - the boiler automatically starts working, so to prevent freezing of pipes. Safety of boiler operation. Protection against boiling and overheating Protection against wind blowing Protection against the accumulation of gas residues in the combustion chamber - purges before ignition Protection against lack of water - warns with sound signals about: low pressure, lack of gas, insufficient water volume Works on natural and liquefied gas When changing injectors in boiler you You can easily convert from natural gas to liquefied gas and connect gas cylinders or gas tanks. Saving on components Remote thermostat (remote control), technical data sheet is already included in the package of the Daewoo boiler. All types of generators are suitable for it, it does not need powerful stabilizers, you do not have to install an RCD and build a chimney - there are coaxial chimneys for the Daewoo boiler.

Installation

Installation of Daewoo equipment does not cause any difficulties for experts in their field, while an inexperienced user may have questions and problems during operation. Dealers who sell Korean equipment may well refuse repairs under warranty if the buyer did the installation himself. It is worth remembering that when tying, you need to connect to electrical networks and connect thermostats. To carry out similar work, you need special permission and knowledge of the rules of electrical installations.

During installation work, it is important to strictly follow the manufacturer's recommendations. Look at the instructions and read about the wiring diagram

Conclusions and useful video on the topic

Replacing the heat exchanger of Daewoo MSC series boilers:

Determining the type of fault associated with the flame ignition electrode:

Instruction for a specialist in working with MSC series boilers. Suitable for other Daewoo lines. Strict adherence to these recommendations prevents the occurrence of many malfunctions:

It should be remembered that improper handling of flammable gas can lead to an emergency situation - a fire or explosion. Therefore, if you have doubts about the ability to solve the problem yourself, you need to call technicians from the service center or gas service.

Tell us about your own experience in identifying and eliminating breakdowns of Korean-made gas units. It is possible that your advice will be useful to interested site visitors in solving their problems. Please leave comments in the block below, ask questions and post photos on the topic of the article.

Source

Review of the best models

The most popular model from the line of this brand among Russian buyers is the Daewoo DGB 100 MCF boiler.

Main technical characteristics:

- Operating power is 10 kW, enough to heat an individual residential building with an area of up to 100 m2.

- A closed combustion chamber with a turbine flue gas removal system prevents carbon monoxide from escaping into the boiler room.

- Ignition of the boiler with an electronic igniter, which not only starts the Daewoo boiler into operation, but also controls the quality of the combustion process during operation. Electronic burner control takes part in the automation and safety control system, as well as adjusting the operation of the boiler depending on the outside air temperature and the set coolant parameters.

- To increase the durability of boiler equipment, the pipe system of heat exchangers of Daewoo boilers is made of copper.

- The network circuit is equipped with a built-in forced circulation system, which allows you to work with low gas pressure in the main line or low pressure of tap water.

- The computerized control unit allows you to configure basic parameters and integrates well into the Smart Home system.

- Cost, 29900 rub.

The next standard size is the energy-independent condensing boiler Daewoo DGB 160, which provides a high level of heat supply to individual houses of increased area.

Technical data:

- Maximum heating load -18.8 kW.

- The maximum load in hot water heating mode is 23.3 kW.

- The maximum heated area of the heating facility is 160 m².

- Boiler efficiency in operating mode, efficiency – 90.3%.

- The number of circuits is two.

- The combustion chamber is closed.

The interesting atmospheric wall-mounted model DGB 200 MCF provides heat and hot water to thermal objects with a heating area of up to 110 m2.

Technical data:

- The system is open, double-circuit for heating and hot water supply.

- Low noise, small-sized weighing 33 kg.

- The heat exchanger is made of copper.

- Efficiency – 92.0%.

- Power – 23.3 kW.

- Heating area – 186 m2.

- Cost - 34,590 rubles.

Since the unit has an open firebox and operates with natural circulation, it is installed in a separate room with an internal air temperature above +7 C, otherwise the boiler will only operate for self-heating.

Operating principle of the Daewoo DGB 200 MCF condensing boiler:

- Electronic ignition of the gas injector.

- When gas is burned, its hydrogen content turns into water vapor. The condensing device of the boiler is capable of turning the generated steam into liquid, while extracting additional heat and increasing the efficiency of the steam power cycle.

- The infrared sensor of the unit controls the combustion process in the furnace, establishing optimal combustion conditions in the fuel-air ratio based on the color of the flame, which leads to significant gas savings. The system operates on two types of fuel: natural and liquefied gas.

- Water is supplied by a circulation pump to two heating circuits: heating and domestic hot water, where it is heated and supplied to consumers.

- The control panel controls the operating mode of the boiler unit. The shut-off valve turns off the gas supply to the heating boilers; when emergency values for the temperature and pressure of the coolant are reached, the process is accompanied by an audible alarm, while the operating parameters are preserved.

- The diagnostic system will display an error code on the screen so that maintenance personnel can take measures to eliminate the operating failure.

The model range of this type of units is completed by the Daewoo 400 boiler, which in terms of its operating principle is no different from the previous boiler, but is capable of heating 500 m2 of area and has a unique combustion automatic system made in Japan “EN-US”, the cost of the model is 53,200 rubles.

Errors and methods for eliminating them

The number of automatically detected faults in Daewoo boilers is grouped into 19 events, each of which has its own code. Seeing the display, you can try to solve the problem yourself or give called technicians a first idea of the problem that has arisen.

Some malfunctions of gas boilers do not depend on the type of combustion chamber or other features of the equipment. And there are problems that are typical only for a certain line. Daewoo Altoen (Gasboiler) boilers have continuous numbering of errors, and the methods for eliminating them are almost the same for all models.

Error type "E0"

This code indicates an error in the room temperature sensor, which is built into the control panel. The example of this malfunction shows that it is not every time that you need to call a repair team.

It is necessary to disassemble the device, clean the contacts and check the sensor using a tester. If necessary, it must be replaced. If you do not have the skills to disassemble and repair such products, then you can take the remote control to any workshop specializing in electronics.

Error type "E1"

A decrease in pressure in the heating system was recorded. The simplest case that leads to this problem is a breakdown of the minimum pressure switch or a lack of signal between the sensor and the control board. However, first of all, you need to immediately check the heating circuit for leaks.

Leaking pipes or radiators can occur in places where the presence of water is not immediately noticeable. These are interfloor ceilings, storage rooms or basements. Therefore, you need to sequentially go around the entire circuit

Coolant leakage can occur not only in the circuit, but also in heating equipment components, such as:

- heat exchangers;

- hydraulic pump;

- relief valve;

- make-up tap, etc.

In this case, the hydraulic unit will have to be changed, although sometimes replacing the gaskets may be sufficient.

The supply may also be cut off for some reason. Although in this case the issue of leakage also arises, which is gradual.

A decrease in pressure in the circuit without leakage of coolant can occur in the event of a drop in pressure in the closed expansion tank, which is installed in the boiler. In this case, it will have to be repaired.

After eliminating the cause of the leak, it is necessary to fill the circuit and restore the operating pressure.

Error type "E2"

Triggering of a gas analyzer, signaling incomplete combustion of the supplied mixture or smoke entering the chimney.

The problem lies in insufficient traction, which can be caused by:

- Change in the open cross-section of the smoke exhaust duct as a result of its contamination. It happens rarely, mainly due to a foreign object or small animal getting into it. Icing is also possible in the area where the pipe exits. The chimney of a gas boiler needs to be cleaned.

- Strong wind pressure. A difficult case, since it is necessary to recalculate the geometry of the pipe or install a windproof structure.

There may also be a problem with the fan. Most often, this is contamination of the blades, which can be seen, or a rotation disorder, which is easy to hear.

The chimney for a gas boiler has parameters different from the exhaust for stove heating. The fact is that the temperature in the boiler burner is relatively low, so the draft force will be less

You can identify the problems described above yourself. If the chimney and fan are functioning normally, there is still a possibility of sensor failure. It will have to be replaced.

Error type "E3"

An error occurs when the fact of overheating of the coolant is detected. There are two main reasons:

- malfunction of the emergency thermostat;

- slowing down or stopping coolant circulation.

If such an error occurs, you need to wait until the device has cooled down, reset it (turn it off and on) and start it again. If the error repeats, this means that the trigger was not false (this happens) and will have to be sorted out.

First of all, it is necessary to determine whether the coolant circulation rate is sufficient. To do this, you need to start the boiler without heating and listen to the operation of the pump. Its hum should be normal.

Problems with this node can be caused by several reasons:

- No power supply. You'll have to call the wiring and find a break.

- There is power, but the pump does not work. You need to show it to an electrician. If there is a break in the winding, it is cheaper to replace the entire assembly. If other wires break down, the problem can be eliminated and the pump will work again.

- Rotor shaft jamming. This event rarely occurs without damage, so it is best to replace the pump.

- Impeller wear. The pump needs to be replaced.

It is also possible that the contacts of the signal wire from the pump to the board are disconnected or the central board itself is damaged.

Poor coolant circulation can be caused by a clogged dirt filter. It needs to be cleaned periodically, but not everyone carries out this procedure on time.

If the pump is running at full power, then the cause of poor circulation is in the circuit. She may be:

- Reduced pressure in the system and failure of the pressure sensor. Rare case.

- Air lock formation. It is necessary to check the entire circuit by bleeding air through Mayevsky taps and similar fittings.

- Accidental closure of one of the shut-off valve elements. All taps and plugs must be checked.

- Formation of blockage. Rare case. A difficult problem primarily due to the difficulties associated with finding the location of the mud plug.

If the pump operates normally and the circuit normally passes coolant, then the temperature sensors need to be replaced. Most likely they are out of order.

Error type "E4"

This code signals the activation of a pressure switch - a draft sensor in the chimney. The main reasons are the same as for error code “E2”.

If the gas boiler chimney and fan are working normally, then the problem may lie in the signal from the sensor. First of all, you need to check the tightness of the connection of the contacts to the sensor and to the central board, and also check the wiring.

It is also possible that condensation may form in the tubes or that they are poorly connected to the sensor. Failure of the pressure switch itself is unlikely.

Error type "E5"

Receipt of an alarm signal from the flame sensor. If visually, when turning the boiler on and off, ignition occurs normally, then you need to check the flame sensor.

First of all, you need to make sure that it is in good contact with the main board (check the wire connection and test it). You also need to make sure that there is a voltage of 5 Volts between the terminals of the CN05 sensor.

If there is no ignition, the problem may not be with the boiler. The position of the gas shut-off valve must be checked first.

If the sensor works normally and ignition does not cause problems, then the error is in the central board. It will have to be replaced.

If you can visually detect a problem with ignition, you must perform the following steps:

- Reset the unit and try to ignite again. Perhaps the reason is one of the capacitors or a residual charge on the ignition transformer.

- Make sure that the maximum and minimum gas pressure is properly adjusted for the injectors installed in the device. Standard indicators can be found in the instruction manual.

- Inspect the ionization electrode for contamination. Make sure that there is an acceptable gap between it and the burner device. Make sure there is a spark (by first shutting off the gas).

- Adjust the ignition power in the service menu. You need to use the parameters that are specified in the user manual.

- Make sure that there is no breakdown on the body (that is, the user does not receive an electric shock when touching the boiler elements).

- Make sure that the grounding is present and not broken.

- Check that the gas valve is not stuck. Simply insert the silicone tube into the fitting and press firmly.

- Check for a broken valve coil.

If the problem is in the gas valve, it will have to be replaced.

Often, a broken gas valve coil (above) and other electrical problems can be recognized visually or identified by the characteristic smell of burnt wiring

Using this error as an example, it can be seen that sometimes to repair a Daewoo gas boiler, knowledge in several areas is needed: electrical, electronics, and mechanics. Therefore, in case of complex errors, it is still better to call experienced gas service technicians, with whom an agreement has been concluded for the supply of blue fuel and maintenance of units.

Error type "E6"

Gas leak sensor triggered. If you smell gas in the boiler room, you must first turn off the shut-off valve at the entrance to the house. Then you need to check the gas pipeline (up to the boiler valve) and fittings for damage. If you find them, you should contact your gas service.

If the smell of gas is not felt, then after a while you can start the boiler again. It is advisable to be nearby at this time and have a gas analyzer with you. If the sensor triggers falsely, it needs to be replaced.

Error type "E7"

This code is displayed if the board has “lost” the remote control. The problem may be a breakdown of the control panel or the board unit responsible for communication.

Control devices from other Korean manufacturers (Navien, Hydrosta, etc.) are suitable for Daewoo boilers, so there is no particular problem in replacing this part.

Error type "E8"

Lost connection between the heating circuit temperature sensor and the central board. Typically, the problem occurs when the thermistor breaks. First, of course, you need to see if the contacts have come loose, then call the wiring. If it is working properly, then the sensor should be replaced.

You can replace the sensor yourself. All modern measuring devices for this purpose are equipped with special sockets, so you don’t have to solder anything

Theoretically, a breakdown of the central board unit is possible, although usually in this case it fails completely, rather than partially.

Error type "E9"

Leak in the boiler. The water presence sensor has tripped. You need to open the boiler and look where the fistula has formed. There may also be a problem with the gaskets of the sockets where the heating and hot water temperature sensors are installed.

Error type "EA"

The circuit is refilled with water more often than once every 5 minutes. This indicates the presence of a leak. Its volume is not so significant as to stop the boiler as a result of boiling water or releasing pressure.

This situation cannot be ignored, since a small leak at any moment can turn into a full-fledged leak with an emergency stop of the boiler and serious consequences for objects in the house.

Error type "EC"

Central control boards are universal for all models within the same line. The error code “EC” indicates that the boiler model was incorrectly selected. This usually occurs when the central board is replaced or when parameters are reset due to a sudden power outage.

It is customary to install a stabilizer in front of a gas boiler. This allows you to avoid breakdowns of expensive electronics and equipment downtime during the heating season.

To solve this problem, just configure the settings using the service menu.

Error type "Ed"

The second letter of this code is lowercase “d”. Manufacturers moved away from the template so that users do not confuse the capital “D” and the number “0”, which have similar shapes. The error means that the built-in stabilizer has detected a deviation in the current frequency.

If power parameters often deviate from standard values, the boiler electronics may fail.

Error type "EE"

This code indicates a problem with the smoke exhaust fan. The speed sensor shows a low value.

The malfunction may be caused by:

- clogged impeller;

- violation of shaft lubrication;

- inaccurate sensor readings.

Also, a board error cannot be ruled out, although this option is unlikely.

Error type "EF"

A signal that the three-way valve responsible for switching the water flow has been open for more than 90 minutes. This indicates that it is jammed. To prevent this damage, it is necessary to install a filter that will prevent clogging.

The three-way valve is equipped with power wires and a communication cable with the central board. If the “EF” error occurs, first of all you need to ring the wiring and secure the contacts well

The most serious failure is a burnt out valve servomotor. In this case, it is better to replace the entire distribution assembly.

Error type "U0"

The flame sensor does not “see” the fire. Ignition problem. If the flame lights up and goes out, the reason may be the quality of the supplied mixture, gas pressure or lack of exhaust hood.

The chemical composition of liquefied gas differs from the main gas. Each specific mixture has its own set of burner nozzles. Don't forget to supply the appropriate kit.

If the flame lights up, the auto-ignition electrode continues to click, but the error still remains, then the reason may be a defective sensor or a poor connection to the board.

One of the defects of the sensor is simply its contamination. If you wipe this part, the problem is often solved.

Error type "U1"

The buttons on the control panel are stuck. Such repairs do not relate directly to the gas boiler, but can be carried out by any electronics specialist. To do this, you need to disconnect the panel from the boiler body and take it for repair.

Error type "U8"

Hot water temperature sensor error. The reasons for the breakdown and the necessary actions in this case are similar to the situation with error “E8”. The boiler does not stop its operation, but operates only in heating support mode.

While replacing the sensor, the boiler will need to be stopped and disconnected from the power supply.

Error type "U9"

Signal from a temperature sensor located in the chimney. The most likely situation is clogged pipes. They need to be cleaned. If no contamination is detected, then the problem may be with an uncorrected sensor.

Almost half of the stoppages of the Daewoo gas boiler are associated with problems that arose in other components of the heating circuit.

In addition, many boiler malfunctions can be eliminated independently if you have at least minimal skills in repairing any equipment. Therefore, it is necessary to analyze the type of error and only after that make a decision either to repair it yourself or to call specialists.

Daewoo MSC series

Daewoo MSC boilers are double-circuit devices with a closed chamber, the rated power of which, depending on the modification, can range from 7 to 46.5 kW. This line of units is represented by 8 different models.

This technique has some peculiarities. In particular, its main heat exchanger is made of copper, which provides the equipment with a long service life. In turn, the hot water heat exchanger has a plate shape, which ensures rapid heating of the coolant. The burner installed in Daewoo MSC boilers is made of stainless steel. In this case, the unit is equipped with all the necessary automation and security systems. You can control the operation of the boiler using a remote control with an LCD display.

The device has several modes that make it easier to control its operation. Among them:

- "Heating";

- "DHW";

- “Heating + DHW”;

- "Minimum heating";

- "Accelerated DHW"

- And so on.

The coaxial chimney provided by the design of the MSC unit prevents the burner flame from blowing out in the event of sudden gusts of wind outside the window. It is possible to install separate chimneys, which is important when heating several apartments. The factory design of the MSC boiler is designed to operate on natural gas, but the nozzles can be changed at any time, and the unit will be able to operate on liquefied fuel.

conclusions

Daewoo boilers today are represented by a large selection of heating systems offered on the domestic market for relatively little money. If you are looking for reliable and at the same time innovative equipment, but are not ready to overpay for European units, then the equipment of the South Korean brand is ideal for you.

Main characteristics

Automatic testing will help identify malfunctions.

The devices are a mini-boiler room that can heat a room of up to 200 m2. Features of atmospheric and turbocharged mechanisms:

- Power is adjusted automatically.

- The circuits operate independently of each other, separately.

- The burners are made of stainless steel.

- Microprocessor control makes it possible to monitor the operation of the boiler from anywhere in the house.

- Convenient remote control.

- Circular two-way pump with ball switch.

- Uniform heating of water.

- Automatic system testing to identify faults.

Despite the ease of use, equipment owners note that some parts have to be replaced frequently due to malfunctions.

Operation and setup

Boilers are adjusted during manufacturing, in the factory. Additional setup is a small adjustment made during installation and first run.

The operating limits of temperature and pressure of gas and working fluids are determined. These actions must be performed by specialists from the warranty workshop, otherwise the warranty agreement will be void.

After the first launch, no special actions are required from the owner. Adjusting the temperature to your liking is done as a matter of routine.

It is necessary to invite a specialist once a year to carry out maintenance.

If problems occur, you should immediately invite a technician from the service center.

Kinds

The Daewoo company produces the most popular and convenient wall-mounted gas boilers for use in a private home.

There are no floor-standing models in the company’s arsenal, which is not a drawback, but demonstrates the approach of the company’s engineers to creating the most compact and multifunctional models.

According to the type of combustion chamber, two options are available:

- Atmospheric boilers. The combustion chamber is open type, and the air required for combustion and smoke removal is taken directly from the room in which the boiler is installed. They are connected to a common house chimney and require the creation of certain conditions for operation. DO NOT tolerate drafts or sharp gusts of wind outside - the flame may go out.

- Turbocharged boilers. The air supply occurs under the action of a turbocharging fan. This design makes the boiler completely independent of external factors, and the operating mode is stable and sustainable. Connecting the boiler to a common chimney is not required; special chimneys of the coaxial type (“pipe in pipe”) of the horizontal type are used, which can be led directly out of the room through the wall. Forced air units are stable and in higher demand.

By type of heat transfer there are:

- Convection boilers. They work on the usual principle - heating the coolant in a burner flame.

- Condensation models. A new type of design that uses two-stage heating of the coolant. First, the thermal energy obtained by condensing water vapor from the exhaust smoke is used. Then the coolant, which has received some heating, is sent to the primary heat exchanger, where it is finally heated to a given temperature.

The use of condensing boilers began recently, but statistics have already been collected. They provide significant fuel savings due to the recycling of thermal energy.

It becomes possible to reduce the heating intensity of the heat exchanger, which saves gas and increases the service life of boiler components that are not subject to too much load.

NOTE!

Condensing boilers require specific operating conditions. The temperature difference between the outside and inside of the building should not exceed 20°, otherwise the condensation process will become impossible. Because of this feature, the use of condensing boilers in Russia does not make sense. When purchasing such installations, you should know in advance about the existing restrictions so as not to pay extra money.

Popular models of Daewoo gas boilers

Let's look at popular models of Korean Daewoo gas boilers, reviews of which have more positive characteristics.

DGB 160 MSC

Double-circuit gas boiler Daewoo DGB-160 MSC

An electricity-dependent unit that is designed to heat most apartments in Russian territory. It is installed on the wall, heats the premises and prepares water for domestic needs (double-circuit). Weight is 27 kg.

In order for the boiler to function stably and economically, high-quality installation and proper operation of the control system are required. Has an advanced security system. The company's specialists stabilized the fuel supply system.

The efficiency of the Daewoo DGB 160 MSC boiler is 91%. A unit with a closed combustion chamber, with automatic ignition. In addition, the following turbocharged analogues are available to the buyer.

| Model | Characteristics |

| DGB-130MSC | The Daewoo DGB 130 MSC gas boiler has a power of 15.1 kW. Heats up to 151 m². The efficiency is 91%. Weight 27 kg. |

| DGB 200 MSC | The heating area of the unit is 230 m². Thermal output is 23.3 kW. Built-in self-diagnosis, anti-freeze and overheating protection functions. Expansion tank for Daewoo DGB 200 MSC gas boiler, 6 liters. The weight of the structure is 27 kg. Gas consumption - 2.4 m³ / h. |

| DGB 250 MSC | Heating area 290 m². Power is 29.1 kW. Weight 33 kg. |

| DGB 300 MSC | Thermal output (max/min) 11.6-34.9 kW. The weight of the unit is 38 kg. The boiler is designed to heat an area of up to 349 m². |

| DGB 400 MSC | The maximum heating output tends to 46.5 kW. The unit is capable of heating 465 m². Weighs - 35 kg. |

https://youtube.com/watch?v=LX0V82bc6_8

Altoen Daewoo 110 MCF

This Daewoo DGB gas boiler is atmospheric, wall-mounted. It has electronic control that maintains the required temperature in the room. The unit has two circuits, so it heats the area and heats the liquid. Almost silent. Has a copper heat exchanger. Weight is 29 kg. The body is painted white. The efficiency of this Korean gas unit tends to 91% with a power of 12.8 kW.

Atmospheric gas double-circuit boiler Daewoo DGB - 110 MCF 12.8 kW

The boiler has an open combustion chamber and requires boiler room equipment. The best option would be to install it in a private home. Daewoo can offer the buyer units that differ in power (see table).

| Model | Characteristics |

| 130 MCF | This is a Daewoo 130 MCF 15,000 W gas boiler. Has a weight of 29 kg and similar characteristics as the 110 MCF model. |

| 160 MCF | Boiler weight 29 kg. Power 18,600 W. |

| 200 MCF | 23,300 W model. Weighs 35 kg. |

DWB-201 GOM (Turbo)

Wall-mounted gas double-circuit boiler Daewoo DWB 201 GOM Turbo

Gas units of this model heat large houses and premises, unlike previous models. The equipment has a high power of 23.3 kW and easily heats 250 m². The boiler is wall-mounted, with an 8-liter expansion tank. Weight is 28 kg.

A chimney is not required for operation. It differs from classic turbocharged models in that the turbine is located at the bottom. Electronic ignition.

Daewoo DGB 100 MSC

Gas double-circuit boiler Daewoo DGB MSC

The Daewoo DGB 100 MSC double-circuit boiler with a closed combustion chamber is popular. Its power is 11.6 kW, the unit heats an area of 130 m². The efficiency is 91%. The maximum hot water heating temperature is 40 °C, and the productivity is 6.7 l/min. Weight 26 kg. The Daewoo DGB 100 gas boiler is an excellent option for heating a home and preparing water for domestic needs.

Popular models

DGB 160 MSC

Double-circuit model – gas/boiler, designed for heating a room up to 180 sq. m.

The device is wall-mounted and is suitable for heating an area of up to 186 m2. In order for the unit to operate without interruption, stably and economically, it must be connected correctly. Features an improved security system. Several modifications of this model have been developed.

Main characteristics:

- double-circuit;

- energy dependent;

- wall installation;

- Efficiency – 91%;

- runs on natural gas;

- maximum hot water temperature – 85;

- minimum temperature – 40;

- voltage – single-phase;

- closed combustion chamber;

- auto diagnostics;

- electronic control;

- There is a thermometer and pressure gauge.

Altoen Daewoo 110 MCF

A model with an open burner and the need to install a chimney is intended for a private home

Atmospheric type apparatus, mounted. Constant temperature conditions are maintained using electronic control. Designed for heating private country houses. Since the firebox is open, a separate room is required to install the boiler. Works quietly.

Specifications:

- heated area – 128 m2;

- open combustion chamber;

- two independent circuits;

- Efficiency – 91%;

- depends on the presence of electric current;

- there is a circulation pump;

- nominal gas pressure – 4 mbar;

- maximum hot water temperature – 85;

- minimum temperature – 40;

- room thermostat and remote control available;

- autodiagnostics of equipment.

Boiler design and main control devices

The copper heat exchanger has a long service life.

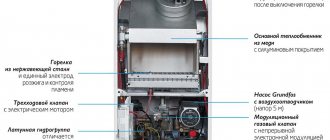

The design features of the Daewoo boiler are not particularly difficult. The boiler has the following main elements:

- the combustion chamber;

- double-circuit heat exchanger;

- circulation pump - one or two;

- measuring instruments - pressure gauge, thermometer, thermostat.

The devices are produced in the form of boilers. When heated, the water circulates inside the device, and the entire system operates. Wall-mounted models take up a small area, are convenient and allow owners to heat the room using a compact model.

The boiler has a built-in control unit. Using a backlit digital console, you can see all the information about the operation of the equipment and control the process. The operation of the device is also programmed using an electronic daily timer.