Italian gas boilers Ferroli are products of one of the strongest European manufacturers.

The equipment manufactured by this company demonstrates high quality and stable operation; all components and parts of Ferroli gas boilers are assembled on the basis of advanced technologies and fully meet the most stringent technical requirements.

Each unit is equipped with an extensive self-diagnosis system, consisting of a network of sensors that are located on all critical components and parts of the boiler.

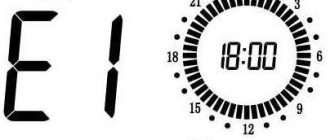

If any malfunction occurs or the unit leaves the set mode, the self-diagnosis system immediately reacts by notifying the user using an alphanumeric code on the boiler display.

Let's take a closer look at her work.

Main malfunctions of Ferroli gas boilers

The design of Ferroli boilers is distinguished by well-thought-out and high-quality elaboration of all components and parts.

However, any system has weak points, and gas boilers are no exception..

The operating conditions of some parts of the units are very complex; temperature loads contribute to the occurrence of fatigue of metals and other materials.

According to experts, the most common malfunctions include:

- The boiler does not turn on. There may be different reasons and ways to eliminate them, one of the most common problems.

- Blood pressure drops or rises. This is a serious problem that leads either to a coolant leak, which causes overheating and blocking of the boiler, or to excess pressure and blocking. Particularly dangerous is the increase in pressure, which can cause parts of the unit to burst.

- Fan or circulation pump failure. The loss of both functions means the system is unable to operate - the inability to remove smoke causes sudden overheating and blocking, and the lack of fluid movement has the same consequences, only detected by other sensors.

- Problems with the electronic control board. The cause of these problems is most often an unstable supply voltage or lack of quality grounding. The boiler electronics are very sensitive to any changes in operating mode. When drops or jumps appear, it begins to produce a continuous series of errors that do not repeat when restarted. Often, a static charge accumulates on the housing, which is transmitted through ground to the control board and ionization electrode, which causes error A02 to appear (the system sees a flame when there is none). The solution to the problem is to completely disconnect the boiler from the power system for some time and restore (or create) high-quality grounding.

In addition to those listed, there are a lot of problems with the combustion mode:

- Flame too small.

- Spontaneous start of combustion.

- There is no DHW heating.

- A sharp flash of flame with a pop.

All these problems are associated with deterioration in gas supply due to clogged injectors, failure of a thermocouple or fuel valve coil.

IMPORTANT!

The elimination of all problems should be entrusted to qualified technicians from the service center; repairing the boiler yourself may give the opposite result to what was expected.

Warranty repair

While the warranty period has not yet expired, the owner has the right to receive free repairs and maintenance. Repair may be refused if the following rules and conditions have been violated:

- ventilation was not organized;

- grounding is not done;

- factory seals are broken;

- there is damage on the case, such as dents and scratches;

- high indoor humidity;

- the boiler room is very dusty;

- power surges in the network;

- main gas is of low quality or with pressure drops;

- the oven was overheating.

In all other cases, you can contact the service department responsible for Ferroli boilers in your city:

- Moscow – “Thermo-Prestige”.

- St. Petersburg - "Energo Garant".

- Yekaterinburg (and 80 km around) – “Hat House”.

- Novosibirsk - "GUDT TeploVodoMontazh".

All main error codes and their interpretation and solution

Let's consider the main errors of Ferroli gas boilers and options for eliminating them:

| Code | Decoding | Ways to solve the problem |

| A01 | No flame (ignition attempt failed) | Check the presence of gas in the line, open the gas supply valve, |

| A02 | False presence of flame (voltage detected at the ionization electrode when the burner is off) | Check the condition of the ground loop or the presence of condensation drops on the control board |

| A03 | Boiler overheating | Wash the heat exchanger, check the condition of the circulation pump |

| A06 | No flame after ignition cycle | Check the gas supply system, clean the gas burner nozzles |

| A08 | Coolant temperature sensor failure | Replace element |

| A09 | Gas valve failure | Check functionality, replace element |

| F04 | Flue gas thermostat overheating | Clean the chimney, check the operation of the fan |

| F05 | Failure of the smoke removal system, fan shutdown | Replace fan |

| F08 | Primary heat exchanger overheating | Rinse the heat exchanger and, if necessary, replace it |

| F10 | Break or short circuit of the exhaust temperature sensor | Restore contact or replace sensor |

| F11 | Break or short circuit of the DHW temperature sensor | Restore contact or replace sensor |

| F14 | Malfunction of sensor No. 2 direct line of the heating circuit | Restore contact or replace sensor |

| F34 | The supply voltage dropped to 180 V | Check the line, install a stabilizer or uninterruptible power supply |

| F37 | Exhaust pressure drop | Detect heating agent leak and fix it |

| F40 | Excessive exhaust pressure | Check the condition of the expansion tank |

| F47 | Open or short circuit of the exhaust gas pressure switch | Restore or replace the relay |

| F50 | Problems with the control board | Replace control board |

Ferroli boiler errors are divided into critical (A) and non-critical (F). Those with the letter A lead to independent blocking of the boiler, but those with the letter F do not.

Accessories

For each category of boilers, the manufacturer also provides additional accessories. In particular, double-circuit wall-mounted models can be supplemented with a kit for smoke removal systems and devices that allow the equipment to operate on liquefied gas. In turn, a Ferroli floor-standing gas boiler can be equipped with boilers, DHW priority systems, turbo nozzles and devices for cascade control. Condensing units have the largest range of additional options. They can be provided with outdoor temperature sensors, control boards for multi-circuit systems, hydraulic arrows, a mounting manifold frame, as well as special fitting kits for connecting boilers.

Operating instructions - how to start correctly

The operation of Ferroli boilers does not differ in any specific actions or procedures.

The owner is only required to organize periodic maintenance, clean the body and interior of the boiler, and maintain the burner nozzles in proper order.

The procedure for starting the boiler is similar to the procedure for igniting other gas units.

A special feature is the need to maintain a pause between startup attempts, during which code D3 or D4 appears on the display (50 or 30 seconds).

Download instructions

Download instructions for Ferroli gas boilers.

The first code occurs after a critical error appears and the unit is blocked.

Until the required time interval has been met, a repeated restart is not possible.

The second code appears between attempts to start normally, if the previous one was unsuccessful.

This is usually due to air in the pump, piping or heat exchanger . Attempts are repeated until the air is removed from the boiler.

Errors marked "D"

Technically, these codes are not a significant error that negatively affects the performance of the boiler.

They point out the following:

- D1 – delay before the next boiler switching on. The code often occurs when the hardware is forced to reboot.

- D2 – waiting time for the next water heating cycle.

- D3 – waiting time before the next ignition, when there is a need to re-ignite the boiler if it did not work the first time.

- D4 – forced pause between starts (about 5 minutes).

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

Codes appear and disappear on their own. The boiler can continue to operate when these values are not shown on the display.

How to setup

The basic settings of the Ferroli boiler are carried out at the manufacturer . At the first start, additional adjustments are made to the parameters of all communications to ensure full compliance with the operating modes of the system and the supply of resources - gas, water, voltage.

The upper and lower limits of temperature and pressure of liquids, gas, and other important parameters are also determined.

Most actions are performed from the external control panel; the casing has to be opened only when carrying out complex repair work or to connect a room thermostat.

NOTE!

The setup must be carried out by a technician from the service center, otherwise the warranty agreement will become invalid or important components of the unit will fail due to improper operation.

The boiler does not start (the burner does not turn on)

Problems with starting a boiler occur most often, since there are many reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board has failed.

- The boiler is blocked due to a problem with a component.

Most possible causes are detected by the self-diagnosis system and display the corresponding code.

However, some possible reasons - failure of the gas supply system, a closed valve and other mechanical obstacles may not be noticed by the system, so you should independently verify that it is ready for operation . In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes, after connections have been made, the wires on the panel are mixed up.

IMPORTANT!

If the phase is connected to the wrong electrode, the boiler will not start. It is also extremely undesirable to have an electrical potential between the working zero and the ground, which causes error A02 to appear.

Installation nuances

The wall-mounted installation instructions for which are presented in the user manual must be installed in a room where the ventilation system is constantly operating. If the air flow is insufficient, the device will not be able to operate normally, and combustion products will not be removed. If such conditions are created, then harmful substances can penetrate into the premises of the house, which can cause harm to human health. If you purchased wall-mounted equipment, you can use a kit with a bracket that attaches to the wall. To mark the surface of the suspension points, a metal template can be supplied upon special order.

Why does blood pressure drop?

A drop in pressure in the boiler can be due to three reasons::

- The appearance of a leak in the heating circuit (including in the boiler itself). The peculiarity of this option is the constancy of the process, since the coolant will not stop leaving, no matter how much the system is recharged. In this case, you need to find the location of the leak. First of all, you need to check the condition of the drain tap or valve to see if it is open or damaged. If no problems are found in this unit, the entire heating circuit is checked sequentially. Sometimes they forget to close the drain valve on radiators, fistulas appear in pipelines, and connections fail. It is most difficult to detect a leak if the tap supplies a water-heated floor system embedded in a concrete screed. You can detect the problem by a wet spot on the floor or ceiling of the lower floor, and to do this you often have to remove the floor covering or suspended ceiling.

- Circulation pump failure. This problem is immediately detected by the self-diagnosis system, and it is easy to check the functionality of the pump. It is enough to carry out a visual inspection of the element and take appropriate measures.

- Expansion tank membrane rupture. In this case, the pressure will drop until the coolant fills the entire volume, after which the process will stop. Then an uncontrolled increase in pressure is possible, especially intense as the temperature of the heating agent increases. If it turns out that the problem element is the expansion tank, urgent measures must be taken to repair or replace the unit. Otherwise, with thermal expansion of the liquid, the heat exchanger or other element of the system will fail, which will require significant costs for repairs and restoration of the boiler’s functionality.

Ferroli floor heaters

The inflatable burner needs to be purchased separately.

Floor-standing cast iron boilers are available with a built-in or removable (inflatable) burner. First, let's look at models with a built-in burner. The equipment of the simplest boilers (up to 1 thousand Euros) is very modest:

- single stage burner;

- heat exchanger made of cast iron;

- gas valve HoneyWell or Sit;

- connectors for additional equipment (pump, thermostat).

Boilers priced from 1 thousand euros, in addition to the standard set, are equipped with a display, connectors for connecting a three-way valve, a boiler pump, outdoor temperature sensors, and boiler sensors. Thanks to this set of options, the heater can independently control the degree of heating of the coolant according to weather conditions. The equipment for each model is indicated in the operating instructions for the Ferroli boiler.

Units over 2 thousand Euros, for example Pegasus-DK, have a built-in 130-liter boiler and a 12-liter expansion tank, two pumps, and a magnesium anode installed in the boiler. A magnesium anode is needed to prevent the boiler tank from rusting. This is a consumable material; the anode must be changed periodically (as it breaks down). Heaters for 3 thousand Euros (Pegasus 2S and PegasusF3 N2S) have the same equipment as the cheapest models, with the exception of the burner - in expensive units it is two-stage. This allows you to expand the range of boiler power adjustment.

If any problems arise during the operation of the Ferroli gas boiler, a fault code is displayed on the liquid crystal display.

The peculiarity of boilers with a removable inflatable heating pad is that they can operate on both gas and diesel fuel, it depends on the type of burner:

- for gas - Sun M;

- for diesel - Sun G.

In the Atlas heater, instead of an external inflatable burner, you can connect an internal one or two-stage gas burner. In a rich configuration, for example, Atlas DK, there is a built-in 10-liter expansion tank and a 100- or 130-liter boiler, two pumps, and a liquid crystal display. The external inflatable burner is not included and is supplied separately.

The better quality adhesive you use for thermal insulation, the better the result of insulation work.

It is described how to properly insulate a house from the inside with mineral wool.