Combined heating boilers are increasingly being used to heat country cottages and private houses. – devices that provide optimal temperature regardless of the presence of a centralized gas supply.

Compared to traditional equipment, combined-type units have many advantages, among which the main one is significant savings in money.

However, in order to purchase suitable equipment, you need to carefully familiarize yourself with the selection criteria and assortment.

Rating of the TOP 10 best combined boilers for heating

| Place | Model | Price |

| Models of small and medium thermal power up to 30 kW | ||

| #1 | Teplodar Kupper OVK 18 18 kW | |

| #2 | Teplodar Kupper PRO 28 28 kW | |

| #3 | ACV Delta Pro S 25 26 kW | |

| #4 | Protherm Bizon 30 NL 27.1 kW | |

| #5 | Buderus Logano G125 WS-25 25 kW | |

| High power models from 30 kW | ||

| #1 | Teplodar Kupper PRO 42 42 kW | |

| #2 | Sime 1R6 FREEST 64.8 kW | |

| #3 | Ferroli Atlas Evo 47 | |

| #4 | Sime 1R7 FREEST 74 kW | |

| #5 | Lamborghini Calor EL DB DN EVO 32 | |

Page navigation:

How to significantly save fuel to reduce costs

Each owner has a real opportunity to reduce the cost of electricity or blue fuel, even if the device does not provide automatic mode switching. To achieve significant savings, you will have to separately purchase a thermostat and install it on the equipment.

A room thermostat is usually programmable and during its operation it is guided by the air temperature in the room. For normal operation and performance of the function specified by the thermostat, it is necessary to program the settings not only for the next day, but also for the entire week in advance.

Saving fuel resources when heating your home Source chiamamicitta.it

If it is a working day and the owners are absent, then the temperature limit is set to 15 degrees. During sleep, it is rational to set priority to 18-19 degrees. By specifying these parameters, the level of comfort will not decrease, and fuel consumption will noticeably decrease. This can be determined by the amount of utility bills.

What are combi heating boilers?

For your information! A combined heating boiler is a device designed for heating a room that can operate on solid (wood) or diesel fuel, electricity or gas.

The equipment is universal in use, has a high efficiency and is considered very environmentally friendly .

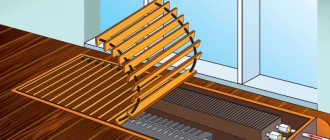

The device is equipped with everything necessary so that it can be easily connected to a home heating system or to a “warm floor” structure - all additional accessories are usually included in the delivery package.

Principle of operation

The wood-electricity combination boiler operates according to the following algorithm :

- Melting and heating of the unit occurs in the traditional way. During the combustion of solid fuel (wood, coal, briquettes), the water temperature is maintained using a thermostat together with a sensor. Electric heating elements do not work at this moment.

- If you do not add fuel to the firebox in time, then after it burns out, the temperature of the water in the system gradually decreases to a certain value, after which a sensor is triggered, which closes the control contacts and the heating element (one or more) turns on. From this moment on, the boiler begins to operate from the mains.

- After the next loading of fuel, the water in the pipes is heated from the side of the firebox and, upon reaching the set temperature, the sensor is triggered again, but this time to turn off the heating elements. The electrical part of the boiler is again inactive until the water temperature decreases again.

Most often, the electric heater in a combination boiler is designed as an auxiliary heating device, but if you wish, you can choose a boiler model that, if necessary, can work continuously, providing hot water to the house and heating system.

A heating element with a sensor connected to a heat exchanger Source anapasunsity.ru

How to choose a combi boiler?

In order not to make a mistake in choosing a combined type device for a private home, it is worth familiarizing yourself with its main technical characteristics.

These include:

- maximum thermal power. On average, heating 1 sq.m. area you need to spend 0.1 kW of thermal energy. However, it is better to entrust the calculations to specialists who will help you find the best solution;

- fuel used. The devices are capable of working simultaneously or alternately with several types of fuel. The most popular are electric-gas, electric-wood, gas-wood, as well as models with a wood-diesel fuel combination;

- type of ignition - mechanical or electronic. According to experts, electric ignition is more economical since the unit does not have a pilot light. In addition, in the event of a short-term drop in pressure, the system will automatically resume operation of the boiler;

- heat exchanger material – steel, cast iron or copper. Steel heat exchangers withstand temperature stress well, cast iron ones have a long service life, and copper ones have high efficiency and are less susceptible to high temperatures.

Minimum required power

For an average house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 100 m2, the minimum required power of heating equipment is 100/10 * 1.3 (30% reserve) = 13 kW. Boilers of this power are not found on the market, so we round up to the nearest higher value - 14 or 15 kW.

When choosing a double-circuit boiler, it is recommended to add another 10-15% to the result, since when heating hot water, the heating circuit is not heated.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Popular models

Keep in mind! It is easy to find suitable heating equipment on the domestic market.

The main thing is to decide in advance on the desired parameters and consider the model range in detail.

Models of small and medium thermal power up to 30 kW

TOP-5 rating of models with average power in terms of price and quality ratio.

Teplodar Kupper OVK 18 18 kW

Powerful equipment that is perfect for installation in a small room.

A combined single-circuit unit, presented in a compact housing that will not take up much space in the room.

The presence of a water-tube heat exchanger can significantly improve heat removal and increase the efficiency of the device, which are the main advantages of this model.

Specifications:

- maximum thermal power – 18 kW;

- heat exchanger material – steel;

- fuel – natural gas, coal, firewood, pellets;

- coolant temperature – 60-80 °C;

- control type – mechanical.

Advantages

- steel primary heat exchanger;

- possibility of connecting external control;

- presence of a hob;

- versatility of use;

- Convenient floor installation.

Flaws

- chimney elements will have to be purchased separately;

- lack of draft regulator included;

- complicated operating instructions.

Teplodar Kupper PRO 28 28 kW

An impressive new product, with which you no longer have to think about how to quickly heat the room.

A single-circuit model from the middle price range, which successfully implements a long-burning mode when working on coal and wood.

The device also provides the ability to install a pellet or gas burner - this allows for complete automation of the process, relieving the user of the need to constantly monitor the situation.

Specifications:

- maximum thermal power – 28 kW;

- heat exchanger material – steel;

- fuel – natural gas, coal, coal and wood briquettes, firewood, pellets;

- coolant temperature – 60-95 °C;

- control type – mechanical.

Advantages

- pre-installed thermometer;

- energy independence of equipment;

- long warranty period;

- the presence of a heating element to maintain temperature;

- extended equipment.

Flaws

- weight and dimensions of the structure;

- fast cooling;

- expensive repairs.

ACV Delta Pro S 25 26 kW

A unique model that can pleasantly surprise with its wide functionality and attractive price.

Double-circuit combi boiler designed for floor installation, ideal for both domestic and industrial purposes.

The device is distinguished by the presence of a well-thought-out system of protection against high pressure and overheating, which guarantees absolute safety of operation.

Specifications:

- maximum thermal power – 26 kW;

- heat exchanger material – stainless steel;

- fuel – natural gas, liquefied gas, diesel fuel;

- coolant temperature – 60-90 °C;

- control type – electronic.

Advantages

- power-on indication;

- presence of a thermometer and pressure gauge;

- possibility of connecting external control;

- presence of a safety valve;

- built-in boiler.

Flaws

- the burner is purchased separately;

- high cost of the model;

- It is better to invite a professional for installation.

Protherm Bizon 30 NL 27.1 kW

A highly efficient device that does not require special skills or knowledge to operate.

Single-circuit combined convection type unit, equipped with a thermometer and pressure gauge.

A nice addition was the detailed overheating protection system.

Convenience, reliability, high level of safety - the design has everything for comfortable work.

Specifications:

- maximum thermal power – 27.1 kW;

- heat exchanger material – cast iron;

- fuel – natural gas, liquefied gas, diesel fuel;

- coolant temperature – 30-90 °C;

- control type – electronic.

Advantages

- intuitive control system;

- no need for special maintenance;

- long warranty period;

- high technical characteristics;

- unobtrusive design.

Flaws

- The delivery package does not include an inflatable burner;

- slight noise during operation;

- easily dirty snow-white body.

Buderus Logano G125 WS-25 25 kW

An easy-to-use unit designed for long-term operation without breakdowns.

High-performance heating boiler, in the manufacture of which the most modern technologies were used.

The low-temperature device can be combined with gas and diesel fuel-powered fan burners.

High corrosion resistance is ensured by the use of special gray cast iron.

Specifications:

- maximum thermal power – 25 kW;

- heat exchanger material – cast iron;

- fuel – natural gas, liquefied gas, diesel fuel;

- coolant temperature – 50-90 °C;

- control type – electronic.

Advantages

- large selection of additional equipment;

- water-cooled combustion chamber;

- excellent quality of materials and workmanship;

- reasonable cost;

- good equipment.

Flaws

- no control panel provided;

- device dimensions;

- Questions for the instruction manual.

High power models from 30 kW

The best high-power models according to customer reviews and ratings.

Teplodar Kupper PRO 42 42 kW

The most powerful combined type unit, characterized by ease of maintenance and use.

One of the best-selling models on the domestic market, which has optimal thermal power and a basic mechanical control system.

To maintain the temperature for a long time, the manufacturer has added a high-power heating element to the equipment.

The combustion chamber in the device is open.

Specifications:

- maximum thermal power – 42 kW;

- heat exchanger material – steel;

- fuel – natural gas, coal, coal briquettes, firewood, pellets;

- coolant temperature – 95 °C;

- control type – mechanical.

Advantages

- ease of maintenance;

- sophisticated security system;

- clear instructions included;

- versatility of use;

- acceptable price.

Flaws

- device weight;

- Before installation, you must carefully study the instructions;

- dimensions.

Sime 1R6 FREEST 64.8 kW

A high-tech design that will be the best option for people living in private homes.

A classic heating device with an open combustion chamber, a basic electronic control system and a built-in thermometer.

The unit has high thermal power, so it is perfect for installation in large houses.

Specifications:

- maximum thermal power – 64.8 kW;

- heat exchanger material – cast iron;

- fuel – natural gas, liquefied gas, diesel fuel;

- coolant temperature – 60-90 °C;

- control type – electronic.

Advantages

- simple control system;

- reasonable cost of the device;

- expanded functionality;

- sufficient heated area;

- significant budget savings.

Flaws

- the burner will have to be purchased separately;

- noisy operation of the device;

- specific smell when first used.

Ferroli Atlas Evo 47

A superbly designed device that has absolutely everything for comfortable use.

Highly reliable and energy efficient equipment, presented in a compact case that does not take up much space.

The unit is distinguished by its operation with a low level of sound power, which means that it will definitely not cause any discomfort.

Specifications:

- maximum thermal power – 47 kW;

- heat exchanger material – steel;

- fuel – natural gas, coal, firewood, pellets;

- coolant temperature – 95 °C;

- control type – electronic.

Advantages

- excellent frost protection;

- preset display;

- closed combustion chamber;

- possibility of connecting external control;

- affordable price.

Flaws

- design for everyone;

- rather complicated instruction manual;

- Some items will have to be purchased separately.

Sime 1R7 FREEST 74 kW

A universal floor-standing unit with high technical characteristics.

Standard single-circuit model with an atmospheric combustion chamber, designed for floor installation.

The device can operate with a single-stage burner, but it is also possible to connect a climate regulator.

The warranty period for the device is one year.

Specifications:

- maximum thermal power – 74 kW;

- heat exchanger material – cast iron;

- fuel – natural gas, liquefied gas, diesel fuel;

- coolant temperature – 60-90 °C;

- control type – electronic.

Advantages

- possibility of connecting external control;

- high-quality assembly and excellent materials;

- simple and unobtrusive design;

- almost silent operation;

- clear instruction manual.

Flaws

- The delivery set does not include a burner;

- short warranty period;

- impressive design dimensions.

Lamborghini Calor EL DB DN EVO 32

An ultra-modern device, which is a prominent representative of the economical line.

Floor-mounted combination heating boiler with an ultra-modern design.

The device body is assembled from high-strength cast iron elements with a special arrangement of ribs, which ensures high efficiency and significant energy savings.

Specifications:

- maximum thermal power – 32 kW;

- heat exchanger material – cast iron;

- fuel – diesel fuel, natural and liquefied gas, waste oil, fuel oil;

- coolant temperature – 95 °C;

- control type – electronic.

Advantages

- high performance;

- innovative protection system;

- intuitive control system;

- simplified installation of the structure;

- enhanced thermal insulation.

Flaws

- expensive equipment repairs;

- increased sound power level;

- meager equipment.

Installation and operation rules

Before connecting, you need to check the draft in the chimney.

The combined heating system is installed by specialists from the gas service or a special organization according to a pre-approved plan.

Stages of work:

- Installation of supports that will provide the required level for the heating unit. As a rule, they are present in the latter's kit.

- Connecting the boiler to the gas supply.

- Electrical connection.

- Installation of special filters for water and gas.

- Leak testing and cleaning of the heating system.

- Connecting the boiler to the pipeline.

- Setting up the chimney.

- Test run of the heating system, troubleshooting problems.

- Final adjustment of the heating system.

Installation of a gas-electric boiler is permitted in a room where, in accordance with the rules and regulations, supply and exhaust ventilation is equipped.

Basic operating rules:

- During operation of the combined unit, acceptable traction is required. In this regard, the chimney must have a sufficient cross-section.

- The chimney used must be insulated to prevent the parts in contact with it from catching fire.

- During regular operation of the boiler, the ash pan should be periodically cleaned. The frequency of such procedures depends on the degree of gas combustion and the intensity of operation of the unit.

- There should be a steel sheet in front of the combustion chamber, which will provide the flooring with protection from sparks.

Electric gas heating boilers are considered the most technologically advanced and advanced.

conclusions

When planning to purchase a combined heating boiler for heating a private home, you must remember that:

- the main criteria for choosing equipment are the maximum thermal power, the type of fuel used and the heat exchanger material;

- Increased attention also to the coolant temperature, control system and design dimensions ;

- For organizing one heating system, a single-circuit device would be a good solution, but if the device is also selected for hot water supply, you should give preference to a dual-circuit model.

Reviews of universal household electric gas boilers: advantages and disadvantages

| Advantages | Flaws |

| Dimensions correspond to single-fuel models | The simplest functionality due to the lack of modern automation |

| The cost of a combination boiler is cheaper than two single-fuel boilers | Lower efficiency compared to single-fuel counterparts |

| According to reviews from owners, a heating element with a power of 6 kW is enough to maintain a comfortable temperature all night in a house with an area of 100-120 m2 | Limited selection of models: today there are only about 8-12 models, some of which are difficult to find on sale |

| Can use both fuels at any time | Owners often note the high noise level of the burners, which is not comparable to the operation of standard burners of gas boilers |

| There are also dual-circuit models | In more than 98% of cases, you need to purchase an additional burner separately, often in another store |

| Lower installation and connection costs |

Insertion into a one-pipe system with an additional pump

This connection option even has its own special name - “Leningradka”. Its use requires installation of a pump and self-assembly of the mixing unit.

In order for the finished system to function without interruption, it will be necessary to take into account the compliance of its parameters with the following requirements:

- the distribution line in internal diameter corresponds to DN25 or more;

- no more than 5 radiators are placed on the ring;

- the heated floor loop is connected to the return pipeline after the batteries;

- the return and supply insertion points are located at a distance of more than 30 cm from each other;

- the degree of heating of the circuit is regulated by a mixing valve (three-way, simplified design).

Layout drawing for underfloor heating and single-pipe heating with radiators

In this system, a valve is necessary to prepare water at the required temperature, and a pump is necessary to move the coolant through the circuit. There is almost no practical use of such a scheme, since it functions unstably, and the radiators lose balance due to changes in water flow caused by the operation of the pump.

Features of assembling a forced circuit

In order for the forced system to justify itself and function properly, it is necessary to correctly select the circulation pump and correctly “embed” it into the heat supply line.

Selecting a circulation pump

The main parameters for choosing pumping equipment: device power and pressure. These characteristics are determined based on the area of the heated room.

Indicative indicators:

- for houses of 250 sq.m., a pump with a power of 3.5 cubic meters per hour and a pressure of 0.4 atm is suitable;

- in rooms measuring 250-350 sq.m, install the device at 4.5 cubic meters per hour with a pressure of 0.6 atm;

- if the area of the house is 350-800 sq.m, then it is advisable to purchase a pump with a capacity of 11 cubic meters per hour, the pressure of which is at least 0.8 atm.

In a more scrupulous selection, specialists take into account the length of the heating system, the type and number of radiators, the material of manufacture and the diameter of the pipes, as well as the type of boiler.

Installing the pump in the main

The pump is placed on the return line so that the coolant that is not too hot passes through the device. It is possible to install modern models made of high-temperature resistant materials on the supply line.

When inserting the pump, the water circulation should not be disrupted

It is important that at any point in the pipeline when the pumping unit is operating, the hydrostatic pressure remains excessive

Four acceptable schemes for heating systems with pump circulation and an open expansion tank. Hydrostatic pressure is maintained at the desired level

Option 1. Raising the expansion tank. A simple way to convert a natural circulation system to a forced one. To implement the project you will need a high attic space.

Option 2. Moving the tank to a distant riser. The labor-intensive process of reconstructing the old system and installing a new one is not justified. Simpler and more successful methods are possible.

Option 3. Expansion tank pipe near the pump nozzle. To change the type of circulation, it is necessary to cut off the tank from the supply line, and then connect it to the return line - behind the circulation pump.

Option 4. The pump is included in the supply line. The simplest way to reconstruct the system. The disadvantage of the method is unfavorable operating conditions for the pump. Not every device can withstand high temperatures.

Connecting a heated floor to a single-pipe heating system (option 1)

The diagram below shows a single-pipe heating system, otherwise called “Leningradka”:

The diagram shows a boiler (floor-standing), a safety unit, shut-off valves (valves) on the supply pipe and on the return pipe, an expansion tank and a circulation pump in front of the boiler.

The radiator system is made in the form of two branches; On each branch - immediately after connecting to the main riser - a shut-off valve is also installed. Each radiator has two radiator valves: on the supply and on the return - in case it is necessary to replace a failed radiator without draining the entire system.

The supply and return - the main pipeline - are made of a polypropylene pipe with a diameter of 25 mm, the radiators are connected to the main pipe with a 20 mm polypropylene pipe.

In a single-pipe system, section A should be of a smaller diameter (with a main pipe diameter of 25 mm, the pipe in this section has a diameter of 20 mm). (Why this is done was described in the next article.)

What's wrong with this system?

On the upper branch, the supply to the radiators is from above, and the return from the radiator is from below. This connection gives the greatest efficiency. On the lower branch, both the supply and return of the radiators are connected at the bottom of the radiator. With such a connection, the efficiency of radiators will be only 88%, as described in the article about effective and ineffective connections of radiators.

Another drawback: this connection scheme is not suitable for large houses with about 30-40 radiators. That is, if a building has more than one floor, then when connecting radiators in this way, you need to make its own branch for each floor, separate from the others. In one-story buildings with large areas (more than 150 sq. m.), a different scheme is used, which will be discussed later, but for now we will talk about connecting the heated floor in the scheme under consideration.

How to connect a warm floor?

The coolant leaves the boiler at a temperature of 80 degrees. Having passed through all the radiators, the coolant in the return line already has a temperature of 50-55 degrees, which provides an ideal opportunity to connect a heated floor to the return line, as can be seen in the diagram.

Shut-off valves are also installed on the supply and return of the heated floor, making it possible to turn off the heated floor without stopping the radiator system. There is a bypass on the return line, with the help of which part of the coolant (if it is too hot in the return line for a heated floor) is directed to the boiler.

That is, if the bypass is closed, then all the coolant will flow through the heated floor. When the bypass is open, due to the greater resistance in the warm floor, the coolant will go directly to the boiler, and the floor will not heat up. It is clear that the bypass is not necessarily only completely open or only completely closed. It can be opened slightly to a certain extent to set the desired temperature in the heated floor.

Of course, bypass adjustment is a manual adjustment and is not very convenient, but not everyone has the opportunity to buy expensive mixing units with automatic valves. That is, bypass is a budget option, perhaps for the first time, until it becomes possible to install automation.

Device prices: summary table

In order for the buyer to quickly choose an option that suits his needs and income level, the offer of trading enterprises is as follows:

| Model | Number of circuits | price, rub. |

| Teplodar Kupper OK 15 | single-circuit | 19 900-21 200 |

| Karakan 20 TEGV | double-circuit | 22 500-25 000 |

| STS V25 FG | double-circuit | 330 000-500 000 |

Final choice

Thus, today the choice of boiler equipment for heating a home is quite wide. There are electric, gas and combined appliances. It cannot be said that any particular type of boiler is more profitable. After all, everything depends on a number of factors.

It is worth noting that gas-electric boilers are the most advanced and technologically advanced.

They have a rather complex design. Such units make it possible to expand the services received and to heat a country house in an autonomous mode in a high-quality and economical manner. Of course, their cost is high. But the acquisition and installation costs quickly pay off.

Restrictions and standards when installing a warm water floor

Let's start with the fact that water heated floors do not belong to high-temperature heating systems. According to the standards, the coolant temperature cannot be exceeded or heated above 55C.

In practice, heating occurs to a maximum of 35 or 45 degrees.

However, do not confuse the temperature of the coolant and the temperature of the floor surface. It can range from 26 to 31 degrees maximum.

where you are constantly (living room, bedroom, kitchen) - it’s 26C

in rooms with temporary stay (bathroom, separate hallway, loggia) - 31C

Also, don't forget about the circulation pump. A warm floor is still a separate independent circuit. The pump can be either built into the boiler or mounted outside it.

With the help of a pump, it is easier to fulfill another requirement regarding temperature differences. For example, between supply and return, the difference should be no more than 10 degrees.

Knowing all these limitations and recommendations, let's move on directly to the schemes themselves.

First launch of TP

Warm floors are very convenient.

All that remains is to figure out how to turn on the heated floor. The first start can be carried out only after the screed has completely dried - this is about a month. First, the system is filled with water. This is done manually using a pressure test pump or through a pre-installed connection to the water supply circuit.

The technique is as follows:

- all air vents and all shut-off valves open;

- the circuit is filled with coolant;

- when water begins to ooze from the air valves, they close;

- the temperature regime is set at the mixing unit;

- then the boiler turns on.

As the coolant heats up, air will come out of it, so it will need to be vented. After several cycles of heating the coolant, the system will stabilize and you will only have to adjust the hydraulic resistance on different TP circuits using flow meters. As you use it, you will make adjustments to the coolant temperature.

Video description

Heating with gas and electricity: which is cheaper, comparison.

In the case of the second, the owner must find out about the condition of the power line near the house and what parameters the nearby transformer station has. It must provide enough voltage to the equipment to keep it running smoothly. Also, the electrical network must be able to create a three-phase connection with a voltage of 380 Volts.

Options for gas and electric boilers for home heating Source chiamamicitta.it