In accordance with existing standards, any residential premises must be equipped with a ventilation system, which is designed to remove polluted air from non-residential rooms (toilet, bathroom, kitchen). If the glass on the windows is not functioning correctly, condensation begins to fog up, condensation flows down the walls, the corners become damp, and mold forms in the rooms. If the ventilation system is working properly, such troubles are invisible. If there is a small child in the house, the consequences of poor air exchange can cause the child to develop bronchial asthma or other respiratory diseases.

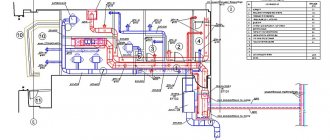

Diagram of forced ventilation in a multi-storey building

To check the functionality of the ventilation system, you need to take a small piece of soft paper (about 10x10 cm), open a window in the room, and then bring the piece of paper to the ventilation grill. If the leaf flutters, the ventilation works well. In turn, if the leaf is not attracted, this is an indicator of poor performance of the ventilation system.

The importance of ventilation system design

Ventilation involves organized air exchange in the room. The system provides both an influx of fresh air and an intake of exhaust air, including odors and gases. Ventilation can also be only supply or exhaust, depending on the purpose of the building. We described in detail the features of the supply and exhaust systems in this material.

Natural air exchange is possible through cracks when windows and doors are not tightly closed. But this type of ventilation is not effective enough and, as a rule, is not able to provide proper microclimatic conditions.

As a rule, small ventilation units are used for apartments and private houses. The best option is a supply and exhaust system with fresh air supply and exhaust air removal. In residential buildings and cottages, separate exhaust systems are installed in bathrooms, toilets and kitchens

It is possible to install equipment without design - this is exactly what new owners of apartments and houses often think, but in the end it turns out that the system does not work at full capacity, does not function correctly, or does not function at all.

Installation without preliminary design can lead to the following violations:

- incorrectly selected diameter of air ducts;

- lack of fresh air supplied to the premises;

- improper installation of ventilation units;

- poor quality installation of equipment.

Poor ventilation contributes to the formation and spread of mold and mildew, and this can lead to increased incidence of illness in households. For normal human life, it is important to maintain optimal room temperature and effective air exchange.

Some comfort issues

Comfort in the house in terms of ventilation is determined not only by the gas composition. The temperature of the incoming air, the pattern of its distribution throughout the room and its mobility are very important.

The entry of cool air into a room can create a convection current, which is perceived as an unpleasant draft. Such a room will always be uncomfortable, even at normal temperatures.

Considering the high requirements for air exchange, neutralizing such “drafts” often requires taking special measures, and when developing the installation of cottage ventilation, this circumstance must be taken into account.

Qualification and accurate calculations are what we guarantee our clients along with modern equipment and high-quality installation.

Features of building ventilation design

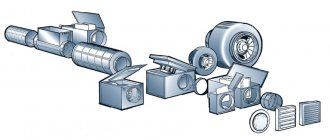

There are 3 types of ventilation systems, and only mechanical general ventilation requires a full-fledged project with the calculation of air ducts, grilles and selection of equipment. Let us briefly examine the design features depending on the type of building.

Designing ventilation in an apartmentVentilation in an apartment should be functional and very compact. The ceiling height is only 3.1–3.2 m. The air handling units of most companies, such as NED, Korf and Systemair, are not suitable for us. They are bulky and will not fit in an apartment.

For apartments, we select compact equipment from SHUFT, Electrolux or Ventmachine. We place air supply units with an electric air heater and a compact recuperator in the ceiling space of technical rooms: storerooms, balconies, bathrooms. Some installations can be placed on the facade of a building. We design air ducts with a height of no more than 10 cm in order to maintain the ceiling height as much as possible, but also to ensure quiet operation of the system.

The ventilation design for the apartment is carried out according to the standards SP 60.13330.2016, SP 54.13330.2016, R NP ABOK 5.2-2012.

Designing ventilation in a private houseVentilation in a private house is designed both general for the entire house and for individual groups of rooms. Recently we have been designing supply and exhaust ventilation in the basement to remove moisture from the sauna with a wet area and a relaxation room, and garage exhaust ventilation with a CO sensor.

We design ventilation with the VAV variable air flow function. We place the equipment in the basement, under the ceiling of the technical room, corridor and in the attic space. The height of air supply units for a private house usually does not exceed 300 mm. We design using NED, Korf, Systemair and Breezart equipment.

The ventilation project in the cottage is carried out according to the standards: SP 60.13330.2016, SP 55.13330.2016, SanPiN 2.1.2.2645-10.

Designing ventilation in a cafe and restaurant Ventilation in a restaurant does not depend on the number of people in the room, but on the saturation of the “hot shop” equipment, i.e. kitchens. The more stoves, convection ovens and ovens, the more powerful the ventilation system.

The ventilation performance of a restaurant depends on the number of exhaust hoods in the kitchen and the period of their operation. When placing a restaurant in a residential building, you will need to install air purification filters such as Tion or AeroLife. For kitchen umbrellas over the barbecue, the installation of IGVT hydrofilters or analogues is required. In our projects we use equipment from Lissant, Veza, KlimatVentMash, Tion, Aerolife and Systemair.

The restaurant ventilation project is carried out according to the following standards: SP 60.13330.2016, TSN 31-320-2000, SP 44.13330.2011, SP 118.13330.2012, R NP "AVOK" 7.3-2007

Design of ventilation for offices and stores We design ventilation in offices and stores depending on the air exchange rate, the number of people and technology. The performance of such a ventilation system is often 100 times higher than the air exchange of a country house.

Supply and exhaust units have large dimensions and are located on the roof and in ventilation chambers. New office and retail centers are often easier to design than other types of buildings. The huge size of the air ducts is compensated by the high ceiling heights and the variety of air exchange schemes and options for laying air ducts.

The ventilation project in office centers and stores is carried out according to the following standards: SP 60.13330.2016, SP 44.13330.2011, SP 118.13330.2012 and other industry standards.

Central air conditioning

Duct air cooler

A good alternative to conventional air conditioners (wall-mounted or ducted) is central air conditioning.

For ease of understanding, central air conditioning is the same supply ventilation, but with increased productivity and with the option of cooling the supply air. That is, in summer, outside air enters the house with a temperature of not + 30 degrees. C, as on the street, and +18, for example, or any other at the request of the user.

Unlike air conditioners, which “drive” the same air, central air conditioning creates a fundamentally better microclimate in the house, since it fills the house with fresh air. This is, in general, a high level.

As a result, the house does not have indoor air conditioning units, hatches, drains, or the like. All equipment is located in one place - this simplifies installation and service.

Freon outdoor units from the same air conditioners or chiller-type refrigeration machines operating according to the freon/water circuit are used as coolers in central air conditioning.

Like any system, central air conditioning in a private home has its strengths and weaknesses.

The main disadvantage of the system is the difficulty in regulating the temperature in the rooms - in this case, you can set the overall temperature of the supply air.

Also, central air conditioning does not create extreme cold, since the performance depends on the multiplicity, and in ventilation the multiplicity is small. Rather, it is a lightweight cooling option that creates a slight background coolness throughout the home.

Advantages:

- High air quality in your home all year round

- Filtration, heating or cooling of supply air

- Management flexibility

- There are no internal blocks, hatches, drains, etc.

- Service in one place

Difficulties:

- Difficulty in regulating temperature by zone

- No extreme cold

- Professional installation required

Design of air conditioning and ventilation systems

This is a complex of works that includes a thorough study of the features of the object and accurate engineering calculations. The final project is prepared taking into account the results of calculations, regulatory requirements and the wishes of the customer. The cooling system is selected from several brand options so that the customer can compare them based on equipment characteristics and efficiency. In addition, during the design process, our company pays attention to the possibilities of energy conservation and cost savings during system operation. Ventilation design - during the design of air conditioning and ventilation systems, our specialists perform the following types of work:

- Develop commercial proposals

- Develop comprehensive design documentation for heating, ventilation and air conditioning systems, automation and electrical systems

- Conducting an examination of finished objects

- Conduct an examination of available equipment and offer recommendations on its use

when performed independently

I have met homemade people who buy ventilation units in the upper price range. This is wonderful, I don’t feel sorry for myself, but if the capabilities of the equipment are used by 10%, then it also seems to be wrong.

The cheapest air supply consists of three components: a fan, a heater and a filter. Compare their price with the price of a monoblock installation, which also contains only these three devices.

Soundproof housing? There is enough thermal insulation and rubber on the market to insulate the fan better than any housing can do - I’m not even talking about special, therefore more expensive, sound-insulating materials.

In recent years, only one worthwhile new product has entered the mass market: electronically commutated (EC) motors. They are worth their price.

| Home | content | up |

Composition of project documentation

Upon completion of the work, the customer receives a finished project, which includes the following documents:

- Project cover and title page;

- Necessary licenses and certificates for design and installation work;

- Technical specifications for the creation of a ventilation system;

- Explanatory note:

- Basic technical solutions for ventilation systems:

- Heat consumption and installed electrical power of ventilation equipment;

- Characteristics of the ventilation system (dimensions, energy consumption, etc.);

- Table of calculations of air exchange in rooms;

- Calculation of basic ventilation equipment using equipment manufacturer software;

The development of design documentation is carried out using computer-aided design systems - we provide a copy of the project in electronic form to the customer.

How is sewer ventilation done?

Removing unpleasant sewer odors is also necessary for comfortable living in apartment buildings. The sewerage “ventilation” system is simplified to the minimum: gases are removed through the same riser as the wastewater is discharged.

To prevent unpleasant odors from bothering residents, the riser is equipped with an extension that goes onto the roof - a ventilation (fan) pipe.

The diagram clearly shows how sewer ventilation is arranged. All apartment plumbing fixtures are “tied” to a common riser, which on one side ends with a drain pipe, on the other – with an outlet leading to the centralized city network

Knowing the diagram, you can understand why work on remodeling bathrooms requires permission. If you change the location of the riser or connect a large number of plumbing fixtures, the operation of the ventilation system may be disrupted.

When equipping the sewer network, taking into account the ventilation of the system, they are guided by SNiP 2.04.01-85 .

Design technology

We use network design technology with the creation of an electronic database, which significantly reduces time, costs and risks when developing projects.

This organization of the process helps to optimize the full range of work: design, packaging, shipment, installation, integration and programming, documentation.

The documentation development process is carried out using advanced software technologies and allows for maximum automation of thermal, hydraulic, aerodynamic and acoustic calculations and optimization of technical solutions to achieve high quality and reliability.

The project is carried out guided by the requirements:

- sanitary requirements

- construction and architectural requirements

- fire safety requirements

- operational requirements

- equipment reliability

- economic efficiency

All design solutions are carried out in accordance with the requirements of building codes and regulations, GOSTs, sanitary and hygienic, fire safety and other standards in force in the Russian Federation.

| increase + |

The grafical part

The graphic part consists of floor plans, sections and fragments of rooms with elements printed on them: air ducts, fans, air distributors, etc.

On a note! Using an automated dispatch system leads to a significant reduction in operating costs!

The process of creating design documentation in our company is carried out by highly qualified engineers using advanced software technologies, which allows for maximum automation of calculations and optimization of technical solutions to achieve high quality design documentation.

All design solutions are carried out in accordance with the requirements of building codes and regulations, GOSTs, sanitary and hygienic, fire safety and other standards in force in the Russian Federation.

Stages of design work:

- Pre-project preparation (development of technical specifications for the project);

- Project, feasibility study (feasibility study);

- Working draft;

- As-built (working) documentation (developed after completion of installation work).

Let's sum it up

Competent design of the drawing, in accordance with current standards, requires specific knowledge, since inaccuracies lead to errors during installation and, as a consequence, failure of the entire system.

Sample Project

In you will find qualified ventilation system designers who will help you correctly calculate and draw the project. We provide services in Moscow and the region, as well as neighboring regions, and practice remote cooperation. We are happy to answer all your questions; contact numbers are located on the “Contacts” page.

Pre-project proposals (PP)

At the stage of pre-project proposals, initial permitting documentation is drawn up and relevant documents are developed, which are approved by various authorities. Development of documentation Development of documentation at the stage of pre-project proposals includes the following items:

- general explanatory note (contains a brief description of the condition of the facility, the main technical and economic indicators and the results of calculations of the economic efficiency of design solutions, data on the volume of construction and installation work, etc.);

- calculation of loads (determination of thermal loads and main loads of the facility for connection to networks);

- schematic diagrams of engineering systems (principal solutions for engineering support - equipment with ventilation, air conditioning, heating systems, dispatch, automation and management of engineering systems);

- technological solutions (drawings, plans, specifications of equipment and materials with reference, etc.);

- engineering systems and equipment (inspection of the possibilities of installing engineering systems and equipment at the construction stage of the facility, changing the quality of engineering support during the reconstruction of the facility, replacing engineering support networks during the overhaul of the facility).

Working draft (DP)

Developed based on:

- building plans;

- thermal characteristics of building structures;

- technological (detailed with specification) task.

At the detailed design stage:

- heat and moisture emissions are calculated and, on its basis, air exchange and air conditioning are calculated for each room that provides the required parameters;

- equipment is selected (with all its characteristics determined);

- pressure losses in the network are determined;

- the type and schematic diagram of the system are finally selected and its characteristics, the number of air distributors, etc. are determined;

- Plans are drawn showing the location of equipment and the layout of air duct and pipeline networks.

Further:

- axonometric diagrams of climate systems are drawn;

- aerodynamic and hydraulic calculations are performed;

- the noise level is determined;

- the specification for equipment, materials, fittings, etc. is filled out. indicating the manufacturer and cost.

The working design of the ventilation system is approved by the coordinating organizations (SES, fire inspection, etc.) Based on this documentation, the equipment is ordered.

This concludes the design stage. Working drawings are transferred to the installation service at the site.

Regulatory framework for design

When planning ventilation systems, a number of domestic and foreign regulations should be taken into account. We will now briefly review the main ones.

Brief overview of domestic regulations

Forced ventilation involves the use of powerful ventilation equipment, so the design is determined taking into account the reserved capacity in terms of power supply.

Ventilation is regulated in conjunction with heating systems by SNiP 41-01-2003. This becomes possible due to the extremely significant influence on the heat balance of a capital construction project, both under construction and at the reconstruction stage.

Expensive and efficient equipment can pay for itself in just three years, but it all depends on air flow and the quality of the ventilation system

For constructed facilities, the design of ventilation systems involves a large number of technical solutions.

But this is only possible if plans for all systems are drawn up, including heating, construction and power supply. In this case, it is possible to make adjustments to documents being developed in parallel.

Owners of private houses who have installed ventilation in cellars without drawing up a project often complain about the insufficient efficiency of the system and its incorrect operation.

The design of the ventilation system must be carried out taking into account regulations.

The list of mandatory building codes and regulations includes the following documents:

- “Heating, ventilation and air conditioning” - SNiP 41-01-2003 >;

- “Construction climatology” - SNiP 23-01-99 >;

- “Protection from noise” - SNiP 23-03-2003 >;

- “Public structures and buildings” - SNiP 2.08.02-89 >;

- “Fire safety” - SNiP 21-01-97 >;

- “Single-apartment residential houses” - SNiP 02/31/2001 >;

- “Industrial buildings” - SNiP 31-03-2001 >;

- “Residential multi-apartment buildings” - SNiP 01/31/2003 >;

- “Public buildings” - SNiP 05/31/2003 >;

- “Warehouse buildings” - SNiP 31-04-2001 >;

- “Sanitary and epidemiological requirements” - SanPiN 2.1.2.1002-00 .

You should also take into account some state standards.

Among which:

- “Noise” – GOST 12.1.003-83 >;

- “General sanitary and hygienic requirements for the air of the working area” - GOST 12.1.005-88 >;

- “Air equipment” - GOST 24751-81 >;

- “Residential and public buildings” - GOST 30494-96 .

When developing a project, territorial acts can also be taken into account, for example, for the capital it will be the Government Decree and the Moscow Urban Planning Code, Moscow City Building Codes.

The ventilation project for a private house with gas heating includes mandatory requirements for the placement of a window, an exhaust ventilation duct, the height of the room, and an opening under the interior door.

The development of a ventilation system project can be carried out not only according to Russian regulatory documents. As an alternative, foreign standards regulating air quality in a building are also suitable.

Design according to foreign standards

In January 2003, the European Directive on energy efficiency in premises 2002/91/EC came into force. The legislation applies to the countries of the European Union. An action plan adopted in 2006 aims to improve energy efficiency in the construction sector.

To implement the requirements in practice, the following standards have been developed:

- Calculation of energy consumption for heating, as well as space cooling and other energy characteristics are provided for in EN ISO 13790 .

- Reference values for the microclimatic conditions of buildings for the design and assessment of energy efficiency, including thermal comfort, air quality, acoustics and lighting.

- Technical requirements for the ventilation system specified in the EN 13779 .

- Description of methods for calculating energy losses in ventilation and infiltration systems - EN 15241 .

- indoor air flow velocity EN 15242 .

Energy consumption for the ventilation system is determined according to the EN 13790 ; the main characteristics of the premises are considered, taking into account the internal environment - the level of infiltration and the ventilation rate.

Air flow calculations for hybrid, mechanical and passive ventilation are described in the EN 15242 .

The standard adopted for the calculation of losses in the ventilation system and infiltration (EN 15241) takes into account the characteristics of the external environment, building design, global energy consumption, and is closely related to EN ISO 13790, which describes a scheme for calculating energy consumption for cooling or heating of buildings

Specific requirements and rules for the design of ventilation systems are specified in the EN 13799 , the document also includes design guidance. Its applications apply to mechanical exhaust and supply ventilation systems, but the document is not intended for residential premises.

For private houses and apartments, the standard CEN/TR 14788 , which provides typical ranges of values that are advisory in nature and are used only if other parameters are not available.

Using calculations of the ventilation system, you can minimize the noise from ventilation equipment, as well as get rid of drafts, by ensuring acceptable air speed inside the building

The use of foreign experience in design is natural, since in this case more stringent requirements for quality of life are taken into account.

TCP and feasibility study in design

Taking into account all the requirements for the ventilation system, that is, finding the optimal design solution, is the most qualified and responsible part of the work. This is a matter for the most experienced designers. It should be noted that in any case, not one fundamental decision is being prepared, but several (2-3). The principle diagram of ventilation for all solutions is usually the same, but there are differences in the nuances.

At this stage, a Technical and Commercial Proposal is written to the Client with the main indicators of design solutions, the approximate composition of equipment for the designed ventilation system, and preliminary calculations. For the selected option, or simply for the option that is most interesting to the Customer, a Feasibility Study is written.

Feasibility study of the ventilation project

A feasibility study is a document that does not yet contain an exact calculation of the designed ventilation system, but has already written down:

- Schematic diagram of ventilation;

- Key performance characteristics;

- What kind of ventilation equipment is expected to be installed?

- Where is the equipment supposed to be located?

- How much will such a ventilation system cost?

This is where the difficult part of the designer’s work ends, because after the approval of the feasibility study by the Customer, almost only calculation work remains, such as the exact selection of ventilation equipment and connection to the building plan, etc. This is already a working project - the logical conclusion of ventilation design.

Selecting the type of ventilation system

In addition to carefully calculating the parameters of the ventilation complex, it is necessary to pay attention to the selection of its type. To do this, pay attention to the following features:

- air pressure from outside;

- need for inflow heating in winter;

- the required power of this heating;

- total demand for air intake and removal.

In turn, these parameters are selected according to the size, intended purpose, location, and workload of the premises served. The natural type of ventilation is simple, which attracts people in most cases. It can be created without the use of special equipment, so it is not initially damaged. Even if the electricity is turned off, the system will freshen the air in rooms or work areas properly. But at the same time, its productivity is limited, and its dependence on external conditions is too great.

The apparent disadvantages of a mechanical ventilation system are not too significant for designers, if only they approach the matter seriously. Professional selection of key components minimizes the risk of breakdown. And the number of options and flexible settings only have a positive effect on the microclimate of the room. Having figured out the natural or artificial method of work, you next need to make a choice of what kind of ventilation will be:

- only ensure the supply of air from outside;

- only throw polluted air outside;

- combine these two tasks.

There is no need to rush when making such a decision. It is necessary to analyze a number of factors: how the room is laid out, how many people use it, what the danger of harmful substances is, how large their intake is, and so on. Both supply and combined ventilation systems in Russia can operate normally only if there is an air preparation complex. The fact is that its temperature, humidity, chemical composition and other parameters when directly collecting air outside are not always ideal. When all these parameters have been determined, one more decision needs to be made - how exactly the ventilation system will be controlled.

If there are no special wishes, and you just need to “make a good microclimate,” you need to settle on a proven option - the supply and exhaust configuration. She will definitely cope with all the tasks assigned. An additional advantage is that the occurrence of pressure differences between the street and the house, and between individual parts of the building, is completely eliminated. But complex treatment systems need to be installed only at production and energy facilities. In residential buildings, unless the environmental situation is close to catastrophic, you can do without them.

Ventilation in an apartment building

Ventilation problems in apartment buildings, especially on the top floors, are quite common. The reason for the problems lies in the fact that to ensure normal circulation in the apartment, air must pass through the ventilation duct at least 2 meters vertically. On the top floor, this condition is problematic, since the attic space acts as an obstacle. Ventilation can be brought outside using three different methods.

- The first is ventilation ducts, in the form of a pipe head, directly leading to the roof. Houses were built in this way until the beginning of the twentieth century, but the increased number of floors in buildings gradually pushed this method aside.

- With the second method, the ventilation, upon reaching the attic, was covered using horizontal sealed boxes connected to a shaft that went outside over the roof.

- With the third method, the most modern, ventilation first enters the attic, which plays the role of an intermediate ventilation chamber. After which the air enters the outside, passing through one common ventilation shaft.

We will not consider the first option, since it is not currently used - we will focus on the second and third methods.

In the second option, the following happens: air from all floors rises up through the channels, to the attic level, falling into a horizontal connected box arranged in the attic room. During this, the air flow hits the cover of the horizontal ventilation duct. The air flow deviates slightly towards the ventilation shaft, but if the internal cross-section of the horizontal attic duct is insufficient, an area of increased pressure appears in the duct, due to which the air seeks an outlet through any nearby opening, for example, a ventilation shaft and an upper floor duct.

If the cross-section of the box is sufficient, but the cover is mounted very low, then the same process occurs - reverse draft - the air flow does not have time to deviate towards the ventilation shaft in time, which entails a blow. The ventilation of the upper floor is “pressed” by the reflected air flow, which is why odors from the lower floors fall precisely into this room. To get rid of this, you can resort to two methods - global and local.

The global method involves increasing the cross-section of the attic horizontal connection box by changing its height by about 2-3 times, followed by installing some devices inside the box, called “cuts”. Keep in mind that all this work must be performed by experienced specialists. In addition, remember that it is not recommended to increase the cross-section of the duct in cases where exactly the same ducts are attached to the ventilation shaft on the reverse side.

Main design stages

It is very important for developers to know this point in order to better control the execution of their plans. At each stage of project preparation, the assistance of experienced specialists is almost inevitably required. To select them, you need to look at the level of qualifications, check the presence of state certificates and other evidence of the performer’s literacy. The contractor must begin by performing calculations that will show the required air exchange parameters in all parts of the facility. Before this moment, selecting the main components and thinking through the circuits makes no sense.

Having determined the key characteristics of future ventilation, designers roughly divide it into parts. This move helps to ensure the highest functionality and achieve safety in the system. Separate fire-fighting apparatus can be installed in individual sectors. Additionally, when creating schemes, it is taken into account what dangerous situations may arise. At this stage, designers must consider how to avoid the penetration of polluted air from one part of the house or industrial building to another.

Only then do they begin to select technical means. Their characteristics are analyzed taking into account the technical specifications and the previously identified specifics of the object and the conditions of its use. Next, it’s time to generate three-dimensional models using modern software. After making sure that everything is done correctly, the model is converted into a flat diagram. In this form, it becomes part of the documentation package submitted for verification and registration with government agencies.

Video description

For some more thoughts on natural ventilation, watch the video:

Some models of recuperators are equipped with electronic control Source stroyres.com

Traditionally, recuperators require heating the air to a given temperature due to the fact that their efficiency is on average about 80%. Is it a lot or a little? Let's imagine the situation. A small house with a living area of 110-120 square meters is approximately 300 cubic meters of air. To maintain a comfortable, stable temperature with normal air exchange, approximately 4.5 kW of thermal energy is required, which must additionally be generated by the heating system. If we are dealing with a recuperator, then it will take 80% of this energy from the outgoing air flow, transferring it to the incoming air flow, the remaining 20% will be removed from the heating element directly in the installation.

This is an effective method of ventilating rooms; the operation of the system does not depend on various natural factors. But the system itself is quite complex, so it must be developed by appropriate specialists. It is important to develop a competent layout of all highways, diameter and length, and select all elements. Periodic maintenance is required, but this allows us to fully guarantee favorable and comfortable living conditions.

Air distribution

Ventilation must not easily supply a certain amount of air inside. Its goal is to deliver this air directly to where it is needed. When planning the distribution of air masses, the following indicators are taken into account:

- daily regimen of their use;

- annual cycle of use;

- heat supply;

- accumulation of moisture and unnecessary components.

Any room where people are permanently located deserves fresh air. But if the building is used for public needs or administrative tasks, approximately half of it can be directed to adjacent rooms and corridors. Where there is an increased concentration of moisture or a lot of heat is generated, it is necessary to ventilate areas of water condensation on the enclosing elements. It is unacceptable to move air masses from areas with increased pollution to places with a less polluted atmosphere. Temperature, speed and direction of air movement should not contribute to the appearance of a foggy effect or water condensation.

Why do you need a competent project?

A competent project is an opportunity to eliminate errors during the construction process, an opportunity to save considerable money through the use of modern technologies and materials, as well as a guarantee of optimal indoor air parameters for life and work. Therefore, designing a ventilation system is a very responsible and important task, which it is advisable to entrust to professionals from design organizations. This will allow you to count on receiving a high-quality result, in the form of a working system that does not cause hassle or problems.

Problems solved during design

When designing ventilation in the premises of a country house, cottage or any other facility, the company’s specialists solve the following main tasks:

- First of all, air exchange is calculated for rooms in which an air ventilation system is provided.

- The second task of designing a ventilation system is to carry out an aerodynamic calculation, as a result of which the total air flow is determined, the cross-sectional dimensions of the air ducts are selected according to the selection criteria, and, based on this, the pressure loss in the air duct system is calculated.

- The third design task is to carry out an acoustic calculation - calculating the sound pressure at the outlet of the air distribution device.

- Based on aerodynamic calculations, a detailed and final selection of ventilation equipment is also made, the locations of ventilation units and air duct routes are determined.

This is what the designed building ventilation system looks like:

Low noise and vibration

The ventilation system obtained as a result of these calculations is checked for compliance with the requirements of regulatory and technical documentation for the maximum values of noise and vibration. If the requirements are not met, measures are taken to reduce them to the required value.

Climate control and energy saving

The ventilation created according to our projects not only fulfills the task of ensuring a given air exchange in the premises, but also allows for climate control in the building, and also takes into account the operation of heating and air conditioning systems. The ability to integrate ventilation with these climate systems, as well as with the electrical supply system, laid down at the design stage, can significantly reduce the energy consumption of the entire building.

Integration

In the process of designing ventilation, our specialists strive for its correct integration with other engineering systems to ensure coordinated operation of the entire complex of climate and other engineering systems. The designed system can operate under the control of the Smart Home system. As a result, you get a modern controlled ventilation system with climate control function.

The video below shows an example of a preliminary design of a supply and exhaust ventilation system, or rather, a climate system in a private cottage, including:

- climate control functions,

- ventilation and heating functions using trench convectors,

- elements for integration with the heating and cooling system,

- the video shows the location of the main engineering equipment, air duct routes and other utilities on the ground and 1st floors of the cottage, as well as the installation location of the Swegon Gold supply and exhaust ventilation unit.

Promising technologies

This motto - “We work with technologies that will become standards in the future” - is not an empty phrase for us. During the design process, our company offers customers only modern technological solutions that will be relevant throughout the entire service life of the ventilation system. We pay special attention to the use of energy-saving technologies. For 90% of the developed facilities, our company used energy-efficient ventilation units for supply and exhaust ventilation.

Ergonomics

The ventilation systems created by our company are very ergonomic - during design, ventilation control devices are located in easily accessible places, which makes it easy to control the indoor climate.

Aesthetics

In addition to meeting ergonomic requirements, when designing ventilation systems, our specialists also fulfill the aesthetic requirements of designers and architects so that diffusers and other final devices of the ventilation system fit seamlessly into the design of any room in your house, cottage, apartment or office.

During the design process, the personal wishes of the customer are necessarily taken into account.

What do experts recommend?

When installing ventilation in a house, there are many subtleties that it is advisable to take into account during design. Often, when work is carried out independently, the system does not work efficiently.

To avoid getting into this situation, experts recommend:

- entrust all calculations to professionals;

- select ready-made installations based on the calculations received - in many cases you can install them yourself;

- ventilation shafts in kitchens and bathrooms are always installed;

- in those rooms where there are heating stoves or fireplaces, ventilation shafts may not be installed;

- equipment that is placed in an unheated room, in the attic or outdoors, needs good insulation;

- It is recommended to use systems with a recuperator - this will reduce electricity costs and make the cottage warmer in the cold season.

Ventilation is an important condition for comfort in a country house. To obtain the most acceptable result, it is better to contact specialists who will carry out the necessary calculations and help you choose the right scheme. And don’t let it bother you that installing ventilation is an additional cost. Practice shows that houses with such systems become even more comfortable to live in.

Did you find this article helpful? Please share it on social networks: Don't forget to bookmark the Nedvio website. We talk about construction, renovation, and country real estate in an interesting, useful and understandable way.

Design cost

| Project Section | Project area, m2 | |||||

| 100-400 | 400-700 | 700-1200 | 1200-3000 | 3000-5000 | 5000-15000 | |

| Design cost, rub./m2 | ||||||

| Ventilation | from 85 | from 80 | from 75 | from 70 | from 65 | Discussed |

| Conditioning | from 85 | from 80 | from 75 | from 70 | from 65 | Discussed |

| Heating | from 85 | from 80 | from 75 | from 70 | from 65 | Discussed |

| Water supply and sewerage | from 65 | from 60 | from 55 | from 50 | from 45 | Discussed |

| Smoke removal | from 45 | from 40 | from 40 | from 35 | from 35 | Discussed |

* This table shows average prices for the design of ventilation systems. The final cost of design depends on many factors, some of which are listed below:

- Purpose of the designed premises (individual housing, office premises, industrial premises, etc.).

- Availability/absence of a design project, the need to work with designers, architects, management company, etc.

- Complexity of the designed system (simple supply and exhaust system, supply and exhaust system with recovery, cooling, humidification, etc.).

- The time frame allocated for the design of a particular object.

Sources

- https://sovet-ingenera.com/vent/raschety/chto-nuzhno-dlya-proektirovaniya-ventilyatsii.html

- https://hvac-life.ru/ventilyaciya/proektirovanie-ventilyacii/

- https://www.mosng.ru/proektirovanie-ventiljacii/

- https://www.air-ventilation.ru/proektirovanie-sistem-ventilyatsii.htm

- https://stroy-podskazka.ru/ventilyaciya/proektirovanie/

- https://ultrasale.ru/services/proektirovanie-sistem-ventilyacii.html

- https://www.tria-komm.ru/airing/projection/

[collapse]

Benefits of working with

Advantages of working with air duct design:

- design is carried out by professionals with extensive experience in drawing up this type of documentation;

- drawing up the document within a working week, the exact deadline is set at the stage of signing the contract, taking into account the complexity of the project;

- free modification of the design in case of changes in ventilation operating conditions;

- opportunity to get acquainted with completed projects;

- availability of necessary documents and certificates proving the legal implementation of activities;

- low prices;

- regular promotions and discounts for regular customers.

You can find out more details about the design by phone. Contacts are listed on the page. You can order a project directly on the website. Leave a request and our employee will contact you shortly.