A beautiful and durable house is the dream of any owner. Nowadays, any residential property can be made attractive in appearance thanks to its cladding. Brick is a reliable facing material. Gone are the days when people covered the facades of their houses with white or red brick. Now there are several types of this material, varying in color. On the one hand, this is good, since you can select products of the desired shade and texture and clad your house with them, but on the other hand, an inexperienced owner can get confused in the variety of materials offered by the market.

Although there are technical specifications for each type of brick, which describe its characteristics in detail, not every person who wants to buy facing material will study these documents for a long time and painstakingly. What are the pros and cons of types of bricks and how to choose the best material to clad your house with?

The difference between ordinary and facing bricks

ordinary bricks and facing bricks on the market , they differ greatly in price, but the scope of application of the products is radically different. Ordinary is used only for backfilling walls, since it necessarily requires subsequent finishing. It is not suitable for cladding facades for the following reasons:

- there are defects on the surface - chips, cracks, potholes, inclusions;

- low frost resistance - withstands 25-50 freeze-thaw cycles;

- have a high water absorption coefficient;

- unstable geometric dimensions will not allow laying out a perfectly even row;

- uneven coloring.

A wall made of this material requires plastering or facing with façade bricks. The facing brick has an ideal geometric shape; standards do not allow deviations from the standard by more than 3-4 mm. Most manufacturers try to produce material whose deviations do not exceed 1-2 mm. Among other differences between facing bricks and ordinary bricks:

- flat smooth surface;

- high frost resistance - from 50 to 300 cycles;

- high strength - facing bricks of grades M150-M300 are used for work; for clinker this indicator reaches values of M500-M1000;

- low water absorption coefficient;

- uniform color throughout the mass.

For facing bricks, the main criteria are external characteristics, frost resistance and strength. The façade should not absorb water during rain or be destroyed by minor mechanical impacts. Criteria such as heat capacity are not important when choosing facing bricks. If it is necessary to improve the thermal performance of a building, it is better to install a layer of thermal insulation between the façade and cladding materials. Despite this, manufacturers produce solid and hollow facing bricks, which have all the necessary characteristics for building a beautiful and reliable facade.

SIZES AND TYPES OF BRICKS

Unlike ordinary (ordinary) brick, facing brick has a smooth, neat surface with high aesthetic characteristics. The main task performed by facing bricks is, of course, the beautiful external and internal appearance of the building, coupled with the protection of structures from atmospheric influences. Modern industry makes it possible to realize the broadest possibilities when decorating facades using facing bricks. The variety of not only the colors of the products, but also a decent selection of shapes and textures of facing bricks is very, very pleasing.

In addition to finishing the facades (walls, plinths, etc.) of buildings, such bricks can be used in the construction of garden and park fencing, or parts thereof, for example, a fence (individual posts, columns), fencing balconies. Another option is the design of gazebos, summer kitchens, arches, and any architectural forms conceived by the customer or designer.

Each facing brick has standard, unified dimensions, just like any other structural building material. At the same time, at least two sides - the poke and the spoon - must be decorated with a decorative (front) surface. Today, the building materials market offers a large number of varieties of facade (facing, facing) bricks.

Fireclay brick parameters

For the construction of stoves and fireplaces in the area of contact with fire, special fire-resistant bricks are used.

In its production, a special type of clay is used - fireclay. That’s why such a brick is also called fireclay. The production process is the same as for building red bricks - molding, drying, firing in a kiln. But, due to the special properties of fireclay, the resulting building material can easily withstand prolonged contact with open fire. There are two brands of general-purpose refractory bricks used in everyday life: ShA and ShB. ShA can withstand temperatures up to 1690°C, ShB - up to 1650°C, all other parameters are identical. Therefore, their scope of application is the same - this is the molding of fireboxes for fireplaces and stoves. Some types of fire bricks: sizes may vary, but they are all standardized

Encode the size of the refractory brick in the number that appears after the abbreviation:

- ШБ-5, ША 5 - 230*114*65 mm;

- ShB-6, ShA 6, ShA 14 - 230*114*40 mm (flying blade);

- ШБ-8, ША 8 - 250*125*65 mm;

- ШБ-9, ША 9 - 300*150-65 mm;

Most often they use ShA 8 or ShB 8. They are the same in length and thickness as the ceramic red brick from which the rest of the stove is made. There is also a wedge-shaped refractory brick - for forming firebox arches and smooth curves in the horizontal plane.

There are two types of wedge refractory bricks:

- end - for forming curves in the horizontal plane ША, ШБ 22 - 230 * 114 * 65/55 mm;

- ША, ШБ 23 - 230*114*65/45 mm;

- ША, ШБ 48 - 250*124*65/45 mm;

Types of wedge fireclay bricks: edge and end wedge

- ША, ШБ 44 - 230*114*65/55 mm;

These are not all the sizes and types of fireclay bricks. You will find more in GOST 8691-73.

Features of the sizes of facing bricks

In Russia, a unified standard for brick production appeared in 1927. It concerns not only the size, but also its other parameters and remains unchanged all this time. The application of the standard applies to both ordinary and facing products. They can change types and be produced using different technologies, but their sizes will always comply with established standards:

.

- single has dimensions 250 x 120 x 65 mm;

- one-and-a-half or thickened has dimensions 250 x 120 x 88 mm;

- double will always correspond to the dimensions 250 x 120 x 138 mm.

To order, manufacturers can produce bricks that do not correspond to these data. It is used for cladding old buildings, but even non-standard forms are also specified in GOST. Of the non-standard sizes, the most widely used size is 0.7 NF, with sides 250x85x65 mm. Its use helps reduce the load on the foundation when restoring the facades of houses built a long time ago.

Hyper-pressed brick, often used for cladding, made without firing, solid, smooth, together with standard dimensions 250x120x65, can be like this:

- 250x60x65 mm;

- 250x90x65 mm.

The handmade ceramic brick product has dimensions of 188*88*63 and weighs 6 kg.

Laying a brick facade. Practical advice

“Should I or should I not make a ventilation gap when facing walls with brick?” - This is perhaps one of the main questions that arise before starting work.

The answer to this question is given by the vapor permeability indicator of materials. A wall lined with brick is multi-layered, and the vapor permeability of the wall layers should increase from the inside out. The brick facade has a fairly low vapor permeability. And if we clad a house built of wood or aerated concrete, whose vapor permeability is higher, with brick, then the presence of a ventilation gap between the layers of the wall is mandatory. If the main load-bearing material of the wall is a ceramic block, which has the same vapor permeability as brick, then a ventilation gap is not necessary.

“How to calculate the required amount of brick?”

ContinentUser FORUMHOUSE

Everything is as simple as day: the size of a single brick is 250x120x65, it is also called conventional. consumption 51pcs/sq.m. taking into account mortar joints. (for masonry half a brick or 120 mm thick). If you use one-and-a-half bricks 250x120x88, then the consumption is 37 pcs./sq.m. If the brick is NF format (240x115x71) then you need 48 pcs/sq.m. If hand molded in WFD65 format (215x102x65) then 58 pcs/sq.m. Calculate the area of the facade of the house, throw out the area of windows and doors, add 10% for defects, damage and trimmings and move on.

“What cladding options are there?”

There are quite a lot of ways to lay bricks, here are the most common:

- Stepped cladding. All bricks are laid only with the long side, each subsequent row is shifted relative to the previous one by half or a quarter of the brick;

- Chain masonry. With this method, the spoon brick alternates with the bond brick.

- Savage. A rather complex type of masonry in which there is a deliberate asymmetry in the alternation of spoons and pokes. Despite the apparent chaos, this installation has a fairly rigid system.

- Bavarian masonry. Its essence is not in a special alternation of spoons and pokes, but in the distribution of shades of brick, when several tones neighboring in the palette are taken and laid with a certain alternation. This creates a special style. Masonry, which appeared as a necessity, is today a fairly cool design technique.

“What is the order of work?”

Ilya Efremov

When building walls made of ceramic blocks lined with bricks, it is first recommended to lay the bricks, starting from the corners. The first row is laid for waterproofing. The row must be laid out along the entire perimeter of the building, filling the seams completely. It is recommended to moisten the brick with water before laying it so that it does not actively absorb water from the mortar.

Blocks, like bricks, are also laid starting from the corners of the building, at a distance of 1 cm from the brick cladding. Each subsequent row of blocks is laid offset. Every two rows of blocks, the main wall and cladding are tied together using basalt, galvanized mesh or flexible ties.

It is recommended to lay no more than 2 rows of blocks or 6 rows of bricks per shift.

During work, you should constantly check the masonry using levels and plumb lines - the more often this is done, the better the result will be.

In the case of cladding an already built house from aerated concrete or wood, the most suitable material for connecting a brick facade with a load-bearing wall is stainless steel plates or flexible basalt-plastic connections.

Why is the size of the bricks standard?

.

It has been verified experimentally and confirmed by construction practice that the created wall structure will receive the necessary strength thanks to the standard proportions of the product. When performing masonry bonding, where bricks alternate longitudinally and transversely relative to the axis of the masonry to evenly distribute the load and resist cracking, the dimensions 250 x 120 x 65 mm ideally perform their functions. The proportional size allows you to lay out a cube.

A brick having such a length and width helps to carry out work with relatively less physical energy. The weight of the brick, which ranges from 3.2 to 5 kg, allows the mason to grasp it with one hand, lift it and hold it, which is important in this difficult work. The standard size allows you to use simple mathematical calculations to find out the required number of facing bricks per square or cubic meter.

In general, they can be divided into the following types:

- Facing and ceramic bricks can be solid or have voids to improve the thermal properties of the masonry. The presence or absence of voids, of course, will affect the weight of the facing brick and the total load on the foundation of the building.

- Clinker bricks are produced by processing special types of clays at elevated temperatures. Due to its very dense structure, the product absorbs a minimal amount of water and has excellent frost resistance characteristics. Such a surface will last a very long time without additional repairs or processing. However, due to the high density of clinker bricks, it has an increased thermal conductivity coefficient. The color and texture palettes are also very diverse. For example, the assortment includes the so-called “long brick” with dimensions of 528x108x37 mm. When finished, the cladding looks very original and fresh. Hyperpressed facing bricks are produced using a non-firing method, pressing the mass under very high pressure. It does not contain clay or sand: crushed limestone with the addition of cement as a binder and pigment are used.

- The brick produces an incredibly expressive, jagged chip “like a stone,” thereby increasing the possibilities for creating designer masterpieces. Outwardly, it is very reminiscent of natural stone, while being easy to machine, maintaining its properties. The material also meets high construction requirements: wear-resistant, durable, frost-resistant, and has an ideal geometry. Among the disadvantages, it is worth noting the low thermal efficiency of such a facade (due to the high density of the brick). This problem can be solved by laying insulation with the appropriate parameters. Silicate brick as a facing material has lost its relevance today. On one side of the scale is the low price of a product with acceptable characteristics, on the other there are very controversial decorative qualities for the exterior decoration of buildings. In former times, in conditions of total shortage and lack of normal housing, sand-lime brick was widely used. Today, with such high requirements for the quality of construction products, the use of this type of brick in the construction of buildings is rare.

- The main demand is for standard brick sizes: single (250*120*65) and one-and-a-half (250*120*88), less often double sizes (250*120*138) are used. Some manufacturers offer other options.

Classification of facing bricks

The gradation of façade cladding is determined by its manufacturing technology.

There are four categories of facing bricks:

- Ceramic.

- Clinker.

- Hyper-pressed (concrete).

- Silicate.

Brick in each of the listed categories is available in two versions: solid and hollow. The weight of hollow core brick is on average 25-35% less, and its resistance to heat loss is approximately 10-15% higher.

Ceramic facing brick

It is produced by firing a raw material mixture consisting of red fusible clay, organic and mineral additives that regulate plasticity. Coal dust, slag, fireclay, sawdust, ash and quartz sand are used in this capacity. The initial mixture successively goes through the processes of molding, drying and firing. The main difference between facing ceramic bricks and ordinary ones is the careful preparation of the components before molding. Therefore, there are no foreign inclusions or cracks in it.

The material obtained at the exit from the firing chamber is resistant to moisture, high strength and good energy-saving qualities. The types and colors of ceramic facing bricks are varied.

On sale you can find not only ordinary, but also shaped material (for laying complex architectural elements). To expand the color range, manufacturers use mineral dyes (chromium oxide, finely ground iron or manganese ore), adding them to the composition of the feedstock.

Decorating the surface of ceramic bricks is done in several ways. In addition to the smooth matte and shiny surface, finishing options are available that give this material a resemblance to wild stone.

Clinker brick

The closest “relative” of ceramic brick. The main difference between them is the raw materials and firing temperature. Medium and refractory clays are used to produce clinker. Accordingly, they are fired at a higher temperature. The result is a very dense and durable facing brick with minimal water absorption. These qualities make it possible to use it not only in facade decoration, but also for cladding the base of the foundation, building fences and paving paths.

The thermal conductivity of clinker stone is higher than that of ceramic stone. This disadvantage is compensated by its high resistance to cracking under the influence of low temperatures.

The color palette and texture of clinker stone are extremely diverse, since each manufacturer offers customers its own collections. The size range of this cladding also cannot be called boring. In addition to the standard single version 250x120x65 mm, you can buy bricks of reduced thickness and height, as well as long clinker (528x108x37 mm).

Hyperpressed brick

Firing clay is an energy-intensive process and not very profitable. Therefore, many manufacturers are switching to pressed unfired bricks. Its basis is granite screenings, water and cement. At its core, it is super-dense concrete, which has been shaped into masonry bricks.

The main requirement for façade finishing is resistance to weathering. According to this indicator, hyper-pressed brick is perfect for finishing external walls.

In terms of strength and other quality characteristics, it is practically not inferior to clinker. Thanks to the texture of the surface (rock, torn stone) and the use of persistent dyes, this material looks excellent in masonry.

Finishing the facade with hyper-pressed brick looks elegant, solid and reliable

Sand-lime brick

Belongs to the category of non-firing materials. It differs from hyperpressed brick in its raw material composition. There is no cement in it. High mechanical strength is achieved here by hardening a mixture of silicate sand and slaked lime in an autoclave (high temperature and pressure).

Nowadays, silicate facade brick as a facing material is losing its former popularity. In the struggle for buyers, manufacturers have developed several color options for the silicate mixture. Unfortunately, they all look rather pale and cannot compete with the rich colors of ceramics and clinker.

This material behaves well in building cladding. Compared to clinker bricks, they absorb moisture more strongly, but at the same time, they can withstand repeated soaking, freezing and thawing better than ceramics.

Figured (shaped) brick

Today, no one is satisfied with the straight lines of the facade, so each type of facing brick is complemented by a wide range of shaped elements. Using them, you can lay out complex architectural elements without laborious hewing and cutting, dressing your house in a beautiful “stone lace”.

Advantages and disadvantages

Having decided to clad the house with ceramic bricks, the owner will do the right thing, because ceramics have a number of excellent qualities. This brick is very durable in its structure and tolerates mechanical stress well. It is resistant to ultraviolet radiation, and even the color of the southern facades lined with it does not fade in the sun. Facing bricks have good frost resistance and can withstand low temperatures. Manufacturers produce ceramic products with wavy and even shapes, with smooth and rough surfaces, which allows you to turn an ordinary house into a work of art. Another advantage of facing brick is low water absorption, thanks to it, moisture is not absorbed into the product, and water vapor freely leaves the room to the outside, that is, the walls of the building can “breathe” and do not become damp.

To prevent water from freezing on the facade in winter, you need to cover it with water repellents. But do not choose among them those that form a vapor-proof film on the surface of the cladding. It will block steam from reaching the surface, and as the temperature drops, the water underneath will begin to condense into liquid form. When the temperature drops below zero, the water will freeze, expand and destroy the lining. It turns out that ceramic bricks have only one drawback, the effect of which can be prevented in a timely manner by purchasing the right water repellent agent.

The difference between ceramic bricks by manufacturing method and type of molding

The production of ceramic bricks is divided into two main types according to the molding method. Brick of plastic type of molding and brick of semi-dry type of molding.

1. Plastic molded bricks . Plastic molding involves several processes and is performed from plastic clay masses with a moisture content of 15-21%. The main types of building bricks are produced by extrusion through profile molds of various screw presses. There are both vacuum installations and conventional ones. Solid stone is usually pressed on equipment without a vacuum, and hollow stones are pressed on vacuum installations and presses.

2. Semi-dry molded bricks . Semi-dry molded products are also made from clay using pressing and firing. But the main difference from the plastic method is that the raw materials are first brought to a certain humidity (about 8–14%). Then it is pressed in molds, and only then is it fired in rotary or tunnel kilns. The low humidity of the workpieces allows the finished products to maintain the correct shape and clear surface.

High-quality types of bricks for building a house are mainly obtained by plastic molding. They have smooth edges and smooth surfaces.

Strength and frost resistance

If we talk exclusively about functional indicators, then two parameters are critical for cladding - mechanical strength and resistance to low temperatures:

- The strength of the facing brick primarily provides the wall with resistance to mechanical stress, and also reduces the risk of cracks and deformation of the masonry under its own weight. The strength grade is indicated using an index in which the number shows the permissible load in kilograms per square centimeter of surface.

- For example, if we mention double sand-lime brick M 150, this means that its strength is 150 kg/cm2.

- The frost resistance of a brick is determined by the number of freezing-thaw cycles that the brick can withstand without signs of destruction, and is designated by the index F (Frost). Thus, F50 brick can withstand at least 50 such cycles without losing its characteristics.

Note! Frost resistance of finishing is important not so much in cold latitudes as in the temperate climate zone. It is in the middle zone that winter is characterized by multiple changes in temperature, which leads to the rapid failure of cladding with insufficient frost resistance.

Technological features

Lego blocks are not much different in characteristics from their regular ceramic counterpart:

- frost resistance – 35-40 cycles;

- strength grade – M 150;

- density – 1550 kg/m3.

But there are also differences from ceramic bricks. Among them:

- Less water absorption. For Lego blocks the figure is 5.5%, and for ceramic building materials - 14%.

- Light weight. Due to the holes, blocks with Lego clutches weigh about 3 kg. Sand-lime or ceramic bricks weigh more.

- Higher seismic resistance. According to this indicator, Lego brick is 1.5 times superior to ceramic brick.

In most cases, the standard dimensions of a one-and-a-half Lego brick are 250x125x90, and a single one - 250x125x65.

How much does facing brick cost?

Before you begin cladding the house, you need to calculate the required amount of material and the approximate cost. Thus, the price of ceramic bricks ranges from 9 to 44 rubles per piece. Material with a textured surface or glaze will cost more. The price of sand-lime brick varies from 8.5 to 22 rubles per piece.

Hyperpressed bricks, depending on color and texture, cost from 8 to 38 rubles per piece. The most affordable of all types of materials is sand-lime brick. It has good physical characteristics and an attractive appearance. Purchasing bricks should not be difficult. Now many construction stores sell a wide range of facing bricks. If desired, you can place an order from the manufacturer with delivery to your destination. The only thing is that you need to correctly calculate the amount of material and, best of all, with a reserve so that you don’t have to buy additional bricks.

Artificial stones

Artificial stones are divided into fired and unfired stones.

Burnt stones

Fired stones are mainly wall bricks, light bricks, facing bricks and clinker. They differ in their production at different firing temperatures.

Wall bricks

Manufacturing To make wall bricks, you need a mixture of clay and loam. Since both of these materials are in most cases not available in the quantity or proportions required, they must be prepared. The mixture is kneaded, kneaded, made plastic in the presence of water vapor and pressed using a belt press. Depending on the type of brick desired, the inserts that are removed will create different holes or gaps. The molded strip is cut with wire into the desired raw bricks. Depending on the water content, raw bricks must be molded to larger sizes than required, since they shrink during subsequent drying and firing. In the drying room, the water in the raw materials is slowly evaporated at a temperature of 100 ° C, so that shrinkage cracks do not form in them. At the final stage, the raw materials are fired in tunnel kilns at temperatures from 900 to 1200 ° C, so that the particles of the substance are sintered together using the chemical transformation of silicates. The color of a brick is determined by the metal compounds contained in the raw materials. The reddish color of brick is formed, for example, due to iron oxides. Depending on the amount and composition of iron oxides, as well as on the firing temperature, colors from yellow to red and then dark brown are obtained. For face bricks, the spoons are ground. The fired stones are sorted, palletized and packaged ready for sale (Fig. 1).

Rice. 1. Making wall bricks

Properties The properties of wall bricks are standardized according to DIN 105.

Compressive Strength Wall bricks are supplied in 6 compressive strength classes. To distinguish them, the colors on the packaging given in the table are used. 1.

| Table 1. Compressive strength and color designation for wall bricks | |||

| Compressive strength class | Compressive strength, N/mm2 | Color designation | |

| average value | Smallest value | ||

| 4 | 5,0 | 4,0 | blue |

| 6 | 7,5 | 6,0 | red |

| 8 | 10,0 | 8,0 | black stamp |

| 12 | 15,0 | 12,0 | without designation |

| 20 | 25,0 | 20,0 | yellow |

| 28 | 35,0 | 28,0 | brown |

Density. Wall bricks have 6 density classes, which range from 1.2 to 2.2. In this case, the figures give the highest density value in its class in kg/dm3. Bricks are porous. Since air is a conductor of heat, air enclosed in pores and voids increases the heat-shielding qualities of bricks. Wall bricks can absorb heat, store it over a long period of time, and then release it slowly. The same thing happens with the moisture contained in the air. These qualities improve the indoor microclimate.

Capillarity. Porosity leads to capillarity, which means that stones gain moisture when exposed to water. Since water conducts heat better than air, the thermal conductivity of the material increases, and the thermal insulation ability decreases. Moisture at the edges of stones can increase and increase the moisture content of adjacent building materials. This leads to damage to building structures. When water freezes in the pores, it causes the outer layer of the stone to chip off.

Frost resistance. Wall bricks are not frost-resistant. Therefore, when used in external structures, they must be protected from frost if they are wet.

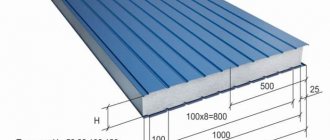

Dimensions, formats, hollowness

Dimensions. The dimensions of wall bricks are derived from the modular system of above-ground construction and correspond to the system given in Table. 2. Formats. Depending on the length, width and height, wall bricks are divided into thin format (DF), normal format (NF) and formats that are derivatives of the thin format (see Table 2). Emptiness. Based on their voidness, a distinction is made between solid brick and brick with voids (Fig. 2).

| Table 2. Dimensions and formats of wall bricks | ||||

| Short designation | Length, mm | Width, mm | Height, mm | Number of stones per 1 m height |

| DF | 240 | 115 | 62 | 16 |

| NF | 240 | 115 | 71 | 12 |

| 2 DF | 240 | 115 | 113 | 8 |

| 3 DF | 240 | 175 | 113 | 8 |

| 4 DF | 240 | 240 | 113 | 8 |

| 5 DF | 240 | 300 | 113 | 8 |

| 6 DF | 240 | 365 | 113 | 8 |

| 8DF | 240 | 240 | 238 | 4 |

| 10 DF | 240 | 300 | 238 | 4 |

| 12 DF | 240 | 365 | 238 | 4 |

| 15 DF | 365 | 300 | 238 | 4 |

| 18 DF | 365 | 365 | 238 | 4 |

| 16 DF | 490 | 240 | 238 | 4 |

| 20 DF | 490 | 300 | 238 | 4 |

Solid bricks (MZ) are solid stones without voids in thin, normal and 2DF formats. Solid bricks may have a hollow part perpendicular to the bed plane. However, it should not be more than 15% of the bed plane (see Fig. 2).

Rice. 2. Wall bricks

Hollow-core bricks (HLz) are supplied with a large percentage of voids, but not more than 50% of the bed plane. Depending on the shape and size, there are three different types of voids A, B and C. To designate a brick, the short sign is supplemented with the corresponding letters designating voids. Hollow-core bricks are supplied starting from the 2D format.

Seamless brick is a wall brick polished on the bed surfaces, which is laid with a seam 1 mm thick. A thin layer of mortar is applied to the bed either by dipping the brick into the mortar or by applying it with a roller to the bed plane (Fig. 3). Covering the butt joints with mortar is not required due to the jagged joint of the bricks. Wall stones are standardized to a height of 249 mm and are manufactured for any wall thickness up to 365 mm. They are supplied complete with additional, sliding and corner bricks. Fillable bricks with wall thicknesses of 175 mm and 240 mm are filled with mortar after laying and therefore provide sufficient noise protection.

Rice. 3. Laying walls made of polished bricks

Light brick

During production , easily combustible components, such as sawdust, are mixed into the raw materials for bricks. During firing, air pores are formed in the brick; such bricks are called porous or light bricks. Their special property is their low density, ranging from 0.6 to 1.0 kg/dm3. Therefore, the thermal insulation capacity of lightweight brick is higher than that of wall brick. It should be especially taken into account that light brick in the short designation differs from wall brick only in density class. In addition to the usual classes of compressive strength, lightweight bricks also come in strength class 2.

Designations of wall bricks (examples): Brick DIN 105 - MZ12 - 1.8 - NF Means that this is a solid brick, compressive strength class 12, density class 1.8 in NF format (l = 240 mm, b = 115 mm, h=71 mm) Brick DIN 105 - HlzA8 - 1.2 - 2DF This means that this is a hollow-core brick with perforation A and a minimum compressive strength of 8 N/mm2, a density of no more than 1.2 kg/dm3 in 2DF format (l= 240 mm, b=115 mm, h=113 mm)

Lightweight brick designation (example): Brick DIN 105 - HLzW6 - 0.7 - 10 DF (300) Means lightweight hollow-core brick W, compressive strength class 6, density class 0.7 in 10 DF format for a wall thickness of 30 cm (l = 238 mm, b = 300 mm, h = 238 mm)

Dimensions, formats and hollowness correspond to wall bricks. They are standardized according to DIN 105-2.

Lightweight multi-hollow brick W(HLzW) has a hollowness B and is considered particularly heat-insulating (Fig. 4). Such bricks are produced in formats starting from 2DF and especially often in large stone block formats starting from 8DF. They are not frost-resistant.

Rice. 4. Lightweight hollow-core brick W

Lightweight hollow-core facing brick (VHLz) is frost-resistant. These bricks are suitable for exterior walls and exterior structures. The outer surface of such stones can be structured. Wall slab lightweight bricks (HLzT) have different side lengths of 247, 297, 373 and 495 mm.

Lightweight long-hollow brick (LLz) and light long-hollow slab brick (LLp). Such bricks can be made with small embedded voids in the side zone or with large voids (Fig. 5).

Rice. 5. Lightweight hollow core brick

Facing brick

During manufacturing , it is fired at a higher temperature than wall bricks; in this case, a denser structure is obtained as an improved property. The stones almost do not absorb water and are frost-resistant. Dimensions, formats and hollowness correspond to wall bricks.

Designation of facing brick (example): Brick DIN 105 - VHLzB28 - 2.0 - 2 DF Means facing hollow-core brick with hollowness B, compressive strength class 28, density class 2.0 in 2 DF format

Cladding bricks (VMz) and hollow core bricks (VHLz) are supplied in DF, NF and 2DF formats. Additional facing brick is a brick half or divided in length into two parts with a width of 55 to 90 mm.

Clinker brick and ceramic clinker

During production it is fired at temperatures up to 1500 °C. In this case, the raw material particles are melted into a glazed mass with almost closed pores. Clinker, as a special property, has very low moisture absorption and is therefore frost-resistant. It has a density of over 1.2 kg/dm3 and compressive strength classes of 36, 48 and 60.

Dimensions, shapes and hollowness correspond to wall bricks. They are standardized by DIN 105, part 3 and part 4. A distinction is made between solid clinker (KMz) and ceramic clinker (CC) , as well as hollow-core clinker (KHLz) and ceramic hollow-core clinker (CC) . They are produced in DF, NF and 2DF formats. Clinker bricks can also be channel clinkers, clinkers for paving, facing works and clinker slabs of various shapes.

Clinker designation (example): Brick DIN 105 - KMz36 - 1.8 DF Means solid clinker, compressive strength class 36, density class 1.8 in DF format (l=240 mm, b=115 mm, h=52 mm)

Special brick

Fired wall stones are made into special bricks for specific purposes with different surfaces or with different structural and physical properties, such as noise protection. Burnt wall stones in the form of special bricks for special purposes can be supplied as connecting stones for doors and windows, as corner stones for sharp and obtuse corners of walls, as slope and rounding stones, for example for rounding window sills, for ceramic filling of ceilings, for chimneys in in the form of radial bricks. Channel shells for brick lintels are made in widths of 11.5 and 17.5 cm. This width allows you to install lintels for walls of any width.

Special ceramic stones are made for casings for blinds, as well as for placing roller shutters. For the installation of supporting parts of the floors on the walls there are L-shaped stones with or without additional thermal insulation; for beams and ring anchors for U-shaped elements they can also be with or without thermal insulation filling (Fig. 6).

Rice. 6. Special bricks for special purposes

Fired wall stones with different surfaces are available with smooth or rough surfaces, with surfaces for hand painting and painting, with or without sand coating. They are made in almost all colors. For noise protection, baked wall stones are made, for example, soundproofing bricks with a density of 1.6-2.2 kg/dm3, acoustic bricks with a large percentage of voids and filling, soundproofing bricks with a voidness percentage of up to 54% of the cross section. After laying, these bricks are filled with mortar in layers (Fig. 7).

Rice. 7. Installation of polished infill brick stones in the noise barrier wall

Ceramic stone products

Ceramic stoneware is made from clay, quartz sand and a small percentage of feldspar. After preparation, mixing and shaping, the material is fired at a temperature of approximately 1050 °C. The resulting products are porous and can absorb water by capillary action. Therefore, the surface receives a glaze during secondary firing. This glaze can be transparent or opaque, and can also be colored with metal oxides. The finished fired ceramic material is called a ceramic stone product. Ceramic stone products in the form of facing tiles have a porous surface on one side with high water absorption of more than 10% of the mass. As a result, their ability to adhere to the surface of another material is very high, but their strength and chemical resistance are lower. Wall tiles are mainly made from ceramic stones (Fig. 8).

According to DIN 18155, a distinction is made between white and ivory tiles, as well as majolica tiles. In addition, there are tiles with a plain glaze and colored glazed tiles. White and ivory tiles have a colorless or top (yellow) glaze. Majolica tiles have a colored top glaze with a shiny, matte or crystalline surface (Fig. 9).

Rice. 8. Wall tiles as ceramic stone products

Rice. 9. Majolica tiles

Ceramic stone products

Stone pottery consists of clay, quartz sand and feldspar. The ground, mixed and molded raw materials are fired to sintering at a temperature of approximately 1300°C for three days. Sprinkling table salt before firing gives stoneware a glazed surface. The surface becomes hard and resistant to abrasion. A fine-grained, very dense and heavy ceramic material that is resistant to chemical influences is obtained. Stone ceramic products have very low water absorption, no more than 3% by weight, and are therefore considered frost-resistant.

Stoneware is used for drainage pipes and shafts, for plumbing sinks for dirty water and chemical materials in laboratories, and for tiles and related molded elements (Fig. 10). Stoneware tiles come in glazed and unglazed varieties. They are mainly used as floor tiles.

Rice. 10. Ceramic stone sewer pipes

Sewage pipes are manufactured with nominal widths DN 100 - DN 1400 and lengths from 1.00 to 2.50 m. For drainage from houses, pipes with nominal widths DN 100 - DN 200 are mainly used. They are equipped with threshold seals installed at the factory (type L couplings ) so that tight and durable pipe connections can be ensured on site. When the end of the pipe is pushed into the coupling, the plastic thresholds or lips are pressed against the pipe and thus create a tight connection (see Fig. 10). For pipes starting from DN 200, the tightness of the sewer pipeline is achieved by sealing elements made of synthetic materials, which sit both at the end of the pipe and in the coupling.

Fire-clay

Fireclay is made from clay mixed with fireclay. Chamotte is pre-fired clay, which in ground form is mixed with clay in order to make it thinner. The fired stones then become fire-resistant up to a temperature of about 1700 °C. They are suitable for the internal lining of furnaces and for the construction of chimneys. The shard of the material is porous, so finishing products made from it requires a thick white or colored layer of porcelain glaze. With this finish, fire clay can be used for wash trays and tap sinks (Figure 11).

Rice. 11. Washing trays made of refractory clay

Unfired stones

As raw materials for unfired stones, aggregate, binder and water are mixed to mix the mixture. Hardening of the molded blanks occurs in air when they are stored or when the corresponding blanks are processed in an autoclave at high temperature under controlled steam pressure. After this, the stones can be stacked on pallets, delivered to the construction site and used for masonry (Fig. 12). Unfired stones include sand-lime bricks, heavy concrete blocks, lightweight concrete blocks and aerated concrete blocks.

Rice. 12. Making unfired stones

Sand-lime brick

For manufacturing, fine quartz sand (SiO2) is used as an aggregate, and quicklime (CaO) in the form of fine lime (finely ground lime) is used as a binder. Mixing is carried out in a forced-action mixer or in a quenching drum. With the help of pressing, stone blanks receive their shape and their exact dimensions. When hardening in an autoclave, sand particles combine with lime to form a lime-silica-acid compound (calcium hydrosilicate). Temperature and pressure accelerate hardening. After being removed from the autoclave, silicate stones can be sent to a construction site without additional holding and immediately laid into walls.

The properties of sand-lime bricks are standardized according to DIN 106. The bricks have a gray-white color, sharp edges and precise dimensions.

Compressive strength. Sand-lime brick is manufactured in the same compressive strength classes as fired wall stones. Their designation is made by printing a stamp on every two hundredth stone or by color marking. The colors correspond to the designation of wall bricks (see Table 2).

Density. Sand-lime bricks are divided into 11 classes according to density, which lie between 0.6 and 2.2 kg/dm3. Frost resistance. Sand-lime bricks absorb water slowly, which means that they are capillary and therefore not frost-resistant. Cladding stones and face stones, however, are made frost-resistant. The sizes and formats are consistent with the modular system in construction and correspond to those used for fired stones. For stones with a polished bed, the dimensions are consistent with the thickness of the seam 1-3 mm.

The voids in sand-lime bricks are not through, which is due to their manufacturing technology. However, the grip holes and grip sockets extend the full height of the stone and can be used from the top of the stone (Fig. 13). They must be installed in all stones starting from the 2DF format.

Rice. 13. Silicate wall stones

Solid sand-lime bricks (KS) come in hollow-core formats DF - 5DF. Their cross-section can be reduced by voids perpendicular to the bed by no more than 15%. Grip holes are possible. Hollow sand-lime bricks (KSL) in formats 2DF - 5DF, in addition to gripping holes, can have voids of more than 15% of the cross-section perpendicular to the bed. Silicate blocks (KS) are stones with a height of over 113 mm with a weakening of the section perpendicular to the bed below 15%.

Silicate hollow blocks (KSHbL) are stones with a height of over 113 mm with a weakening of the section perpendicular to the bed of more than 15%. Sanded silicate stones (KS(P)) are solid stones, blocks and hollow blocks that are laid on a thin mortar joint. Frost-resistant silicate bricks are available for facing brickwork. Sand-lime bricks for external walls (KsVm) are stones that correspond to at least strength class 12. They are manufactured with and without voids in formats up to 5DF.

Sand-lime facing bricks (KsVb) are stones that correspond to a strength class of at least 20. They are subject to increased requirements regarding frost resistance, the absence of efflorescence, color changes and dimensional deviations from the standard. For rational cladding without mortar joints, silicate stones from format 4DF and higher are equipped with a “key and groove” profile on the sides. Therefore, when ordering stones to mark the joining face, the wall thickness is indicated in parentheses behind the short format designation. These stones are designated by the letter R (Fig. 14).

Rice. 14. Silicate stones

Designation of silicate stone (example): Silicate stone DIN 106 - KSL -6-1,2-3 DF Means hollow-core silicate stone, compressive strength class 6, density class 1.2 in format 3 DF (l= 240 mm, b = 175 mm, h=113 mm)

KS-R stones with a height of 113 mm, as well as KS-R blocks and hollow core KSL-R blocks are laid on a regular mortar layer . KS-R ground stones with a height of 124 mm, as well as large-format KS-R ground stones and KSL-R ground hollow blocks are laid on a thin layer of mortar .

Lime-sand (silicate) building slabs 115 mm wide with profiled thin edges “key and groove” are laid on a thin layer of mortar, which is also used in vertical joints. Silicate panel elements (KS-PE) are supplied as wall elements with all additional elements and corresponding installation plans. The preferred elements are density class 2.0 and compressive strength class 20. In addition to the usual wall thicknesses, elements are available for wall thicknesses from 100, 150, 214 and 265 mm. Silicate stones - quadro - are stones corresponding to a 125 mm module, which are used for mechanized laying. In addition to the usual wall thicknesses, they can have a width of 150 and 200 mm, a compressive strength class of 12 and 20 with a density of 1.8 and 2.0 kg/dm3.

Molded silicate stones are prefabricated silicate lintels for covering openings up to 3.0 m clear, 115 and 175 mm wide, as well as channel silicate elements for frame beams, lintels and slots, for example on facing masonry. Special silicate stones are, for example, interior cladding stones, industrial cladding stones, corner stones for wall corners of 45° and 135°, acute or rounded corner stones for cladding window and door casings or wall corners, sound-absorbing stones as well as installation stones with drillings for hidden electrical wiring (Fig. 15). For facing wall masonry, stones with a chamfer on the front edge are available (KS design). In this facing masonry, the mortar joint is not visible, but the 45° chamfer forms a shadow, creating divisions in the masonry.

Rice. 15. Special silicate stones

Designation of silicate stone (example): KS LR (P) - 12 - 1.2 - 12 DF (240) Means a silicate hollow block with “key-groove” side edges, ground on a thin layer of mortar, compressive strength class 12, class density 1.2, format 12 DF for wall thickness 240 mm

Normal concrete stones

There are standardized concrete wall stones and non-standardized concrete wall stones, which, however, are allowed as wall stones as normal concrete by the building supervision authorities (Fig. 16).

Rice. 16. Normal concrete stones

Standardized concrete wall stones

Concrete wall stones are manufactured in the form of hollow blocks (Hbn), solid blocks (Vbn) and solid stones (Vn), as well as stones and blocks for external walls (Vm and Vmb) (Table 3).

Table 3.7. Wall stones made of normal concrete

Concrete wall stones approved by building authorities

Wall stones are suitable for interior and exterior walls. They are often used for facing masonry, for example in two-layer masonry for the construction of the outer layer (Fig. 17).

Rice. 17. Facing wall masonry made of concrete stones

The characteristics of these stones are, for example, their color and the structure of their outer surface. This is already taken into account during their manufacture, for example through the appropriate selection of colored sand and natural crushed stone (Fig. 18). Also, by adding coloring agents and colored stone flour, you can create one or another color of the stone. White cement is mainly used as a binder.

Rice. 18. Natural crushed stone of various colors

The dimensions of the concrete stones correspond to the octal module for above-ground construction. In addition, they can also correspond to the decimal module according to the modular system. Using solid stones (Vn) up to a height of 115 mm, you can lay walls with a thickness of 115 and 240 mm. It is preferable to use stones of 4DF and 6DF formats for this. In addition, there are concrete stones for walls with a thickness of 90, 100, 140 and 190 mm of various lengths and heights. Solid blocks (Vbn) - without voids, have a height from 175 to 238 mm (Fig. 19).

Rice. 19. Concrete stones

as specialty stones for a variety of applications, such as finishing stones, chamfered and rounded corner stones, concealed wiring stones, cornice stones, window sill stones and lintels. Concrete stones are often used as paving stones, and they can come in various shapes.

Lightweight concrete stones

Lightweight concrete stones are manufactured for load-bearing and non-load-bearing internal and external walls, as well as as filling for floors, floor slabs and prefabricated elements.

For production , a porous filler is taken. It can be made from natural pumice (NB), as a natural aggregate, and from expanded clay (expanded clay) (EC), as an artificially manufactured aggregate (Fig. 20). In addition, blast furnace slag, broken bricks and lava slag can be used as filler. Standardized cements or binders approved by construction inspection authorities can be used as a binder. Hardening occurs in air or in autoclaves using steam under pressure. When hardened in air, lightweight concrete stones gain their minimum compressive strength after 28 days.

Rice. 20. Filler for lightweight concrete

The properties of lightweight concrete stones are standardized according to DIN 18151 and DIN 18152. Density. There are 11 density classes, which lie between 0.5 and 2.0 kg/dm3. This is achieved by using a very porous aggregate. The binder coats the aggregate and thereby reduces capillary suction, so that the stones absorb less water. Lightweight concrete stones, as a rule, do not create efflorescence in the masonry. They have a rough surface that creates good adhesion to the plaster. Flat-ground stones on bedding surfaces can be laid dry without mortar. Compressive strength. Lightweight concrete stones are manufactured in compressive strength classes from 2 to 20.

Dimensions. The dimensions of lightweight concrete stones, as a rule, correspond to the octal module (1/8 m). However, this depends on the type of masonry. When laying on a normal or light mortar, take into account the thickness of the seam from 10 to 12 mm; when laying with a thin seam, the thickness of the seam is only 2 mm. When laying dry, a two-millimeter tolerance must also be taken into account. There are solid stones, solid blocks and hollow blocks.

Solid stones (V) are lightweight concrete stones without voids up to 115 mm high. On the butt sides they can be flat or with projections (front keys) or with a “key-groove” profile and can have a slot (slot) for gripping (Fig. 21). Solid blocks (Vbl) are lightweight concrete stones without voids with a height of 238 mm. On the vertical (butt) sides they can be profiled in the same way as solid stones. Solid blocks with slots (Vbl S) have slots about 1 mm wide running at equal distances through the entire stone.

Rice. 21. Lightweight concrete solid stones

Solid blocks with splines and improved thermal insulation properties (Vbl SW) have slots offset relative to each other, which should not pass through the entire height of the block, so that closed voids with air remain during laying. For such stones, only natural pumice (NB), expanded clay (BT) or a mixture of them (NB/BT) can be used as a filler. These stones are made only in density classes from 0.5 to 0.8 (Fig. 22).

Rice. 22. Lightweight concrete solid blocks

Hollow blocks (Hbl) are lightweight concrete stones with voids perpendicular to the bed. There are single-hollow (1K) stones and up to six-hollow (6K) stones (Fig. 23). The voids should be evenly distributed throughout the entire cross-section of the stone and offset relative to each other. The voids reduce the weight of the wall and its thermal insulation increases. On the vertical joint planes, frontal keys or “key-grooves” can be profiled. Hollow blocks can be density classes from 0.5 to 1.4 and compressive strength classes 2, 4, 6 and 8 (see Fig. 23). Hollow core blocks can be factory equipped with a continuous layer of thermal insulation. It is designed in such a way that, due to the heat-insulating layer, a multi-layered structure of wall stone is obtained. In this case, a smooth base for plaster is formed on the outside of the masonry.

Rice. 23. Lightweight concrete hollow blocks

Porous concrete stones (aerated concrete blocks)

Porous concrete is used to make not only wall stones, but also panel elements, roofing and floor slabs, storey-high prefabricated wall panels, as well as reinforced wall panels and slabs.

Manufacturing

Porous concrete (aerated concrete) is mixed from cement or lime, fine-grained or finely ground quartz-containing sand, mixing water and a blowing agent. After this, the mixture fills the molds (Fig. 24). The mixing water quenches the lime, and a blowing agent of finely ground aluminum powder is combined with lime-containing (alkaline) water. This produces hydrogen, which swells fresh concrete when heat is applied and forms small pores with a diameter of up to 1.5 mm. The stones, cut to size, are taken to an autoclave chamber for hardening and gain strength using steam at 190 °C and under a pressure of 12 bar. After this, the stones can be laid.

Rice. 24. Making stones from aerated concrete

Properties. The properties of aerated concrete stones are standardized according to DIN 4165. Compressive strength. Aerated concrete stones are supplied in compressive strength classes 2, 4, 6 and 8. Marking is carried out on at least every 10 stones using paint, and when stacking stones - on the packaging or on the accompanying packing slip. The density lies between 0.3 and 1.0 kg/dm3. A high percentage of porosity, for example 80% of the volume at a density of 0.5 kg/dm3, increases the thermal insulation ability. Aerated concrete stones are not frost-resistant and therefore must be protected from weathering, for example by plastering, painting, or cladding. Aerated concrete stones can be easily processed, such as sawing, planing and drilling.

Sizes, formats

Stones can be made to very precise sizes. Their sizes depend on their installation. When laying on a normal or light mortar, a joint thickness of 1-1.2 cm should be taken into account. When using a thin mortar layer, it is sufficient to reduce the dimensions from the calculated ones by 1 mm on the bed and vertical joint sides.

Aerated concrete blocks (AC) are solid, large-format stones that are suitable for masonry with normal mortar. Their vertical butt sides can be smooth and profiled in the form of frontal keys or “key-groove” (Fig. 25).

Rice. 25. Blocks and building slabs

Aerated concrete building slabs (PPl) are laid on a normal or light mortar and are used for non-load-bearing walls, for example for partitions. Building slabs with dowels are additionally designated by the letter N, and those with a tongue-and-groove profile are additionally designated NF. Aerated concrete polished building slabs (PPpl) are laid on a thin mortar joint and are only allowed for use in non-load-bearing walls. They also have the short designations N and NF depending on the profile of the butt side.

aerated concrete panels are mounted using light lifting devices, for example using mini cranes. They are installed on a thin layer of mortar (Fig. 26).

Rice. 26. Panel elements

Wall building panels are used for protruding volumes of frame buildings made of steel, reinforced concrete and wood. They can be reinforced or unreinforced, but they should not bear loads. Their width is usually 825 or 750 mm. Their height is up to 3.5 m. Roofing and floor slabs consist of reinforced aerated concrete. They meet the fire resistance requirements of all classes and are marked accordingly. The slabs are typically 6000 or 7500 mm long, 625 or 750 mm wide and are available in 100 and 300 mm thicknesses. The longitudinal sides of the slabs can be profiled as a “key-groove” and additionally have a small cross-sectional area for embedding (Fig. 27). To form a roof disc, it is possible to ensure a tight and smooth embedment due to the shape of the sides.

Rice. 27. Roofing slabs with different joint shapes

Special building elements made of aerated concrete can be produced quite simply on a construction site by sawing and cutting into additional elements. The special elements manufactured at the factory are:

- channel elements, for example for rand beams, lintels, projecting wall elements and gables in masonry;

- multi-purpose stones that can be used as channel elements. For these stones, the size of the open section can be formed by removing the side stones (if necessary);

- facing stones, for example for lining pillows under ceilings to form a uniform base for plaster.

How does the size of the facing brick affect the size of the plinth?

.

Knowing the standard dimensions of facing bricks helps to calculate the dimensions of the plinth required for cladding. It must be taken into account that there should be a distance of 2-3 cm between the insulation layer and the facing brick, which is necessary for ventilation.

This will help prevent moisture buildup. To achieve the same goal, between every 4-5 bricks in the first row a seam is left unfilled with mortar.

After all the work has been completed, the plinth should protrude a few centimeters so that the wall has something to rest on. If, after the calculations made, the plinth turns out to be not wide enough, then it is increased before starting the facing work.

HOW TO CHOOSE A FACING BRICK

Today there are a large number of its forms on the market. The most common are the following:

- wedge-shaped;

- trapezoidal;

- twisted;

- figured.

Usually the choice is made based on the purposes of construction. For a low-budget option, for example, non-fired brick is perfect. Ceramic brick will allow you to realize the most bizarre ideas. And special strength can be obtained through the use of clinker type. The most popular is the type with two or one beveled corners, a figured “pumpkin” or one that matches the “wild stone”.

- Behavior in local climate

In fact, it is simply ideal for our climate, as it has

increased frost resistance and low moisture absorption. But that’s not all: the absorbent properties of this material make it possible to prevent the passage of numerous harmful substances that enter our home from the outside. Rain is a good help in this, during which a certain cleansing occurs.

- Cost of facing bricks

Of course, the price of such a brick will differ significantly from the cost of a regular one. But within the proposal itself, the cost will be determined by the following parameters - strength, frost resistance, water absorption, hollowness and weight. For example, one of the most popular facing building materials for cottages—red brick—has the following characteristics: compressive strength ranges from 150 to 200 kgf/cm2, frost resistance has one hundred cycles, water absorption is 8%, hollowness will be a third of the entire form, and the weight and It will be even lower than the standard - a little more than two kilograms.

Types of bricks depending on the material of manufacture

Each type is intended for its own range of applications or technological processes. And the first indicator by which a brick can be classified is the material from which it is made.

Ceramic

Ceramic bricks are made from high-quality clay without marl and sulfates. Usually, raw materials with a minimum percentage of undecomposed calcite in the composition are used. First, the brick is molded, after which it dries and is fired in a kiln at a temperature of 1000 0 C.

When subjecting the brick to heat treatment, it is very important to prevent overburning or underburning. In both the first and second cases, the quality of the brick will deteriorate significantly. An unburnt brick will look light, while a burnt brick will have shades of black. A good clay product has a semi-matte surface, produces a characteristic ringing sound when struck, and has a porous structure when broken.

Brick price:

Silicate

Sand-lime brick consists of purified quartz rocks (sand), and lime and moisture itself account for about 10% of the mass of raw materials. The percentage may vary depending on the composition and quality of the prepared mass. The main condition in the production of a good product is the purification of the components from organic impurities, clay, and manganese.

Lime should not contain a lot of calcium oxide and should not be burnt. The manufacturing process takes place under great pressure. This type of brick is warmer compared to ceramic. It is used for the construction of walls and partitions.

Brick price:

Hyper-pressed

The composition of this type of brick usually includes various screenings of limestone, marble, shell rock and dolomite, formed during open-pit quarrying. These components account for up to 90% of the volume of the raw material. The second irreplaceable component of the composition is high-quality Portland cement. It plays the role of the main binding component, occupying 6–8% of the prepared mass by volume.

Bricks are created by pressing in special molds. Of great importance for pressing is the quality of the water itself, which is included in the composition as an agent of the chemical reaction. As a result of pressing, bricks of ideal shape and size are obtained. Hyper-pressed bricks are used for cladding the walls of buildings. The surface of the brick itself can be smooth or have a texture similar to the so-called “torn stone”.

Brick price:

What are the characteristics of ceramic facing bricks?

Ceramic facade bricks are produced by firing molded clay blanks at temperatures of +900...+1000 C°. This building material with ideal geometry has a rather significant drawback - high water absorption - approximately 12%. It is lower than that of ordinary blocks, but in regions with a humid climate it is better not to use ceramic facing bricks, since water penetrates the pores and contributes to the appearance of cracks.

Ceramic products are produced with various finishes on the front surface, which can be: smooth, textured, glazed, engobed. Engobing is a fashionable trend in the production of facing bricks, which consists of coating a brick block with a fine suspension - colored or white, followed by firing. This technology allows you to: create an original pattern on the surface, make it smoother, reduce the coefficient of water absorption and protect the facade from pollution.

Ceramic facing bricks are produced full and hollow. Solid blocks are heavy and have low heat-saving properties, but they have good frost resistance, and are therefore recommended for use in regions with harsh climates. Hollow blocks reduce the mass of masonry and have good thermal insulation properties. But their disadvantage - low frost resistance - limits their use in cold regions.

What are the advantages?

The advantage of lightweight building materials is their low cost, fire resistance, and resistance to mold and mildew. Thermal and sound insulation characteristics allow you to create the necessary microclimate in the room and reduce the impact of acoustic stimuli from the outside. Made from natural materials. Environmentally friendly brick does not have a harmful effect on the health of its owners. They have good vapor permeability, as a result of which it is as easy to breathe in houses made of lightweight brick as in wooden ones.

What are the characteristics of concrete products?

Facing concrete bricks can have one or two front surfaces - smooth or textured.

produces high-quality products with ideal geometry, in different colors: straw, red, gray, light brown, brown, black.

For the manufacture of our products we use:

- Portland cement grades M400 and M500;

- sand cleared of clay inclusions;

- fine crushed stone with a grain size of up to 10 mm;

- purified water;

- additives to improve performance;

- coloring pigments.

Our facing products are characterized by:

- Good insulating properties. The products provide high heat, noise and waterproofing of the internal space.

- Resistance to damage by fungi and insects.

- High fire resistance. Thanks to this valuable characteristic, concrete facing bricks can be used for laying areas located near chimneys and fireplaces.

- High water resistance and frost resistance.

- Good environmental and hygienic characteristics. The material does not accumulate radiation and does not emit toxic substances.

- Good machinability. If necessary, holes and grooves can be made in such bricks for laying utility lines.

How to calculate the required amount of facing bricks?

To determine the amount of facing bricks, it is necessary to determine the area of the facade and subtract the area of window and door openings from the result. The resulting square meters are multiplied by the number of bricks in one square meter. This value cannot be determined unambiguously, since it depends on the thickness of the masonry mortar.

Our online calculator and specialists from the Vibrocompressed Products department will help you figure this out.

How to properly care for a facade with a facing brick surface?

The aesthetics of an external wall made of facing bricks can be spoiled by efflorescence - large whitish spots. Their occurrence can be avoided through measures taken at the stages of construction work and during operation:

- When carrying out masonry work, use non-additive Portland cement.

- Eliminate the presence of water-soluble salts in fine aggregate (sand) and water.

- When laying bricks with low water absorption, use only rigid masonry mortars.

- Work at positive temperatures, since the use of antifreeze additives is undesirable. Freezing of masonry is prohibited.

- Prevent masonry mortar from getting on the front surface of the blocks.

- After completing masonry work, cover the masonry with waterproof film every day.

If efflorescence does appear, you cannot wash it off with water or wipe it with a dry cloth. For this purpose, it is necessary to purchase a special composition that will not only remove existing efflorescence, but also prevent its further appearance.

Facing brick and design features

High competition in the market has led to the emergence of hundreds of types of facade bricks, which differ in color, format, and surface features. For facing materials, appearance is one of the main selection criteria. The design of the facing brick must correspond to the architectural features of the building. It emphasizes the status of the property owner and indicates that he has a sense of taste. The following types of facade bricks are produced:

– an exclusive material, each stone has a front surface with a complex relief, which is formed by hand. The work is carried out using technologies used many centuries ago. This type of facing brick is suitable for premium real estate, the architecture of which is made in a castle style. The process of forming facade bricks is labor-intensive, the cost is the highest in its category;- textured - has a surface like “torn stone” or decorative plaster, is produced on automated lines, so the design of each facing brick is similar for its batch. Used in the implementation of original projects in a castle, classical style;

- torqueted - before firing, the front surfaces of the facade brick are sprinkled with mineral chips, as a result of which an original texture is formed. The overall structure is formed as a result of high-temperature firing, so the crumbs do not crumble. The only drawback is that it is difficult to maintain; this material is not recommended for regions characterized by dust storms. Facing brick has a unique look and can be used for projects in any architectural style;

- engobed - a ceramic solution of a contrasting color is applied to the surface of the dried brick, after which the blanks are fired. As a result, the stone can be given any color, and with incomplete surface treatment, unique color transitions can be created. When sintering ceramics with brick, the strongest possible bond is formed and all the characteristics of the base material are preserved;

- glazed – the front side is decorated with glaze with a glass sheen. The technology allows you to experiment with colors, and the facade brick receives additional protection from moisture and mechanical stress.

Classic ceramic facing bricks are red-brown or beige in color. Adding natural pigments allows you to change the shade. Brick factories produce yellow, brown, white and gray stone. A wide range of colors allows you to give the facade the color that best matches the chosen architectural style. When choosing, you must give preference to facing bricks from the same batch. The final shade largely depends on the firing temperature and may differ between products from the same manufacturer. If it is not possible to purchase the entire volume from one batch, then before laying it is recommended to mix facade bricks from different pallets in order to avoid spots of different colors on the wall.

Dimensions and shape of facing bricks

Facade bricks are produced as single, one-and-a-half and double. Single facing bricks are in greatest demand. This is due to the fact that its format allows you to make the masonry pattern more attractive with small wall sizes. The material is used for cladding private houses, commercial and municipal real estate up to 2-3 floors high. One-and-a-half and double facing bricks are used in the construction of multi-story buildings. European and American standards differ from Russian standards. The domestic market mainly sells bricks of the NF format. It has dimensions of 240x60x71 mm, which are close to the dimensions of a single brick. The solid façade of a building in the minimalist style is being used less and less. Architects at the design stage propose decorating buildings with decorative elements - half-columns, cornices, platbands. This gives the buildings an individual look. Manufacturers of building materials produce shaped facing bricks for arranging complex facade elements. There are a variety of options available that differ from the traditional rectangular shape:

- with a rounded butt, the radius of curvature can have different diameters;

- with cut corner

- beveled along the length at a certain angle;

- beveled with a protrusion, which is necessary for fixing to the window frame;

- the poke is beveled at two angles;

- wavy;

- radial;

- with a concave semicircular corner;

- with profiled corner.

If the facade project contains complex decorative details, then it is necessary to choose a facing brick, the collection of which contains all the necessary shaped products.

Standard sizes

The main point of standardization of brick sizes are the following proportions: 1: 1/2: 1/4. This aspect ratio is optimal for its laying with rotation of transverse and longitudinal placement. In individual construction, single brick is in demand; its consumption per 1 m³ of masonry is 513 pieces.

According to state standards available in the Russian Federation, the size of a standard single product is equal to:

- 25 centimeters in length;

- 12 centimeters in width;

- 6.5 centimeters in height.

In addition to single bricks, the building materials market also offers other types of standard sizes:

- one and a half;

- double.

One and a half building materials began to be produced during the industrialization of the country in order to speed up the pace of construction. The standard brick consumption is 318 pieces per 1 m³. A characteristic indicator of a one-and-a-half product is the added height; GOST defines the following standard parameters of the product:

- 25 centimeters in length;

- 12 centimeters in width;

- 8.8 centimeters in height.

The double brick, having the same 25 centimeters in length and 12 centimeters in width, has a height of 13.8 centimeters. Due to its considerable size, to reduce the weight of the product, double bricks are usually made hollow. He is widely practiced in various fields of construction. Products with added height are used for the construction of both civil and industrial facilities.

Quantity calculation and budgeting

Before you start choosing facade bricks, you need to calculate its quantity. To do this, you will need to calculate the area of the external walls, subtract the area of window and door openings from the resulting value. Multiply the resulting value for the area of the brickwork by the number of bricks in one square meter. This parameter does not have a constant value, since each craftsman has his own thickness of the seam in the masonry. When working with a single brick, its quantity per square meter of masonry is 51-56 pcs. Imported face brick standard NF is slightly smaller than domestic single stone. There are 60-65 pieces of this brick per square meter of masonry. Having decided on the quantity of bricks and the budget for facade work, you can understand in what price range you should choose the material. If the products of domestic factories cost an average of 15 rubles per piece, then the cost of European facing bricks often exceeds 75 rubles. Taking into account the larger amount of material and the need to use special masonry mortars, the cost of facade work may differ by 5-10 times. Price becomes an important factor in choosing facing bricks.

How many pieces in a pallet

Products are placed on pallets to simplify the transportation process. Pallets are produced in several sizes and types; accordingly, the number of products that can be placed varies. According to GOST, structures of two sizes should be used: 770x1030, and 520x1030 mm. When purchasing, it is better to personally count the number of stones on the pallet. Quickly calculate the quantity like this:

- determine the number in a row;

- recalculate the number of rows;

- multiply the resulting values by each other.

The weight of a pallet of facing bricks also depends on the number of materials laid on it. Permissible load – 1.5 tons. The manufacturer always reflects the exact weight, since the choice of transport for transporting cargo depends on it.

Data is provided on the number of products of different parameters that manufacturers usually put on a pallet

For cladding, as well as for building a house, it is better to buy 5% more material. The process may be damaged or defective.

Material selection

Having decided on the budget and price of the material, we begin to select facing bricks. The procedure is simple:

- color and texture are selected - we are talking about the facade - the calling card of the house, so it is necessary to pay special attention to visual parameters. They must correspond to the architectural style of the project, the color of the facade must be combined with the shade of the roofing material;

- practical parameters are analyzed - preference is given to facing bricks with a strength grade of M200 or more, frost resistance should be at least 50 cycles;

- design characteristics are determined - it is better to give preference to solid artificial stone, this will reduce the amount of cement mortar used. If this is not possible, then the hollow facing brick should have holes with a minimum area.

In all respects, clinker facing bricks have advantages. This material is available in a wide range of colors and can have any surface texture. The basis of the range is solid artificial stone, which allows reducing the consumption of special masonry mortars. The service life is more than 100 years, this is explained by high strength and low water absorption. The only drawback is the price, but if it suits the buyer, then it is better to give preference to clinker.

After the final selection, it is recommended to purchase the entire batch of products at once. This solution has several important advantages:

- transportation costs are reduced, many companies provide free delivery for large volumes;

- facing bricks from the same batch are purchased, this will eliminate the need to control the color in order to avoid stains on the wall;

- Transshipment of products at intermediary warehouses is eliminated; large quantities are delivered to the buyer from the factory. As a result, the risk of mechanical damage during loading and unloading operations is reduced.

When purchasing, it is worth checking the date of manufacture of the façade brick. Preference should be given to material that is more than 20 days old. Such artificial stone has already gained more than 80% of its strength; its transportation will not lead to mechanical damage.

Pros and cons of brick facades

First, let's look at the practical advantages of brick facades. The main reason for the widespread popularity of using facing bricks in exterior decoration is a solid list of high technical characteristics and qualities. What does the consumer need from a façade? Reliability, resistance to precipitation and other adverse factors and long-term, defect-free operation. The brick fully meets all these requirements. Even a façade lined with metal is unlikely to withstand competitive comparison with a brick one in terms of durability, not to mention plaster.

KodokopatelFORUMHOUSE user

With plaster, the main ambiguity is durability. Brick, built and forgotten. Rain, snow, sun - it doesn't matter. If suddenly there are some small defects, then sometimes they even improve the house, but defects on the plaster are not aesthetically pleasing.

Since we are talking about aesthetics, the visual component of brick, as a designer finishing material, is also at its best. Brick is presented on the modern market in a wide color palette, in several standard sizes and with different surface textures. So, with a little imagination and a little desire, you can not only make a reliable cladding of the house, but also give it any stylistic direction from noble antiquity to modernity.

However, brick cladding also has its disadvantages, which would be unfair not to mention:

— Large weight, which requires serious design preparation and the construction of a reinforced foundation. Traditionally, this is the first limiting factor. If a private developer does not take it into account or does not fully appreciate the importance of the moment, with a high degree of probability it can be argued that he risks encountering serious and even fatal problems for the house.

— The complexity of the work and high requirements for the qualifications of builders. Can this be called a full-fledged disadvantage? Most likely not, to a greater extent it is a limiting factor or a risk factor, since there are not enough smart workers with steady hands and an understanding of technological aspects for everyone.

Miracl635FORUMHOUSE user