Today we will discuss houses made of timber. There are reviews from owners of such houses both on construction forums and on specialized websites. Our website also has reviews from owners, to which you can also add reviews from builders on such houses.

In general, if we talk about houses made of timber, reviews from owners will be more positive than negative. After all, when a person makes a decision about what material he should use to build a house in which he and his family will live over the next few decades, he usually thinks about the future. And makes a conscious decision.

However, it happens that the future owner of an individual home makes a decision based on advertising materials that promise him the quick construction of a building for very little money.

And in this case, there may also be negative reviews, which mean that the timber structure did not live up to the expectations of its future owner.

To understand what the positive and negative reviews of the owners of log houses are based on, we will go through all the stages of construction and finishing of such housing.

Foundation for a house made of timber

Let's start with the foundation for a house made of timber. Feedback from owners at this stage is mostly positive, since a light wooden structure does not require a heavy and durable foundation. At this stage, the owner has all the prerequisites to save on reinforcement and concrete, as well as on drainage work.

In terms of stability, a log house can be compared to a wooden frame structure. Which means it is possible to build it both on MZFL and on a FBS foundation.

And this significantly reduces the cost of construction and will not further affect the strength of the entire structure.

Construction of a timber house

Once the base is ready, you can begin building the walls. And here timber walls show their best side. The main advantage of this material is the speed with which the structure grows in height. If a crane is working at the construction site, then the timber frame can be assembled in 1-2 days.

And speed, as we know, greatly influences the overall cost of construction. The faster the walls are assembled, the less you will have to pay for builders and rental of construction equipment.

However, after the log house is assembled, the pros end and the cons begin. Like any structure made of logs or timber, the house must stand at least until the next season. The timber will settle and it is impossible to do anything now with the house, and especially with its interior.

However, every cloud has a silver lining - you can start arranging the roof and carrying out work on the site.

A fly in the ointment or something to be wary of

Wood is very capricious, and if errors or inaccuracies were made during the manufacturing or storage of profiled timber, then the finished house loses some of its positive qualities. This primarily concerns chamber or natural drying. Since the cross-section of the material for building a house is at least 150 mm, it takes time to dry it evenly. Manufacturing companies save their money and time and do not always deliver the dried product to the site.

You can check the quality of drying using a hand-held moisture meter. You can purchase it in specialized stores or ask the lumber manufacturer to measure the humidity in front of you.

If drying is insufficient or natural moisture is used to build a house, over time the walls begin to dry out. Cracks form that spoil the appearance and allow cold to pass through. Due to the specific nature of the connection, it is almost impossible to re-caulk.

The second indisputable disadvantage concerns houses made of laminated lumber. Adhesive compositions for connecting lamellas must be of high quality, but their price is appropriate. The manufacturer is trying in every possible way to reduce the cost of the process, and small companies often use cheap phenol-containing glue. It is difficult for an ordinary buyer to distinguish a deadly material from a high-quality material by sight. Phenol vapors affect the respiratory system, have a general toxic effect, and in some cases provoke cancer. You can avoid low-quality purchases only by purchasing houses from trusted manufacturers. Remember, a house made of glued profiled timber cannot be cheap!

The third disadvantage is the inflated price for chamber drying with a complex profile and glued material. In rare cases, the estimate for building a house outperforms a similar project made from rounded logs. And if the walls dry out over time, you will have to spend additional money on interior and exterior decoration.

Roofing for a timber structure

Modern chemical compositions make it possible to protect wood from any weather conditions. However, this does not exclude the fact that a wooden structure will require a roof with larger overhangs than a brick or frame house.

However, the roof of a timber building does not raise any big questions and can be either a classic gable roof or any other shape. The material used on the roof should not be heavy; timber walls can bear the load from a metal or polymer roof.

You should not install a roof made of natural tiles or slate on a log house.

What is profiled timber?

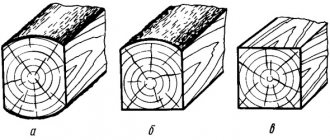

Profiled timber is a modern version of industrially produced lumber. It is made from different types of wood and when it comes out of the sawing machine, the cross-section has a different shape from a rectangle. The sides of the finished timber are smooth or rounded, and the bottom and top have recesses of a tongue-and-groove type locking joint.

Production of profiled timber

When making profiled timber, the following is most often used:

- Cedar;

- Pine;

- Aspen;

- Spruce;

- Larch.

Pine profiled lumber is the cheapest; it is usually chosen for the construction of private log houses. Cedar and aspen are ideal for building baths. They are resistant to changes in temperature and humidity. Larch timber will last the longest, but it is quite heavy and costs the most. You will have to spend money on this material, and additionally on a massive foundation under the walls made of it.

Pine timber

Spruce is not very strong and has low resistance to rotting. However, the timber made from it looks the most presentable in appearance among the listed competitors. The spruce option is best used for constructing internal partitions in the house.

Profiled spruce timber

The main feature of profiled timber and its main advantage is the presence of a profile lock on two technical sides. Such a connection guarantees, when assembling a house, wooden walls with a minimum of gaps for drafts. Builders spend less time and effort on sealing the seams between beams, which significantly reduces work time. An ordinary rounded log cannot boast of such an advantage.

Insulation of timber walls

According to modern SNiP standards, the thermal resistance of the walls of a timber house is not sufficient, even if the building is assembled from 20 by 20 timber. This means that the walls will need to be insulated from the outside.

Those owners who neglect insulation subsequently complain about increased costs associated with heating their homes.

What should I use to insulate timber walls? It is best to use materials that are vapor permeable. When insulating externally, such materials must allow moisture to pass out and not trap it in the insulation. An example of such materials is basalt wool or polystyrene foam.

At the same time, it is not worth using extruded polystyrene foam on timber walls, since its vapor permeability tends to zero. This means that condensation will accumulate between the insulation and the timber, which will lead to premature destruction of the wooden walls.

Reviews about profile types

Profile types are also of greater importance during construction. Experts say that the more complex the profile, the better it will retain heat, and additional thermal insulation is not needed. A popular one is the “comb”. When there are more than two tenons and grooves. But, alas, according to user reviews, this material also needs to be insulated over time.

A profile not made by specialists may not have exact shapes, and this nullifies all its quality characteristics.

Of course, there are exceptions, such as large manufacturers. Their entire process is automated, and the tenon and groove have an accuracy of up to mm. But given that delivery to the buyer is not always carried out with all the rules and regulations, and storage at a construction site is usually in the open air, the wood changes its moisture content. This means that the profile is violated.

The new Finnish profile is interesting. It has a complex lock and even with minor violations it will still be sealed. But it also needs interventional insulation.

For construction, it is better to use the simplest profile option with additional insulation. Any construction team can handle this and no additional skills are needed to lay the walls.

Interior decoration

After the house has settled, it will be possible to begin interior decoration of the house. Naturally, it is worth considering your interiors before starting to build the foundation. After all, if you choose a timber house, you deliberately limit yourself in possible options for the interior of your home.

The use of timber imposes certain restrictions on the materials used for decorative finishing. Although if you turn to specialists, you can use a variety of materials without restrictions. For example, you can order an interior design from the Rezenko Design Studio https://rezenko.com.ua/services-and-prices/, whose specialists will be able to advise you on possible options.

Chamber drying baths

Having built a house from profiled timber, many owners want to build a bathhouse from the same. Profiled baths are easy to assemble and finish. It will not be difficult to decorate the steam room and dressing room with clapboard. And the rest room breathes and allows oxygen to circulate.

To build a bathhouse from profiled timber, it is important to properly design the exhaust system. It is because of an error in the hood that baths accumulate moisture and begin to rot. This is where negative user reviews appear.

Before building a chamber-drying sauna, think about what kind of wood is best to purchase. Larch, aspen and linden profiled materials are well suited for the construction of baths. It is possible to build from pine and spruce, but in the steam room, when heated, the walls will begin to “cry”. You can avoid this by using additional interior finishing made of aspen or linden lining. But it is better to make the canopy and furniture from linden or aspen.

The washing department is a room with high humidity. Larch and aspen profiles work well here. Many companies take these subtleties into account when building a bathhouse and offer mixed options. For example: the dressing room and steam room are made of aspen, and the washing compartment is trimmed with larch. But such options are rare. When building it yourself, you can take this into account.

If the house is assembled from profiled timber, then it is better to assemble the bathhouse from the same material. This way the buildings will look like a single ensemble. But, before you start building from this material, you should carefully read our article and think about whether to believe the reviews on the websites of the manufacturing companies.

Durability of timber walls

If you want your wooden house to stand for a long time, then already at the stage of laying the crowns you should take care of its protection. Using modern protective compounds, you can not only protect wood from rot and mold, but, using fire retardants, also protect wood from fire.

More on this topic on our website:

- Wood concrete houses - reviews from residents and owners Future owners of country houses try to use materials for construction that are as cheap as possible. And if you read reviews from residents of wood concrete houses, then exactly...

- There is serious competition in the building materials market. Various manufacturers say that only their material is suitable for building a country house. In fact, how to navigate this...

- Among the proposals from different manufacturers, we will have to select the most efficient radiators that will produce the required amount of heat, and will not need to be serviced or repaired. TO…

- How do houses made of dry profiled timber differ from other wooden houses? First of all, it makes sense to compare them with other types of timber houses - from raw...

Construction site use – pros and cons

Profiled timber is produced using high-precision equipment. Therefore, with the correct manufacturing process, the material is obtained with precise shapes. But this only applies to species produced in large production facilities.

Unfortunately, we have quite a few “handicraft” ones. Having purchased material from such a company, the user receives low-quality products and is disappointed. Building a house from timber of this quality causes many problems. This is why there are so many negative reviews online.

Of course, you can purchase a milling machine and cut the tenon and groove at home. But achieving factory accuracy without special skills is difficult. After all, large manufacturers have automated the entire process and were able to achieve accuracy down to mm. Of course, this only applies to large manufacturers.

Before starting from all sorts of reviews, you need to understand that profiled timber comes in two types:

- Natural humidity.

- Chamber drying.

And this is a completely different lumber with separate characteristics. If the quality of your home is important to you, then it is better to opt for chamber drying or build a house from laminated veneer lumber. Reviews for each type are usually combined into one, and this misleads many buyers. Let's try to figure it out:

| Characteristics of profiled timber, what is emphasized when choosing | Feedback on natural moisture material | Feedback on chamber drying material | Expert opinion |

| Humidity | Most negative reviews concern the material with natural moisture. When it dries, it will twist, crack and lose its geometry. | Kiln-drying material undergoes careful screening. Even during drying, those links that have cracked and lost their shape will be selected. Only high-quality goods are delivered to the buyer. | Of course, you can purchase chamber drying, but unfortunately it is very difficult to find a product with the actual required humidity. Typically, timber with a larger cross-section, for example 200x200, is not completely dried; as a result, the natural moisture remains inside. And such a beam will bend and break no less. The second problem is that the structure of the timber is fibrous and it absorbs all moisture from the environment. If you purchase kiln-drying timber that you are going to store under a canopy, and it’s raining outside, then within two days you will receive material with natural moisture. You can avoid this by purchasing winter goods. |

| Quality | Natural moisture can be of good quality if produced in a large facility. | It undergoes careful selection, so in most cases it is of high quality. | The quality of the material is directly related to the choice of the manufacturer. If you purchase from “handicrafts,” then you should not expect good material, even chamber drying. |

| Availability | There is always | To order | A cross-section larger than 200x200 is becoming increasingly difficult to purchase for more than 2 cubes. It must be pre-ordered. |

| Profile | Several variants | Several variants | The simpler the profile, the more convenient it is to work with it. Although it is believed that the "comb" profile is better, this is a misconception. All the same, over time you will have to insulate the walls additionally. |

| Ease of installation | Convenient | Convenient | Construction from profiled lumber is directly related to the qualifications of builders - carpenters. For self-assembly, only ready-made kits are convenient. |

| Price | From 9,000 rub. | From 13,000 rub. | This construction option cannot be called cheap. Especially when it comes to chamber drying. And you shouldn’t believe that additional finishing will not be needed. |

The main thing that should be done before purchasing such material when building a house from profiled timber is to control its quality before delivery to the construction site. And the rest will depend on the skills and abilities of the construction team. The moisture content of the timber greatly affects its quality characteristics.

Both dry and wet timber are made from the same type of wood with a moisture content of 40-50%. When drying, the humidity decreases to 20%. Based on reviews, the main advantages of chamber timber:

- Eco-friendly. But this can be said about any type of lumber, except laminated veneer lumber.

- Minimum shrinkage of up to 3%, almost like building a house from laminated veneer lumber. This is enough to make the wall askew. This means that chamber drying requires considerable subsequent investments and careful processing.

- During chamber drying, timber with increased knotiness is rejected. Indeed, you can purchase the highest quality goods from large manufacturers in dried form.

- Construction of a house from profiled timber is possible in the shortest possible time. It will take the same amount of time to build a house from dry or natural moisture material. Simply, with chamber drying, you can immediately begin finishing and lay a finished roof.

- Less cracking. Yes, if the correct technology is followed, and in Russia this is only 10-20% of the total, there will be fewer cracks.

- Does not require additional finishing or caulking. This is a misconception, but it will be difficult to caulk profiled timber.

- The dried material has increased water resistance and lower thermal conductivity. This is also a misconception. Indeed, such walls will retain heat better. But the timber will not acquire water resistance after chamber processing. To do this, it must be treated with special compounds. And their quality also depends on the price. It is unlikely that manufacturers will prefer an expensive treatment option.

- The dimensions allow this type of timber to be used in buildings of any complexity. Indeed, timber for building houses has sections of 150x150 or 200x200 mm, which makes it most convenient to use. The standard length is 2.4.6 m. But what does this have to do with the moisture content of the lumber?

You can talk a lot about the advantages of this type of timber, but it’s better to watch the video of professionals:

Of course, you can purchase a glued profile. This will give you dry material. We have already discussed reviews of laminated veneer lumber in a previous article.