Most often we think about how much fuel we have used when bills for the heat received arrive. And if the amount is frighteningly large, we begin to carry out calculations. There are methods that make it possible to calculate, for example, both at the design stage and in a completed building, the gas consumption for heating a 200 m2 house. The results obtained will help to audit the heating system and develop methods to reduce the costs of maintaining a comfortable microclimate in the house.

Having managed to calculate gas costs, heating bills will be more pleasing Source tengrinews.kz

Types of gas connection - what determines the cost and quality of heating

Many consumers begin to think about how much “blue” fuel was consumed only after receiving a significant bill for the consumed heat. If the amount is significant, then the homeowner begins to figure out how to spend less gas.

There are different methods to determine what the consumption of a gas boiler will be for heating a private home. It is important to take into account one point here - gas can enter the home in different ways:

- main gas. The composition is purified from methane, but a fragrance is added to it, which makes it possible to detect a leak. The mixture is supplied through gas transportation systems to consumers;

- liquefied gas. Propane is mixed with butane and enters the gas tank. In the future, an autonomous supply of gas to the living space is ensured. Before supplying the composition, the liquid turns into a gaseous state and the pressure in the container increases. The usual red cylinders are used as an analogue of a gas holder.

Note! Each option has its own advantages. The gas tank provides complete autonomy, but it is very expensive to maintain. Main gas is cheaper, but its quality is worse.

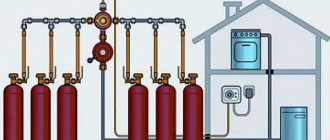

Connection diagram to the boiler

The connection of the working elements of the system is carried out according to a special scheme using a gearbox. The device converts liquid fuel into a gaseous mixture and supplies it to the boiler chamber. If the gas supply is provided by several tanks, you will need to purchase reducers for each tank.

Components for balloon heating systems

The main components of the system are:

- Boiler with burner.

- Tanks 50 l.

- Gearboxes.

- Locking mechanisms.

- Rubber fabric sleeve.

- Ramp.

The installation diagram is simple and understandable even for a beginner.

Why does gas consumption increase when heating a home?

Before you begin calculations and determine how much gas a gas boiler consumes per month, you need to know what factors can affect the final figure:

- Climatic features of the territory. All calculations must be performed taking into account the lowest temperature indicators characteristic of these geocoordinates.

- The area of the building, the number of floors and the height of the room that needs to be heated.

- The type of building, and what material it is made of - wood, stone, brick or other types.

- The type of profile on the windows, the presence of double-glazed windows. How the ventilation system works.

- Power within the limits of the heating equipment.

- Year of construction of the building and location of heating radiators.

All these factors are important to take into account when calculating the number of liters of gas that a room of 100 square meters can consume on average per day.

Reducing consumption

This is known: if you insulate your house well, the fuel consumption for heating will be significantly reduced. Therefore, before selecting and installing equipment and laying main routes, it is necessary to properly insulate the house: walls, roof and attic, floor, replace windows, and make an airtight sealing loop on the doors.

Particular attention should be paid to the roof and windows. It is assumed that out of 100% of lost heat, 35% goes through the roof, about 25% is lost at the windows. Therefore, use the best thermal insulation materials and good double-glazed windows, which have a low thermal conductivity coefficient. Cheap double-glazed windows are immediately obvious: their aluminum or steel “skeleton” is always very cold in winter, and a lot of heat is lost directly through it. Even the glass itself does not transmit heat as much as the metal profile on which the glass is held does.

How to calculate the consumption of main gas when heating a home?

Standard calculations are performed based on the current formula. The general formula for each case is A = Q / q * ɳ, where:

- Q is the boiler power that is required to heat a certain area. To calculate this indicator, you will need the number of square meters. meters in the home multiplied by the base value;

- q is the type of gas and its specific heat. For example, G 20 gas has a characteristic of 9.45 kW;

- ɳ is the efficiency of the boiler, expressed in relation to unit. If the efficiency is 95%, then the described indicator is 0.95.

Now it remains to use this formula to make calculations for rooms of different sizes.

So that readers can get a more clear idea of how special calculations are carried out, we will create a table. For each example, let’s take the gas consumption of a 24 kW double-circuit boiler and the gas grade G 20. The efficiency of the unit will be 95% (0.95), and the base value for determining Q will be 50. Taking into account all the indicators, we will make calculations for rooms of different sizes .

| Room area, in sq. meters | How much is the Q indicator, in kW? | How many cubic meters of gas per hour will be used for heating? | Gas consumption per day | Monthly fuel consumption | Number of cubic meters of gas per year |

| 70 | (70*50)/1000=3,5 | 3,5/9,45*0,95=0,390 | 0,390*24=9,36 | 280,8 | 3369,6 |

| 100 | (100*50)/1000=5 | 5/9,45*0,95=0,557 | 0,557 *24=13,368 | 401,04 | 4812,48 |

| 150 | (150*50)/1000=7,5 | 7,5/9,45*0,95=0,835 | 0,835*24=20,04 | 601,02 | 7214,4 |

| 200 | (200*50)/1000=10 | 10/9,45*0,95=1,114 | 1,114*24=26,74 | 802,08 | 9624,26 |

Summing up the results, we can conclude that the larger the housing, the more gas mixture will be consumed for its heating per hour, per month and per year.

Additional Information! The lower the efficiency of the heating boiler, the greater the consumption of the gas mixture during the main supply.

Safe Operation

It is prohibited to use heaters, electric heaters, heating cables, etc. as a means of heating heating cylinders.

Tanks with fuel reserves can only be stored inside separate cabinets, the top of which is drilled to form ventilation. It is recommended to insulate the structure from the inside on the sides and below with polystyrene foam, without covering the ventilation holes. It is not allowed to insulate the cylinders themselves by heating them from the outside, even if they are partially covered with frost.

Frozen cylinders

It is important to follow the rules for filling tanks so that equipment does not explode at home.

Immediately after assembling the heating unit, it is necessary to check for leaks.

Gas pipes must have walls 2 mm or more thick, and in places where they pass through the wall, before pulling the pipeline, a special case with soft filling or a piece of pipe of a slightly larger diameter is placed. In the latter case, the voids are filled with construction foam.

Initial data for calculations

To perform a preliminary calculation, you need to find out the following parameters:

- calorific value (calorific value) of natural gas supplied in your area;

- thermal load on the heating system;

- Efficiency of the boiler that is planned to be installed in a house or apartment.

The calorific value of the fuel is taken based on the value of the lower calorific value of the main gas.

Theoretically, when burning 1 m³ of blue fuel, 9.2 kW of thermal energy is released. In practice, this value differs and, as a rule, to a lesser extent. Due to the same rise in price, some unscrupulous suppliers dilute gas with air, which is why its calorific value can decrease to 7.5-8 kW/m³.

To determine gas consumption for heating a house, it is better to find out the caloric value from the management company, and when this fails, use a reserve figure: 8 kW/m³. If they share with you information about the specific heat of combustion and give you a figure expressed in other units, kcal/h, then you can convert it to Watts by multiplying by a factor of 1.163.

Another important indicator that directly affects fuel consumption is the thermal load on the heating system, which consists of heat losses through the building structures and losses due to heating of ventilation air. The best option is to perform or order an accurate calculation of all heat losses, but in the absence of any other option, you can determine the load using enlarged methods:

- If the ceiling height does not exceed 3 m, then the heat consumption is assumed to be 0.1 kW per 1 m² of heated area of the building. Thus, for a house of 100 m2 you need about 10 kW of heat, 150 m2 - 15 kW and 200 m2 - 20 kW of heat energy.

- Apply 40-45 W of heat per 1 m³ of heated room volume. The load is determined by multiplying this value by the volume of all heated rooms.

The efficiency of the heat generator, which affects the efficiency of fuel combustion, is indicated in its technical data sheet. If the unit has not yet been purchased, then you can take the efficiency of gas boilers of various types from the list:

- gas convectors - 86%;

- boilers with an open combustion chamber - 88%;

- heat generators with a closed chamber - 92%;

- condensing boilers - 96%.

What to choose – a convector or a cylinder?

A convector is a type of radiator with an independent system that does not require connection to the main boiler. Autonomous equipment, which is located under window openings, that is, in places of heat loss.

Safety is achieved due to the fact that gas and combustion products are removed outside without penetrating into the room.

The device is convenient to use for individual small rooms that need to be warmed up quickly. This is a great option for a small cottage.

The device automatically adjusts the intensity of the flame depending on the degree of heating, heating the surface no more than that of a conventional battery.

Cylinder heating is sometimes used in combination with a convector, but it is also suitable for connecting to an entire system to heat several rooms.

How to calculate liquefied gas consumption

To perform the calculations, the same formula is used here, but with a slight difference in the initial values. The fact is that the density of the mixture of propane and butane is 5.24 (while the gas supplied through the main line is 9.45).

To perform the calculation you will need to use the standard formula, but with different values. We present the data in a table.

| Room area, in sq. meters | How much is the Q indicator, in kW? | How many cubic meters of gas per hour will be used for heating? | Gas consumption per day | Monthly fuel consumption | Number of cubic meters of gas per year |

| 70 | (70*50)/1000=3,5 | 3,5/5,24*0,95=0,7 | 0,7*24=16,8 | 504 | 6048 |

| 100 | (100*50)/1000=5 | 5/5,24*0,95=1,0 | 1 *24=24 | 720 | 8640 |

| 150 | (150*50)/1000=7,5 | 7,5/5,24*0,95=1,5 | 1,5*24=36 | 1080 | 12960 |

| 200 | (200*50)/1000=10 | 10/5,24*0,95=2,1 | 2,1*24=50,4 | 1512 | 18144 |

Important! Considering that the capacity of one gas cylinder is approximately 42 liters, we can say that for an average area of 100 square meters. meters you will need a little more than one cylinder to heat the room for two days.

Gas cylinders

Connecting cylinders

A special reducer is used to regulate the pressure Source stroyinstal.ru

Connecting liquefied propane-butane is carried out in exactly the same way as connecting natural methane, but given the fact that the LPG pressure is higher, there should be a reducer at the outlet of the manifold from the cylinders. Only it’s not the same as what you’re used to seeing when connecting a gas stove at the dacha, although the essence is the same - it’s adjusting the pressure. In our situation, it is a device with a regulator and a pressure gauge.

Gas consumption and rate for heating a house of 100 m2

Today, one of the most popular types of heating systems is equipment operating on gas. In terms of environmental friendliness, this method is at the level of electrical installations, it is considered a reliable and economical option; naturally, we are talking about installing a stationary type of system, and not about cylinders that require regular refilling.

In order to decide on the type of heating installation, you must first calculate the gas consumption for heating a house of 100 m2. Thus, the owner will be able to determine how much he can expect to pay for utilities after installing the equipment.

What to consider when calculating?

If the device is already installed, we suggest exploring ways to reduce the average gas consumption in a private home.

When making calculations, it is very important to consider the following factors:

- How many floors are there in the building;

- What type of insulation material was used to build the cottage;

- Total area of the house and dimensions of heated rooms;

- Are there plastic windows, solid doors or open interior arches?

- What is the maximum power produced by gas heating equipment.

VIDEO: Gas consumption by a boiler for heating 1 sq. m. / year in apartment

Procedure for calculating blue fuel consumption

The meaning of natural fuel type is any type of gas used as a fuel mixture, extracted from the bowels of the earth. At the moment, this is the most optimal option for network heating systems, since it has a relatively high level of energy efficiency and low cost. It is also worth noting that there is no need to create fuel reserves.

Natural fuel is the most inexpensive heating method

To calculate natural gas for heating a 200 m2 house, you should take into account the performance of not only the boiler, but also the entire heating system as a whole. If you want to obtain more accurate data, in addition to the main factors, additional additional factors are taken into account:

- in what climate zone the property is located;

- what material is the house built from?

- is there a heat-saving installation in the cottage;

- what is the total area of the building and the maximum elevation of the ceilings.

Before deciding on future expenses, cottage owners calculate the required thermal power of the equipment for heating a certain area. When identifying the optimal value, it should be taken into account that the power indicated in the device passport is considered the maximum indicator that the indicator can produce. Based on this, you need to select a device with higher values. For example, if during the calculation it turned out that 13-14 kW is required to heat the area, then preference should be given to models with a power of 16 to 17 kW.

This factor is explained in such detail in order to clarify the situation - whether the required power for heating the individual parameters of the house was initially calculated correctly, so that subsequently the spending rate would be closer to real indicators.

Often, property owners use a simple heat engineering formula - for a house of 100 m2 there is 10 kW. It should be taken into account that the heat-conducting liquid is consumed almost twice as much as it comes out according to the formula. Since the air temperature is not stable throughout the heating season, the meter readings in the cottage will also change daily from higher to lower consumption values.

Example: for every square meter there is 1 W of energy, but if we take into account real indicators, it comes out to 0.5 W/m2/hour. It turns out that for heating a house 100 sq. m. 5 kW/h required. This option is considered very convenient, but the solution to the problem will have large errors.

To correctly calculate the gas consumption for heating a house of 100 m2 in cubic meters, you should use the formula:

Symbols:

| "I" | The value that determines the required volumes of fuel for heating in cubic meters |

| "G" | Maximum thermal power consumption (kW) |

| "QH" | Lower calorific value of the fuel mixture = 1.175 kW/m3 |

| «0,92» | Equipment efficiency |

Substitute the values:

| 5/(1.175 x 0.92) = 0.53 m3/h |

Next, we multiply the resulting value by 24 hours (days) and 30 days, result = 384. This is the gas consumption for heating a house of 100 m2 in cubic meters.

Knowing all the necessary values, you can easily calculate expenses for one day, month, or even the entire heating season. It is enough just to count the number of days when the heating system will be used and multiply them by the daily consumption of natural fuel.

Calculation of liquefied fuel

Using a centralized gas pipeline is undoubtedly convenient and easy, but not everyone has this opportunity, since it was simply not installed in some settlements. Owners of such real estate use liquefied gas instead of natural fuel, which is stored in cylinders or gas tanks.

Calculation of liquefied gas for heating a house or apartment

The consumption value of this type of fuel has some differences. If you need to calculate the consumption of liquefied gas for heating a house of 100 m2, which burns for 60 minutes, you need to insert the designation of the efficiency of this fuel into the basic formula.

Remember, the result of the liquefied mixture consumed is indicated in kilograms, which then need to be converted into measurement units - liters. The coolant combustion level is 12.8 kW/kg.

| 5/(12.8 x 0.92)=0.42 kg/h |

Naturally, if it is necessary to calculate gas consumption for heating a private house with total dimensions of 300 m2, the value of “5” must be multiplied by three, since it corresponds to heating 100 m2.

Next, we convert kilograms to liters, 1 liter of propane-butane = 0.54 kg, it turns out that for one hour of gas operation you need 0.78 liters = 0.42-0.54. For a whole day, 18.7 liters are spent on heating a room with an area of 100 sq.m., per month - 561 liters.

If we take into account that standard cylinders are designed for fuel with a volume of 42 liters, then in 30 days the average gas consumption for heating a house will require 14 filled tanks, which is considered very expensive compared to natural gas.

For quick orientation, we present an approximate table of calculations with standard dimensions, what gas consumption will be for a larger heated area.

| 100 m2 | 561 l |

| 150 m2 | 841.5 l |

| 200 m2 | 1122 l |

| 250 m2 | 1402.5 l |

Expert advice - options for reducing heating costs

There are some construction and technical measures that can significantly reduce the total consumption of fuel intended for heating a cottage. Naturally, first of all, you will need to replace all windows and entrance doors, since these factors are one of the main causes of heat loss. Next, you should pay attention to the insulating material and use it to create a heat-insulating layer on the outside of the walls, floors and roofs, especially for cottages built of brick or reinforced concrete.

You can reduce the average gas consumption in a private home using the following tips:

- Install a “warm floor” system, the maximum temperature level of the device’s coolant reaches 50°C, which is 40°C less than radiator units, but the effect is the same.

- Program the equipment for several home heating modes. For example, if heating is less intense during the day than at night, you can save up to 30% of fuel. Besides, what is the use of heating the house strongly during the day when the owner is at work?

- Carry out high-quality thermal insulation of a house or apartment, including replacing windows and doors - this is the very case when it is better to spend money once, in order to later save up to 40% on heating costs.

How to reduce fuel consumption for the owner of a private house

The amounts mentioned above can stun an impressionable tenant or an ordinary citizen. Well, what can you do - “your own home” was an expensive pleasure at all times. However, unlike a city dweller living in an apartment, the owner of a private home can change heating costs in his favor.

Insulating your home will help reduce heating costs

To do this, he will need to do the following:

- Insulate the facade, foundation, roof, attic and basement floors - even a thin layer of thermal insulation material can make up at least a couple thousand, or even a whole ten, from the gas bill.

- Replacing old windows with modern double-glazed windows, installing a heat-resistant panel in the doorway is another 5-10 thousand minus. Moreover, doors and windows should be tackled first, since they generate at least 40 percent of heat losses.

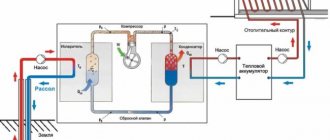

- Install a heat accumulator in the basement or boiler room, change the wiring diagram to a double-circuit or manifold version, which provides the possibility of point thermoregulation of radiators, purchase a boiler with high efficiency. Now there are excellent 95% devices on sale. In this case, savings can be up to 10-15 percent of the total bill.

In short, it is necessary, firstly, to increase the heat resistance of the house, and secondly, to use more energy-efficient equipment. And no one is forcing you to make these changes in one season. You can start with windows, then improve the boiler and get to the walls and ceilings. As a result, you can save up to a quarter of the stated costs.

Calculation method for natural gas

The approximate gas consumption for heating is calculated based on half the power of the installed boiler. The thing is that when determining the power of a gas boiler, the lowest temperature is set. This is understandable - even when it is very cold outside, the house should be warm.

You can calculate gas consumption for heating yourself

But calculating gas consumption for heating using this maximum figure is completely incorrect - after all, the temperature is generally much higher, which means much less fuel is burned. That’s why it is generally accepted that the average fuel consumption for heating is about 50% of the heat loss or boiler power.

We calculate gas consumption by heat loss

If you don’t have a boiler yet, and you estimate the cost of heating in different ways, you can calculate it from the total heat loss of the building. They are most likely known to you. The technique here is this: they take 50% of the total heat loss, add 10% to provide hot water supply and 10% to remove heat during ventilation. As a result, we obtain the average consumption in kilowatts per hour.

Next, you can find out the fuel consumption per day (multiply by 24 hours), per month (by 30 days), and, if desired, for the entire heating season (multiply by the number of months during which the heating operates). All these figures can be converted into cubic meters (knowing the specific heat of combustion of gas), and then multiply the cubic meters by the price of gas and, thus, find out the heating costs.

| Natural gas | 1 m 3 | 8000 kcal | 9.2 kW | 33.5 MJ |

| Liquefied gas | 1 kg | 10800 kcal | 12.5 kW | 45.2 MJ |

| Coal (W=10%) | 1 kg | 6450 kcal | 7.5 kW | 27 MJ |

| Wood pellets | 1 kg | 4100 kcal | 4.7 kW | 17.17 MJ |

| Dried wood (W=20%) | 1 kg | 3400 kcal | 3.9 kW | 14.24 MJ |

Example of heat loss calculation

Let the heat loss of the house be 16 kW/hour. Let's start counting:

- average heat demand per hour - 8 kW/h + 1.6 kW/h + 1.6 kW/h = 11.2 kW/h;

- per day - 11.2 kW * 24 hours = 268.8 kW;

- per month - 268.8 kW * 30 days = 8064 kW.

The actual gas consumption for heating also depends on the type of burner - modulating ones are the most economical

Convert to cubic meters. If we use natural gas, we divide the gas consumption for heating per hour: 11.2 kW/h / 9.3 kW = 1.2 m3/h. In calculations, the figure 9.3 kW is the specific heat capacity of natural gas combustion (available in the table).

By the way, you can also calculate the required amount of fuel of any type - you just need to take the heat capacity for the required fuel.

Since the boiler has not 100% efficiency, but 88-92%, you will have to make further adjustments for this - add about 10% of the obtained figure. In total, we get gas consumption for heating per hour - 1.32 cubic meters per hour. Next you can calculate:

- consumption per day: 1.32 m3 * 24 hours = 28.8 m3/day

- monthly demand: 28.8 m3/day * 30 days = 864 m3/month.

The average consumption for the heating season depends on its duration - multiply by the number of months while the heating season lasts.

This calculation is approximate. In some months, gas consumption will be much less, in the coldest month - more, but on average the figure will be about the same.

Boiler power calculation

The calculations will be a little simpler if you have the calculated boiler power - all the necessary reserves (for hot water supply and ventilation) have already been taken into account. Therefore, we simply take 50% of the calculated capacity and then calculate the consumption per day, month, per season.

For example, the design power of the boiler is 24 kW. To calculate gas consumption for heating, we take half: 12 k/W. This will be the average heat demand per hour. To determine fuel consumption per hour, we divide by the calorific value, we get 12 kW/hour / 9.3 k/W = 1.3 m3. Then everything is calculated as in the example above:

- per day: 12 kW/h * 24 hours = 288 kW in terms of the amount of gas - 1.3 m3 * 24 = 31.2 m3

- per month: 288 kW * 30 days = 8640 m3, consumption in cubic meters 31.2 m3 * 30 = 936 m3.

You can calculate gas consumption for heating a house using the design capacity of the boiler

Next, add 10% for the imperfection of the boiler, we find that for this case the consumption will be slightly more than 1000 cubic meters per month (1029.3 cubic meters). As you can see, in this case everything is even simpler - fewer numbers, but the principle is the same.

By quadrature

Even more approximate calculations can be obtained based on the square footage of the house. There are two ways:

- You can calculate according to SNiP standards - on average, heating one square meter in Central Russia requires 80 W/m2. This figure can be used if your house is built according to all requirements and has good insulation.

- You can estimate based on average statistical data: with good insulation of the house, 2.5-3 cubic meters/m2 is required;

- with average insulation, gas consumption is 4-5 cubic meters/m2.

The better the house is insulated, the lower the gas consumption for heating will be.

Each owner can assess the degree of insulation of his home; accordingly, one can estimate what gas consumption will be in this case. For example, for a house of 100 sq. m. with average insulation, 400-500 cubic meters of gas will be required for heating, for a house of 150 square meters it will take 600-750 cubic meters per month, for heating a house with an area of 200 m2 - 800-100 cubic meters of blue fuel. All this is very approximate, but the figures are derived based on many factual data.

Finding the amount of energy loss

In order to determine the amount of energy that a house loses, it is necessary to know the climatic characteristics of the area, the thermal conductivity of materials and ventilation standards. And to calculate the required volume of gas, it is enough to know its calorific value. The most important thing in this work is attention to detail.

Heating a building must compensate for heat losses that occur for two main reasons: heat leakage around the perimeter of the house and the influx of cold air through the ventilation system. Both of these processes are described by mathematical formulas, which you can use to carry out your own calculations.

Thermal conductivity and thermal resistance of the material

Any material can conduct heat. The intensity of its transmission is expressed by the thermal conductivity coefficient λ (W / (m × °C)). The lower it is, the better the structure is protected from freezing in winter.

Heating costs depend on the thermal conductivity of the material from which the house will be built. This is especially important for the “cold” regions of the country

However, buildings can be stacked or insulated with material of varying thicknesses. Therefore, in practical calculations, the heat transfer resistance coefficient is used:

R (m2 × °C / W)

It is related to thermal conductivity by the following formula:

R = h/λ,

where h is the thickness of the material (m).

Example. Let's determine the heat transfer resistance coefficient of aerated concrete blocks of grade D700 of different widths at λ = 0.16:

- width 300 mm: R = 0.3 / 0.16 = 1.88;

- width 400 mm: R = 0.4 / 0.16 = 2.50.

For insulating materials and window blocks, both the thermal conductivity coefficient and the heat transfer resistance coefficient can be given.

If the enclosing structure consists of several materials, then when determining the heat transfer resistance coefficient of the entire “pie,” the coefficients of its individual layers are summed up.

Example. The wall is built from aerated concrete blocks (λb = 0.16), 300 mm thick. From the outside it is insulated with extruded polystyrene foam (λp = 0.03) 50 mm thick, and from the inside it is lined with clapboard (λv = 0.18), 20 mm thick.

There are tables for various regions that indicate the minimum values of the total heat transfer coefficient for the perimeter of the house. They are advisory in nature

Now you can calculate the total heat transfer resistance coefficient:

R = 0.3 / 0.16 + 0.05 / 0.03 + 0.02 / 0.18 = 1.88 + 1.66 + 0.11 = 3.65.

The contribution of layers that are insignificant in terms of the “heat saving” parameter can be neglected.

Calculation of heat loss through building envelopes

Heat loss Q (W) through a homogeneous surface can be calculated as follows:

Q = S × dT / R,

Where:

- S – area of the surface under consideration (m2);

- dT – temperature difference between the air inside and outside the room (°C);

- R – coefficient of resistance to heat transfer of the surface (m2 * °C / W).

To determine the total indicator of all heat losses, perform the following steps:

- select areas that are homogeneous in terms of heat transfer resistance coefficient;

- calculate their areas;

- determine thermal resistance indicators;

- calculate heat loss for each section;

- summarize the obtained values.

Example. Corner room 3 × 4 meters on the top floor with a cold attic space. The final ceiling height is 2.7 meters. There are 2 windows, measuring 1 × 1.5 m.

Let’s find the heat loss through the perimeter at an air temperature inside “+25 °С”, and outside – “–15 °С”:

- Let us select areas that are homogeneous in terms of resistance coefficient: ceiling, wall, windows.

- Ceiling area Sp = 3 × 4 = 12 m2. Window area So = 2 × (1 × 1.5) = 3 m2. Wall area Sc = (3 + 4) × 2.7 – So = 29.4 m2.

- The coefficient of thermal resistance of the ceiling is composed of the ceiling (board 0.025 m thick), insulation (mineral wool slabs 0.10 m thick) and the wooden floor of the attic (wood and plywood with a total thickness of 0.05 m): Rп = 0.025 / 0.18 + 0.1 / 0.037 + 0.05 / 0.18 = 3.12. For windows, the value is taken from the passport of a double-glazed window: Ro = 0.50. For a wall built as in the previous example: Rс = 3.65.

- Qp = 12 × 40 / 3.12 = 154 W. Qо = 3 × 40 / 0.50 = 240 W. Qс = 29.4 × 40 / 3.65 = 322 W.

- The total heat loss of the model room through the enclosing structures is Q = Qп + Qо + Qс = 716 W.

Calculation using the above formulas gives a good approximation, provided that the material meets the declared thermal conductivity qualities and there are no errors that could be made during construction. The problem may also be the aging of materials and the structure of the house as a whole.

Typical wall and roof geometry

When determining heat loss, it is customary to take the linear parameters (length and height) of a structure internal rather than external. That is, when calculating heat transfer through a material, the contact area of warm rather than cold air is taken into account.

When calculating the internal perimeter, it is necessary to take into account the thickness of the interior partitions. The easiest way to do this is using a house plan, which is usually drawn on paper with a scale grid.

Thus, for example, with house dimensions of 8 × 10 meters and a wall thickness of 0.3 meters, the internal perimeter Pin = (9.4 + 7.4) × 2 = 33.6 m, and the external perimeter Pex = (8 + 10) × 2 = 36 m.

The interfloor ceiling usually has a thickness of 0.20 to 0.30 m. Therefore, the height of the two floors from the floor of the first to the ceiling of the second from the outside will be equal to Hexternal = 2.7 + 0.2 + 2.7 = 5.6 m. If you add up only the final height, you will get a smaller value: Hinternal = 2.7 + 2.7 = 5.4 m. The interfloor ceiling, unlike the walls, does not serve as insulation, so for calculations you need to take Hext.

For two-story houses with dimensions of about 200 m2, the difference between the area of the walls inside and outside is from 6 to 9%. Similarly, the internal dimensions take into account the geometric parameters of the roof and ceilings.

Calculating the wall area for cottages with simple geometry is elementary, since the fragments consist of rectangular sections and gables of attic and attic spaces.

The gables of attics and attics in most cases have the shape of a triangle or a vertically symmetrical pentagon. Calculating their area is quite simple

When calculating heat loss through a roof, in most cases it is enough to apply formulas for finding the areas of a triangle, rectangle and trapezoid.

The most popular forms of roofs of private houses. When measuring their parameters, you need to remember that internal dimensions are included in the calculations (without eaves overhangs)

The area of the laid roof cannot be taken into account when determining heat loss, since it also goes to the overhangs, which are not taken into account in the formula. In addition, often the material (for example, roofing felt or profiled galvanized sheet) is placed with a slight overlap.

Sometimes it seems that calculating the roof area is quite difficult. However, inside the house the geometry of the insulated fencing of the upper floor can be much simpler

The rectangular geometry of the windows also does not cause problems in calculations. If the double-glazed windows have a complex shape, then their area can not be calculated, but can be found out from the product passport.

Heat loss through the floor and foundation

Calculation of heat loss into the ground through the floor of the lower floor, as well as through the walls and floor of the basement, is calculated according to the rules prescribed in Appendix “E” of SP 50.13330.2012. The fact is that the speed of heat propagation in the ground is much lower than in the atmosphere, so soils can also be conditionally classified as insulating materials.

But since they tend to freeze, the floor area is divided into 4 zones. The width of the first three is 2 meters, and the fourth includes the remaining part.

The heat loss zones of the floor and basement follow the shape of the foundation perimeter. The main heat loss will go through zone No. 1

For each zone, the heat transfer resistance coefficient added by the soil is determined:

- zone 1: R1 = 2.1;

- zone 2: R2 = 4.3;

- zone 3: R3 = 8.6;

- zone 4: R4 = 14.2.

If the floors are insulated, then to determine the overall coefficient of thermal resistance, the insulation and soil indicators are added.

Example. Let a house with external dimensions of 10 × 8 m and a wall thickness of 0.3 meters have a basement with a depth of 2.7 meters. Its ceiling is located at ground level. It is necessary to calculate heat loss into the ground at an internal air temperature of “+25 °C”, and an external air temperature of “-15 °C”.

Let the walls be made of FBS blocks, 40 cm thick (λf = 1.69). The inside is lined with boards 4 cm thick (λd = 0.18). The basement floor is filled with expanded clay concrete, 12 cm thick (λk = 0.70). Then the thermal resistance coefficient of the plinth walls: Rс = 0.4 / 1.69 + 0.04 / 0.18 = 0.46, and the floor Rп = 0.12 / 0.70 = 0.17.

The internal dimensions of the house will be 9.4 × 7.4 meters.

Scheme of dividing the basement into zones for the task being solved. Calculating areas with such simple geometry comes down to determining the sides of rectangles and multiplying them

Let's calculate the areas and heat transfer resistance coefficients by zone:

- Zone 1 only goes along the wall. It has a perimeter of 33.6 m and a height of 2 m. Therefore, S1 = 33.6 × 2 = 67.2. Rз1 = Rс + R1 = 0.46 + 2.1 = 2.56.

- Zone 2 along the wall. It has a perimeter of 33.6 m and a height of 0.7 m. Therefore, S2c = 33.6 × 0.7 = 23.52. Rз2с = Rс + R2 = 0.46 + 4.3 = 4.76.

- Zone 2 by floor. S2п = 9.4 × 7.4 – 6.8 × 4.8 = 36.92. Rз2п = Rп + R2 = 0.17 + 4.3 = 4.47.

- Zone 3 goes only on the floor. S3 = 6.8 × 4.8 – 2.8 × 0.8 = 30.4. Rз3 = Rп + R3 = 0.17 + 8.6 = 8.77.

- Zone 4 goes only on the floor. S4 = 2.8 × 0.8 = 2.24. Rз4 = Rп + R4 = 0.17 + 14.2 = 14.37.

Heat loss of the basement Q = (S1 / Rz1 + S2c / Rz2c + S2p / Rz2p + S3 / Rz3 + S4 / Rz4) × dT = (26.25 + 4.94 + 8.26 + 3.47 + 0.16) × 40 = 1723 W.

Accounting for unheated premises

Often, when calculating heat loss, a situation arises when the house has an unheated but insulated room. In this case, energy transfer occurs in two stages. Let's consider this situation using the example of an attic.

In an insulated but not heated attic space, during the cold period the temperature is set higher than outside. This occurs due to heat transfer through the interfloor ceiling

The main problem is that the floor area between the attic and the upper floor is different from the roof and gables. In this case, it is necessary to use the heat transfer balance condition Q1 = Q2.

It can also be written in the following way:

K1 × (T1 – T#) = K2 × (T# – T2),

Where:

- K1 = S1 / R1 + … + Sn / Rn for the overlap between the warm part of the house and the cold room;

- K2 = S1 / R1 + … + Sn / Rn for overlap between a cold room and the street.

From the equality of heat transfer, we find the temperature that will be established in a cold room at known values in the house and outside. T# = (K1 × T1 + K2 × T2) / (K1 + K2). After this, we substitute the value into the formula and find the heat loss.

Example. Let the internal size of the house be 8 x 10 meters. Roof angle – 30°. The indoor air temperature is “+25 °C”, and outside – “-15 °C”.

We calculate the thermal resistance coefficient of the ceiling as in the example given in the section for calculating heat loss through building envelopes: Rп = 3.65. The overlap area is 80 m2, so K1 = 80 / 3.65 = 21.92.

Roof area S1 = (10 × / cos(30) = 92.38. We calculate the thermal resistance coefficient, taking into account the thickness of the wood (sheathing and finishing - 50 mm) and mineral wool (10 cm): R1 = 2.98.

/ cos(30) = 92.38. We calculate the thermal resistance coefficient, taking into account the thickness of the wood (sheathing and finishing - 50 mm) and mineral wool (10 cm): R1 = 2.98.

Window area for pediment S2 = 1.5. For an ordinary two-chamber double-glazed window, the thermal resistance R2 = 0.4. We calculate the area of the pediment using the formula: S3 = 82 × tg(30) / 4 – S2 = 7.74. The heat transfer resistance coefficient is the same as that of the roof: R3 = 2.98.

Heat loss through windows accounts for a significant portion of all energy losses. Therefore, in regions with cold winters, you should choose “warm” double-glazed windows

Let's calculate the coefficient for the roof (not forgetting that the number of gables is two):

K2 = S1 / R1 + 2 × (S2 / R2 + S3 / R3) = 92.38 / 2.98 + 2 × (1.5 / 0.4 + 7.74 / 2.98) = 43.69.

Let's calculate the air temperature in the attic:

T# = (21.92 × 25 + 43.69 × (–15)) / (21.92 + 43.69) = –1.64 °C.

Let's substitute the obtained value into any of the formulas for calculating heat loss (assuming they are equal in balance) and get the desired result:

Q1 = K1 × (T1 – T#) = 21.92 × (25 – (–1.64)) = 584 W.

Cooling through ventilation

A ventilation system is installed to maintain a normal microclimate in the house. This leads to the flow of cold air into the room, which also must be taken into account when calculating heat loss.

Requirements for the volume of ventilation are specified in several regulatory documents. When designing the intra-house system of a cottage, first of all, you need to take into account the requirements of §7 SNiP 41-01-2003 and §4 SanPiN 2.1.2.2645-10.

Since the generally accepted unit of measurement for heat loss is the watt, the heat capacity of air c (kJ / kg × °C) must be reduced to the dimension “W × h / kg × °C”. For air at sea level, we can take the value c = 0.28 W × h / kg × ° C.

Since the ventilation volume is measured in cubic meters per hour, it is also necessary to know the air density q (kg / m3). At normal atmospheric pressure and average humidity, this value can be taken as q = 1.30 kg/m3.

Household ventilation unit with recuperator. The declared volume that it passes is given with a small error. Therefore, it makes no sense to accurately calculate the density and heat capacity of air in the area down to hundredths.

Energy consumption to compensate for heat loss due to ventilation can be calculated using the following formula:

Q = L × q × c × dT = 0.364 × L × dT,

Where:

- L – air flow (m3/h);

- dT – temperature difference between room and incoming air (°C).

If cold air enters the house directly, then:

dT = T1 – T2,

Where:

- T1 – indoor temperature;

- T2 – outside temperature.

But for large facilities, a recuperator (heat exchanger) is usually integrated into the ventilation system. It allows you to significantly save energy resources, since partial heating of the incoming air occurs due to the temperature of the outlet flow.

The efficiency of such devices is measured in their efficiency k (%). In this case, the previous formula will take the form:

dT = (T1 – T2) × (1 – k / 100).

Gas consumption per house 100 m2

Let's take a closer look at the need for heating in houses and year-round country cottages with a small area using a liquefied gas boiler.

The required volume of liquefied gas is calculated using the formula V = Q / q × B, where: V is the estimated amount of gas; Q – thermal power required for heating housing (taken at 5 kilowatts at a nominal 10 kW, since throughout the heating season the ambient temperature can vary widely, which allows saving on the rate of LPG production); q – calorific value of fuel, for liquefied gas it is assumed to be 12.8 kW/m; B – efficiency of the existing heating boiler in absolute value (that is, less than 1).

Thus, the gas consumption for a house of 100 m2, based on the given formula for a boiler with an efficiency of 93%, is:

V = 5 / 12.8×0.93 = 0.42 (kg/h).

Based on this, the daily gas consumption for heating a 100 m2 house is: 0.42×24 = 10.08 cubic meters.

Accordingly, the monthly consumption of liquefied hydrocarbons will be: 10.08 × 30 = 302.42 cubic meters of fuel.

Taking into account that a liter of liquefied hydrocarbons weighs 0.54 kg, then the hourly gas consumption for heating a house of 100 square meters of area will require 0.42 / 0.54 = 0.78 (l) of liquefied hydrocarbons.

Speaking in more tangible terms, per day the consumption of liquefied hydrocarbons for heating a 100 m2 house will be 18.7 liters, and per month – 561 liters.

Accordingly, knowing the duration of the heating season in your place of residence (5-6 months), you can rationally select a gas holder of the optimal volume, one or two refills of which will be enough for all the household and heating needs of the inhabitants of your cottage.

We use modern automation

Well, and the obvious things: you can save gas by correctly setting the heating time. For example, if you are away from home from morning to evening, then in the boiler (if it supports such a function) you can set the thermostat to a low temperature and program an increase in power at a certain time. And if you are away from home for weeks or even months, then ideally you need to set the coolant temperature to 3-5 degrees. And let it be cold in the house. The main thing is that the pipes do not freeze.

Modern technologies have gone far ahead in this regard. Many boilers can be equipped with modern automation, which allows you to control the device remotely. You can command the boiler to change mode from your smartphone while at work. For this purpose, special GSM modules are installed on the equipment. And there are many similar smart systems. If used correctly, actual heating costs can be reduced. Sometimes savings can reach 30, 40 and even 50%. Of course, this depends on how often you are at home and what the temperature is outside.

How to calculate gas using a calculator

The amount of fuel consumed is determined according to the following rules:

- LPG consumption excluding hot water: S x Hп x Qк x K, where: S – heated area, Hп – ceiling height, Q – thermal energy losses through the enclosing structures, K – coefficient used for additional premises (storage room, attic, basement) .

- Consumption for hot water: values obtained in kW/h must be converted into units of l/h (converted through Kcal and m3).

- We recalculate the final l/h to an annual value (we multiply the consumption per hour by the operating hours of the equipment for the year).

When calculating, we take the following coefficient values (K):

- K hot water supply – 1.15;

- K (o) heated additional areas (basement + attic) - 0.95.

- K (n.o.) total (unheated (n) basement + heated (o) attic – 1.

- K (o) basement – 1.

- K (n) basement – 1.05.

- K without basement and attic floor - 1.1.

- To convert Q (thermal) values in kW to Kcal – 1.163.

- To convert m3 to l of liquefied fuel - 2.37.

- The number of operating hours of equipment annually is 2,265.

- The average equipment efficiency is 0.92.

General parameters influencing the volume of fuel burned

The amount of fuel for heating a home is calculated either in liters or in cubic meters. If gas is supplied to a residential building via a centralized gas supply system, then accounting is carried out in cubic meters.

When connecting a house to an autonomous heating system, natural liquefied gas is used in cylinders and records are kept in liters.

For the same area of the home, fuel consumption for heating depends on several parameters:

- year of construction;

- number of floors;

- construction materials;

- design features of window and door openings;

- type of heating unit.

Walls, roof, doors and windows are sources of heat loss. No powerful heating boiler will save you if the doors and windows do not close tightly, if there are cracks in the wall seams and ceiling. When installing a gas boiler in a house, measures are required to restore the thermal insulation.

LPG gas boiler: fuel consumption for heating

1. Boilers running on liquefied gas

2. Range of boilers on the domestic market3. Calculation of power of gas boilers using liquefied gas: fuel consumption

Today, autonomous heat supply systems are in demand among owners of private households. The source of heat for them is often liquefied gas for heating the house. The type of “autonomy” using a gas boiler using liquefied gas, the consumption of which is minimal, is the most popular.

Boilers running on liquefied gas

Modern gas heating using liquefied gas involves the use of a whole complex consisting of several types of equipment and a heat supply system.

But the main unit still remains the boiler, which provides heat from fuel.

As in traditional heating designs, a liquefied gas boiler for private buildings allows, through its combustion, to provide heating for residential premises and hot water supply, since a combination of these two functions is possible.

Even with low pressure in the design, liquefied gas heating has insignificant fuel consumption. This allows you to save a considerable amount of money from the family budget. At the same time, liquefied gas for heating will be used as efficiently as possible.

note

Owners of private households should know that liquefied gas heating boilers can be easily switched to another operating mode - using a different type of fuel, or rather main gas. For this purpose, not only injectors are replaced, but also other equipment elements.

Thus, it turns out that the buyer purchases two boilers in one and saves a lot of money and time. The choice of heating units operating on liquefied gas on the domestic market is simply huge. There are also products from various global manufacturers. Each model has unique performance characteristics and, accordingly, cost.

In order for heating a country cottage or summer house with liquefied gas from a gas tank to be economical and efficient, it is necessary to choose the right type of heating unit and take into account all the operating features.

When purchasing a device, you should consider:

Type of heating device. Heating boilers using liquefied gas are single-circuit and double-circuit. The first of them are intended exclusively for heating, but the second type provides both space heating and hot water supply. Heating devices can be hung on the wall or installed on the floor. And the combustion chambers are made open or closed.

Efficiency It can be said that all units operating on liquefied gas are characterized by high efficiency rates (90-94%). Therefore, they are installed in houses, country houses or other buildings. As a result, the higher this indicator is for the equipment, the more economically and efficiently the fuel is used.

Power. It is one of the main parameters for this type of heating equipment.

Manufacturing company. As practice has proven, it is advisable to give preference to companies that have been proven for a long time, whose products are distinguished by quality that meets the standards, reliability, and long service life.

Only employees of companies professionally involved in the supply and installation of such heating units can make accurate calculations of the power of heating equipment operating on liquefied gas. To do this, they will need to provide all the data about the room in which they plan to install it. Also, when calculating heating a cottage with gas, the characteristics of the model are taken into account and the liquefied gas consumption of the gas boiler is determined. Such calculations are not cheap, so many consumers limit themselves to rough calculations performed independently. To do this, it is generally accepted that for 10 “squares” of room area, 1 kW of thermal energy is required to provide heating, despite the fact that the ceiling height does not exceed three meters. This option for gas heating of a country house is not very accurate in determining the required power, but it will help you choose heating equipment. If it is necessary to accurately select a unit, a large number of parameters and factors should be taken into account, including the volume of the room, the presence/absence of additional insulation, the size and number of windows and doors, etc. The propane-butane mixture, which is the main source of energy in autonomous gas supply systems, is an economical and inexpensive type of fuel and therefore it is not advisable to save on the boiler.

Starting a gas boiler using liquefied gas, video:

Advantages and disadvantages of units

Gas equipment for heating a private home has the following advantages:

- Autonomy and independence from the central highway, changing prices and emergency situations.

- High efficiency rates - 92-95%. Sometimes the values reach 97%.

- Quiet operation.

- Ease of maintenance and repair in case of failures. The system is easy to maintain, since all maintenance consists of replacing fuel filters, injectors and cleaning the coolant.

- Possibility of converting the system to work with centralized gas supply. If you want to connect it to the highway, you will not have to buy additional equipment.

- Long service life. For some models it reaches 25 years.

- Work safety. The fuel remains non-flammable even at high temperatures inside the chamber.

Non-volatile units are available on the market, guaranteeing complete autonomy in remote communities.

The disadvantages of the equipment include the following points:

- The need for simultaneous use of 3-4 cylinders. In this case, a gas reducer is used to connect the cylinders to the boiler.

- Fuel tanks should not be installed near the boiler - it is better to place them in adjacent rooms with a working ventilation system.

- When performing installation work, it is important to be careful and careful.

- The desire to re-equip the system will require considerable financial investments. Sometimes they reach 30-50% of the cost of the unit.

Gas consumption using specific examples

To determine what the natural gas consumption will be when heating a one-story house of 100 m2, you first need to determine the heat load.

Heat load calculation

To obtain the most accurate data on the heated volume of the house, the volume of each room and auxiliary premises where it is necessary to maintain heat is separately calculated. Length and width measurements are taken along the baseboards using a regular or laser tape measure.

We will do it simpler: we take the ceiling height as 2.5 meters, multiply it by the indicated area and get the volume of the house V = 250 m3.

If the room has a complex architectural shape, it is divided into rectangles, triangles, circles, the area of each of them is calculated and summed up

To determine ΔT, column 6 in table 3.1 SP 131.13330.2012 is used. The air temperature of the coldest period is indicated here, calculated based on average monthly temperatures.

We find the name of the locality where the heated facility is located. Let's say this is Bryansk, therefore, the desired value is -12 °C. The temperature in living rooms according to GOST R 51617-2000 should be within 18-24 °C. Taking the average value of 22 °C, we get ΔT= 34 °C.

We determine the degree of thermal insulation of the house and apply the appropriate coefficient. In the context of rising prices for coolants, most homeowners strive to increase the energy efficiency of heating by improving the thermal insulation of their home, so it is quite reasonable to use the first indicator of the average degree of thermal insulation, which is equal to 1.

We summarize all the values using the formula:

250 m3 × 34 °C × 1 / 860 = 9.88 kW/h.

Let's apply the rounding rule to the nearest integer and get Q = 10 kW/h.

Don’t neglect automatic control - set different heating modes for night and daytime to ensure a comfortable microclimate regardless of the temperature outside and save up to 30% on gas

Let us remind you that we have only done a thermal engineering calculation of the house and now the next step is to calculate the gas consumption. But for now it would be appropriate to make a small digression and clarify that the heating load can be calculated in a simplified way.

Note that the power of a gas boiler can be calculated for a specific facility, taking into account all the technical nuances. According to average data, for every meter of standard living space there is 100 Wh of thermal energy. Therefore, for a house with an area of 100 m2, this figure will be 100 W/h × 100 m2 = 10,000 Wh or 10 kW/h.

In this case, calculations using the formula and the simplified method gave the same result, but this does not always happen, and the difference often reaches 20% or more. Moreover, heating engineers always recommend buying turbocharged and atmospheric boilers with a margin of 20-25%, with the expectation of being able to cover heat losses on days with critically low temperatures.

How to pay less

Since you won’t be able to significantly win in price by installing autonomous heating, you need to turn to energy-saving technologies.

- Carry out thorough insulation of not only the walls of the building, but also the roof, floor, foundation, even the basement, if there is one.

- Replace double-glazed windows with energy-saving ones, the profile is frost-proof.

- Install a boiler with maximum efficiency and an electronic thermostat.

- Check the condition of the house's thermal insulation using a thermal imager to identify cold spots and eliminate them.

- Change the ventilation and air conditioning system. Just an open vent or a window set for ventilation takes in more heat than a window opened for 5-7 minutes and a complete change of air in the room.

- Install heated floors , especially in hallways and hallways.

- Install electronic sensors to block heating above the set temperature.

It is very effective to use the smart home system, which will reduce gas consumption by at least 25%. If you follow all the tips, your home will be warm and cozy, and your gas bills won’t be terrible.

The smart home system is easier and more comfortable to control using a remote control Source archidom.ru

Calculation formula for main fuel

The power of the boiler affects gas consumption in a private home, so the owner must first calculate the fuel consumption, focusing on gas equipment. The area of the cottage is also taken into account. Each room is calculated separately, based on the average annual street temperature and starting from the obtained minimum value.

To calculate gas consumption, the identified number must be divided by 2, since each winter season has different air temperatures. In the northern regions, it can reach serious disadvantages; accordingly, resource consumption will be higher than in the southern regions.

According to all the rules, it is calculated as follows: the ratio is 1 kW per 10 sq. m. area of the house. Divide the resulting number in half, resulting in 50 watts for 60 minutes of heating. A house with an area of 100 m² will consume approximately 5 kW. Formula for calculating gas consumption in a private home (A=Q/q*B):

- A - cubic meter of resource consumption in 60 minutes;

- Q is the power of equipment for heating the house, in this case 5 kW;

- q - determines the minimum specific heat, it all depends on the type of fuel, for example, for G20 - 34.02 MJ per 1 cubic meter comes out to almost 10 kW;

- B is the efficiency of the equipment, for example, it works at 90%, which means they take the figure at 0.90.

All that remains is to substitute the required numbers instead of the letters in the formula. In this case, gas consumption per 100 sq. m. will be like this: 0.560 cubic meters per 60 minutes of boiler operation. For heating a room with an area of 150 sq. m. it will turn out to be 0.840 cubic meters and 7.5 kW. For suburban real estate, 1,115 cubic meters and approximately 10 kW will be spent on 200 m².

For a room of 250 m² it will be 1,392 cubic meters. A house of 300 m² will use 1,662 cubic meters. resource. The resulting number is multiplied by 24 hours and the consumption per day is determined, and then multiplied by 30 days.

Warm floor or conventional radiators

Also, the correct heating design plays an important role. It is estimated that a well-designed and implemented heated floor will reduce gas consumption. Conventional radiators would require more gas to heat indoor air to the same level. This is due to the fact that thanks to a warm floor, heat rises from bottom to top and spreads throughout the entire area of the room. But conventional batteries heat the outer wall, which is why their efficiency is lower.

Also, the standard floor temperature is 50 degrees, the radiator is 90 degrees. Obviously, the floors will be more efficient and economical. Yes, the project and installation of flooring will cost more, but the difference in price will pay off very quickly.

Example for district heating

Note!

The initial data was taken for a gas mixture of grade G 20. It is this that enters houses from a centralized main.

In order to calculate gas consumption for heating, you need to use a fairly simple formula.

V= Q / (Hi x efficiency)

Where:

V – fuel consumption m3/h; Q is the estimated thermal power required to heat the house; Hi is the lowest value of specific heat during fuel combustion. In accordance with the DIN EN 437 standard, for G 20 fuel this value is 34.02 MJ/m3. Efficiency is the efficiency coefficient of the boiler unit, the value of which shows the efficiency of using the thermal energy released during the combustion of the gas mixture to heat the coolant.

Important!

Initial data: house area 100 m2, recommended heat generator power 10 kW. The efficiency of the boiler unit is 95%.

- The first thing to do is convert joules to watts. To do this you need to know that 1 kW = 3.6 MJ. For G 20 gas, the calorific value will be 34.02/3.6 = 9.45 kW.

- The value of 10 kW is the amount of heat that will be required to heat a house in the most unfavorable conditions. During the rest of the heating season, significantly less power is required to heat the house. Based on this, for correct calculations it is necessary to use half of the recommended power. In our case, half is 5 kW.

We substitute the obtained data: V = 5 / (9.45 x 0.95) Total: gas consumption for heating a house of 100 m2 is 0.557 m3/h. Based on the data obtained, it is easy to calculate the consumption of main gas per day and for the entire heating season, which in most regions of Russia lasts 7 months.

- In 24 hours 0.557 x 24 = 13.37 m3;

- For 30 days 13.37 x 30 = 401.1 m3;

- For 7 months (heating season) 401.1 x 7 = 2,807.7 m3.

Knowing the tariffs for paying for a cubic meter of “blue fuel”, you can quite accurately calculate the financial costs of heating for the billing period.

Stepping away from the topic, we would like to inform you that we have prepared comparative reviews on gas boilers. You can familiarize yourself with them in the following materials:

- Gas wall-mounted double-circuit boilers - comparison of models from world brands

- Rating of gas wall-mounted single-circuit boilers with a closed combustion chamber

- Russian-made gas floor-standing boilers: ATON, Concord, Lemax

- How to choose a gas floor-standing boiler based on reliability? Rating of proven models

Why choose gas

In the last century, firewood was chosen as an economically viable fuel. With the development of mechanics and technology, the palm passed to coal. The discovery of natural combustible gas deposits has replaced coal, and there are fewer harmful emissions into the atmosphere.

The era of the development of green energy and the exploitation of renewable energy sources in the form of solar radiation and wind has arrived. But not everywhere the number of windy days is sufficient to generate and accumulate electricity necessary to heat a water boiler. Solar panels are still expensive. A person adheres to a conservative and inexpensive method of heating his home - with natural gas.

Let's compare emissions from the combustion of coal and natural gas.

| Pollutant | Emissions from combustion, maximum | |

| Hard coal, g/t | Natural gas, g/m3 | |

| Ash | % of working mass of fuel | No |

| Carbon dioxide CO2 | 3000 | 2000 |

| Nitrogen oxides in terms of NO2 | 14 | 11 |

| Sulfur oxides in terms of SO2 | 0,19 | — |

| Benzopyrene | 0,014 | 0,001 |

As can be seen from the table, the content of substances hazardous to human health in gas is lower than in coal. Therefore, natural blue fuel is used to heat homes.

Liquefied gas consumption per month and year

Let's go over the costs of refilling a gas tank for houses of different sizes. We use the LPG price current at the beginning of 2022 - 17.80 rubles/l. This is the cost of refueling in our company.

House area (m2) Gas consumption per month (l) Gas price per month (rub.) Gas consumption per year (l) Gas price per year (rub.)

| 50–100 | 316 | 5 624 | 3 802 | 67 675 |

| 150 | 475 | 8 455 | 5 703 | 101 153 |

| 200 | 633 | 11 267 | 7 603 | 135 533 |

| 250 | 792 | 14 097 | 9 504 | 169 171 |

| 300 | 950 | 16 910 | 11 405 | 203 009 |

| 350–450 | 1 425 | 15 365 | 17 107 | 304 504 |

| 500–600 | 1 900 | 33 820 | 22 809 | 406 000 |

| 800 | 2 534 | 45 105 | 30 412 | 541 334 |

Thus:

- gas consumption for heating a house of 100 m2 is 68 thousand rubles per year;

- gas consumption for heating a house of 150 m2 is 101 thousand rubles per year;

- gas consumption for heating a house of 200 m2 is 136 thousand rubles per year.

Gas holder or cylinders as storage?

For many homeowners, it is more convenient to store supplies in cylinders, which pose a potentially greater danger. The absence of a safety valve increases the risk of tank rupture.

That is, it is not the gas inside that explodes, but the cylinder itself.

Gas holder for storage

The gas holder is considered a safer method of storage, which does not require the assembly of an insulating cabinet, and also comes with an electromagnetic safety valve.

The unit is placed underground, buried with sand, leaving it under pressure. This way, the integrity of the walls is maintained and the chance of fire getting in is completely eliminated.

In practice, there are cases when, during the burning of peatlands, a gas holder, which began to heat up, completely released the existing gas into the surrounding space and became completely safe. The installation circuit heats up to a red state, but no explosion occurs.

How much propane-butane do you need for the heating season?

Modern gas boilers are designed to use not only main gas, but also liquefied gas. To stock up on the required amount of fuel, they use not ordinary gas cylinders, but more capacious tanks - gas tanks.

The use of gas tanks solves the problem of storing liquefied hydrocarbon fuel sufficient to heat a house of 100 square meters. m, throughout the heating season in a temperate climate zone

When calculating the consumption of liquefied gas required to heat a 100m2 house, the same methodology is used, but the values of some variables in the formula change.

A liquefied propane-butane mixture is supplied for household needs.

Its calorific value is 12.8 kW/kg. We substitute this parameter into the formula and get:

V = 10 / (92.5 / 100 × 12.8). V = 0.8 kg/h.

When operating on liquefied fuel, the efficiency of the equipment decreases, so gas consumption increases by approximately 10% and amounts to 0.88 kg/h per day. The correction may be different for your boiler model. The specific value is indicated in the attached documentation.

Now we calculate the required amount of gas for the heating season: 0.88 × 24 × 183 = 3865 kg. This value must also be divided by 2 due to temperature fluctuations. Final result: 1932.5 kg of propane-butane is required for the heating season.

It will be useful to convert kilograms to liters. Based on reference data, 540 grams of liquefied propane-butane mixture corresponds to 1 liter. That is, for the entire heating season, 3578 liters of liquefied gas will be required.

The nuances of using cylinders in winter

If bottled gas is used to heat a country house, then in winter you need to take care to protect the fuel from freezing.

This is especially true for buildings for seasonal use, for example, dachas, when the owners come to the house only on weekends. If fuel containers are stored outside the house, then at sub-zero temperatures the pressure in them decreases. If the pressure drops significantly, heating equipment may stop working. To avoid this situation, containers with fuel during cold weather are installed in a special cabinet with a built-in ventilation system. Non-flammable insulation is used to insulate the cabinet.

If there is no such cabinet, then it is better to store containers with fuel in an extension to the house, in which there is no heating, but a positive temperature is constantly maintained due to good insulation. Do not forget about other safety requirements when choosing a suitable place to install cylinders for the winter.

Conclusions and useful video on the topic

Are you careful about heat energy, but your neighbor still uses less? The author of the video decided to share his own experience of using LPG for home heating. Perhaps this information will be useful to you too.

Do thermostats and temperature sensors really help to significantly reduce gas costs during the heating season? The video demonstrates how this happens in practice.

To determine the upcoming gas consumption for heating, a higher education is not required. Knowing how the simplest mathematical operations are performed, you will calculate the necessary parameters with an acceptable error.

Along the way, you will be able to identify weak points in your home, minimize heat losses, eliminate heat leakage to the outside and, as a result, take advantage of all the benefits of blue fuel.

Please comment on the information we provide with calculation balls and formulas for determining gas consumption. You can share useful information on the topic of the article, or post a photo in the block below. It is possible that your recommendations will be useful to site visitors.