The kitchen in an apartment or house is rightfully considered the embodiment of family hearth and comfort. But how much will this room sparkle with other colors if you add a hand-made touch to its design. An excellent solution for implementing this idea would be a self-made countertop.

The dining table in the kitchen involuntarily attracts the eye, so it must be beautiful in appearance and fit into the interior, but we should not forget about such qualities as strength and reliability.

Of course, the range of modern furniture stores is very wide and varied. You can choose a tabletop to suit almost every taste, however, not to suit every budget.

To save a lot of money and also make your kitchen original, you can try making a kitchen countertop with your own hands.

You need to understand that when choosing a high-quality and modern countertop, you also need to pay attention to the kitchen furniture - it should not be inferior in quality to a modern countertop.

Preparing for work

Before you begin manufacturing the product, you must prepare all the necessary tools and materials. When everything you might need is at hand, your work will become much more productive, rational and you can save a lot of time. To do this, first of all, you should decide on the type of product that will soon appear in the kitchen.

Installation rules

Rules to consider during transportation and installation:

- The product is fragile, so it must be transported carefully. Particular attention is paid to smooth glossy surfaces.

- Weak spots in the tabletop sometimes bend when moved, so only two people need to move it.

- If the measurements are incorrect, the tabletop will not fit the set, and you will have to buy a new surface.

- The cut areas are treated and hermetically sealed.

What types of countertops are there?

There are quite a lot of materials for making a table. To decide, first of all you should take into account the interior and design of the kitchen as a whole, and also do not forget that the surface must be resistant to damage, temperature changes and mechanical stress.

With a successful combination of all these nuances, a hand-made tabletop will last a long time, while maintaining a presentable appearance.

It is worth noting several of the most popular materials for making countertops:

- tree;

- concrete;

- chipboard;

- MDF;

- ceramic tile;

- natural or artificial stone.

A fairly common option is a tile countertop. The choice of ceramics is very large and you can choose absolutely any design.

A countertop made of artificial stone will also fit beautifully and unusually into any room. This option is more economical than using natural stone. But at the same time it is distinguished by its environmental friendliness and durability.

Details

Varieties

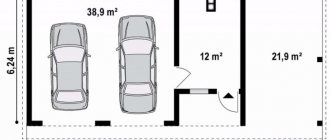

Such designs can be very different. They can be roughly divided into linear and corner countertops for the kitchen, which are not difficult to make with your own hands. It’s easier to make linear ones, since in this case you don’t have to take into account angular curvature, which often makes the workflow more complicated. This is extremely important for structures made of tiles, which will reveal any flaw in the walls by the mismatch of seams between the tiles. So, if everything is clear with linear structures, then corner countertops can have a laconic or complex shape. For example, the table may have smooth corners, which will ensure safety when moving around the kitchen in conditions of lack of space. Moreover, corner models according to the drawings can be made from 3 conventional figures - 2 rectangles and a square in the corner with a beveled corner. Depending on the type, it can be monolithic or prefabricated. Joining in products made of MDF and wood, chipboard can be seamless. It is believed that sawing became the most technologically advanced option, and therefore monolithic structures have become a rarity.

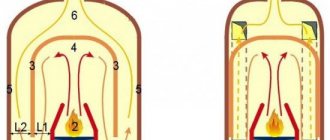

How to make a concrete countertop with your own hands

To give a homemade concrete countertop a beautiful appearance with a marbled texture, in addition to the necessary accessories, you need to consider the presence of a grinding machine. For the work, it is worth preparing plywood (chipboard), aluminum profiles, boards, crushed stone, sand and wire for reinforcement. Even during creation, you need sealant, drying oil, assembly adhesive and paint and varnish for concrete. First, make formwork from boards 4 cm thick. You need to cut the chipboard sheets to size, install the sides, and secure them with self-tapping screws. The places where plywood and beams are fixed are filled with silicone, which will prevent concrete from getting into the cracks. The formwork should be treated from the inside with drying oil so that the solution does not stick to the boards.

As reinforcement, you need to use wire with a thickness of no more than 0.8 cm. A lattice is made from it, slightly smaller than the formwork, and placed in a container into which glue is poured. The grating needs to be glued to the plywood, and after complete drying, you can pour in a concrete solution. To prepare, mix crushed stone, cement and sand in a ratio of 2:1:2. To improve quality, it is worth adding a plasticizer to the solution. The dye is added at the rate of 1 to 50, leaving a little for the finished tabletop. The excess is removed with a spatula, and then the countertop is covered with polyethylene for approximately 1 week. After drying, the surface should be sanded smooth and placed on an old kitchen table. Before this, the old tabletop needs to be removed and the body reinforced with timber supports. You can put the stove in a permanent place.

Manufacturing from chipboard

To make such a tabletop, prepare chipboard boards (this will be the working surface). When working, use 1st grade material with a minimum number of visual defects. To make the chipboard tabletop more durable, it should be made monolithic. Before you start marking the slab, prepare drawings with exact dimensions, holes for tiles and sinks. After this, transfer the dimensions onto chipboard sheets, cut the material with an electric jigsaw with knives of the required size. If it is not there, then use a sharp hacksaw. For smooth sawing and cutting without chips/burrs, stick masking tape along the sawing line. When working, you should use blades with fine teeth. The composite needs to be shaped by grinding the corners and ends, and then checking the surface for smoothness and evenness. If you notice unevenness, then sand everything “to the level”. You can use sandpaper for this.

Afterwards, you can begin to impregnate the composite, and then decorate the surface and produce finishing coatings. The tabletop is treated with protective coatings, and after drying, it is varnished several times. In this case, all new layers are applied only after the previous one has completely dried. Before processing, it is imperative to apply a primer layer to the composite. Only after all this can you paint the slab. A chipboard countertop for the kitchen is made by hand and treated with stain. This substance is suitable for processing particle boards, and this composition usually dries out after 10-12 hours. Varnishing is done with water-based paints, and the ends can be treated with melanin edge or veneer.

Tile covering

The tile countertop is laid on 2 plywood layers, and they must also be glued together. To improve the quality of the product, the slabs should be treated with waterproofing material. The convenience of the technology is the fact that the design can be made larger than the original one. At the initial working stage, measurements are taken and the material is selected so as to reduce the number of cuts. If you plan to update old countertops, then you can use a pedestal kitchen set. In other cases, painted chipboard should be used. It is worth cutting it with a circular saw (taking into account the required dimensions). After cutting the edge of the substrate, it is worth treating the coating with a moisture-resistant impregnation. You can apply oil putty, but first apply masking tape. Afterwards, the ends are sanded and treated with an oil-based paint and varnish composition. Assembly is carried out using metal corners, screws and dowels. Before you start tiling the countertop, you should coat it with a moisture-resistant impregnation using a paint brush with natural bristles. After that, drying oil is applied, and when the structure dries, you can begin finishing the surface with ceramic material.

It is best to use epoxy/acrylic based glue, as cement glue will not adhere well to the surface of the wood. Laying is done in a thin layer, distributing the mass of glue with notched spatulas. Work begins from the front side and leads to the rear edge (wall). New rows are laid end to end, and when working, special clamps or crosses are used. The ends should be decorated with mosaics or wooden slats. At the final stage of finishing the countertop, you need to grout the seams with a grout mixture. Afterwards, wait for the grout to dry and use a regular dishwashing sponge to get rid of the excess, polishing the finished surface.

Formwork

After installing the diagonal braces and horizontal lintels, you can begin assembling the formwork and base for the table.

It must be remembered that after pouring the concrete solution, the formwork will need to be removed, so it should be made taking into account the fact that the canvas must remain intact. For the same purpose, you can cover it with polyethylene, which will also prevent concrete leaks onto the floor.

Experts say a goose flying upside down is just showing off

This photo was taken at the beginning of the year by a Dutch amateur photographer.

The trick is that the geese turn their body upside down and turn their neck and head 180 degrees to their normal position.

Why are they doing this? There has been a lot of debate on this topic. It was assumed that this is how they protect themselves from land-based predators that can grab them by the paws, or that it is easier to fly in a headwind.

But experts have studied and given the answer: Geese simply show off in front of their relatives in order to become respected in their flock.

I can just imagine this picture: “Guys, look what I can do. Hoba!

Pouring the solution

Reinforcing bars are placed in the formwork and fastened together. Prepare a concrete solution: mix cement, sand, crushed stone in a ratio of 1:2:2. The mass is thoroughly mixed. Water is added. Until the mixture reaches a creamy consistency. Next, the solution is poured into the formwork to the desired height.

DIY fan: how to make a homemade powerful fan. Basic parameters and properties of fans (130 photos)- Why do you need a security alarm, what functions does it perform?

- How to choose winter workwear and not make a mistake - recommendations from the pros

Natural migration

“We are already afraid to look at them, but soon we will bow to them and wash our feet.” Police Major General Vladimir Mikhalevich issued a prophecy about the future of Russia, which is already being divided with might and main by migrants.

After another mass fight between migrants in Moscow, society started talking about the need to urgently solve the problem with newcomers. A member of the presidium of the all-Russian organization “Officers of Russia,” Police Major General Vladimir Mikhalevich is sure: if we do not address this issue right now, we will lose the country.

They are dividing our country. We’re even nobody here anymore, and they’re sharing—not sharing with us anymore, but with each other. And they will not calm down,” the general expressed concern.

The critical mass has already been reached. And everyone understands this, it is impossible not to see it. At the same time, it seems that migrants no longer consider us to be people. They don’t even behave the same way at home as we do, allowing themselves to do whatever they want, but we can’t even give them a reprimand.

Look what's going on in the metro, especially in the evening. It feels like you are no longer in Moscow, not even in Russia. And look how defiantly they behave. Why is this so? Because we allowed them - both the authorities and society.

There is no good way here. You can’t use exhortations here,” Mikhalevich is trying to reach the authorities. He explained that the “guests” perceive each of our retreats as our weakness: “If we are weak, then they can continue to treat us like this.”

At the same time, a high-ranking police officer is confident that no new laws are needed - you just need to monitor the implementation of those that exist:

There is no need to invent anything new, we have everything. What are you doing here? Collected and checked. You had to work, are you labor migrants, do you have a work permit? Yes, I have. All work permits have been raised. They are at least 50 percent, I think even more, fictitious. We figured out who. Firstly, there is already criminal liability for these work permits; this is Article 327, a document granting the right. The right to work, but they don’t work. This is a fictitious document. We have everything in laws.

“If we start working, we will restore order,” Mikhalevich promised.

Epoxy countertop

If the main thing when choosing a material for making a table is such qualities as uniqueness and inimitability, then an epoxy tabletop will be an excellent solution; making it with your own hands is not as difficult as it might initially seem. This material is incredibly easy to use, and also has an affordable price and functionality.

An epoxy countertop will be an incredibly durable product that is not susceptible to chips, scratches and other damage.

Moreover, the resin can be used as a coating for a ready-made countertop made of stone, wood or other material, or as an independent base.

Having considered many options, assessing the pros and cons, it becomes much easier to choose the material for the manufacture of the future product.

- How to choose an air conditioner for your home or apartment

- Do-it-yourself bait - composition, application features and storage methods (115 photos and videos)

- DIY sliding gates - how to build simple and automatic gates. Schemes, drawings and review of the best ideas (90 photos)

Knowing how to install a countertop with your own hands, you can not only save money, but also purchase an unusual, extraordinary and completely individual piece of furniture that will last for years.

Compound

The composite material is created from certain components:

- aluminum trihydrate (natural mineral);

- acrylic resins - methyl methacrylate (MMA) and polymethyl methacrylate (PMMA);

- fillers of natural origin;

- coloring pigments.

A distinctive feature of good quality composite stone is the relatively high cost of polymethyl methacrylate (PMMA). But it is to him that the finished tabletop, resistant to mechanical damage, owes its strength.

Methyl methacrylate (MMA) is less durable and less expensive. The predominance of any acrylic resin in the composition is not visually obvious, but significantly affects the operation of the surface and its durability.

Artificial stone is produced according to the conditions of the technological process. Fillers are added in specific proportions, and mixing is carried out in a vacuum environment at the appropriate temperature. The resulting homogeneous mass with a viscous consistency hardens in special molds, where the composite is finally formed. Sheet thickness is up to 25 mm.

In modern industry, there are several varieties of such material. They will be discussed below.

Acrylic

It is a mixture of filler and acrylic resin. It is the most popular artificial stone. It is unique, attractive and durable.

Polyester

A rather pleasant structure is obtained due to polyester resins. Due to its inability to bend, like acrylic, it costs less and is a high-quality and popular material.

Quartz agglomerate

It is natural quartz (93%). The remaining 7% of the composition is occupied by sedimentary rocks, coloring pigments and other substances. The material is practical and resistant to acids and other chemicals.

Cast marble

This is a variation of liquid stone. It is also called granite, artificial marble, polymer concrete or cast stone. The downside is that it has a not very pleasant smell. It dissipates in the finished product after a few months of use.

The characteristics of the composite are also influenced by the technologies used in production.

It is necessary to take into account the country of manufacture and brand, since the origin of the material is reflected in the finished product

DIY tabletop photo

Pros and cons of the material

Furniture panels made of larch or any other wood have many advantages that make it a practical, profitable, convenient material, one of the best in its category. Its advantages include:

- Eco-friendly, hypoallergenic, natural.

- Beauty and resemblance to solid wood.

- Longer service life than MDF or chipboard.

- Possibility of repair with replacement of damaged fragments without compromising aesthetic qualities.

- Hygroscopicity, that is, the ability to tolerate different humidity levels.

- Absorbing ability that reduces the concentration of harmful substances in the room, characteristic of wood.

- The optimal combination of cost and quality.

What are furniture confirmations, advantages and disadvantages

However, in cases where the correct technology was not followed during production, for example, the raw materials were wet, the larch furniture panel may change its shape, bend or stretch. There is also a risk of internal cracks forming, which lead to unexpected failures, especially when driving nails or screwing in screws. For this reason, it is necessary to choose only trusted manufacturers, otherwise there is a high probability of encountering defects.

If you need a light, durable furniture panel, larch will be an excellent choice. It is slightly susceptible to rotting, insects, fire or warping, is durable, and has a pleasant pine smell. Compared to other types of wood, its cost is very affordable. Some facing products can be spoiled by an abundance of resin.

Over time, a larch panel becomes hard as stone, making it increasingly difficult to drive nails or carry out repairs.

Eco-friendly, hypoallergenic, natural Long service life

Hygroscopicity

Absorbency

Varieties

More than 20 varieties of larch have been identified. Of these, 14 grow in Russia. In our country, Siberian larch and Daurian larch are mainly represented, which are among the most common varieties.

Siberian larch (also called Sukachev larch) occupies about 13-15% among other varieties. It can be recognized by the branches extending from the trunk at right angles. Their ends smoothly rise upward. The tree is quite unpretentious and grows in an urban environment. It almost entirely has properties beneficial to humans (bark, needles, and resin).

Daurian larch is the most common tree. This is one of the most frost-resistant varieties. It grows on many soils, but not on excessively swampy ones with a large excess of moisture.

In addition to Siberian and Daurian, European and Japanese (kaempfera) are also widespread.

European most often grows in Europe (Central and Western). It should be noted that this variety has about 5 breeds (Horstmann Recurved, Kornik, Puli and others). This is the tallest variety: in the Alps the height reaches 50 m, the trunk diameter is more than 1 m. In Russia, European larch cannot grow to such parameters due to climatic conditions (here the maximum height will be 25 m, but this does not always happen).

Japanese larch got its name from the country where its characteristics were first discovered. Widely grown in Korea. Used for decorative purposes only. Characterized by a height of up to 35 m, in autumn the needles turn bright yellow.

In addition to the varieties mentioned above, there are also Kuril and Olga varieties. Hybrids have also been bred: Amur, Chekanovsky, Lyubarsky, Okhotsk. Nowadays, to improve the territory of a personal plot, you can buy varieties of decorative larch species specially bred by breeders from nurseries. They are considered, unlike wild species, to be dwarf trees (their height does not exceed 2 meters). These are the varieties “Puli”, “Kornik”, “Krejci” and others.

Nuances of processing structures

The characteristic features of the breed, which are highly valued in furniture production, make it difficult and labor-intensive to process the material. Given its hardness and high resin content, manufacturers use special technologies aimed at preventing cracking and oiling of cutting equipment.

Raw materials go through several stages of production:

- harvesting - selection, marking of trees, cutting;

- mechanical processing - includes cleaning trunks from branches, bark, sawing into boards;

- atmospheric, chamber drying;

- cutting, grinding on a machine;

- gluing, finishing.

Processing the material has its own nuances:

- quick drying is not applicable;

- The wood is easy to paint and can be tinted after preliminary de-resining.

A shield made in this way is not subject to deformation; there are no visible defects, cracks, stains, or knots on its surface. Boards for the production of furnishings are panels made of timber or continuous lamellas glued into strips.

The lamellas are made from solid wood, which is more resistant to bending and durable. It is preferable to choose such lumber for work surfaces, countertops, and bookshelves.

An indicator of quality during production is the radial cut, which is visible on the left side of the lamella.

Gluing the material can have several options:

- single layer;

- two-sided;

- spliced along the length of the fiber;

- cladding with valuable species.

When choosing a glued board, you need to take into account the purpose of the product: strength, reliability of the structure, or an effective decor that complements the interior. Furniture made from larch does not require additional processing. However, you need to remember that wood products must be in harmony with the interior style and overall color scheme. If the natural color of the products does not match the decor, it can be changed using stain, paint, varnish, but only in a darker direction. When making furniture, you can achieve the effect of artificial aging using chemical, mechanical, and thermal methods.

Material advantages

Molded larch materials have a number of positive qualities:

- strength and moisture resistance;

- resistance to microorganisms and insects;

- aesthetics of products;

- durability;

- not susceptible to cracking or deformation;

- attractive surface texture;

- fire resistance.

Due to the presence of resins in the structure of the tree, larch moldings can be used in all spheres of human activity. And the pleasant aroma of pine needles will bring the feeling of being in nature into your home.

Humidity, temperature fluctuations, shuffling and intensive use do not affect the building material. Over time, it is able to harden and become harder.

The decorative qualities of wood allow the molding to fit into any interior. A warm brown and beige color scheme will make the room bright and attractive.