Installing a sink on a vanity is a common type of work ordered from plumbers. However, sometimes even masters make offensive mistakes, as a result of which sinks begin to leak, crack and quickly lose their appearance. The only way to avoid such dire consequences is to take matters into your own hands.

And if the installation of a bathtub or toilet is hardly accessible to a non-professional, but even an uninitiated person in the secrets of plumbing can cope with the installation of a sink and even the cabinet itself, with the proper skill. We'll talk about how to attach a sink to a bathroom cabinet below.

How to attach a sink to a bathroom vanity

Bracket installation technology

- Determine the density of the load-bearing wall using a small-diameter drill. If the wall is not dense, then powerful and long dowels will be needed for fastening.

- Drill through the plaster to the base (brick, concrete, other material), going 3-4 cm deep into it.

- Choose special anchors with a length of 8 to 12 cm.

- Be sure to insert a plastic or nylon dowel.

- Secure the bracket.

- Check the installed (attached) bracket for reliability: pull it with your hand - it should not move.

- Proceed to install the bowl onto the attached brackets.

Attaching the sink will not be a big problem if you do not disturb the order of work

It is important to choose high-quality brackets that match the type of bowl

Now you know how to secure a sink. Mounting on brackets is the most difficult installation option. They need to be matched to the interior of the bathroom and securely fixed, because there will be no other support for the sink.

Tips that will not be superfluous

You may find the installation process too simple. But it is not so.

Errors or negligence during this work can lead to deterioration in the appearance of the sink or damage to the countertop if water constantly penetrates into the space between it and the sink.

If you are not sure that you are able to cope with the task, invite a specialist. But then you won't be able to save money. Think about what is more important to you.

To completely dispel your doubts, we suggest you watch a video in which the installation process is performed by a professional.

Installation of a sink without brackets

A mounting kit must be included with the sink upon purchase; if for some reason it is not available or the quality leaves much to be desired, purchase such a kit separately. Focus on products from well-known brands so as not to worry about the quality of installation later.

Decide on the location where the sink will be installed and take measurements. It is usually recommended to install the bowl at a height of 70 - 85 cm from the floor.

At the selected height according to the building level, draw a horizontal line. Now we place the upper edge of the bowl to the set aside line and mark the attachment points. We drill holes according to the marks and insert dowels. We screw the pins into the dowels. The screwed-in pin should be 2 cm longer than the width of the washbasin. After final installation, tighten the nuts until they stop.

A few more tips for choosing

To ensure that your new washbasin brings you only positive emotions from the convenience and beauty of the product, you should remember a few simple rules when choosing:

Choose a sink that matches the style of the entire bathroom

- Check items carefully, especially those made from materials such as porcelain and glass, for cracks or chips. If found, request a replacement item. After all, even the smallest crack can grow into a big nuisance over time.

- If there are children in the family, it is better to refrain from purchasing models with sharp corners to avoid possible accidental injuries.

- Decide on the sizes in advance. When choosing a countertop sink, you should know the expected countertop size and placement location.

- The selection of the mixer must be carried out according to the height of the washbasin. The deeper your sink, the higher the faucet should be.

Installation of a wall-mounted sink with a cabinet

This option is good because you can hide all the plumbing connections in the cabinet.

At the required height, draw a horizontal line along the level. We try on the cabinet, see how it will fit with the siphon and mixer. If necessary, immediately measure and drill additional holes for plumbing in the back wall. Now we install the brackets and the cabinet on them. We described above how the brackets are attached.

We install a washbasin on top, connect a siphon and sewerage to it. If the bowl model provides for additional fastening to the wall, then drill holes in the right places and tighten the anchor bolts. Or glue the sink to the wall with silicone for greater reliability.

Shape of countertop sink

Since a variety of materials can be used to make overhead containers, the finished products are given different shapes.

The round sink is traditionally good. This one is made of glass and looks more like a glass vase than a sink

On sale you will find bowls of the following shapes:

- Round. This is the most capacious form. In addition, round models are similar to ancient ablution bowls, so they have additional charm and will not go unnoticed.

- Oval. If the room in which you are going to install the sink cannot boast of large dimensions, it is better to choose another model. An oval needs space to show off its full appeal.

- Square or rectangular. But this shape is chosen quite often. Rectangles are well suited for bathrooms in different styles. The only nuance is that a bowl of this shape should be harmoniously combined with other plumbing items located in the same room.

- Triangular. Unexpectedly, this form can be comfortable, despite its apparent instability. It can be placed, for example, in a corner of the room. There it will take up little space and organically complement the interior.

- Non-standard. Today, custom-made models can be given any, most incredible shape. But in the pursuit of originality, it is important not to miss the essence of the product and its functionality.

Today you can bring to life everything that your wild imagination suggests. Sometimes the result is such non-standard design solutions

Secrets of the master

In order to efficiently install a sink on a wall, it is worth learning some of the nuances of this process, without which the installed structure will not be as reliable and stable. These are tips from the best installation specialists:

- The wall structure has a significant disadvantage - it is visually open pipelines and fittings. The excellent aesthetics of the bowl is achieved thanks to a cabinet that matches the design, which will cover all these connections and the siphon. An additional advantage of this installation is a good place to store various necessary accessories.

- In practice, the entire set of fastening equipment should be included with the product. Check this issue yourself, because often: either the manufacturer forgets to complete the sink with fasteners, or their quality itself is not particularly high.

- To avoid moisture vapors from entering the space between the bowl and the wall, it is necessary to use a high-quality sealant, for example, silicone.

Upon completion of installation work, check the system drainage for leaks by filling the siphon with water. If you find a leak, make a tighter twist and an additional sealing layer.

- Install the bowl only after completing all finishing work. Be very careful when installing fasteners.

- The surface of the wall on which you mount the bowl must be strong and stable, otherwise use a supporting frame.

- If after installation the sink does not “move”, this is a clear indicator that the bowl installation procedure was successful.

A well-executed installation procedure is synonymous with excellent functionality and durability of the product. In view of this, before installation work, seek the support of an experienced specialist.

Determining the optimal installation location

One option is to install a new sink in the same place where the old plumbing was located. But this is not always possible, since the cabinet box most often does not fit into the previously allocated space. And moving the location of plumbing fixtures during repairs is not uncommon. Therefore, it is best to think through the location of all plumbing fixtures, as well as pieces of furniture, at the renovation design stage. To do this, the bathroom is conditionally zoned into several areas, in each of which a device is installed (bathtub or shower, toilet, sink, washing machine).

Based on the planned location of the plumbing, water supply and sewerage pipes are laid, because the optimal supply points are different for each plumbing fixture. When supplying hot and cold water, the location of the fittings for connecting flexible hoses must be calculated so that they are located between the shelves. This will ensure convenient connection and replacement of hoses during operation.

As for the siphon and connecting the corrugated sewer pipe, you often have to cut holes in the shelves to connect it. It is for this reason that it is better to calculate everything in advance and bring the sewer pipe to the level of the connection points to the water supply.

To avoid having to cut holes in the shelves of the cabinet, all supply points must be brought out in advance to a place convenient for connection.

Frame structure for installing a washbasin

If the walls in your bathroom are not strong enough to install a sink, and you really want just such a model, then you can solve this issue by installing a frame structure. It is attached to the floor and walls and consists of profiles. The height is adjustable with legs, so that the sink can be installed at the desired height from the floor. All communications are hidden inside the structure.

The procedure is as follows:

- the frame is leveled and secured to the floor and wall;

- At the required height, screws are screwed in to secure the sink;

- cover the frame with moisture-resistant plasterboard and line it with tiles or any other finishing material;

- between the wall and the sink, a rubber washer is placed on the stud to reduce noise during operation;

- attach the wall-mounted sink to studs on top of the cladding.

A properly assembled installation can withstand a load of up to 400 kg, and this is not only a sink, but also other plumbing fixtures. In addition, you can make a niche in the design and use it as a shelf.

Material for the production of washbasins

Despite the constant search by designers for new ideas and materials for production, washbasins made of sanitary porcelain and sanitary ware remain the most popular. This material is resistant to scratches and cracks, and does not collapse under the influence of temperature changes.

And although they can split from an impact, this still happens quite rarely. The traditional white color of the material will suit almost any design.

Glass sinks look airy and elegant. The disadvantage of such washbasins becomes obvious after you start using them - every drop of water, when dried, leaves a mark. Since it is unlikely that anyone will wipe it after each use, such a washbasin does not look very neat. From this point of view, frosted glass behaves much better.

Natural or artificial stone sinks can be made from marble, stone chips, sand and a binder. It would seem that this is a very durable material, but even with stone products problems can arise if used incorrectly - small cracks appear, or even completely split.

The manufacturer describes how to properly care for such plumbing fixtures in the product instructions. Most often, there are recommendations to wipe them dry and not to use too hot water.

Like any product made from natural material, a countertop sink made of stone always looks expensive and elegant.

Wood sinks are also produced, using hardwood with a beautiful texture. Washbasins arouse interest simply by the choice of material, and in combination with a successful design they can become a real decoration of the bathroom.

The wood from which plumbing fixtures are made is treated with special oils that prevent water from penetrating into its pores. Caring for such a sink is quite difficult. It cannot be cleaned with detergents containing high acids or alkalis, or with abrasive substances.

To produce sinks from natural wood, oak, teak, and bamboo are used. Some of them require periodic treatment with special oils

They also produce overhead sinks made of acrylic. The material is more familiar in connection with the production of bathtubs, but washbasins made from it are also deservedly popular. Strength, lightness, resistance to temperature changes, ease of maintenance, as well as the ability to create the most incredible design solutions make acrylic attractive to both buyers and manufacturers.

Specifics and models of wall-mounted sinks

The latest modern trend in sink installation is to mount the unit to the wall surface. This type of arrangement is one of the most familiar and favorite among Russians, since this type of installation has worthy and significant advantages. By installing the sink on the wall, you will save the desired meters of space, and the space under the sink is very convenient to use and keep clean.

Before you begin installation work, choose the model of wall-mounted sink that has the most ergonomic design. A separate model has specific design aspects, which, of course, affects the method of its installation. Therefore, it is so necessary to have at least some knowledge about the installation and specifics of connecting the device to the general water supply system.

An interesting solution is to install a sink above the washing machine; this saves precious space in the bathroom.

How to correctly determine the size of a sink?

All plumbing fixtures can be divided into several groups, differing in size:

- compact miniature sinks designed specifically for small spaces;

- standard equipment - provided in the product lines of most manufacturers;

- combined appliances , combining two or more sinks;

- non-standard equipment of various sizes and shapes is carried out according to individual projects.

When placing plumbing equipment in a room, its three main parameters must be taken into account: depth, width and height. This is the only way to choose the optimal size device for a specific room.

This is very important, because a sink that is too large will take up a lot of free space, and a small one will be inconvenient to use. Not only the width, but also the depth of the product is important.

The size of the sink must exactly match the area of the bathroom, otherwise it will be very inconvenient to use. This is especially true for cramped bathrooms.

To correctly select the width of the sink, you need to remember that the optimal option is 0.5-0.65 m. Such equipment fits well into a medium-sized room and does not “eat up” the free space in it. It is convenient for washing and allows you to avoid splashing water on the floor.

Such a sink would look good in a large room, but wider models that solve some special design problems are also appropriate here.

The minimum width of sinks sold in stores is only 0.3 m. They are certainly not convenient enough to use, but for small rooms there are no other options.

When choosing a plumbing fixture, you also need to evaluate the method of installing the mixer. Most often, it crashes into the middle of the so-called installation site, where a special hole is provided for this purpose. The dimensions of the installation site are also important.

If you intend to install a double sink, and this is very appropriate in large families, you need to choose models where the distance between the centers of the two devices exceeds 0.9 m. Otherwise, using such equipment will be very inconvenient.

The distance to the wall also matters. Practice shows that the optimal option is 0.48-0.6 m. In this case, you need to focus on the arm length of the person who will use the device.

Water lily sinks are specially designed to be mounted above the washing machine. This saves space in small bathrooms

It's easy to do. You need to stand near the sink and extend your hand, its opposite edge should be at your fingertips or in the middle of your palm. It will be convenient to use such equipment.

It is worth paying attention to the depth of the bowl. The larger it is, the less chance there is of splashing water falling into it. The best models in this regard are the “tulip” or “half-tulip” type. They are quite deep. The worst of all are the flat “water lilies” that are placed above washing machines and some overhead sinks.

And the last important nuance: the installation height of the device. It is selected based on the height of those living in the house. It is desirable that everyone is comfortable using the equipment. On average, the installation height is 0.8-0.85 m.

Console models can be hung at the desired height, while devices with a pedestal are installed at the height specified by the manufacturer.

Image gallery

Photo from

Wall-mounted sink

Ease of use of plumbing fixtures

Displacement of the sink from the location of communications

Design reasons for choosing height

All sinks are divided into two large groups: wall-mounted or base-mounted. The second option involves the presence of a pedestal on which the bowl rests.

When attaching a sink to the wall, its entire weight falls on the fastenings or on a special frame. Therefore, they need to be secured especially carefully. It is highly undesirable to install such models on partitions. You should choose a strong load-bearing wall as the base. Otherwise, the structure may simply fall to the floor.

Console sinks are distinguished by the fact that the utilities connected to them remain visible. This is not aesthetically pleasing enough, so they try to hide them behind some decorative element.

Alternatively, you can install beautiful details, for example, chrome, which will decorate the interior of the room.

Tulip sinks rest on a pedestal, so the weight of the bowl is distributed between the wall mounting and the floor-mounted base

“Tulips” are considered a practical type of wall-mounted sink. Their bowl is fixed to the wall. However, part of the weight of the sink is taken by the base, which is also called the pedestal.

A big advantage of such equipment is the hidden supply of utilities. The pipes are laid inside the pedestal. The disadvantage of the design is the inability to adjust the height of the bowl.

For those for whom this is important, you can purchase the so-called “half-tulip”. This modification assumes that the pedestal does not rest on the floor. It, like the bowl, is attached to the wall. This base is shorter than the pedestal of a standard sink. But the supply pipes are still hidden inside the base.

Step-by-step installation instructions

https://youtube.com/watch?v=8d-LyqQfngQ

Mark the central horizontal line using a ruler, marker and spirit level. Installation will be carried out along its line

This will be, sort of, the upper limit of the bowl. It is important to consider the thickness of the side walls of the sink. They must be strong enough to withstand the pressure of the brackets

Measure the thickness and record the remaining parameters of the future installation on both sides of the bowl. Connect horizontally all the existing marks indicating the mounting height of the brackets. Finally, work begins on the sink itself. Turn the bowl over and fix the brackets on its outer walls.

- Move the sink closely to the horizontal and mark with a marker the places for mounting fasteners. This is done through recesses on the outside. Constantly check the alignment of all brackets and lines.

- Using a drill, make holes that are slightly smaller in diameter compared to the size of the fastening devices and dowel screws.

- Drive plugs or bushings made of durable plastic or nylon into the prepared drilled places, and screw the screws into them.

Support brackets are installed on this mount, on which the sink bowl is mounted. Mark the places where the device will be attached to the wall, drill and install the sink. Connect the outlet end of the siphon pipe into the socket of the sewerage system, install the mixer, and connect the water supply. Having made a light fastening “bait”, finish aligning the bowl horizontally. Then go through all the fasteners again and secure them.

Materials used to make siphons

| Material of manufacture | Short description |

Plastic | The most popular material for the manufacture of siphons, in terms of its performance indicators, completely satisfies the majority of consumers. Due to modern fillers, it has high levels of mechanical and chemical resistance. The material is very technologically advanced, which not only reduces production costs, but also allows you to create various geometric shapes. In terms of cost, plastic siphons are the cheapest and have many types and modifications. |

Stainless steel | The service life is virtually unlimited, they have excellent design characteristics, and are often used in open sewer systems. The price is much higher than plastic siphons; during installation they require accurate measurements. Assembly and installation require some experience in plumbing work. |

Non-ferrous copper-based alloys | The most expensive materials for the manufacture of sanitary equipment are used only on exclusive sinks. Physical characteristics do not differ from stainless steel products. They are not afraid of large dynamic and static loads. |

Cheap chrome or nickel alloys | They occupy a middle position in terms of cost and performance indicators; they are most often used for the manufacture of individual elements of plastic siphons. |

Sink siphons

Despite the different types of materials and the wide range in prices, all siphons operate efficiently and perform their main technical tasks for a long time.

Features of operation depending on the model

The types of fastening for a sink to the wall differ greatly depending on the modifications of the device:

For suspended installations, installation is carried out directly to the wall, so gravity is directed not only to the mount itself, but also to the wall

Therefore, it is very important that the base is strong and thick. Usually there are no problems with this if the installation is carried out in the place designated by the builders.

The “Tulip” model will look good in a spacious bathroom. When installing between the planes of the sink, floor and wall, polymer gaskets are installed, gluing them to silicone sealant

This technique prevents the appearance of squeaks and ringing of ceramics in the event of a careless impact. Another important point is that fastening and pulling the bowl to the wall should in no case cause it to be lifted on its “leg” in order to avoid splitting

Which countertop to choose for the sink?

The overhead washbasin does not have fastenings for wall mounting and can be installed on any flat surface. This can be a cabinet or a wall-mounted shelf made of MDF, wood, artificial or natural stone, or glass.

To install MDF countertops under the washbasin, a material with a laminated coating is used. The coating itself is not afraid of moisture, but at the joints between it and the edge or at the cut points (for example, if the washbasin is built into the cutout of the countertop), the slab, when wet, absorbs water. This leads to its swelling and delamination of the laminate.

You can use a countertop made of MDF, but you need to do it correctly - protect it from prolonged contact with water, wipe dry after use

A wood tabletop is a beautiful and environmentally friendly material that fully justifies its use both in terms of aesthetics and practicality. But there is one thing.

Wood itself does not serve well not only in direct contact with water, but also in conditions of high humidity. Therefore, it is important that the manufacturer of such products knows his business well - after all, properly processed material can even be used for the production of bathtubs and sinks.

You need to care for a wooden tabletop in much the same way as for a product made from MDF - wipe dry, protect from mechanical damage

Natural stone countertops are most often used for built-in types of sinks or a sink is cut into them themselves. But they can also be considered as a support for a counter-mounted washbasin; the main thing is to choose compatible materials.

Another option for decorating the surface for a washbasin is tiling or mosaic. The basis can be a shelf, niche or wall ledge. This countertop is easy to care for, it is not afraid of moisture, does not scratch, and there are no visible stains on it.

Glass surfaces are suitable for interiors in the style of Hi-Tech and minimalism. They are made from fairly thick and durable glass and if you do not expose them to shock, they can be called quite safe. Glass is not afraid of moisture and can be washed with any detergent. One of the main disadvantages of the material is traces of water drops and stains.

The glass countertop gives the impression that the washbasin is floating in the air. Beautiful chrome siphons are used to connect to the sewerage system

Types of sink brackets

The fasteners for mounting a washbasin on the wall must be able to withstand the weight of the plumbing fixtures with a margin. They are made from various metals.

special mounts designed for mounting a specific model. Often these are exclusive designer washbasins with an unusual shape. Brackets for such plumbing fixtures are included and can be made in the form of specially shaped pins, pipes that go around the sink, or unusual welded structures. Such fastenings are treated with special decorative compounds (ceramic or metal).

Brackets for standard wall-mounted sinks are made of cast iron or steel and coated with anti-corrosion paint. They are produced in the form of T-shaped or L-shaped racks, and can also be made in the form of frames with a sliding unit to adjust the size of the fastening. Brackets in the form of a metal frame into which the washbasin is placed are particularly reliable.

Color palette of sinks

As we have already noted, color solutions when decorating bathrooms matter. The color of the sink can be combined with other plumbing fixtures or wall decoration, or it can be a bright accent spot.

In this sense, manufacturers do not limit buyers’ choice and offer washbasins in both traditional and unexpected colors.

White

No one will argue that white color is universal and can be combined with any other colors. Plus, take into account the specifics of the room. The bathroom is associated with cleanliness, which means that white is best suited for it.

The snow-white surface reflects light well, and water leaks on such a sink are less noticeable.

White shell.

Black

The antipodean color is popular in techno interiors and modern styles with contrasting solutions. Black pairs perfectly with white and red and is a popular trifecta of colors for bathroom decor.

Dirt is invisible on a black sink, which is both good and bad. But limescale makes it necessary to wash the plumbing fixtures frequently, so its hygiene is no longer questioned.

Black shell.

Other colors

If you really want it, finding a red, pink, blue or ivory shell today is not a problem.

But when the type of bathtub sink suits you, but you need a different color, it is possible to make an individual order in production. It won't be cheap, but all the parameters will suit you.

Red shell.

Pink shell.

Blue shell.

Ivory colored shell.

Complex colors

Washbasins imitated in wood or stone are also more expensive due to complex staining.

Sinks with marble patterns or realistic wood grain textures are often installed on pedestals and semi-pedestals. They look very original and the dirt on them is hardly noticeable.

Wood-effect sink.

Sink under the stone.

Tools and materials

For installation you will need: a sink, a set of auxiliary materials and various tools. Make sure everything is at hand. Tools you will need:

- Gas key.

- Electric drill + drill with pobedit tip.

- Screwdriver.

- Building level.

- Hammer.

- Marker.

- Special tape for threaded connections or tow.

The choice of fasteners is important if you have to deal with installing a sink in the bathroom for the first time. Most models are mounted on metal brackets, which come in different shapes (including openwork forged ones) and sizes. Installation is carried out using powerful bolts and studs. It is not always necessary to mount the sink to the wall. Depending on the model, it can only be placed on mounting brackets.

There are several types of shells:

Depending on the variety, the methods of attaching the bowl to the wall also differ. Most often, in about 50% of cases, conventional suspended structures are installed, this also includes “water lilies”. The installation of “tulip” type models is somewhat different: the bowl rests on the “leg”, and the sink needs to be attached to the wall only for additional fixation.

Installation instructions

Installing an overhead sink is actually similar to installing a regular kitchen sink. The only nuance is the insert into the tabletop.

The slot for the siphon in the countertop should be of such a size that the drain pipe fits into it, no more. There is no need to cut a large hole; the siphon flask is placed lower.

Sealing the countertop sink before installation

There are several ways to install mixers:

- If the sink has a connector for the faucet, then you can install it there, but then the hole in the countertop will have to be cut a little larger than just for the pipe.

- If there is no hole on the washbasin, you can install the faucet by cutting it into the countertop.

- Another installation option is a wall. You can do the same as when installing a bath mixer.

Advice.

When choosing an option for connecting the mixer, it is necessary to take into account that each slot in the countertop must be accompanied by mandatory subsequent sealing. When purchasing, you may be offered a special siphon with an additional clamping nut. You can use that, or you can get by with silicone.

The mixer above the countertop sink can be mounted into the wall

Basically, that's all you need to know about installing an overmount sink. As we can see, it is not much different from the installation of other washbasins.

Preparatory work

The sink for the bathroom has been purchased, the necessary tools are ready, all that remains is to install the structure correctly. To do this, you need to prepare the wall on which the washbasin mounts will be mounted, and make markings so that the bowl is located at a height convenient for all household members.

The fastening for the sink to the wall must be installed after careful preparation of the surface. It is best if it has been finished (textured plaster, tiles or any other finishing material for the bathroom). If the wall is simply plastered, it must be treated with an antiseptic. There are many varieties of them in different price categories.

It is more convenient and easier to use liquid glass. It will perfectly protect the surface from exposure to water and at the same time destroy possible bacteria and fungi. After treatment, you need to wait a while until the surface is completely dry, then paint and begin installing the sink.

- Turn off cold and hot water.

- Stand at your full height in front of the installation site for the future sink.

- Select the upper limit for installing the bowl so that all household members can comfortably reach the sink.

- At the marked place, using a long ruler, pencil and level, draw a horizontal line along which the main work will be carried out.

- Check the dimensions of the sides of the bowl (measure it).

- Record the size with marks on both sides.

- Connect the marks with a horizontal line, thus obtaining the installation height of the sink brackets.

- Turn the bowl over and place it against the wall. Mark where the grooves for the brackets are.

Care requirements

Of course, a lot depends on the material from which the overhead device is made, what its porosity is, whether the coating absorbs dirt strongly and whether it is prone to streaking.

Countertop sinks made of earthenware or porcelain are easy to clean. In order to clean such products, you need to have a soft cloth and any liquid detergent on hand, preferably without an abrasive component.

Acrylic overhead bowls do not like hard brushes with coarse bristles. To clean acrylic, use gel-based detergents that do not contain alcohol.

Caring for a countertop sink will depend on the type of material.

Glass sinks that are overhead must be handled with extreme care, and not primarily because they can break, but because any drops and splashes after drying leave untidy marks and stains on the glass surface. That is why it is recommended to wipe them dry.

Wooden devices can withstand everything except rough processing and abrasives. But if scratches appear on the surface and the top protective layer is damaged, the product may become moldy and even begin to rot.

Do not wash natural marble countertop sinks with acid-containing solutions or caustic powder. Damage to the stone increases its porosity, which means that the resulting dirt and stains will be almost impossible to remove.

Wall-hung or console sinks

Wall-mounted sinks are attached to the wall using a special installation system designed for each type. Console washbasins are distinguished by a variety of designs:

- Compact wall-hung bowls are great for small baths. A compact wall-hung sink will fit perfectly into the interior of a small bathroom.

- Wall-mounted sinks with a cabinet or cabinet in which it is convenient to store detergents and other items. This option is suitable for large and medium-sized bathrooms. Console sink with storage drawer.

- A hanging water lily sink designed for installation above a washing machine. It differs in the organization of drainage through the rear wall. Installing such a plumbing fixture allows you to ergonomically use the space in a bathroom of any size.

A water lily sink will significantly save space in the bathroom.

The advantages of wall-hung sinks include their versatility: they suit any interior, from retro to ultra-modern minimalism. The disadvantages include the complexity of installation and the need to attach only to solid walls.

Installation nuances

Installing a wall-mounted washbasin is similar to installing a sink with a semi-pedestal: first, the supplied brackets or a frame structure that encircles the bowl on all sides are attached to the wall. Installing the bowl in a frame is preferable in the sense that the sink is securely fixed and does not move in any direction.

The main difference in installation is the use of a special bottle siphon for wall-hung sinks. It is made of stainless steel (since it remains visible and must have a presentable appearance) and has a direct outlet to the sewer.

The assembly of the siphon for a wall-mounted sink must be carried out strictly according to the manufacturer's instructions.

Note! The assembly and installation of the siphon for a console sink must be carried out in the strict order specified in the manufacturer's instructions.

Device and functions

A sink drain is a plumbing device that connects the drain hole at the bottom of the bowl and the entrance to the sewer. It is a curved structure consisting of a drain pipe and a siphon. The drain is a mandatory element, the installation of which is carried out when installing a sink, bathtub or shower. It performs the following functions:

- Carries out timely and efficient transfer of “waste”, dirty water from the sink through the drain pipe into the sewer.

- Filters out light debris.

The grate, which is placed on top of the drain hole in the sink, not only performs a decorative function, but also protects against the penetration of small debris and hair, thereby preventing the formation of blockages in the sewer. Drain grate - Prevents the penetration of unpleasant odors from the sewer. The siphon for a bathroom sink is designed in such a way that it forms a “hydraulic seal”, a natural water barrier that prevents sewer odors from penetrating into the bathroom.

Important! The main feature of the sink drain system is a curved, sigmoid pipe. Thanks to its special shape, water never leaves the bend of the drain pipe, which is why a so-called “water seal” is formed, which locks sewer odors inside, preventing them from penetrating into the bathroom.

Purpose and design

The device is divided into a pipe and a bent siphon, which helps protect the apartment from the unpleasant odor that spreads from the drain.

The design prevents the water drain pipe from clogging with solid particles coming from plumbing fixtures.

How does a siphon drain work?

During draining, the liquid flows into the siphon, passes along the bend, rises and enters the sewer. In this case, part of the water remains in the lower part of the curved tube. It is a hydraulic seal that does not allow odors to pass through. The curved section of the siphon traps solid particles and small objects. To clean this area, the parts are removed and reinstalled after cleaning.

Main types of drain devices

There are several types of drain systems. One of the most common options is a design in which the drain is secured with a large locking nut. This method of fastening can be found even in the bathrooms of houses built more than two decades ago.

Classification by device principle

Drain siphon systems used when connecting sinks come in three types: flask-shaped, elbow and combined.

They differ according to the type of construction:

- Bottle-shaped or flask-shaped . The main structural elements are two cylinders immersed in each other. A tee is installed inside the flask of the device, distributing the liquid and forming a hydraulic barrier.

- Pipe . The main element of the double-turn design is the “S” or “U”-shaped bend of the pipe, which forms a hydraulic barrier.

- Mixed type devices . In addition to the structural elements of the bottle structure, supplemented by two partitions, they are equipped with a corrugated hose.

In bottle-type devices, the waste, entering the siphon, moves down through an internal pipe of smaller diameter. Having reached the bottom, the wastewater rises through the cavity between the inner and outer cylinders and is discharged into the sewer pipe.

Bottle models got their name because of the oblong shape of the tank, which looks very similar to this glass vessel

Bottle siphons are advantageous in that even with rare use of the plumbing fixture, the water seal in the sewer system does not dry out for quite a long time. This effect is achieved due to the fact that the outlet from the siphon is located approximately in the middle of the flask.

Many owners prefer bottle siphons for the reason that, if necessary, they can always connect several drains. To do this, the structure only needs to be equipped with an additional element.

By equipping the bottle siphon with an auxiliary fitting, you can always connect an additional pipe from the washing machine to the drain system

Siphons of mixed type have proven themselves to work well. The corrugated siphon, used when arranging a mixed-type drain structure, is a modified version of a conventional curved tube.

The key difference between the pipe used in arranging a mixed-type drain structure is that it is not a rigid part, but a movable flexible hose

Unlike analogues of bottle and pipe versions, among the combined options there are no models with bells, and therefore they cannot be connected to overflow systems and household appliances.

Division by material of manufacture

There are two types of sink drains available for sale, depending on the material of manufacture: those made of polymers and those made of metal alloys.

Polymer products are famous for their low price and ease of installation. Structures equipped with a corrugated pipe can be conveniently adjusted in length.

But the service life of PVC structures is relatively short. And the sealing properties of the assembled structures leave much to be desired. Therefore, all joining elements must be equipped with rubber gaskets during assembly.

In an effort to reduce the risk of clogging the internal walls of pipes from layers of dirt, leading manufacturers include antibacterial components in their composition when creating polymer products

In terms of reliability and durability, metal elements of drain systems are more beneficial. The models made of non-ferrous metals: brass and bronze are most in demand in everyday use. The harness made from such materials often has a chrome coating, due to which it acquires a rather presentable appearance.

The only drawback of metal pipes is the tendency of the inner walls to retain and accumulate mucus and dirt, which can cause blockages.

To prevent the accumulation of dirt deposits on the inner surface of the walls during the manufacturing process, manufacturers coat metal products with a protective film of chromium.

Installation of metal structures does not present any particular difficulties. A hitch can only arise at the stage if you need to shorten the outlet pipe.

Siphons for non-standard equipment

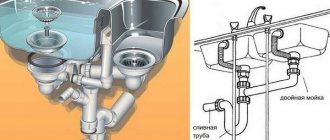

For non-standard models of double “pair” sinks, siphons equipped with two outlets are used. Such siphon devices are connected to the drains of both sinks, and a little lower along the flow of waste water they are combined into a common flask.

As with single models, the design of siphon devices for drain systems with two outlets can be pipe-type or bottle-type

Do you need to connect a sink located on an open shelf to communications? Then choose a model that offers hidden installation. Yes, the price will be somewhat more expensive than traditional options, but it will allow you to completely hide unesthetic elements of communications.

In addition to corrugated pipes D32/40/50 mm, you can also find universal products on sale, equipped with a stepped spout end, which can be conveniently adjusted to any size

Drain systems of such designs will not be difficult to hide in a niche, covered with a decorative screen. But it is worth remembering that if the bend of the outlet pipe is too short, there is a high risk of an unpleasant sewer “aroma” appearing.

Installation of siphon and outlet tube

- Install the drain into the bottom of the sink. Use washers or silicone mastic. This way you will get a strong joint.

- Make sure that the drain and overflow slots fit together.

- Fix the clamping nut located at the bottom of the sink body.

You need to tighten the nuts with long-nose pliers while simultaneously holding the drain in place behind the grate.

If you have a complete siphon, it becomes possible to make an adjustment to the old pipe. If you want to install a drainage pipe with a diameter of 3.2 cm, make a recess in the wall for fasteners using a core drill for stone. The pipe is laid, tilting 0.6 cm every 30 cm so that its end is above the inlet funnel of the external sewer riser. The pipe should be fixed with clamps to the wall.

Technology for installing a drain with overflow

There is nothing difficult about installing an overflow drain on your own. Each device usually comes with instructions. It contains information about the order in which the structure should be assembled.

The simplest path will be taken by an independent craftsman who installs a sink with an overflow channel provided in the design of the sink:

Image gallery

Photo from

Stage 1: Assembling and connecting the drain pipe

Stage 2: Installation of a pipe to connect the drain to the siphon

Step 3: Connecting the siphon to the sink drain

Step 4: Hand tightening the plastic nuts

Step 1. Preparation of necessary materials and tools

With all the variety of models of drainage equipment, the technology for installing siphons is almost identical. Therefore, even if your plumbing fixture had a drain system installed, for example, a bottle type, you can easily replace it with the same combined option.

Regardless of the design, any drain works on the principle of two communicating vessels: at the top there is an inlet pipe that receives waste liquid from the sink, below there is a drain hose that leads it into the sewer, and between them there is a water seal

The standard siphon package includes the following elements:

- device body;

- outlet pipe;

- decorative cover for drain;

- plastic and rubber cuffs;

- connecting nuts and screws;

- rubber flat gaskets.

To better understand the sequence in which you need to assemble the structure, lay out all the elements of the siphon on a table or on the floor.

For work with plumbing equipment (sealing connections), it is best to choose a semi-liquid sealing compound based on silicone or rubber.

It will be impossible to install the system without a set of necessary tools.

To work you will need:

- flat screwdriver;

- adjustable wrench;

- FUM tape;

- sealant;

- container for collecting water;

- cotton fabric.

If during the work you need to cut pipes and corrugation to the required size, prepare a tape measure and a hacksaw in advance. To sand the edges of the pipe, use sandpaper.

Step #2. Removing the old siphon

To remove an old siphon device, you need to unscrew the screw installed in the center in the grate located in the drain hole.

Often the drain grate screw and nut “stick” to each other during operation. If you can’t unscrew them, then first dismantle the lower part of the siphon, leaving the upper pipe intact. By rotating this part you will help free the stuck nut and screw.

Having dismantled the old equipment, you need to clean the internal cavity of the sewer pipe, removing any remaining dirt and crumbled cement from it.

From the moment you dismantle the old siphon until you start connecting the new equipment, it is better to “clog” the sewer pipe with a rag or plug of the appropriate size.

Step #3. Assembly of structural elements

When installing a pipe drain system, the structure can be assembled during the installation process, sequentially “stringing” all the elements. If you have to work with a flask-shaped system, before assembling such a drain for the sink, it is necessary to carry out a number of preparatory work.

First of all, the device is placed under the bowl and preliminary fitting is performed to ensure that the dimensions match. After this, check the reliability of the lower plug.

To do this, unscrew the plug along the thread and inspect whether there are chips or other flaws in the rubber seal. This stage should not be neglected, since the lower plug constantly takes on the pressure of the system.

Before assembling the structure, it is also necessary to check the mating surface of the body thread for defects and burrs.

If burrs are found on the surface, they can be cut off with a sharp knife. If not removed, they may damage the O-ring during installation.

Having ensured the quality of the installed gaskets and threaded connections, proceed to assembling the flask.

The work is carried out in several stages:

- Putting a rubber gasket on the threads of the device, screw the bottom.

- A gasket is placed on the ends of the spout tube, and a tightening nut is placed on top.

- By inserting the end of the spout tube into the hole in the upper part of the siphon body, fix it in a given position by tightening the nut.

- Having equipped the device cover with a rubber gasket, the drain is screwed to the body with a nut.

To increase the reliability of the connection, the ring gasket inserted into the groove must be coated with a sealing compound. They should also cover the lower part of the threaded connection.

To be able to easily unscrew the device cover at the junction of the housing when sealing the connection in case of repair work, make a plumbing wrap with FUM tape

After this, the sink is installed in its seat and the installation of the drainage device begins.

Step #4. Overflow assembly features

When dealing with models equipped with overflows, before assembling this element, you need to determine the height of the tube. This parameter must correspond to the depth of the bowl. If everything matches, the tube is connected at a given height to the main pipe.

If the overflow tube is a prefabricated structure, then its height can be easily adjusted using the principle of telescopic extension. The corrugated pipe is simply stretched to the required length and bent in the right place.

Before tightening the screw, make sure that the outlet of the overflow tube exactly matches the hole provided for its installation in the side of the bowl

When fixing the overflow tube to the sink, do not forget to place the included rubber gasket between the surfaces. The connection point of the outlet with the overflow pipe is secured with a clamping nut. To avoid damaging the connection, tighten the nut by hand without applying much effort.

Step #5. Installation of a drain device

Before connecting the assembled structure to the waste system, the surface of the sink in the area of the drain hole is thoroughly degreased and cleaned. During the installation process, the first step is to combine a protective grille equipped with 5-6 divisions with the drain hole of the bowl.

If the diameter of the drain hole and the size of the grille coincide, it is enough to install a gasket, but if there are small differences, additionally use sealant

The upper end of the outlet pipe is equipped with a rubber gasket and connected to the hole in the sink. Pressing the upper side of the pipe tightly against the drain, fix it using a D6 mm screw inserted into the protective grill.

The thread into which it must be buried is pressed into the body of the pipe itself. When tightening the screw with a flathead screwdriver, it is important to achieve as tight a seal as possible while avoiding rotation of the flange and gasket.

The lower end of the pipe is chamfered. This is necessary in order to ensure free insertion of the end of the pipe into the siphon cavity.

A plastic coupling nut is “strung” onto the outlet pipe, placing it with the thread downwards, and a conical gasket, placing the wide side towards the nut. Then they connect it to the outlet pipe, not forgetting to seal the connection.

To connect the outlet pipe to the sewer pipe, the diameter of which is traditionally 50 mm, an installation rubber collar is used.

To ensure that it tightly covers the pipe, thereby preventing the spread of sewer “odors,” a product is used whose internal diameter is slightly smaller than the outer diameter of the outlet pipe.

If you use a soft corrugated pipe, make the length of the horizontal sections such that during operation they are tension-free, but do not sag

Tip: if the diameter of the outlet does not match the size of the sewer pipe, use a ready-made plastic adapter.

The corrugated siphon is extremely easy to connect. It is equipped with two rigid pipes at both ends. To connect it, you just need to attach it to the outlet pipe, then stretch it a little and give it the desired bend. After this, remove the second pipe to the sewer.

Step #6. System health check

At the final stage, all that remains is to check the tightness of the connections and the functionality of the system. To do this, the area of the floor under the siphon is covered with a piece of cotton napkin or a paper sheet. Some craftsmen place a container under the siphon for this purpose.

Open the tap and watch as the water goes into the drain hole and, passing through the siphon, falls into the sewer.

If there are no leaks at the joints and no drops appear on the napkin, the work has been done efficiently. If any are found, tighten the nuts more tightly, and the connection is additionally sealed.

The technology for installing branched siphons, which allows you to connect washing machines to a common drain, is practically no different. The only difference is that flexible hoses coming from household appliances are additionally screwed to the outlets of the structure.

For those who are planning to install and connect a new sink to the sewer system, we recommend that you read the article Installing a sink in the bathroom: installation instructions for modern models