During the construction of a country house, its owner is faced with the question of choosing a floor. Both concrete and wooden structures have advantages. Both of them have features that need to be taken into account. Therefore, do not worry when choosing a base. First you need to consider the type of room, how often and for what purposes it is used. Even the area of the rooms is important. But the last thing you should look at is the price, because the cheapness of building materials often leads to problems in the future.

Comparing all these parameters, let's consider the features of wooden and concrete floors.

Pros and cons of concrete floors

As a rule, such bases are preferred due to their strength and durability. Concrete screeds are quickly installed and are moisture resistant. In addition, concrete is completely uninteresting to rodents and insects. This material is fire resistant.

Healthy! Concrete floors, unlike their wooden counterparts, can reduce the thickness of the floor. Usually a 5 cm concrete screed is sufficient.

If we talk about the price of the issue, then, of course, a concrete screed will cost less. You will need to buy cement, sand and preferably reinforcing mesh. On average, 1 m2 will cost 230-250 rubles.

But a concrete floor is much heavier than a wooden one. This means that it will heavily load the supporting structure of the house. This option is rarely used for the second floor, and even more so for an old wooden dacha. In addition, if you prepare the concrete mixture incorrectly and do not take into account the installation technology, then such a floor can easily crack. For example, the mixture should be poured evenly. If there is much more of it in one place, then the composition will set differently, in one area it will already harden, and in another it will only begin to gain the required strength. Therefore, it is important to use special beacons to monitor the level of the concrete composition.

Another significant drawback is that the floor cannot be used for quite a long time after pouring. The composition gains strength in 28-30 days, so the room cannot be used for a month.

You also need to understand that concrete is much cooler than wood. Therefore, in living rooms on the ground floor it is necessary to lay flooring (for example, laminate). But even if the room is warm, the concrete looks very unsightly. Wood can be treated or varnished and this will be quite enough.

The coating will also be needed to increase the noise and heat insulation of the room. The tree also benefits in this sense.

Healthy! The problem with thermal insulation can be easily solved by adding expanded clay to the concrete mixture during its preparation.

Communications (heating, water supply, etc.) are laid in the floor. If you fill them with concrete, then if a pipe breaks or if it simply needs to be replaced, you will have to destroy the entire floor. If a wooden base is laid, then it will be enough to remove a couple of boards, carry out the work and then lay the same boards back.

Technical characteristics of logs and requirements for their installation

Logs are distinguished from beams by their smaller size and mobility. If beams cannot be moved after installation, and repairs are very long and labor-intensive, then logs are a mobile architectural element. They are much easier to install and, if necessary, repairs are carried out faster.

Distance between joists

Optimal section proportions

Before you start building a floor, you need to study the requirements of regulatory documents for the size of the joists and the distance between them, taking into account the thickness of the floorboards.

Table of lag sections at a pitch of 70 cm

| Distance between joist supports | Linear dimensions of logs |

| 200 cm | 110×660 mm |

| 300 cm | 150×80 mm |

| 400 cm | 180×100 mm |

| 500 cm | 200×150 mm |

| 600 cm | 220×180 mm |

Table of distance between joists depending on the thickness of the board

| Thickness of pine floorboard, mm | Distance between adjacent joists, cm |

| 20 | 30 |

| 25 | 40 |

| 30 | 50 |

| 35 | 60 |

| 40 | 70 |

| 45 | 80 |

In order to learn how to independently make calculations based on tables, it will be useful to consider a simple example. Initial data: the length of the room is 10 m, take a floorboard 30 mm thick.

floorboard

Lags

Batten

Calculation method

According to the table, with such a thickness of the board, the distance between the logs is 50 cm; with a room length of 10 m, 20 logs will be needed. The distance between the logs and the walls cannot exceed 30 cm. This means that we will have to increase their number by one piece, the distance between the others will decrease to 45 centimeters.

Important note. During calculations, all roundings should be done only downwards, thus creating an additional margin of safety.

There is no need to calculate dimensions and distances accurate to the millimeter; no one takes such measurements. By the way, during construction, the vast majority of architectural elements and structures are measured in centimeters, the greatest accuracy is half a centimeter. Millimeters are almost never used during measurements.

Floor joists

A wooden beam of rectangular cross-section can be used as a log

When should you pour a concrete floor?

A similar base is suitable for industrial premises, garages and rooms where supplies are stored. Concrete is used if the building is expected to experience strong mechanical loads. But this does not mean that it is not used for houses, just as it is used.

For example, a concrete floor is rational on the first floor of a two- or three-story house with a massive structure. It is also the only correct solution when it comes to the basement. No matter how you treat the wood, if it is in constant contact with wet soil, it will still begin to rot.

Preparation of mortar for screed

Let me remind you that we make a screed from a mixture of leveling agent. Make the solution according to the instructions on the package. The leveler mixture is added to the water, not the other way around. The mixture is stirred mechanically with a mixer at low speed until it becomes thick sour cream.

How to check the thickness of the mixture

To check that the consistency of the mixture is correct, find a container with a diameter of 70 mm so that it can hold 1 liter of solution. From this cylinder, pour 1 liter of solution onto a 50x50 cm plexiglass plate. The diameter of the spread solution should be 34-38 cm. This means that the density of the solution is correct. The density of the solution must be checked constantly.

Wooden floors

Such floors have a huge number of advantages. For example, wood is certainly much more environmentally friendly than concrete. If you choose high-quality materials, you don’t need to think about spending on additional flooring.

In addition, the tree has other advantages:

- Retains heat much better.

- Does not create increased load on the supporting structures of the house.

- If one of the boards is cracked or damaged, it can be easily replaced with a new one without replacing the entire structure.

- If you are tired of the shade of the floor, then the wood can be repainted without any problems. It will not lose its aesthetic appearance.

Healthy! If you need to wait almost a month after pouring concrete, then a wooden floor can be used immediately after installation.

But there are also disadvantages. For example, if the house does not have a basement floor, then you will have to make a double floor. First, the so-called subfloor is laid (for this you can use boards of no better quality), then comes the insulation and finishing layer (you need to use the best materials for it).

Healthy! If a concrete screed costs about 230 rubles per “square”, then a tree will cost at least 1,000 rubles. Moreover, there is always a risk that you bought low-quality material. In addition, to lay such a floor you need to have at least minimal carpenter skills or you will have to hire a craftsman.

You will also have to take care of impregnating the wood with specialized compounds that will increase fire and moisture resistance. But even this may not save you from insects and rodents, which will gradually destroy the structure. Thus, wood has a shorter service life than concrete.

Healthy! Over time, the wooden floor begins to creak. This is annoying, especially when you go to drink water at night and wake up everyone in the household.

It is also worth paying attention to such disadvantages as:

- Wooden floor is higher than concrete. During the installation process you will have to use logs. These additional structures make the installation process more labor-intensive and expensive.

- The tree is prone to drying out. The boards may crack.

- Wood should not be used for rooms with high humidity. The material will quickly begin to rot.

Therefore, when installing a floor, you need to take into account not only the characteristics of the building material, but also the type of room.

Conclusion

Should I install a concrete or wooden floor? It is, of course, up to you to decide. We have covered the main points of installation and given practical advice, but everyone has their own situation and if this information is not enough for you, then the video in this article clearly shows the process of installing the coating. Look, decide!

Installation of wooden covering on a concrete base.

As you can see, there are quite a lot of materials on our website about concrete and wooden subfloors, but having installed any of them, you have another pressing question. And this, as you might guess, is a matter of care! There is a current article on our website - “How to clean carpet?” It is very interesting and definitely worth your attention.

We, in turn, wish you successful renovations - so that the space around you pleases and creates a great mood for you. Make both cool luxury renovations and modest and cozy ones, based on our materials. And, have no doubt, your floor will serve you for a long time, it will be perfectly smooth, beautiful and without defects!

If you need to buy tile leveling systems on excellent terms, feel free to contact us, we can do it most profitably. We are a direct partner of an online store selling hovercraft with the best prices in the capital. We sell 100 percent originals.

Which base is best for different rooms?

Every house has an entrance hall. This is the place where a large amount of dirt and dust accumulates from shoes (especially in winter). Therefore, even if you prefer wood, you will have to consider a floor covering with high moisture resistance. Usually tiles are laid in this room. But then the weight of the wooden floor will increase, and the whole point of using natural material will be lost. Therefore, in the hallway, the best option would be to pour concrete and lay tiles on it.

Something is constantly being prepared in the kitchen. The room is filled with steam, and grease ends up on the floor. If you lay a wooden floor, you must cover it with varnish or another compound that forms an easy-to-clean protective film.

But in living rooms it is better to install eco-friendly wooden floors. They retain heat well, so at night you won’t have to deal with a surprise in the form of an icy floor that you accidentally stand on while you’re looking for slippers.

The bathroom is always damp. In rooms of this type, fungus and mold often begin to grow, so the bathroom and toilet are often treated with rather aggressive chemicals. A tree is not able to “survive” such an amount of chemicals without serious protective treatment. Therefore, for bathrooms it is better to equip a concrete screed, on which tiles can again be laid.

Comparative analysis

Of course, a wooden floor is more environmentally friendly, its price is often lower than concrete, it is warm and reliable, but short-lived. And there is a possibility that your descendants, having decided to change their gender, will remember you “with a not evil, quiet word.”

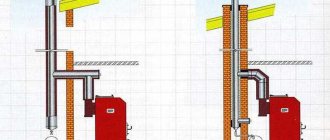

In our opinion, it is more reasonable to make a combined version of the covering, in other words, the base is poured from reliable, durable concrete, and then you make a slab flooring on the joists. If necessary, you can tear it down and install an economical heated water floor or other covering to suit your taste in its place.

Installation of slab flooring.

Using microfiber instead of reinforcement

Reinforcement is the process of strengthening a concrete layer with steel reinforcement. However, working with metal elements can damage polyethylene. Therefore, it is possible to replace steel rods with fiberglass. This is a special material that strengthens the concrete screed.

The use of microfiber greatly simplifies the installation process, because it just needs to be added to the concrete during mixing. The absence of a metal structure significantly reduces the weight of the monolithic slab.

Construction of alignment beacons

The lighthouse is a metal guide. It is used for convenient and effective leveling of the surface of a concrete screed after pouring.

The lighthouse can be purchased at the store, or you can make it yourself from any available material. The only requirement for a lighthouse is levelness.

The presence of polyethylene complicates the process of installing beacons, because the solution does not stick to its surface, and self-tapping screws cannot be used due to the tightness of the coating. But the solution is quite simple:

- Divide the entire area of the room into oblong zones, no more than 1200 mm wide. At the same time, leave a distance of 300 mm to the walls.

- Prepare concrete of the same grade that will be used for pouring the screed.

- Lay concrete in longitudinal lines according to the markings.

- Install beacons on top of the concrete, checking against a pre-made mark on the wall. For greater accuracy, you can use a bubble level.

Waterproofing

A layer of polyethylene film is laid on a floor that has been well dried after treatment with an antiseptic. Rolled materials are rolled out along the long side of the room, from the entrance to the window. Overlapping areas of 100-150 mm are glued with adhesive mastic. Places of contact with the walls of houses are applied with mastic or pressed with damper tape with a thickness of at least 5 mm.