Heating systems for non-residential and residential premises are presented on the market in huge quantities. And among all this variety, the film infrared heater stands out for its high efficiency, long service life and increased operational safety.

The article we presented describes in detail the operating principle of the equipment used to form radiant heating. Advantages and disadvantages are listed, technical characteristics are given. We will introduce applications and methods of constructing popular film systems.

general description

Until recently, heating of premises was carried out using convector heating, in which the air is first heated, and from it the heat is transferred to people and objects located in the room.

Ultraviolet heating works on a different principle - its waves first act on objects, transforming them into heat accumulators, which subsequently release heat to the air. A person in a room heated by infrared rays feels heat from all sides, including the floor and ceiling. Because of this, there is a feeling of more complete heating, so the temperature necessary for a comfortable stay in the room can be reduced by several degrees - and this is already a significant saving in heating costs.

True, we can talk about noticeable savings only if the house is well insulated. Of course, if heat losses are minimized, any heating system will be more economical - but heating with infrared heaters in this regard is characterized by maximum efficiency, since the optimal temperature for living can be reduced without loss of comfort.

In addition, all infrared heaters for heating rooms are equipped with a thermostat, which allows you to maintain the desired temperature. If the room temperature exceeds the upper permissible value, the heating is switched off, thereby avoiding unnecessary energy costs. When the room gets colder, heating starts again.

Calculation of the cost of PLEN using the example of a house of 100 square meters. m

We talked about the technical characteristics of PLEN, but the price remained unspecified. It starts at 1100-1200 rubles per 1 sq. m. m. To whom this price seems high, you need to take into account the lack of costs for the purchase of a boiler, pipes and radiators. There are also no costs for labor-intensive services of heating engineers. If you install PLEN heating yourself, then the costs will be minimal.

A simple table for calculating the power required to heat a room.

How to calculate the required amount of film? Our starting point will be the required thermal power of 100 W per 1 sq. m area i. Knowing the power of one “square” of film, we can calculate its quantity per room. We will need at least 10 kW of heating power for the whole house. If we use a film 510 mm wide and 5000 mm long with a power of 434 W, then we will need approximately 24 PLEN elements.

Also, in calculations it is necessary to focus on heat losses, which we have written about more than once in our reviews. For example, in rooms with single-glazed windows, heat loss increases by 10%, which requires a commensurate increase in the power of the PLEN. We recommend reducing heat loss rather than increasing power - this will reduce energy costs.

The essence and advantages of the method

Traditionally, wood and gas stoves, convector heaters, and water heating are used for heating greenhouses and greenhouses. All these methods require large material and physical costs for installation and maintenance.

Features of infrared heating

The infrared heating system for greenhouses differs from the traditional methods listed above in that it does not heat the air, but all objects located in the radiation field - the ground, plants, walls, etc. This radiation is similar to solar energy: heated earth and other objects emit infrared photons, which are reflected back by the walls of the greenhouse.

All other methods are aimed specifically at heating the air, the warm vapors of which rise upward, practically without warming the soil and leaving the plants cool.

The fundamental difference between convective and infrared heating is clearly visible in the diagram

For reference. The situation can be corrected by installing water pipes buried in the ground. But the price of such a system is very high, which increases the cost of grown products, and it is quite difficult to control the soil temperature.

Infrared heating systems for greenhouses are distinguished by the fact that their radiation is directed from top to bottom and affects plants and soil, which is important for rapid germination, development and fruiting. Numerous studies have proven that, thanks to them, seed germination increases by 30-40% precisely due to warming up the soil, in which the air does not heat up so much

In addition, infrared heating for greenhouses can also be installed under a layer of soil - special films are designed for this.

Advantages of the method

The main advantage of an infrared heating system for greenhouses is its high efficiency, reaching 95%. This impressive result is explained by the fact that all the radiated heat is spent on heating the soil and plants, and not the air surrounding them.

It, in turn, warms up due to the reflected energy. Other advantages are no less significant.

This:

Significant reduction in heating costs both due to directed radiation and due to the small amount of electricity consumed.

Note. Compared to convector-type heaters and cable electric heating, infrared heating systems for greenhouses consume 40-70% less energy

- There is no need for additional air humidification, since these heaters do not dry the air.

- The operation of the system is similar to solar radiation and therefore is completely safe for both plants and people working in the greenhouse.

- The heaters do not make noise and do not glow, so they do not create any discomfort.

- Fast heating: you can raise the air temperature in the shelter to the specified parameters in a matter of minutes.

- The ability to create several zones with different temperature conditions in one greenhouse. Depending on the needs of a particular crop, you can change the power and height of the heaters above them, thereby creating the optimal temperature in the growing area.

The photo shows that the radiation extends only to the area under the heaters

- Simplicity of installation and dismantling - heaters are easy to install with your own hands or with the help of one electrician, which also allows you to save money compared to installing heating systems.

- The presence of a thermostat (see Thermostat for a greenhouse - choosing the right one) is a very important option for growing plants that require different regimes at different stages of the growing season.

- Fire safety due to the absence of open flames and heating elements.

- Mounting on walls or ceilings frees up valuable greenhouse floor space.

Saving space is especially important for small greenhouses

Purpose

The main purpose of an infrared heater is to expose any absorbing surface to the rays it produces. Such surfaces include any objects around you that absorb light energy, that is, not transparent and the person himself. Due to this property, heating of the surrounding air space is a side effect of the operation of an infrared heater, when thermal energy from heated objects is transferred to the air. This determines the main advantage over classical systems - direct impact on a specific area and the absence of such large losses.

Rice. 1: fundamental difference in heating

In practice, an infrared gas heater is designed to heat any space in places where it is not possible to connect electric convectors to the network or where power supply is impractical.

As specific examples, an IR heater can be used for:

- Heating of gazebos and tables in nature, in park areas and recreation areas, etc.;

- Heating tents in the cold season from a gas cylinder;

- Heating garages to ensure comfortable working conditions;

- Heating of residential premises in summer cottages;

- Ensuring temperature conditions in the working area of industrial premises;

- Heating of greenhouses, chicken coops and nurseries for livestock;

- Heating any area in the open air (at construction sites, quarries, geological exploration sites, terraces, etc.).

Also, using this type of gas heaters, various surfaces can be dried and heated. An important advantage of an infrared gas heater is the use of a special element for burning fuel and producing infrared radiation. This feature makes its operation identical to that of electrical appliances, with the difference that it can function regardless of the presence of a centralized fuel source.

Selection of equipment and materials

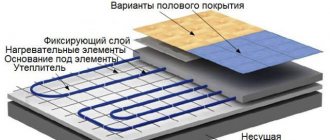

The infrared floor is connected according to the following scheme:

- preparation of the base;

- fastening of insulating material;

- laying film/mats;

- installation of protective material;

- flooring (with or without screed).

How to lay infrared heated floors depends on the type of heating system. There are film and rod structures. The basis of the former is a heating carbon or bimetallic element that supplies IR rays and anions to the room. It is protected from external influences on both sides by additional layers. The material is produced in rolls of a certain width and length. Heated infrared film floors can be installed in the shortest possible time. Of all heating systems, it is the most economical in terms of size and floor load. By the way, the film can also be used for walls with ceilings.

The basis of the rod structures are flexible carbon rods connected by wire. They come in the form of mats that look a bit like a rope ladder. Installation of an infrared floor of this type can be carried out either with or without a finishing screed. The advantages of rod systems are the ability to self-regulate and the ability to install in high humidity areas. That is, the film cannot be placed in areas where heavy objects will stand, or in the bathroom, but mats can.

In both cases, the installation of infrared heated floors is carried out according to the above scheme. Damage to the coating is also eliminated in the same way: by replacing the problem area (strip or mat). Rod systems are much more expensive than film systems. Their energy consumption is approximately comparable, and directly depends on the quality of the thermostat and temperature sensor.

Thermostat

The connection diagram for an infrared heated floor through a thermostat is classic. There is an option to activate the heating elements directly through the network by connecting to the panel, but such a solution can hardly be called practical. Firstly, you have to turn the system on/off every time, which in itself is inconvenient. Secondly, manual control leads to unnecessary energy consumption.

Connecting an infrared heated floor to a thermostat is not that expensive, so such a device is almost always installed. Using temperature sensors, the thermostat automatically turns off or activates the system. The regulator can be:

- electromechanical;

- electronic;

- programmable.

If you need to decide how to connect an infrared heated floor to a programmable controller, it makes sense to seek help from specialists. These are expensive and complex devices that are very sensitive to any error. Such a device is capable of controlling the system according to a given program. Such models help to use energy most efficiently.

If the installation of infrared heated floors is carried out in a technical room, bathroom or on a balcony, a cheap and reliable electromechanical regulator is quite suitable. Electronic thermostats are the “golden mean” in terms of cost and functionality, therefore they are always in stable demand. Thermostats are usually installed on the wall, at a height of 1.0-1.5 m. The power of the device is determined by the parameters of the heating system. It is recommended to use a separate thermostat for each room.

Finish coating

Installation and connection of infrared heated floors must be carried out taking into account the finishing coating. This equipment can be considered universal. It is suitable for heating tiles, parquet, porcelain stoneware, laminate, as well as soft carpet and linoleum. For heating systems located in bathrooms, toilets, and kitchens, tiles are usually chosen. If you plan to install infrared heated floors yourself, then in this case it is better to lay mats. The rays they generate easily pass through the screed and dense surface material. The tiles can also be laid on film structures.

Main technical characteristics

Despite the large number of PLEN manufacturers, the main parameters of their products are quite similar, here are the main ones:

- Power specifications: 220-240 VAC, 50 Hz.

- Maximum power ≈ 200 W/m2.

- Average daily power is 25-65 W/m2.

- Permissible heating temperature 150°C, melting point 250°C.

- The temperature of the heating elements is 45-50°C.

- Width 0.50-1.0 m.

- Roll length – up to 50 m.

- The maximum laying length is 8 m.

- Thickness – up to 0.4 mm.

- Heating inertness – no more than 3 minutes.

- Efficiency up to 90%.

How to calculate the power of IR heaters

In this section we will mainly talk about ceiling heaters, which are planned to be used as the main heating of the room.

If the area of the room is large enough and the ceiling is not too high, as is often the case in unheated country houses, it makes sense to install several less powerful ones instead of one powerful heater. This will, firstly, make the heating more uniform, and secondly, eliminate the possibility of overheating a separate section of the floor.

The general recommendation for the total power of heaters is 80-100 watts per square meter of area. It is clear that this value is approximate; it can be influenced by many factors: ceiling height, wall insulation and much more. But as a starting point, such a value is quite suitable.

As for other types of heaters, calculating power does not make sense for them, because they are used only for additional heating.

Installation features

The installation procedure for infrared heating panels is not complicated: just follow the instructions in the instructions. It can be found on the website of the manufacturer of the purchased equipment. After completing the installation work, you only need to plug in the device into the electrical network.

IR heaters are mounted on walls and ceilings. When choosing a ceiling device, you should consider the following recommendations:

- It is important to prepare suitable fasteners: they must be strong in order to reliably hold the weight of the device being installed.

- The heater is fixed using the fasteners that come with it. Often these are steel chains and rigid brackets.

- During the installation process, it is necessary to prevent contact of the heating surface with flammable substances and materials.

- Using a special tape, it is important to insulate the electrical wiring contacts.

Ceiling infrared heating

Under ceiling infrared heaters goes from? before ? ceiling area. The remaining space is enough to accommodate lighting fixtures and communications. Decorative finishing material, plasterboard panels, suspended ceilings, etc. do not interfere with functioning and do not deteriorate themselves.

Diagram of an IR heating film device

- Stage 1. Installation of a heat-reflecting screen

- Initially, a foil heat-reflecting screen (folgoizol, penofol, etc.) is installed on the entire ceiling surface of the room. This achieves an almost twofold increase in the downward heat flow. If thermal insulation is insufficient, it is better to use insulation with a thickness of 10 mm, otherwise insulation with a thickness of 5 mm is sufficient.

- Fastening to a wooden surface is done with metal staples or a regular furniture stapler.

- Fasteners are placed on the concrete floor in increments of 0.5 meters. Most often this is a wooden sheathing. The strips are attached with an overlap of 2-3 cm, followed by gluing the joints with foil tape.

Advice: whether you work alone or with an assistant, it is easier to use a 60 cm wide roll of thermal insulation and film material: it is easier to hold and there are fewer mistakes.

- Stage 2. Installation of film heaters.

- A pre-calculated number of heating elements is attached similarly to heat-reflecting material. It is only necessary to install brackets or other fastening elements in specially designated places so that the infrared film for the ceiling is not damaged at other points.

- Stage 3. Electrical installation.

Connecting individual elements

- The wire cross-section is selected according to the total power of the connected heaters.

- All wires are hidden in the cable channel.

- Thermostats are installed in each room at a height of 1.1 - 1.4 m. For a small heated area, up to 5 m2, they are connected “into the break” of the line.

- A larger area requires a high-power heater, and the thermostat is connected exclusively through a magnetic contactor.

- The lines, hidden in the corrugation, pass to the distribution board, in which the power and control wires are connected to the circuit breakers and magnetic contactors.

- The first testing of the system is carried out after connecting the common “Input”.

Installation of heating panels

The total load power is calculated, wires and boxes are selected. After this, a panel with differential automatic machines is installed. There are as many differential circuit breakers installed in the panel as there are rooms planned to be connected. Wiring is laid from the shield.

Ceiling infrared panels can be installed independently. Installation of infrared ceiling heating panels follows the procedure for installing fluorescent lamps.

Calculation of infrared heating power

It is not difficult to independently calculate the required equipment. For a 10 m2 area with ceilings of 2.5-3 m, a house with good thermal insulation requires infrared ceiling heaters with a power of 1 kW. More rigorous figures can be obtained using data from a specific device. Of course, we are not talking about constant electricity consumption: during operation, the equipment, maintaining a given mode, works for approximately 20 minutes out of every hour. Effective power consumption for a house with an area of 55 m2 is about 2 kW, which is quite a bit!

Varieties

There are three types of infrared heaters: film, panel, stationary. There are design features between them. Stationary ones are the simplest. These are separate devices that are installed on a leg (or attached to the wall) and plugged into a free outlet. They can be directed to the sofa, and then moved and plugged into another outlet.

Film and panel ones are not mobile. The latter can be installed in the ceiling or on the wall, while film ones can be installed on the ceiling or floor. Each type has its own characteristics.

Panel

When organizing infrared heating of a private house or apartment, panels are more often used, and films are less often used. Flat panel equipment allows you to save room space, as it does not involve changing the height of the room. This is a relevant solution for rooms with low walls.

They consist of:

- Heating element - heating element. It is made from one of three materials: quartz, ceramics, tungsten.

- A special panel that receives heat and transfers it to objects in the room.

- Insulation on the back side. It reflects heat waves from the back of the device and eliminates heat loss.

- Cases.

Infrared panels can be built into the ceiling or hung. Built-in ones are more popular and aesthetically pleasing. In this case we are talking about infrared plasterboard heating with special thermal insulation and graphite thread. They are also built into the walls around the perimeter of the room. Each panel has an average power of 150–200 W.

Film

This type of heater is ideal for organizing a warm corner somewhere on a loggia or veranda. It is used for zonal heating, although no one bothers to cover the apartment with “warm films” over the entire area.

In film infrared heating, the main material is a thin layer of graphite, which is applied to a thermoplastic film. Instead of graphite, a carbon thread can be used - when heated, it creates a heat flow. Note that film heaters create a single integral system, but it consists of separate modules. If some section fails, it is not difficult to replace it with a new one without compromising its integrity.

These panels do not have high power, so their efficiency is low. For this reason, they are used for local heating and are rarely installed along the entire perimeter of the apartment.

Infrared heating of greenhouses in winter

But there is also infrared heating of greenhouses. This method can be called one of the latest technological achievements in terms of heating communications. This method is good because heat rays emit from the device, which transfer thermal energy to objects around. In this case, the air does not receive heat. The advantages of infrared heating include absolute harmlessness in relation to nature. The humidity level does not decrease. And by heating objects rather than air, it is possible to save money, even though the network runs on electrical energy.

The choice is large. There are many nuances that should be taken into account when choosing. In order not to get confused in the proposed methods, contact our specialists who will help in word and deed! — a guarantor of reliable and high-quality heating of a greenhouse and any other facility. We are professionals, and you can trust us with your greenhouse heating system. Call!

Options for using technology

Infrared heating is used quite widely today.

Regardless of whether a person lives in the house permanently or uses the home as a temporary shelter, such devices are ideal for heating living rooms at any time of the year. But this is not the only area of their application. Such units can be used for heating balconies and loggias, unheated garages, dressing rooms, terraces, verandas of open and closed gazebos, greenhouses and winter gardens, chicken coops and other premises for animals.

With the help of such devices, you can very quickly reach the desired room temperature, warm the soil, extend the summer season, reap a good harvest, and achieve amazing results in livestock farming. At the same time, creating a comfortable microclimate will not provoke an increase in electricity costs, which leads to significant financial savings.

Infrared heating: history, properties and device

Despite the perception of this type of heating as a novelty, infrared rays have been used for a long time.

- The beginning of the 19th century was marked by the unique discovery of the infrared range of light by William Herschel.

- In the twentieth century, Henry Ford put this discovery to good use by using radiation to dry cars in a factory after they had been painted.

- Since the mid-sixties, the forerunners of modern versions of these devices, created in Switzerland, demonstrated all the advantages of infrared heating in Finnish baths.

And only recently have entrepreneurs paid attention to the possibility of using infrared radiation to heat rooms

Properties of infrared radiation used in heating

Solar radiation spectrum

Based on the principle of solar heating, when the Sun warms the Earth, and not the air of the planet, scientists created the first infrared heaters

It is important that the achieved ability to exclude intermediate media in the process of heat transfer from source to consumer has made it possible to significantly reduce their power indicators. This ensured a reduction in energy consumption by heaters

They don't heat the air. People, things, furniture - everything receives heat from such a heater. These objects, cooling for a long time, transfer the accumulated heat to the air, which increases the period of comfortable stay in the room.

Thus, there is no need for a powerful heat source, which must first heat a large volume of air space in the room. To make sure that the efficiency of infrared heating is significant with minimal energy consumption, it is enough to compare the characteristics of this equipment and electric heaters. So, when heating a room of 16 m2 with an infrared heat source, a power of 900 W will be required. At the same time, effective heating of the same volume of space using electric heaters will require the latter to have a power rating of 2 - 2.5 kW!

IR heater design

Understanding the operating principle of such equipment and the properties of this type of radiation itself will ensure its correct placement and effective use. Humans cannot see infrared radiation. But the thermal effect is felt instantly. The wave range of this radiation is quite wide - from 0.75 to 100 microns. Therefore, it is divided into three main groups:

- close to the visible spectrum;

- average;

- far or long wavelength, located in the range of 5.6-100 microns.

Long-wave infrared heating of the house is mainly used for heating, reviews of which are of great interest to everyone who wants to get an effective source of heating

It is worth paying attention to the fact that the human body emits heat at wavelengths from 6 to 20 microns, and PLEN radiant heating is in the range from 9 to 15 microns

The design of the heater itself is based on a plate made of aluminum. The heating element built into the heater ensures heating of the plate. It can heat up to 250°, but the body never becomes the object of such heating. A conventional two-phase power supply is used for power supply.

Results

As a result, we can say that heated floors are definitely not suitable for round-the-clock heating; it is most effective to install a floor with infrared film in the hallway and bathroom, and use electric radiators in the room. You can read more about them here: (link here). Thank you for your attention, if you liked it, save the article and share it with your friends. Subscribe to our blog, and if you have any questions, ask us in the comments! See you again here on our blog!

conclusions

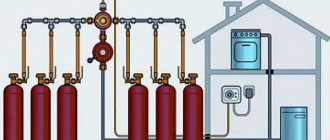

We looked at the options and prices for heating a country house. The cheapest types of fuel are gas and coal. It is possible to connect to a free geothermal heat source, but the cost of installation is not yet affordable for most consumers.

In any case, when planning a home heating system, take into account the availability of energy sources and choose the best option

Take the time to do careful calculations and consult with heating experts. Their professional opinion will help you make the right choice.

Most owners of private houses are accustomed to gas heating from a boiler, which is considered the most economical and affordable. However, what about those where it is not possible to install such a heating system? An excellent alternative option is PLEN heating. Specifications, prices and reviews vary between models. We will analyze all the features and independent installation of such a “warm film”.

Installation option in a wooden house

What is a heating system project?

For design, the area of heated premises, boiler power and probable heat loss are taken into account. The number of batteries in each room and the length of the pipes are calculated. The number of windows, doors and the nature of wall materials also matter.

Detailed calculations allow you to optimally spend funds and further minimize system maintenance costs. Water heating can be included in the heating system.

When designing a system, it is necessary to take into account the climatic characteristics of the region. For example, in the conditions of the far north, a liquid fuel boiler will be ineffective, since its fuel loses its ability to ignite at minus thirty degrees.