Using a bathhouse is impossible without various types of water procedures. Waste water is usually poured directly onto the floor, from where it goes into a pre-prepared drain system. Its design, as a rule, is known only to the owner and is of little interest to ordinary users.

However, sooner or later, any person may face the problem of building their own bathhouse, where they will have to create all the necessary systems. Among them, the drainage system is the most important. Therefore, having an idea about the structure and types of drainage in a bathhouse is very useful, and sometimes necessary.

Let's take a closer look at this issue.

5/5 — (1 vote)

Why does a sink need outlet fittings with an overflow?

We all know the problem when the drains from the sink stop flowing or don’t flow well. This is usually a consequence of clogged drain fittings with grease deposits or pieces of solid waste. Since this situation repeats itself periodically, some may have the idea of connecting the sewer directly, eliminating the problematic siphon for the sink. Naturally, such a connection will help get rid of frequent small blockages, the outflow will speed up, since there will be no additional resistance to the flow, however, a number of other undesirable consequences will appear:

- unpleasant odors from the sewer;

- midges and other insects living in sewage areas;

- blockages in the depths of drain pipes, which are quite difficult to eliminate;

- If you accidentally drop a small valuable item, such as a ring, into the sink hole, you can say goodbye to it forever.

Siphon with overflow - protection against floods

Therefore, in order to prevent these troubles, you cannot do without installing drain fittings. In addition, an outlet for a sink with an overflow will save you and your neighbors from natural floods as a result of its accidental overflow.

Homemade prune wine recipe

Plums are sweet fruits, so little sugar is used for wine. From fruits you can make both semi-dry light wine and strong wine with a rich taste. The second goes especially well with meat dishes. You can make wine from different varieties of plums, and prunes will produce a dark red drink. True, the juice obtained from plums is small and thick, which is why they dilute the wine with water. This increases the volume of the drink and the wine acquires a wonderful taste. After all, wine made from juice alone will not be tasty.

Prune wine recipe

Components:

- Plums – 7.2 kg

- Sugar – 975 kg

- Water – 1175 l.

Prune Wine

Process:

- Peel the plums, just select ripe soft prunes first. Then place the plums in a glass bottle. Pour boiled, cooled water over the entire surface of the drain so as not to kill natural yeast.

- Let the mixture ferment. After about five days, squeeze out the juice, add sugar to the mixture, stir with a wooden spatula three times a day.

- Leave the wine to ferment within two to three months and you will get a sweet and sour drink of a beautiful red color, which will need to be poured through a straw without sediment into bottles for storage in a cool cellar.

The structure of siphons

Siphons, regardless of their type, have approximately the same design and a similar operating principle. They are a metal or plastic pipe or a pipe system that includes pipes and a tank.

On one side, the devices are connected to the drain opening in the sink, on the other, they are connected to the sewer system. The used water flows into the siphon, then passes through the pipe and enters the general sewer riser.

The system is protected from clogging by a mesh filter located at the sink opening. The slightly curved shape is given to the siphon for a reason: a certain volume of liquid is retained at the bend, forming a so-called water seal. It is this that prevents unpleasant odors from getting inside from the sewer.

It is desirable that the connecting screw for the siphon be made of stainless steel. Regular coated metal rusts too quickly during use.

The standard equipment set includes the following elements:

- metal grate for drainage - the optimal cell diameter is no more than 10 mm;

- inlet/outlet pipe;

- connecting screw with a diameter of up to 8 mm;

- frame;

- union nuts;

- sewer outlets;

- O-rings for sealing joints.

If the siphon is equipped with an overflow function, then the package includes an additional pipe, which is attached to the overflow hole in the sink.

The water seal in the siphon becomes a reliable barrier that prevents odors from the sewer from entering the room.

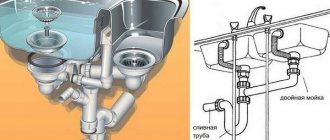

Some models have special side fittings for connecting hoses of household appliances (washing machines, dishwashers). Products for sinks with two bowls are equipped with a duplicate outlet.

Video description

Installation of a drainage well:

Ground filtration

This is an optimal drainage system that can be used as a general sewer system for the entire site. Wastewater is transported through inclined pipes into a septic tank, where it is purified and distributed through several pipelines. They take it to the garden to organize irrigation, or accumulate it in a prepared tank. In some designs, the filtered liquid is simply poured into the ground and absorbed.

Advantages of the soil system:

- autonomy, no special maintenance required;

- water can enter the filtration part from different sources, that is, not only from the bathhouse (you can connect your house here);

- The septic tank has a high degree of purification, so it is used not only for gray wastewater, but also for black wastewater.

Flaws:

- To install a septic tank, you will need a large plot of land; it is recommended to start planning the distribution of pipes around the site in advance, in the first stages of building a steam room;

- creating a deep pit requires special equipment with which it is dug.

Ground wastewater filtration system Source orchardo.ru

How to install the system step by step:

- The septic tank is installed first. Sufficient depth is 1.2 - 2.5 meters.

- A sewer pipe is being installed. It is placed in a groove at a distance where the soil will not freeze.

- Drainage pipes are being installed. They have perforations along the entire length. Closer to the end of the pipe, the holes become smaller.

- The trenches are being prepared. To do this, pour 10 cm of sand or a mixture of sand and gravel onto the bottom.

- Pipes are laid in trenches with a mandatory slope.

- In some cases, due to soil conditions, pipes are wrapped in geotextiles.

- They are covered with an additional layer of gravel on top and then covered with soil.

- To allow air access, ventilation tubes are installed closer to the end of the pipes and covered to prevent foreign objects from entering.

The gravel layer will need to be changed periodically (every 10-12 years)

Design is carried out not only from the side of the site, but also inside the bathhouse.

Ground filtration installation Source aquaf.ru

Siphon dimensions

If the dimensions of the drain do not correspond to the diameter of the sewer pipe, then installation will be problematic. In addition, the throughput of the device is important. Another important thing is the length of the interval between the exit to the sewer and the siphon.

According to the standard, the device has a length of 75 centimeters. Usually, a piece of pipe is enough to connect it, but various situations arise, so it becomes necessary to purchase adapters. They are still needed when the exit to the sewer is not opposite the drain.

Connection diagrams with dimensions

The entrance to the sewer under the washbasin is most often mounted at a height of about fifty centimeters. The diameter of the inlet pipe varies from 30 to 92 millimeters, so the pipe must be the right size or thinner. If the diameter does not match, then all that remains is to install an adapter.

The need to purchase an adapter also arises in cases where the sink has an unusual design. For example, this applies to products with a pedestal. Under such circumstances, the compact drain will not be visible inside.

Operating principle of siphons

A simplified scheme of operation is as follows: water from the sink or sink goes into the flask through the outlet of the siphon, passes through a pair of settling pipes and goes into the sewer through the outlet pipe. If the siphon is installed correctly, a water seal is formed that does not release unpleasant odors from the sewer.

They can enter the room only if the plumbing has not been used for some time, for example, during the absence of the owners. Odors are eliminated by flushing the toilet or opening the water tap to restore the water seal.

Siphon designs are constantly changing. You can choose, for example, a bottle siphon with a wide or standard outlet, with one or two outlets.

Advice! The siphon parts are connected using rubber cone gaskets. The reliability of the siphon connections and the absence of leaks depends on their quality.

The gaskets should be elastic and fit onto the tube with some effort.

If the gasket is of poor quality, then, for example, the siphon bulb, which is attached to the tube with its help, may fall off at the most inopportune moment.

How does he work

The principle of operation of the siphon is based on its design feature. The lower part of the device, called a reservoir or sump, constantly contains water coming from the sink bowl. At this moment, high pressure arises in the drain - this leads to the displacement of the “old” liquid.

When the water supply stops, the pressure in the siphon equalizes. As a result, some of the liquid remains in the curved part. This water plug prevents unpleasant odors from entering the room from the sewer.

Water flows freely from the siphon and enters the sewer, and air cannot enter the room from the sewer, since the vertical pipe is located below the water level

The siphon plays another important role. Since it is installed after the kitchen sink, it is able to trap some debris. It accumulates in the sump and is easily removed by partial disassembly when removing the tank - the homeowner can carry out this procedure independently, without the involvement of a professional plumber. Preventing waste from directly entering the sewer system will prevent it from becoming clogged.

Device classification

There are two main classifications used:

- by design features;

- according to the method of removing liquid.

According to the design features, the siphon for air conditioners can be of 4 types:

Device with water seal

It has an arched shape. The two tubes are connected to each other by a special element in the form of an elbow. The knee plays the role of a water seal mechanism. This type of siphon is simple and popular, but has a number of disadvantages: large size; an excellent environment for the development of fungus and bacteria, which can spread to the air conditioner itself; With rare use, the water in the unit dries out and an unpleasant odor spreads from the siphons.

Unit with water seal and odor-locking mechanism

It is similar in design to the first type, but has a small ball-shaped valve that limits the spread of odor from the body. The valve freely allows condensate from the split system to pass through, but does not allow liquids and odors from the sewer to pass through. Such models are complemented by devices for collecting dirt and cleaning pipes.

Boxed device for flush mounting

The entire condensate drainage system is located in a square (rectangular) plastic box. There are 2 pipes connected to the box: from the system drainage and to the sewer. The elbow with the ball odor-locking device is located in the box. The device operates on the principle of a float; when water enters the siphon, the ball that closes the hole into the sewer floats up. As soon as the water leaves the device, the ball, under its weight, closes the hole again.

The siphon is designed in such a way that, if necessary, it can be easily removed from the box for cleaning and replacement.

Dry aggregate

Used in cases where it is not possible to install a conventional condensate drainage device. The siphon is equipped with a compressed rubber tube, which perfectly inhibits the spread of odor. It allows condensate to pass through using the drip principle: the valve opens as liquid passes through and contracts again.

This dry siphon is used in combination with a straight adapter and a funnel.

According to the method of removing liquid, the siphon for air conditioner drainage can be of 3 types:

- with vertical outlet;

- with horizontal outlet;

- combined type.

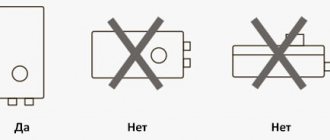

The siphon for air conditioners is mounted in two ways. If possible, the device is hidden in the wall. A special niche is made for this. If there is no way to hide the unit, it is mounted openly, along the wall.

Manufacturers of siphons for climate control equipment:

- Profcool (Russia).

- Vecam (Italy).

- HL (Austria).

Common types

Manufacturers produce several types of sink siphons. They are selected depending on the characteristics of the installation site.

Some types of siphons: bottle with a tube, bottle with partitions, tubular

Corrugated drain

The corrugated tube is convenient to use when the sink drain hole has a non-standard location. This device is also used if you plan to install additional equipment or some necessary items under the sink

When connecting it to the sink, you need to pay attention to the amount of water in the curved place. It should be enough to create a reliable water lock, which guarantees reliable protection against the penetration of odors from the sewer

A drain in the form of a corrugated tube is not an ideal design, because dirt quickly accumulates on the ribs of the product.

Structurally, the corrugated siphon consists of the following elements:

- pipe with grille and union nut;

- corrugated tube

Additionally, pipe fastening may be required.

Drain with corrugated pipe

The corrugated drain is installed in a matter of minutes. First, we attach the outlet pipe with the grate to the sink. Fixation is carried out using the gasket and screw included in the kit. Then the corrugation is inserted into the pipe at one end and secured with a nut, and the other side is inserted into the sewer pipe. If cleaning is necessary, the corrugated hose is disconnected from the pipe and the sewer. Then it is washed or replaced with a new one.

Bottle drain

Bottle siphons are most often installed. They are well suited when you need to drain dirty water and other waste from multiple sinks. In this case, the required number of special bends is installed.

The design of the bottle drain consists of the following elements:

- metal or plastic grille;

- intake pipe;

- bottle container;

- pipe for draining sewage into the sewer;

- a transition piece that allows you to connect the siphon to the sewer system.

Bottle drain is a completely rigid product

If necessary, the design is supplemented with corrugation for more convenient connection to the sewer. Cleaning the bottle drain is done by unscrewing the bottom part of the bottle-shaped container and removing accumulated dirt.

Pipe drain

This type of siphon is installed not only on sinks, but also on bathrooms. It has a completely rigid structure - outwardly similar to the letters S and U.

Since many modern kitchens have dishwashers, the pipe siphon may have an additional outlet.

Straight pipe (direct flow) siphon

Pipe siphon for sink McAlpine (UK) with outlet for household appliances, 40 mm (MRSK6). The MRSK4A model is equipped with an angular outlet. When choosing, be guided by the specified sizes

There are models of tubular siphons with a break in the stream flow. Such siphons are not attached to the sink - after installation there is a difference between the siphon and the sink. It is necessary to prevent germs from the sewer from entering the sink. They are used in preschool institutions and catering establishments.

Flat drain

This is a small siphon under the sink, where size is critical. It is usually used when a “washing machine” or dishwasher is installed under the sink. There are models with a break in the jet flow.

The design is a regular knee, but it saves space

In addition to small dimensions, a distinctive feature of a flat drain is also its rigid design. Such siphons rarely become clogged. If there is a need to perform a complete cleaning, the grille is unscrewed, and then the entire structure is removed from the sink.

With overflow

When the sink has overflow protection, a siphon with overflow is installed under it. The design of the product includes an additional pipe, to which a small diameter tube is connected from the overflow hole in the upper part of the sink. This design prevents the sink from overflowing with water and reduces the risk of flooding the room and neighbors living on the floor below.

A siphon with overflow is installed not only for sinks, but also for sinks

There are also drains with one or two outlets at the neck. They are used when it is necessary to additionally connect a dishwasher or washing machine.

The overflow tube connected to the tee body can be corrugated or rigid. At the same time, rigid pipes are produced both solid, for certain models of plumbing, and sliding, the length of which can be adjusted for a specific model of equipment.

Overflow pipe siphon for two sinks

The drainage from the overflow unit enters the water seal (the lower part of the siphon), the design of which determines what type of siphon for the kitchen sink is.

Please note how many components a pipe siphon with overflow has. If you are afraid of getting confused when installing it yourself, it is better to invite a professional plumber.

Click-clack

A special valve is mounted between the water seal and the drain device. Thanks to the spring inside, they regulate the discharge of water from the bathtub and sink. Pressing the valve cap once will block the drain. Double pressing opens the plug and water flows into the sewer pipe.

Telescopic

The siphon is equipped with additional connectors and pipes, thanks to which you can adjust the distance to the drainage devices. The design of the telescopic siphon can provide for the simultaneous connection of up to 4 drain bowls: to two sinks, a dishwasher, and a washing machine.

Telescopic siphon has additional connectors

Wall-mounted

The peculiarity of the water seal is that the configuration allows it to be mounted close to the wall. The advantage of the device is that it is not noticeable and allows you to install additional equipment.

Angular

With a siphon of this type, a pipe extends from the glass at a right angle to connect to the sewer in the wall.

A schematic representation of the operation of any siphon, which acts as a reliable barrier to unpleasant odors trying to break through from the sewer system into the apartment

Table 1. Popular types of siphons

| View | Description |

| Corrugated | This is the most primitive design, which is a type of curved pipe with folds. Thanks to the elastic frame, you can attach such a siphon in any sink. One of the disadvantages of corrugation is the accumulation of a large amount of debris inside. In addition, the pipe may become deformed due to boiling water. |

| Pipe | It is a solid pipe with bends. On sale you can find both collapsible and non-collapsible options. Installation in this case is complicated by the fact that the drain must be installed exactly in the direction of the sewer hole. |

| Bottle | This is one of the most popular designs. The water seal is located at the bottom, so the siphon can be quickly cleaned of dirt. |

Note! Branched models of siphons allow you to cope with complex installations when you need to connect several washbasins. In addition, they are convenient when you also need to connect a dishwasher and washing machine.

general information

In the process of arranging a bathroom, the modern user is faced with the problem of a huge range of models of plumbing fixtures. We have to take into account the material of their manufacture, design style, size, etc. It is important to understand that external beauty is not always supported by functional reliability. Therefore, the quality of such a part as a toilet siphon cannot be overestimated.

Despite the wide design variety of hygienic devices, the principle of draining water inside them is almost identical. This greatly facilitates the maintenance and repair of the toilet filling. Problems with the water supply usually indicate problems with the drainage mechanism. It should be kept in mind that it is this unit of the plumbing fixture that breaks down most often. Therefore, when choosing a toilet, it is important to pay attention to its quality and durability.

Connection materials and standards

In the production of the vast majority of models of overflow devices, polymeric materials are used: polyethylene or propylene. Brass, copper and stainless steel are less common, as they occupy the segment of high-quality expensive products. The chrome-plated sink siphon is distinguished by its special aesthetic sophistication, which will look impressive on plumbing fixtures installed in an open manner, without installing it in furniture or decorative structures.

Despite the huge variety of forms of outlet fittings, all of them are typical water seals, with the exception of the siphon of a dry design.

Thanks to the inert materials of modern water seals, they are not subject to corrosion, unlike their previous cast-iron counterparts, and the low roughness of their internal surfaces makes it difficult for fatty deposits to form. For the same reason, models in which the outlet and overflow channels are assembled from rigid pipes are preferable. Sometimes they are more difficult to assemble and connect to the sewer, however, they will have to be cleaned less often than flexible corrugated connectors. In addition, the strength and service life of corrugations, especially polymer ones, leaves much to be desired.

Overflow siphon-spark with outlet for washing machine

When choosing a siphon for a kitchen sink, it is important to determine the diameter of its outlet and overflow pipes. If Ø 25 mm is sufficient for an overflow, then the main outlet should be much thicker. Today, the most common standards are Ø32 mm and Ø 40 mm. For households where you have to cook a lot, and even more so when there is an abundance of fatty food, preference should be given to products with outlets Ø 40 mm, they are less susceptible to blockages. Convenient for connection is the drain fitting, which has an outlet of Ø32 mm or Ø 40 mm, adapted by a transition to Ø 50 mm for direct connection to a sewer of the same standard diameter.

On a note. All types of drain fittings with an overflow pipe can have additional outlets with Ø 19 mm herringbone fittings for connecting washing and dishwashing equipment, and can also be equipped with a bifurcated inlet designed for installation on a double sink.

Assembly and installation on the sink

The most common type of drain plumbing fittings are products with bottle designs. Despite the fact that they are somewhat more difficult to assemble than other types of products, they provide an optimal set of consumer characteristics. Therefore, let's look at how to assemble a sink siphon, complemented by an overflow function, based on a regular plastic bottle model. Installation will be easier if you initially completely screw together all the elements, thoroughly compress the threads and carefully position the gaskets, and then connect the finished product to the outlet and overflow holes of the sink.

We assemble a siphon for a sink, complemented by an overflow function:

- We twist the two lower parts of the flask through a large flat gasket. The threaded cap (cup) is tightened until it stops, while you need to control the position of the gasket, preventing it from distorting.

- An intermediate pipe is inserted into the upper hole of the flask, which can be without an outlet or, if you have a siphon for a washing machine with or without a check valve, have an additional outlet to which a herringbone fitting is attached with a union nut through a flat gasket-valve. Union nuts must first be put on the upper and lower parts of the intermediate pipe, and then conical gaskets with the sharp parts facing outwards.

- We tighten the flask with the lower nut, and the overflow unit with the upper one.

- We insert and tighten the outlet pipe with a union nut and a cone gasket into the larger side hole of the flask, similar to the intermediate pipe. The outlet can be a straight or angled tube, or a corrugated hose.

- The same connection diagram is for the overflow tube, which must be connected at the lower end to the side outlet of the overflow tee, and at the top to the overflow pipe.

- Now you can attach the assembled structure to the outlet and overflow holes of the sink. The siphon for the kitchen sink is attached with screws to the corresponding holes through decorative grilles. For some models of plumbing fixtures, a decorative grille is provided only at the outlet hole, and the overflow is mounted by screwing a screw into the body of the overflow pipe through the wall of the sink. Regardless of the fastening features, flat elastic gaskets must be inserted from the side of the drain fittings.

All that remains is to connect the sink siphon with overflow to the sewer outlet. If the diameter of its outlet corresponds to the mounting diameter of the outlet, then it is simply tightly inserted through the o-ring into the sewer socket. To facilitate the operation and increase the reliability of the connection, silicone lubricants or sealants are used. If the outlet is thinner, then adapters or rubber cuffs with holes of suitable diameter are used.

Important! It is better to purchase the entire set of plumbing fixtures, including a siphon for a sink with overflow, at one retail outlet, so that unforeseen difficulties do not arise during installation of the equipment. This recommendation especially applies to products of non-standard designs and shapes.

Adjusting the water level

If water is supplied from the side, then the maximum level in the tank is regulated by changing the length of the spoke. It is at its end that the float is attached. In old and many new models, the role of this lever is performed by a thick brass wire.

You just need to bend it in the middle so that the float moves down or up. The higher it ends up being, the larger the volume of the tank will be filled.

However, now metal is increasingly being replaced with plastic. But it will not be possible to bend the plastic elements at the desired angle; they may simply break.

In this design, the float must be moved along the axis of the plastic pin, thereby increasing or decreasing the lever arm. The farther the float device is from the valve, the more water will flow into the tank.

Image gallery

Photo from

Step 1: Prepare to Adjust the Float Position

Step 2: Adjusting the float position with the nut

Step 3: Checking the operation of the flush device

Step 4: Change the level based on actual results

The float arm in toilet models with bottom water supply is located vertically. Here the water level is much easier to regulate.

The float element simply needs to be moved up/down and fixed at the desired height with the clamps or nuts provided for this purpose.

To simplify the adjustment of the float position, some mechanisms have a threaded connection on the rod or a rotating block to adjust the position of this “displacer”

The main problem when making adjustments is not changing the position of the float, but the need to remove the toilet tank lid. A drain button is attached to it, which in many models is rigidly connected to the drain mechanism.

To avoid breaking anything, this structure should be disassembled extremely carefully. First you need to carefully unscrew the clamping ring of the button. And only after this will it be possible to move the lid without fear.

Have you ever had an unfortunate toilet lid break? You can try to fix it yourself. In this article we looked at how to do this step by step.

If, with the float in the upper position, water still continues to flow into the tank, then the problem lies in the inlet valve. It will have to be disassembled and cleaned or completely replaced

Almost all the working elements of the flush cistern mechanism in the toilet are now made of plastic rather than metal. Because of this, they often break.

Plumbing stores sell both ready-made drain and supply structures, as well as their individual components for repair. In some situations it is cheaper to replace only part of the device, while in others it is easier to replace the entire assembly.

You may also be interested in reading about how to properly disassemble the drain tank so as not to accidentally damage anything.

Which siphon is better

So, which sink siphon is best? It's simple. One that will be selected taking into account the quality of the room, such as:

- Availability of free space;

- Decorative purposes;

- Available funds;

- Skills in working with plumbing components.

So, if there is enough space under the sink in the kitchen or bathroom, then the best option would be a siphon with a flask under it. This is due to the passage of a large number of clogging elements through the siphon structure (hair, nails, pieces of food, etc.).

If the siphon becomes more of a means of self-expression than a plumbing unit, then, of course, the choice should fall on pipe varieties. They are often made of chrome-plated metal, which, when combined with other bathroom elements, will help complement the decorative image of the room. The only thing worth remembering is that servicing such siphons is quite problematic, and in the event of external mechanical damage, it will be impossible to eliminate their traces.

For people on limited budget, a classic bottle siphon for sinks or a corrugated one would be an excellent choice. Such options are common today as plumbing elements, and are also easy to maintain and relatively durable.

As for skills or abilities, without them it is better not to try to install the siphon yourself. Errors in installation, violation of technology, etc., can lead to the likelihood of leaks, breakdowns and other unpleasant situations that will only cause discomfort to any owner.

Some useful tips

To make the problem of choosing a siphon and its subsequent installation even easier, here are a number of practical tips that will help make the task easier:

- It is better to opt for smooth-walled systems, because they are easier to clean;

- When replacing a damaged or old siphon with a new one, it is better to cover the sewer drain socket with a rag or something dense during all stages of installation;

- All surfaces are thoroughly degreased and cleaned before installing the protective grille;

- It is better to carefully seal all connections and joints to eliminate the possibility of leaks. An exception would be the thread of the lid of the bottle-type siphon flask;

- It is recommended to purchase a siphon strictly with a pipe size similar to the diameter of the socket;

- Purchasing a siphon for sinks and sinks when you plan to connect appliances (washing machines, dishwashers) is recommended along with them and taking into account the advice of a plumber. It is important to pay attention to the design features and structure of the structure.

Basic selection rules

To ensure effective drainage of used water in the kitchen, you need to choose the right siphon. To do this, consider the following recommendations:

- You need to purchase the kit immediately. In addition to the siphon, it must contain all the necessary components for connecting it to the sewer. If parts are purchased separately, there is a possibility that they will not be able to be assembled into a single structure.

- It is necessary to measure the free space under the sink in advance. If it is minimal, you should give preference to a short siphon.

- With closed installation, there is no need to purchase an expensive designer siphon. It is better to buy a less beautiful product of good quality, but at a lower price. After all, no one will see it, and it will not spoil the interior of the kitchen.

- If the sink siphon is open, it makes sense to buy a product with a decorative design.

Each device always comes with instructions - you need to study them carefully before installation. It is also necessary to pay attention to the absence of damage to the siphon, the quality of the threads, sealing elements and plugs.

Leading manufacturers

If there is a choice, products from leading manufacturers are preferable. We advise you to pay attention to the following products:

- Siphons made in Israel are easy to use. They have a reliable design and long service life. The manufacturer offers many modifications;

- The Austrian company has been working on the market for a long time. Offers quality products with stylish designs;

- Wunder-bar. The American manufacturer offers modern high-quality models.

Sodastream – high quality products

Design characteristics of semi-automatic

The semi-automatic bath fitting has a rather complex design, which is characterized by an additional shut-off valve controlled by a lever on the overflow hole. It can be made in the form of a button, a decorative valve, or a rotary ring. Control occurs using a system of cables and other additional connecting parts. The advantages of such a siphon lie primarily in convenience and comfort of use. The closed overflow device has a high aesthetic appeal.

On the other hand, the complexity of the design and the presence of many moving parts reduce the reliability of such systems.

When purchasing siphons of this type, it is important to pay special attention to manufacturers of high-quality fittings for sanitary equipment that have proven themselves well. The durability and uninterrupted operation of these drains directly depends on this.

Dismantling the old drain

Before assembling a new drain, it is necessary to dismantle the old structure. If you have a plastic system of the old model, there will be no difficulties. No additional tools are needed.

Stages of dismantling the old drain:

- It is necessary to turn off the water;

- Prepare a container to collect water from the siphon (bucket or basin);

- We disassemble the siphon by unscrewing the nut on the sewer channel;

- Disconnect the siphon mount from the sink;

- You can remove the siphon and drain the accumulated liquid;

- Dismantling the drain with the grate (you need to unscrew the union nut).

When disassembling a new type of plastic drain, a screwdriver may be useful. The operating sequence is similar, but the grille can be secured with a screw.

The sink opening must be thoroughly cleaned before installing a new drainage system. The drainage elements can be reused without breaking.

Important! It is not recommended to reuse gaskets, as after a while they wear out and cannot fully perform their functions.

Types of toilet flush valve as a system overflow control mechanism

The toilet cistern flush valve can be a float or membrane shut-off device. Models of the first option may differ in structure and principle of operation. Old tanks were equipped with Croydon valves, which consisted of a body, piston, axle, seat and float lever. When the float lever was acted upon, the mechanism began to function. In this case, the piston moved vertically.

Most modern drain mechanisms are equipped with a piston valve, which moves horizontally when the lever is pressed. The water supply is regulated by the contact of the piston and the seat. When the container is filled, the inlet hole is closed using a gasket located at the end of the piston.

The diaphragm valve is not equipped with a piston gasket, but with a rubber or silicone membrane. When a lever acts on it, the plastic piston begins to displace the membrane, which closes the water supply.

The drain valve can be equipped with a membrane or float mechanism

Important! The diaphragm valve facilitates quick and silent filling of the tank.

The disadvantage of this element is the greater sensitivity of the product to dirt and the presence of impurities in water. The diaphragm valve will quickly lose its operational properties due to poor quality water in the system. A mechanical cleaning filter will help avoid problems.

There are floatless options for the drain system. The water supply to them is stopped due to the presence of a special chamber shaped like an inverted glass.

Material for making toilet flush valves

Expensive models of toilet flush systems are made of bronze or brass. These materials are characterized by strength, reliability, corrosion resistance, and the ability to withstand mechanical and chemical loads. The design can be either simple or complex. Metal filling is found in expensive collectible models, which are produced with a certain stylization.

Most drain valves are made from polymers

In other cases, bronze and brass can be used in the manufacture of only the fill valve, which makes the shut-off and drain system universal, easy to install, configure, repair, and allows you to replace each unit individually.

Many valve models are made from polymers. The quality of plastic and precision of production affect the cost of the product. The more expensive the fittings, the more reliable and durable the drainage system will be. However, there are high-quality models that have an affordable price.