Many people are still wary of electric induction cookers: the “cold” heating technology is unusual for the average user. Moreover, not everyone can figure out how such a technique should work correctly. Therefore, users often do not understand whether to call a technician if the induction cooker clicks during operation. There is no single answer to this situation; clicking noises when an induction hob is operating can be either normal or a serious problem.

If you need induction cooker repair in St. Petersburg, please contact. Our service center operates in all areas of the city and offers services for restoring household appliances at home. You can order a visit from a specialist by calling +7 every day from 7:00 to 23:00. When submitting an application before 12:00, a specialist can leave on the same day of application.

Features of the malfunction

When an induction cooker clicks, you should pay attention to several nuances. This type of equipment is characterized by a clicking sound when heating up or operating at high power. If the stove clicks and works, then the relay regulates the power. There is also a sound when the heating level is reduced. In other cases, clicking is associated with malfunctions that arise for the following reasons:

- Manufacturing defects. Parts break during the warranty period. More often in the first 1-3 months of active use. Repairs are carried out inexpensively or under warranty from the manufacturer.

- Natural wear and tear. The relay has failed due to prolonged use. Requires replacement with a new one.

- Incorrect use, care. Violation of the rules of use, cleaning, washing and other manipulations. We recommend that you study the instructions from the equipment supplied with the device upon purchase. If the brochure is lost, you can find it on the manufacturer's official website.

DIY repair

Please note that induction devices have a complex structure and require a competent approach. If you do not have experience or a specialized tool, you risk disrupting the quality of operation of adjacent elements in the device. For this reason, repairs may become unprofitable due to the high cost of restoration and spare parts. It is important to note that every fifth call from Remontano specialists is related to attempts at self-repair.

Common breakdowns

If the hob clicks and does not heat up , the main source of the problem is the burner relay. The problem can be determined by diagnostics by specialists. Do-it-yourself testing is impossible due to the need to disassemble the case. Another source of the problem is the use of unsuitable cookware, which causes heating to occur incorrectly and the electronics constantly changing operating parameters.

If the panel or stove clicks and still works , the cooling fan is the source of trouble. Its design has become contaminated with dirt, crumbs, grease, and the blades cling to them. Damage to the shaft and electric motor is possible.

An unpleasant situation is a short circuit in equipment after penetration of moisture, oxidation of contacts during operation, which leads to extraneous sounds and the activation of any radio components.

Residual heat indicator does not work

You need to run a software test to check the temperature sensor. If it is working properly, the control unit is replaced. There are cases when the LCD display elements light up constantly or not all work. In the event of such a malfunction, the quality of the connections between the control unit and the touch panel is checked. You can try replacing the cable connecting the modules. If this does not help, the control unit must be replaced.

Our advantages

The Remontano workshop invites clients in Moscow and the region who have encountered problems with induction cookers to cooperate. We will promptly restore serviceability at reasonable prices. The cost of work is determined by diagnostics and does not change until the services are completed. Other advantages include:

- Extensive experience working with household appliances.

- We repair induction, electric, gas stoves and panels.

- We work with brands Gorenje, Bosch, Zanussi, Ariston, Kaiser and others.

- We carry out home repairs of any complexity.

- The work schedule is from 7:00 to 23:00 allowing you to choose a comfortable time.

- Travel around the city is provided free of charge.

The stove does not turn on and there is no indication

First of all, you need to check the fuse, and then the mains switch. The next step is to check the connection between the control unit and the power board. Then between the control unit and the touch panel. If a failed module is detected, it must be replaced. If replacing the module does not help, the entire coil block is replaced.

Problems with the touch panel can be confirmed by the error code “E9” that appears on the LCD display of the device. Based on the list of error codes, it means that the touch control panel is faulty. It is recommended to disconnect the device from the network for 30 seconds. If the error reappears, the control panel changes.

Troubleshooting

Immediately after purchase, you should carefully inspect the unit and find out whether all its visible elements (door, switches, grilles, etc.) are securely fastened in place. After this, you should connect the unit to the network and run some kind of gentle program “idle” - this way you can find out whether there is a manufacturing defect.

Most often, owners of electric stoves from the following manufacturers face the problem of extraneous sounds: Gorenje, Indesit, Gefest, Zanussi, Hansa, Kaiser and Electrolux.

Error E3

Error E3 indicates unstable voltage. It can be either low or high.

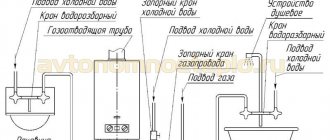

Solution: You need to check the voltage while the device is running. To do this, place the cookware on the burner and turn it on for 1 minute. Then, in operating mode, measure the voltage between phase and zero. To measure the voltage, see the connection diagram drawn under the stove. If the voltage is normal and the stove is working, then there was just a surge. If the voltage is high or low, then you should contact the organization that is responsible for supplying electricity to your home. And if the voltage is normal, but the stove does not work, you will have to call the service center.

Sound source

Despite the fact that the kitchen, by definition, cannot be the quietest room in the apartment, the creators of kitchen appliances have always strived to make their devices as “silent” as possible. But sometimes careless operation or manufacturing defects can cause various malfunctions in the operation of the stove. A direct consequence of these disturbances may be a dull sound, vaguely reminiscent of the hum of the turbines of an airplane flying above you.

If your electric stove is humming, check out the main causes of various unpleasant sounds:

The “Booster” function, as a rule, forces the heating elements to work in forced load mode, so you should not be surprised by the appearance of additional sounds;

The burner may be clogged or deformed. Such damage usually results in a cracking sound due to vibrations on the surface;

Large metal parts of the housing expand when heated and contract when cooled. This process may be accompanied by a soft cracking sound or the sound of a metal sheet bending;

The tubular electric heater (TEH), which is the main heating element of electric stoves, can become loose and hum, as the vibrations it creates have a wider amplitude;

If the sound comes from the oven, the reason may be due to the operation of the fan involved in convection;

The fan cooling the front panel may move off-axis or even lose its blade, resulting in rattling noise;

Sometimes noise is a consequence of the interaction of magnetic coils and the material from which the cookware is made. The volume of the hum depends on the thickness of the walls, the characteristics of the material from which the dishes are made, the smoothness of its bottom, weight and tightness of fit to the surface;

High power burner does not turn on

There are situations when you want to turn on the most powerful burner, with a maximum power of 3 kW, but nothing happens. This is considered normal if other cooking stations are working and the temperature near the induction coil unit exceeds 780 degrees. To prevent overheating of the unit when the most powerful burner is turned on, it is blocked. When the cooking zones have cooled down, the lock will be released and the coil will turn on. But, if the burner does not turn on, you will have to change the control unit.

Troubleshooting methods

A malfunction associated with extraneous sounds, as a rule, is not a consequence of fatal changes in the operation of the stove. However, opening the device casing on your own and subsequently interfering with the operation of the unit can have an extremely negative impact on its technical characteristics. To avoid this, it is better to entrust the repair of an electric stove to specialists.

However, every user should have an idea of possible malfunctions and how to resolve them:

Humans are unable to influence the physical properties of metals, so you and I just have to put up with the occasional rattling of the side panels of the case;

The cooking heating element may be installed incorrectly, which may cause it to suddenly fall out of place. The repairman can easily return it to its original position and secure it tightly.

Any of the two fans installed in the electric stove can either begin to touch adjacent structural elements, or change their shape under the influence of high temperature. In both cases, the temperature regime in the stove may be disrupted, which in the future can lead to serious problems;

In general, any liquid that gets inside an electric stove can cause a variety of malfunctions, some of which can be “audible”;

Operating principle of an induction cooker

An induction heating plate operates on a fairly simple principle of generating eddy currents in a magnetically and electrically conductive material. We are talking, first of all, about metals and their alloys with certain physical characteristics. In order for the induction heating element to work properly, the following conditions must be met.

- Use dishes made of special materials. Most often it is steel. It is this material that not only has good ferrimagnetic characteristics, but also the ability to generate eddy currents and actively absorb the energy generated during their passage.

- The heater power control system must ensure the creation of an alternating magnetic field. It is this that generates eddy currents in the cookware material. The field frequency ranges from 20 to 60 Hz and must be stable.

- The magnetic field of an induction heater is quite highly localized. This means that the item being heated must be placed as close as possible to achieve maximum efficiency of the process.

If we consider the induction cooker and the cookware installed on it from the point of view of physical processes, this system is a transformer. In this case, the heater coil acts as the primary winding. The magnetic field it generates causes eddy currents to appear in the dishes. It is the bottom of this object that acts as the secondary winding. There is no removal of electrical energy from it, so all of it is converted into heat. As a result, the pot or pan heats up.

Important! For normal and efficient operation of the induction panel, it is necessary that the area of the coil be as close as possible to that of the object installed on it. In this case, the energy is transferred almost completely.

If this condition is not met, the following unpleasant things happen:

- eddy currents do not form above an empty place on the stove that is not covered with dishes;

- the coil generated by energy in uncovered, empty places is not disposed of;

- As a result of incomplete energy removal, the coil overheats.

To neutralize this phenomenon, cooling radiators are installed in each induction panel. If they fail, the coil will have to be replaced. And in the most difficult cases, the output stages of the high-frequency power generation circuit will also require repairs.

Preparation for repair work

After all possible causes of problems have been checked, you have to move on to repairs. Preparation necessarily begins with the stove being disconnected from the power supply, in this case electric. By the way, before doing this, you should find out whether the outlet itself is working. This can be done using another, uniquely working device. Next, the surface is dismantled in order to be able to work with the induction system itself.

The first step is to visually assess whether everything is in order with the elements. For example, soot, changed shade and other traces should immediately alert you. Next, a full check of all components begins.

Contacts, cables and fuses are assessed using a multimeter - if resistance is detected in sections of the circuit, broken elements are replaced. The induction coil spirals are checked for cracks and contact between individual turns. Temperature sensors are again monitored using a multimeter. At the next stage, the wiring running from the induction coil to the generator is tested. Next, using an ordinary powerful light bulb and a magnifying glass, you will need to find out whether cracks have appeared on the control board. The latter can provoke a break in the paths carrying current.

Upon completion, the base of the non-working burner is inspected separately, if there is one.