Recently, decorating a home has become a pleasure. Now there are no problems with the choice of floor coverings, cladding for ceilings and walls. Bold design decisions can be implemented and not think about where to find this or that decorative product.

Finishing of the floors begins when finishing work on the walls and ceilings has already been completed. The final floor covering is laid according to the overall interior and design. Materials for finishing floors should not only match the color scheme of the rooms, but also be optimally suited to the purpose of the room. Modern floor coverings meet all these requirements.

Moreover, they are very easy to install; even an amateur in construction can handle the installation. But sometimes the variety of materials can be confusing. Many people get lost in the abundance of floor products. In order to clearly know what kind of flooring is needed in a room at home, you should have an idea of the types of flooring.

In general, types of flooring can be divided into groups according to installation method:

- The first group will include rolled materials. They are very easy to install. The rolls are rolled out and secured using plinths.

- The second group will be represented by prefabricated structures. These are plank structures, the planks of which are secured using special locks.

- And finally, the third group includes materials that are installed for a long period of time. Installation requires the use of glue or cement mortar.

The purpose of the rooms and the characteristics of the material will also help you decide on a flooring product for your home. For example, no good owner would put carpet in the kitchen, because he knows that this room needs moisture-resistant material. The range of floor products is already narrowing due to the special purpose of the room.

Advantages of using cement bonded particle boards for flooring

This material is becoming more and more in demand, which is explained by its excellent parameters.

The main advantages of the product include:

- Strength. This quality ensures the product’s resistance even to severe mechanical stress. Point loads do not weaken the structure of the part.

- Environmentally friendly. The base, consisting of cement and a wood component, to which special modifiers are mixed, does not pose a threat to human health.

- Fire safety. The resulting coatings are highly fire resistant. Exposure to severe temperatures does not result in deformation or release of harmful substances.

- Resistant to mold and mildew. The presence of alkali in the composition prevents the development of microorganisms on the surface.

The tandem of liquid glass and Portland cement determines the unique water-repellent and antiseptic characteristics of cement-bonded particle boards - Moisture resistance. The product has low hygroscopicity, which allows finishing work not only inside the house, but also outside. For example, during frame construction, the floor can be laid long before the walls and roof are erected.

- Additional sound and heat insulation of the room. The parts absorb noise well and improve the energy efficiency of the building, reducing costs and ensuring comfortable living.

- Availability. The price corresponds to the quality of the product. The popularity of DSP is gradually expanding its distribution and increasing production volumes, which affects the price reduction.

- Frost resistance. The slabs do not deform in unheated rooms.

You can install the parts yourself without involving specialists, but the work has certain nuances.

How to level the floor: plywood, OSB, gypsum fiber board or chipboard

To level the floor, different materials are used; among the most common are chipboard, wood sheets, and boards. Some of them are multi-layered, others contain large chips - there are many options. This structure makes it possible to obtain a material with the desired properties. The sheets are durable, withstand moderate exposure to static and dynamic loads, some varieties do not deform when in contact with moisture. When planning to install a floor, first choose a coating. What should be considered first will be discussed below.

Disadvantages of the material

Disadvantages of the product:

- Weight. Due to the presence of some components, the elements have a high density and significant mass, so assistance will be required when transporting and carrying the slabs to their destination. Due to the large load on the surface, when laying on joists, it is necessary to take into account the ratio of thickness and distance between the supporting elements.

Due to the serious weight of the material, powerful freight transport is required to transport cement bonded particle boards - Difficulty of processing. The cutting must be carried out with a suitable tool, otherwise the work may be significantly delayed.

- Dust formation. When cutting, a large amount of suspension appears, which has a detrimental effect on the respiratory system, so work should be performed in a respirator.

When purchasing material, you must check for safety certificates.

What is the problem

The words “level a wooden floor” can have different meanings. Here's what they might mean:

When people talk about wooden floors, they imagine something like this:

- bring to a level a coating that generally has some slope;

- straighten bent boards, preparing the floor for painting or varnishing;

- prepare the base for laying the flooring.

The real picture often looks something like this.

Sometimes the task is multi-purpose. When you need to do everything described at once. Sometimes the goal is to solve individual problems. We will describe several solution options for each case, and determine a comprehensive solution for yourself.

Laying features

To correctly lay the products, you need to accurately select the thickness of the cement bonded particle boards:

- The optimal value when working with a concrete or plank base is 10–16 mm.

- If installation is carried out on logs with a pitch of 50–60 cm, then elements with a thickness of 20 to 26 mm are selected. On the ground floor, it is recommended to lay products with a thickness of 10–14 mm in two layers.

- Prefabricated floors in domestic and technical premises can be made in sheets with a thickness of 24 to 36 mm.

To guarantee high-quality installation of the floor in a private house along joists, it is advisable to use slabs with a thickness of 20 mm or more, and for continuous installation on floor slabs in an apartment, any material is suitable

. The further process consists of successive stages, the observance of which will ensure a high-quality result.

Preparatory work

To ensure that the installation of DSP floors does not take much time, you need to carry out all the preparatory procedures in advance.

Marking

Algorithm of actions:

- The area of the room is measured and a detailed diagram is drawn up with the data obtained.

- It is very important to pay attention to difficult areas. If there are tapering parts or niches in the room, it is necessary to divide such places into several sections in order to get the right result.

- Temperature gaps are left from the walls, which level out deformations during shrinkage of the building.

- According to the plan, taking into account the selected size of the slabs, it is determined how the sheets will be attached. The technology of flooring on logs involves laying parts across.

- Cement particle boards are being prepared. To do this, the dimensions according to the location on the floor covering are transferred to the parts.

When drawing up a laying plan, the slabs are placed with a shift; it is also necessary to take into account the size of the damper gap

Sawing

Further work may cause some difficulties: you need to choose what to cut the CBPB with.

To cut the slab, the following tools are used:

- Bulgarian. This is the most effective option if panels thicker than 12–14 mm are used. The work will require special diamond discs that provide fast and reliable cutting.

- Jigsaw. The use of such a tool is limited: it can only cut thin parts. Thicker elements will require a set of good files, which are selected empirically, and a lot more time and effort.

- Construction knife. You can cut thin slabs with this device in the following way: using a blade resting on the edge of a ruler or slats, a depression is formed along the line, after which the product is moved beyond the edge of the table and broken off.

On a note! When laying CBPB on the floor, all edges must be extremely smooth, so the last cutting option may require additional preparation due to the presence of defects.

The cleanest and smoothest cut is obtained by using a grinder with a diamond blade or a hand-held circular saw with high speeds.

Installation of slabs

To lay parts on a horizontal base in a private house or apartment, you can use different methods, which depend on the type of surface.

Fastening with glue or self-tapping screws

The fixation method is selected based on the specific situation:

- Screws provide reliable fastening to wooden bases.

- When using self-tapping screws, it is recommended to pre-drill holes with a high-speed tool. They should be slightly larger to prevent shrinkage cracking.

- The parts must be glued with a special compound after preliminary priming of the surface of the slabs and the floor.

To obtain a guaranteed quality result when working with DSP boards, it is advisable to use specialized types of glue - It is recommended to lay the elements on the connecting mixture if there is a concrete base. DSP can play the role of a finishing screed.

In some situations, methods can be combined.

Laying on joists

For the process, a wooden beam with a cross-section of 5*8 cm is selected, which will provide the best reliability and rigidity. Parts must be dried and treated with protective compounds.

For ideal leveling of wooden floors on joists, a DSP flooring with insulation is installed

Scheme of work:

- Logs are installed. All elements are aligned with each other and fixed. It is recommended to place under them insulation, cut into strips, which will avoid the appearance of cold bridges. If required, jumpers are installed.

- The empty space is filled with thermal insulation material. Dry screed is created in a similar way.

- DSP slabs are laid according to the drawn up diagram with a gap from the walls. If the house was recently built, it is advisable to leave a small distance between all the parts, sealing it with putty or sealant.

- The panels must be fastened with self-tapping screws in increments of 20 to 35 cm. The cap must be immersed flush.

The choice of method for arranging the seam between the flooring slabs is selected depending on the installation location and the finishing coating that is planned to be laid on top.

If two layers are laid, then they are placed perpendicularly so that the previous joints are closed.

Mounting on concrete screed

You can place the slabs on such a base as follows:

- The surface is cleaned of all excess, dirt and debris are removed. Work is carried out only when the humidity of the coating is low.

- Priming is carried out with a deep-penetrating compound, and the floor is dried.

- The mixture is being prepared. For installation, you will need a notched trowel, which will ensure uniform application without the formation of voids.

DSPs are laid on a concrete base using the same technology as tiles - The glue is distributed over the base. A slab is laid on the treated area, pressed and leveled.

- Adjacent parts must be located on the same level. The required clearances are maintained.

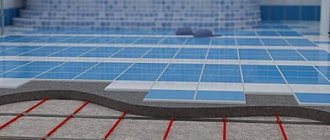

This method is excellent for warm water floors, but all gaps between the tubes are first sealed with a self-leveling mixture.

Cement particle boards are ideally suited for installing a “warm floor” system in a wooden house

What it is

Often, when choosing a finishing material, the consumer has the question of what is gypsum fiber board for the floor. As the name suggests, it is a gypsum fiber sheet. However, unlike the standard well-known drywall, it does not have an outer paper shell. The structure of the slab is homogeneous. The basic necessary properties are given to it during the following production process:

- The main components - gypsum, cellulose and various modifiers are mixed evenly.

- The mixture is filled into the form.

- The workpiece is saturated with water and fed into the press installation.

- The formed slab is dried - the material is brought to a certain degree of humidity.

- The finished product is transferred to the warehouse.

Another important difference between the material and conventional drywall is its higher strength, water resistance and density. Thanks to this set of properties, the GVL slab is used not only and not so much for finishing, but as a substrate for a coating, for example, laminate or parquet, and also as a rough version of the floor and even as a sound insulator.

GVL close-up Source company-megapolis.rf

Useful tips

To achieve better results, you can use some recommendations:

- Installing DSP on the floor is most important when laying tiles: in this case, the highest quality adhesion is achieved.

- Before use, it is better to keep the material indoors for 24 hours. This will eliminate possible errors.

- If work is carried out on a “wet” screed, then you should wait for it to dry completely.

- It is better to carry out the procedures with an assistant, especially when using thick slabs.

If all work is performed correctly, the surface will be more reliable.

conclusions

When choosing a material for installing a floor, it is difficult to immediately answer the question of which is better: OSB or plywood. There are many factors that determine the characteristics of sheets. Both varieties have similar properties, are durable, tolerate contact with moisture, but can behave differently under the same conditions.

When installing plywood, the coating does not bend, because this material fits well and does not “play” under pressure. It better withstands mechanical loads, but does not have sound insulation, and therefore requires the use of substrates. OSB is a sheet that is distinguished by its versatility, which is due to its low content of harmful components and affordable price.

Source

Installation technologies

Despite the apparent simplicity of the material, the procedure for installing gypsum fiber boards is quite complex and has many nuances. It is necessary to take into account both general requirements for the base and specific ones - in each installation option. Let's look at them in more detail.

Laying gypsum fiber board on an expanded clay cushion Source sense-life.com

General requirements for foundation and installation

The versatility of GVL slabs is also evident in the installation methods. They can be mounted either on a solid, level base or on beams with a sufficiently large gap from each other. At the same time, special requirements are imposed both on the surface on which the material will be laid, and on the material:

- The height difference should not exceed more than 2 mm for every 2 meters of the straight line of the base.

When laying soft finishing - linoleum, vinyl, carpet - small and shallow unevenness is allowed. However, leaving such defects for installation of parquet or laminate is extremely unacceptable. At a minimum, this threatens the subsequent spreading of the finish and the divergence of its locks.

- When installing on a non-solid base or on joists/lathing, it is necessary to use gypsum fiber boards of increased density and maximum thickness.

As an option, laying sheets in 2 layers is allowed. In this case, the modification of the material must necessarily be GVLV - moisture resistant, and the seams of the lower layer must be covered with the top sheet.

Laying gypsum fiber sheets on joists Source blogspot.com

- Immediately before laying, the ends of the slabs must be glued - coated with an adhesive base.

If installation takes place on a rigid base, for example, a concrete floor, it is allowed to use PVA, and if on joists or insulation, a sealant that retains elasticity after complete drying is allowed.

Important! The gaps between the gypsum fiber board sheets after installation should not exceed 1.5-2 mm. If the finishing has a soft base, then even smaller gaps between the slabs must be puttied.

Needle roller and its types

To perform the final leveling of the screed with a self-leveling mixture, specialized tools are required. One of these is a roller for self-leveling floors, in particular, a needle roller. In appearance, it is a cylinder with needles that are attached to an axis with a handle.

Its purpose is to roll the uncured bulk mixture. This manipulation helps to get rid of air bubbles, which contributes to the extreme uniformity of the finished coating.

Please note that if you do not use a needle roller, air bubbles will remain in the mixture, which will make the leveling layer porous, which can potentially create problems when laying the finished floor covering.

Metal

The main advantage of a metal roller is its smaller needles, which allows for maximum penetration into the self-leveling mixture. Other advantages include the following qualities:

- Durability;

- Solvent resistance.

Needle rollers, regardless of the material of manufacture, are equipped with a universal handle that allows for the connection of a telescopic extension.

Plastic

The advantages include relatively low cost compared to metal versions. Another plus is the lighter weight, which makes it easier to use.

Advice: a plastic roller is lighter than its metal “brother”, but it will not last long for working over a large area. Therefore, if the work area is large, it is better to purchase a steel version.

Video description

Video about installing gypsum plasterboard on expanded clay:

In this case, a lathing must be created to fix the gypsum fiber. Its depth will correspond to the thickness of the backfill layer. An important feature of using this method is maintaining a gap around the entire perimeter of the room - between the slabs and the walls. Its presence is due to the need for ventilation and the natural vapor permeability of wooden structures.

Laying tiles on GVL

In rooms with high humidity, tiles are usually installed using gypsum fiber board. In this case, the following conditions must be met:

- The floor must have additional waterproofing.

- If the slabs are laid on logs or a base made of boards, they should not sag during operation.

- It is necessary to use elastic glue as a fastening base for ceramics.

- The seams of the laid tiles and gypsum fiber sheets should not match.

Note! An improperly prepared base can cause poor-quality installation of gypsum fiber boards and their subsequent damage during operation. The smallest grains of sand, dirt stuck in cracks, and hidden irregularities can cause significant defects in the floor in the near future after its completion.

Ceramic tile

Tiles are often chosen for installation. Based on the purpose of the premises or simply at the request of the owner. This material is characterized by low abrasion and low water absorption coefficient.

Let's look at the stages of its installation:

- Using a notched trowel, apply a layer of diluted glue to the prepared surface.

- The tiles are embedded in the glue. To improve the fit, tap it with a mallet.

- The following tiles are laid side by side, with plastic crosses installed between them to form a gap. Periodically check the horizontal position with a level.

- If necessary, cut parts of the tiles using a tile cutter.

- After an hour, the crosses can be removed.

- Every other day, the seams between the tiles should be grouted.

- Use a damp sponge to remove excess grout and stains.

Laying tiles

Porcelain tiles

Porcelain stoneware is actively used to cover floors in homes, supermarkets, and public spaces. It is more durable than ceramic tiles, wear-resistant, durable.

Its installation is similar to that of ceramic tiles, with the only difference being that a different adhesive is selected and cutting of the slabs is a much more labor-intensive process due to the size of the material.

Laying porcelain tiles

Choosing a floor covering is extremely important and not easy. It needs to be taken responsibly, having analyzed all the pros and cons. Properly selected and installed coated concrete floors will serve you faithfully for many years.

Cost of repair work

If you do not have free time to level the floor yourself, then the work can be entrusted to repair teams, whose advertisements abound on the Internet. Specialists can do not only leveling, but also provide other repair services. But all this will have to be paid for. Of course, the cost of the work depends on the skill level of the master and the city in which the work is performed (prices for leveling in Moscow are much higher than in other cities).

Cost of floor leveling

Let's consider the average cost of work per 1 sq. m. So, the asking price:

- installation of plywood sheets on a base made of wood – 110-130 rubles;

- leveling with self-leveling floor – 150-180 rubles;

- dry screed – 400-500 rubles;

- leveling the floor with joists – 520-600 rubles;

- cement floor screed with installation of beacons - 600-650 rubles.

Leveling the floor: before and after

Leveling the floor yourself is a difficult job that requires patience and care. Therefore, if you doubt your abilities and are not sure that the leveling will be done efficiently, it is better to entrust the work to qualified specialists. Of course, you will have to pay a lot for their services, especially if the room is large, but the result is worth it.

Using the mixture to level the floor

Prices for self-leveling floors "Starateli"

self-leveling floors prospectors

Briefly about the main thing

Gypsum fiber boards are made from gypsum, cellulose and various fillers. They have a homogeneous structure, do not contain cardboard and are highly durable and moisture resistant.

Laying gypsum fiber board on the floor has the following purposes:

- Dry floor screed.

- Lining for finishing coat.

- Interior partitions.

- Rough floor.

- Heat and sound insulation.

- Formation of heated floors.

- Creation of fireproof structures and surfaces.

- Moisture resistant finish.

In this case, GVL can be standard, moisture-resistant, fire-resistant and moisture-fire-resistant. Gypsum fiber boards are durable, resistant to temperature changes, do not burn, are environmentally friendly, resistant to mechanical and weight loads, but require careful installation, are quite heavy and expensive.

They can be mounted in various ways - on a concrete base, wooden floor or logs, in a prefabricated structure on a pad of insulation and under ceramic tiles. The installation procedure is quite complex and requires strict adherence to technological requirements. Therefore, it is better to entrust it to professionals.