Today, the construction market offers a huge amount of building materials for decorating the facades of houses. They not only decorate buildings, but also provide a high level of sound and heat insulation. Among the many modern facing materials, moisture-resistant plasterboard sheets are very popular. They are specially created for outdoor work, therefore they are highly resistant to external influences, tolerate significant temperature changes, and are not afraid of moisture. The use of facade plasterboard allows you to create an attractive facade, which, with proper care, will serve for a long time.

Cladding the façade of a house with plasterboard gives it individuality and attractiveness Source ob-otdelke.ru

What should be the plasterboard material for exterior finishing?

Before you begin arranging the facade, it is important to purchase suitable finishing building materials. He must:

- Have a perfectly smooth surface and attractive appearance.

- Reliably protect the outer walls of the building from negative atmospheric phenomena: strong wind, scorching sun, heavy rainfall.

- Features a long service life.

Facade plasterboard meets all of the above requirements. For this reason, it has become widespread in the design of external walls of buildings.

Facade plasterboard has excellent characteristics and properties, therefore it creates worthy competition with many other materials for exterior work Source ob-otdelke.ru

Characteristics of gypsum boards for facades

In the production of façade plasterboard, a special impregnation is used. It is applied to the top layer of the building material, as a result of which it increases its moisture resistance and prevents destruction. Plasterboard material intended for exterior finishing of buildings has the following valuable properties:

- prevent the penetration of cold into the house, retain heat inside it, thereby reducing heating costs;

- protects from wind;

- contributes to the creation of a cozy atmosphere in the premises, since it does not allow outside noise to pass through;

- maintains an attractive appearance for a long time;

- prevents the penetration of moisture into the building, which means it prevents the formation of fungal mold on the internal walls;

- resistant to negative weather conditions;

- does not require special care.

Practice shows that plasterboard sheets for facade finishing have the following advantages:

- provide high-quality protection from moisture to the insulation, which is often placed between the wall and the cladding;

- do not contain harmful components, therefore they are absolutely safe for humans and the environment;

- allow you to create perfectly smooth external walls;

- easy to cut, have sufficient flexibility;

- installation of the material does not cause difficulties, it is possible in several ways;

- finishing work is carried out in a short time.

Drywall should be used outdoors very carefully due to its fragility. It should be taken into account that prolonged contact with water or exposure to high temperatures can lead to deformation and gradual destruction of gypsum board panels.

Plasterboard facade panels serve not only to give an aesthetic appearance, but also to insulate buildings, protect against wind and exposure to atmospheric moisture Source remontik.org

Flaws

Despite all sorts of advantages, advantages and affordable cost, plasterboard has a number of limitations in its use for outdoor work:

- Facade cladding is performed exclusively with material specialized for this type of work;

- Prolonged contact with water leads to deformation of the sheets;

- Prolonged exposure to elevated temperatures leads to destruction of the structure of the slabs;

- Installation work and processing of gypsum boards is carried out carefully, due to its fragility.

Facade profiles

When carrying out external work, aluminum strips with anti-corrosion coating are used. They come in various sizes, regular and improved strength. In addition, such products have the following properties:

- light weight;

- high rigidity (do not bend during installation);

- long service life;

- suitable for the construction of curved structures;

- convenient to use.

When creating a profile frame, fasteners must be treated with an anti-corrosion agent. Only then is it mounted, and the free space is filled with insulation (foam, mineral wool). Next, plasterboard slabs are attached to the walls using special fasteners.

The profile used when installing facade plasterboard must certainly be coated with an anti-corrosion compound Source wilisbel.by

GKLO

Fireproof, marked red (GKLO), it is used mainly in dry places or with high air temperatures. Typically, this type of drywall is recommended to be installed in ventilation shafts, attics, and other places where there is a risk of fire.

It should be noted that thanks to reinforcing additives, such drywall is able to withstand very high temperatures, and possibly even an open flame of fire. The color of the plaster is pink.

Decoration Materials

For mandatory treatment of drywall outside, the following types of primers are used:

- deep penetration – increases the level of adhesion of building materials;

- anti-corrosion – prevents the formation of rust;

- antiseptic – prevents the development of mold and the appearance of pests;

- hydrophobic – does not allow moisture to pass through;

- universal – it simultaneously has several valuable properties.

The task of putty is to withstand temperature fluctuations and changes in humidity. It comes in three varieties: starting, main, finishing. High-quality putty mixtures are characterized by elasticity, frost resistance, safety, breathability and durability.

Based on their composition, putties are divided into:

- polymer – designed for outside work;

- cement – shrinkage is possible;

- polyurethane - universal;

- gypsum - it is not advisable to use it outside buildings.

If the finishing building materials are chosen correctly, cladding a house with gypsum board slabs will not cause any difficulties.

Acrylic primer is the best option for treating plasterboard surfaces Source ogipse.ru

Rules for finishing the facade with plasterboard

When covering a building with plasterboard panels on the outside, it is important to adhere to the following requirements:

- The gypsum plasterboard material must be mounted horizontally or vertically on the walls. Under any circumstances, you need to monitor the displacement of the panels.

- The absence of horizontal joints improves the breathability of the base. Therefore, sheets covering the entire height of the outer wall are often used for cladding.

- The contact points between the plasterboard panels must be treated with a non-hardening sealant. It does not allow moisture to pass through and allows the finish to “breathe”.

- Joints near openings for windows and doors must certainly be located on an auxiliary rack.

- A special plastic profile will help protect the open edges of drywall slabs.

You can attach plasterboard sheets to walls in both horizontal and vertical positions Source obustroeno.club

Nuances of work

To create a beautiful individual house facade, you will need to create a metal frame. Frame elements must be galvanized to prevent rust. Before installing frame parts, you should prepare the surface.

The façade of the house must be clean and free of hanging finishing materials. If there is a “belly” in the plaster or “fur coat” of the house, it should be removed. It is also necessary to remove the old whitewash. There should be no dust, cobwebs or dirt.

The surface is primed to prevent the occurrence of fungus and pests. After the primer has dried, this process is quick in the open air; markings should be made. Stretch the fishing line and hang plumb lines (to make the surface even). Installation of profiles begins along the perimeter of the wall, do not forget about windows and doors. After fixing the guide profiles, you should work on the vertical posts and horizontal struts. Each mounted element is checked for evenness with a level.

The metal frame should be made under the very roof and with a slight approach to the foundation line. Once the roof is sheathed, the top edge of the plasterboard wall will be hidden. Below, when insulating the foundation, the lower edge of the facade trim is sealed.

After installing the metal profiles, a corrugated wire is laid on top to illuminate the street. The entire surface is insulated with insulating material.

Installation of gypsum boards on a metal profile

When cladding external walls, waterproof plasterboard sheets are often fixed to a steel frame. The fasteners are self-tapping screws with a semicircular head. If the thickness of the guide parts and posts exceeds 0.7 mm, it is worth using fasteners with a special drilling end.

The screws must be 2.5 cm long or more, with a diameter of 3.5 mm. It is extremely important that the self-tapping screws used to fasten the GLK material have a protective coating. It will prevent the occurrence of corrosion processes.

When attaching facade plasterboard, a certain step should be observed: in the center of the slab - 30 cm, along the outskirts - 20 cm.

Attention! When screwing in the screws, you need to make sure that they penetrate perpendicularly into the frame profile.

Moisture-resistant plasterboard for exterior use is best mounted on a steel frame Source i1.wp.com

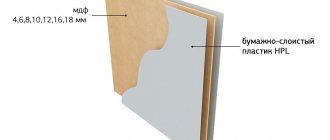

What is gypsum fiber sheet

The abbreviated designation of the material is GVL. The slabs are made from a mixture of gypsum and fibrous pulp (cellulose, shredded waste paper, reeds or straw). The shell is missing.

Varieties

There are 2 types of gypsum fiber sheets with different edges:

- Straight.

- With a chamfer of 2x30 mm. This structural element allows you to level the surface by putting putty on the joints alone. In addition, they can be reinforced with reinforcing mesh.

Gypsum fiber sheet is a finishing material similar to drywall.

Depending on the properties, there are 3 varieties:

- GVL - wall and ceiling for rooms with normal humidity.

- GVLV - moisture resistant. Also designed for installation on walls and ceilings.

- GVLV EP - floor-standing version. The difference is increased strength.

Externally, all types look the same. They are recognized by their markings.

Installation of drywall on a wooden frame

If the basis for a moisture-resistant gypsum board is a wooden frame structure, then when installing the material it is important to follow the following recommendations:

- Fastening is carried out using self-tapping screws, nails, staples. The use of the latter requires the use of special pneumatic tools.

- Metal fasteners must have a protective anti-corrosion layer.

- The recommended distance between fasteners along the edges of the panel is 15 cm, in the middle - 20 cm.

- You need to start the process of fixing the sheet from opposite corners.

- Depth of insertion of fixing parts: nails - 12 diameters, staples - 15, screws - more than 2 cm.

If, during fixation of gypsum boards for external work, the fastening element is deformed, then it must be removed. In this case, further fastening is carried out at a distance of 5 cm from the previous place.

The wood for the frame must be dried to 20% humidity, otherwise the timber will move and the structure will warp over time Source ob-otdelke.ru

Plasterboard column

In order to distinguish their home from many others, owners resort to various unusual finishes. Among them, column-shaped structures occupy a special place. The latter come in the following varieties:

- False columns. They give the building uniqueness. They are hollow inside, which allows you to lay wires for lighting in the interior space, hide the drainage system, and cables coming from the street.

- Support columns. Often they are made of concrete, and then covered with gypsum board sheets.

If a column-shaped structure is created near the house or in its corners, its frame is mounted simultaneously with the sheathing of the plasterboard task.

Plasterboard columns perform an aesthetic function and visually increase the height of the building Source alma-kiev.net