An autonomous heating system for a home, equipped with modern boiler equipment and radiators, requires proper distribution of the coolant. Let's consider what a three-way valve is, how it is designed and works, what types of it exist and where they are used, how the device functions in a standard heating circuit, in a heated floor system and other equipment, what types of devices with automatic adjustment are there, and also what criteria must be taken into account when choosing and rules during installation.

Three-way valve with thermal head Source stroyday.ru

Device, purpose, principle of operation

In simplified terms, a three-way valve for heating is a structure that combines two water taps in one housing. Depending on its purpose, the device mixes, separates or redirects coolant flows. It consists of the following main elements:

- Cases.

- Curtain or spherical element.

- Fastening coupling.

The distribution mechanism can be either manual using a metal ball or automatic using a rod operated by an electric drive based on a signal from a thermostat.

Note! When installing a heating system for a private home, not only a three-way boiler valve is used, but also its two-way analogue. Its main difference is that the rod element does not block the flow of coolant with unchanged hydraulic characteristics.

—

CONDITION 1

RESULTS ROOM ¸ÐºÐ°Ð¼Ð ¸ regurgitation ÑелÑкой. â

RESULTS ºÑÐ°Ð½Ñ ÑÑÑанавливаÑÑ Ñ Ð½Ð°Ð³ÑеваÑелÑнÑÑ Ð¿ÑибоÑоР²Ñи ÑÑем оÑоплениÑ; RESULTS ¾Ð´Ñ, поÑÑпаÑÑей в нагÑеваÑелÑнÑй п ÑибоÑ. â

| RESULTS. â |

RESEARCH, RESULTS ASSESSMENT I'm sorry. RESPONSIBILITY, RESPONSIBILITY ¿Ð¾Ð»Ð¾Ð¶ÐµÐ½ близко к ÑÑоÑÐºÑ Ð¸ Ñоеди → ´Ð¸Ð°Ð¼ÐµÑÑа, ÑÑо ÑаÑе вÑего вÑÑÑÑеÑаеÑÑÑÑ Ð¿°Ñи Ð¾Ð´Ð½Ð¾Ñ ÑÑбной Ñи ASSURANCE, ASSURANCE, CONTROL ±Ð¾Ñом и ÑÑоÑком ÑеÑез обÑаÑнÑÑ Ð¿Ð¾Ð´Ð²Ð¾Ð´ÐºÑ Ð¿ÑÐ ¾ RESULTS RESULTS , , , , , , , , , , , ²ÑаÑаеÑÑÑ Ð² ÑÑоÑк по ниР¶Ð½ÐµÐ¹ ÑаÑÑи подводки. â

Ðñ ° ðory ð´²²ð¹ð¹ð½^ ñ ñµices ”ðñ½ºð (ð¿ñuthently ( " registry ¾Ð±ÑаÑной) ÑоглаÑно пÑоекÑÑ. RESULTS RESULTS ¾Ð²ÐºÐ¸ пÑи RESULTS with the ÑоÑодР°. â

| RESULTS . â |

RESULTS RESULTS Ñ Ð ¿Ð¾ диамеÑÑам в ÑÑÑÐºÐ°Ñ Ñ Ð¿Ð¾Ð´Ñазделением на RESULTS. â

| RESULTS ÑлиÑовки ной ÑегÑлиÑовки. â |

RESULTS 100 Ð ¡. 100 rubles. â

| RESPONSIBILITY. â |

RESEARCH (No. 132, No.) A Ð¾Ð¿Ð»ÐµÐ½Ð¸Ñ . â

| ROSS-READY.| RESULTS. â |

RESULTS RESULTS Ñи гоÑÑÑей Ð²Ð¾Ð´Ñ Ð² нагÑеваÑелÑнÑе пÑибоÑÑ. â

RESULTS Ñ Ð´Ð»Ñ ÑиÑÑем Ð²Ð¾Ð´Ñ Ð½Ð¾Ð³Ð¾ оÑоплениÑ. â

RESULTS RESEARCH, RESEARCH, RESEARCH ¸Ð»Ð¾, подводÑÑей к нагÑеваÑелÑнÑм пÑибР¾Ñам ÑÑÑбе. RESULTS RESULTS ¾Ð²ÐºÐ¸ пÑи RESULTS Ñ ÑÑÑанавливÑÑÑÑÑ Ñ Ñ Ð¿Ð¾Ð»Ð½Ð¾ÑÑÑÑÑ Ð¾ÑкÑÑÑÑм ÑеÑение м пÑоÑоР´Ð°. â

Varieties based on operating principle

According to their operating mechanism, 3-way valves are divided into three main types:

- Separating.

- Mixing.

- Switching.

Three-way mixing-type regulators Source trubypro.ru

Devices of the first type split one flow into two directions. This is necessary for quantitative adjustment of the coolant in the system. A mixing valve, on the contrary, connects two directions with different heating levels into one. It has two inputs and one output. With its help, it is possible to increase the efficiency of thermoregulation when the quality of the coolant is of primary importance, for example, to prevent overheating of the underfloor heating pipeline.

Type 3 mechanisms perform a completely different task - they do not separate or mix flows, but simply redirect them. For this purpose, the device has a special module in its design. Installation of this type of valve is relevant in a dual-circuit heating system. With its help, it is possible to effectively redirect the heat flow from the boiler to the boiler and vice versa.

Good to know! A three-way heating valve with thermostat allows optimal heat distribution between radiators in an autonomous heating system. The degree of supply will be determined by the heating level of the battery, which in turn will be set by the actual air temperature in a particular room

Thermostatic valve with thermal head Source vodocomfort74.ru

Advantages of a three-way valve

The positive qualities of the device include:

- Compact size.

- High level of functionality.

- Easy to use and maintain.

- Good degree of seal tightness.

- Long period of use.

- Low level of hydraulic pressure.

- No stagnation zones.

- Easy installation.

- No need for daily care.

- Convenient and easy switching.

But, despite all the advantages, there are several disadvantages to its work.

Working in a heating system

At the heart of a modern heating system, two types of 3-way valves are most often used:

- Mixing.

- Dividing.

Let's look at the features of their work in more detail.

Mixing

Its design is based on three pipes and a rod. Two of them are located in the middle of the overlapping element, one at the bottom. All three pipes are connected by one cavity. There is a thermocouple on top of the structure to regulate the temperature of the coolant.

The thermostatic block is connected to two round valves mounted on a stem. Their cross-sectional area allows you to completely block the lumen of the pipes (seats). The thermostatic mixing valve of this type operates according to the following algorithm:

- As pressure arises from the thermal head, the rod with the valves lowers.

- Moreover, the higher the temperature, the lower the position it moves.

- As a result, the flow from the lower pipe (cold flow) increases, and from the left (hot flow) decreases.

- When the coolant naturally cools, the temperature sensor causes the rod to move in the opposite direction.

The mechanism of operation of the mixing valve Source strojdvor.ru

- As a result, the shut-off valves begin to act in the opposite direction - the flow of cold coolant decreases, and the flow of hot fluid increases.

The automatic thermal control mechanism is based on a special thermal head. It consists of a sensor and a container with a piston filled with a thermoactive medium. When heated, the liquid begins to expand and put pressure on the piston. This in turn transmits pressure to the rod. As a result of the sequential transfer of mechanical energy, a thrust arises that is sufficient to move the valves themselves by a given amount - to open or close the corresponding coolant flows.

In this case, thermoregulation is carried out strictly in accordance with the specified settings - the temperature value specified by the user on a graduated scale. Thanks to this mechanism, the heating level of the incoming coolant at the inlet of the 3-way valve does not change, but at the outlet - after mixing with the cold flow - it becomes lower.

Mixing hot and cold flow in a valve Source stroyday.ru

See also: Catalog of companies that specialize in water supply, sewerage and related work

Dividing

If a three-way mixing valve mixes cold and hot flow, then a separating valve, on the contrary, splits one heated flow into two. Three pipes are similarly placed in the body. However, only one of them is an input, and two are an output. However, they are not equivalent, and allow the coolant to be split into two directions:

- Constant.

- Variable.

The valve stem is designed in such a way that the constant flow is not blocked when the thermal head reacts. While the second flow necessarily changes. In this way, it is possible to give the first direction constant quality, and the second - to regulate the amount of coolant.

Modern manufacturers produce models with adjustable rod length. This makes it possible to set the volume in a constant flow. In this case, the variable flow may be completely blocked. All this allows you to accurately control the pressure and flow of coolant in the heating system.

3-way separating valve Source docplayer.ru

Recommendation! Coolant control devices of this type can also have manual control. Instead of a rod, they are equipped with a conventional ball mechanism. However, in a private home it is more practical to use a three-way thermostatic mixing valve with automatic adjustment. The user will only need to set the temperature regime for a specific area - depending on the distance of the battery from the boiler.

Features of operation

When operating a heated floor mixing valve, there are special points. The main one is the mandatory installation of a filter. In addition, it is not recommended to place a mixer with a thermal head in a manifold group that serves more than one room or is located in an adjacent room. A device with a remote temperature sensor placed in a heated room is suitable.

The mixing valve is the main element in the water heated floor system. The quality of room heating depends on how correctly it works. Therefore, its selection and installation must be approached responsibly. If you are not confident in your abilities, then it is better to invite a professional.

Operating principle of underfloor heating system

Manufacturers of underfloor heating systems strictly limit the heating level of the coolant that will be used in the equipment. As a rule, this is a fairly low temperature value - 40-500C. However, the heating level of boilers is much higher. In order not to install a separate heating unit, a thermal mixing valve is used for heated floors.

Coolant circulation in such a scheme obeys the following algorithm:

- Through the collector, the hot flow is supplied to the underfloor heating pipeline.

- In this case, the heating level is set by the set value of the thermostat in the 3-way valve.

- When a preset level is exceeded, the thermal head is activated, driving the rod.

Three-way valve in a heated floor system Source ytimg.com

- The supply of hot flow is reduced, and the volume of cooled coolant from the return line increases.

- A less hot flow enters the underfloor heating system.

- When the temperature drops below the set value, reverse processes occur in the mixer.

- The cold flow decreases, the hot flow, on the contrary, increases.

- The cycle repeats automatically throughout the entire period of operation of the system.

Advice! The three-way valve for underfloor heating effectively regulates the required level of heating of the system. In a similar way, the device is used for optimal distribution of coolant over radiators. However, the highest flow temperature is needed for an indirect boiler. Therefore, such a device is never mounted in front of it in the circuit.

Diagram of heated floors with a 3-way regulator Source tproekt.com

Adjusting the flow of working fluid. What to look for when purchasing

Manual adjustment is made using a conventional ball valve. Visually it is very similar to a simple valve, but has an additional output. Fittings of this kind are used for forced manual control.

As for automatic adjustment, a special three-way valve is used here, equipped with an electromechanical device to change the position of the rod. It should be connected to a thermostat in order to be able to regulate the temperature in the room.

Remember that when purchasing a valve, it is imperative to take into account the technical parameters of the device, which include the following

- Diameter of connection to the heating main. Often this indicator varies from 2 to 4 centimeters, although much depends on the characteristics of the system itself. If a device of a suitable diameter cannot be found, you will have to use special adapters.

- The possibility of installing a servo drive on a three-way valve, the operating principle is discussed at the beginning of the article. Thanks to this, the device will be able to work automatically. This point is very important if the device is selected for use in water-type “warm floors”.

- Finally, there is the pipeline capacity. This concept refers to the volume of liquid that can pass through it in a certain time.

Electrically adjustable models

A three-way valve with an electric drive allows you to control the flow of coolant in the heating system of a private home as efficiently as possible. Unlike its manual counterpart, when the user independently sets the immersion level of the control rod in the mixer, this option is equipped with a special electric motor - a servo drive. Compared to a standard motor, the shaft in it does not rotate around its axis, but rotates at a given angle at the command of the controller.

Today on the market of specialized devices you can find two types of 3-way valves with a drive:

- Fully equipped.

- Only with drive and sensor.

Models of the first type are equipped not only with an electric motor, but also with a temperature sensor and controller. The latter are equipped only with a motor and a heating sensor. They will require a separate purchase of a control module. The task of this block is to analyze the signal coming from the temperature sensor, process it and perform the appropriate action.

Electric valve Source armastock.ru

For example, when the heating level drops, the sensor sends a signal to heat up. Having received the information message, the controller sends a command to the drive to rotate the rod accordingly in order to open the valve to allow the hot flow to pass from the pipe into the system.

Note! The electric drive model allows you to quite accurately set the parameters for adjusting the heating system and link events to time or even to smart control. However, a conventional three-way thermostatic valve is more stable, does not require a power source for operation, is inexpensive and allows you to control the temperature according to a strictly specified value.

Installation diagrams

The temperature-regulating 3-way valve is installed in one of the following three configurations:

- In the underfloor heating equipment system, to regulate the heating level of the coolant no higher than 40-50 degrees.

- For optimal heat redistribution in the heating system, as well as establishing different heating levels in different parts of it.

The need for such adjustment arises when an indirect water heater needs the hottest coolant possible, at the same time, the radiators require a slightly lower heating flow, and the underfloor heating system requires a much smaller flow.

Heating circuit with a regulating mechanism Source blog.altep.ua

- As protection against condensation in solid fuel boilers, in cases where the coolant from the return line returns too cold.

In this embodiment, two circuits are used. The first main goes to the heating devices, the second, through a bypass, immediately goes to the valve, which is connected to the return line by a second inlet pipe. Thus, returning from the main circuit, the cold coolant is partially mixed with the hot one that has just left the boiler, and returns to the heating heat exchanger already heated.

Helpful information! A three-way valve of any type is not capable of changing the power parameters of the boiler equipment set by the manufacturer. However, it allows you to reduce energy costs for heating and create more comfortable conditions in your home.

Where to buy and cost

The market offers more than 50 types of battery valves. They can be purchased in almost any department of a hardware store related to equipment for equipping thermal systems in private or apartment buildings.

Also, battery taps can be purchased in an online store, knowing only the composition of the heating system. Considering all these tips, questions about where to buy radiator taps will simply not arise.

The price of radiator taps depends on the following factors: the manufacturer of the product, the region where these products are sold, the metal of the tap itself and its functionality.

Criterias of choice

When purchasing a 3-way regulator, you first need to pay attention to its technical characteristics:

- Diameter of pipes . As a rule, the value of this parameter, with rare exceptions, does not go beyond 20-40 mm. In case of discrepancy, it is easy to select a pipe adapter.

- Possibility of connecting an electric drive with a controller . This is all the more relevant the more complex the heating scheme is or when one of its parts is a heated floor system.

- Bandwidth . The parameter is expressed in the maximum volume per unit of time, for example, liter/min.

- Case material . The most reliable are copper and brass devices.

- Control type . Manually controlled models, although more reliable and cheaper than their electric counterparts, are less functional and are not suitable for controlling complex systems such as heated floors. Electric drive devices have many capabilities, but are more prone to breakdowns.

How to choose?

It is recommended to select a three-way valve in specialized stores. When choosing a model, you need to take into account its characteristics. When purchasing a device you need:

- study all documentation - warranty, manufacturer’s certificate, installation and operating instructions;

- give preference to bronze or brass devices - they will not expand when heated;

- based on the valve capacity - this parameter must correspond to the boiler performance;

- select a valve with a cross-section that exactly matches the size of the floor pipes; if there is a mismatch, you will have to buy adapters.

An important point is that even the apparent coincidence of the diameters of the valve inlet and outlet does not indicate the throughput level. This is affected by the size of the internal cross-section of the holes. This parameter is specified in the accompanying documents.

You need to choose a device based on the size of the heated room - for large areas an automatic device is recommended; it is able to maintain heating at the proper level. For small rooms, a simple one with a thermal head will do the job, so there is no point in overpaying for a more complex model.

When purchasing, you must visually inspect the device for chips and cracks. If the device is brass, then the inside should be golden.

Purchasing automatic devices will facilitate the adjustment process. And the presence of software will allow you to adjust the temperature taking into account the time and day of the week.

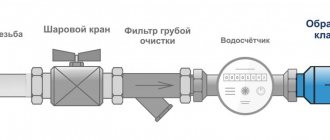

Installation rules

To install the thermal mixing valve in the position specified by the circuit, it is necessary to take into account a number of important nuances:

- Mounting method. Installation can be flanged or with internal/external thread. During fastening, conditions must be created to ensure a tight connection - using special gaskets, materials and mixtures.

- Installation on the return line to pumping equipment.

Only in this case can the condition of an always open outlet pipe be met.

Video description

The video shows a diagram of how the regulator works with a solid fuel boiler:

- The arrow on the body and the direction of the coolant in the system must coincide when installing the device.

- The correct installation is also determined by the designations on the device body - straight, perpendicular, bypass or combined stroke.

- Coolant distribution diagram.

It can be T-shaped or symmetrical, as well as L-shaped or asymmetrical.

Before the 3-way regulator is connected, the heating system must be switched off and the coolant pipe must be de-energized. In addition, it is important that there is no sediment inside the pipes. Otherwise, the device will quickly clog and deteriorate.

Important! It is necessary to install the thermal control valve on a section of the heating pipeline with open free space and easy access. In this case, the thermal head or drive after installation should not be located at the bottom of the housing. Since in the future, with the slightest leak, they will quickly deteriorate.

Application area

Underfloor heating systems are increasingly popular in residential buildings today, but without a control valve it is impossible to ensure proper heating. A three-way tap is an element designed to adjust the heating level in a water floor that is filled with screed.

The valve is installed both as a complete set with a mixing and distribution unit, and as an independent device. In small rooms (bathtub, toilet, kitchen), there is no point in installing a multifunctional collector - it is expensive and not justified.

A three-way thermomixing valve can control the temperature and regulate the volume of liquid for such rooms.

Main areas of use:

- In a radiator heating system.

- In the DHW system.

- In warm floors.

Briefly about the main thing

A three-way valve has the design of two taps combined into a single body - two inlets and one outlet, or vice versa. According to the principle of operation, it can be mixing, separating and switching. Consists of the following main components:

- Cases.

- A rod with valves or a ball.

- Fastening element.

Various modifications of the device are used to increase the efficient distribution of coolant and reduce energy consumption both in a standard heating system and in a complex one - with a boiler, several circuits, heated floors, etc. By type of control, devices can be manual, thermostatic or equipped with electric drives with electronic control.

Traditionally, three installation schemes are used - with heated floors, to create different-temperature areas in the heating system and to protect solid fuel boilers from condensation. When choosing a device, it is necessary first of all to take into account the technical characteristics, and during installation - designations, markings and rules for carrying out plumbing work.

Safety valves

Any boiler equipment is a source of danger. Boilers are considered explosive because they have a water jacket, i.e. pressure vessel. One of the most reliable and widespread safety devices that reduces the danger to a minimum is the safety valve of the heating system. The installation of this device is due to the protection of heating systems from excess pressure . Often this pressure occurs as a result of boiling water in the boiler. The safety valve is installed on the supply pipe, as close to the boiler as possible. The valve has a fairly simple design. The body is made of good quality brass. The main working element of the valve is the spring. The spring, in turn, acts on the membrane, which closes the passage to the outside. The membrane is made of polymer materials, the spring is made of steel. When choosing a safety valve, it should be taken into account that full opening occurs when the pressure in the heating system increases above the value by 10%, and full closure occurs when the pressure drops below the response value by 20%. Due to these characteristics, it is necessary to select a valve with a response pressure higher than 20-30% of the actual one.