Applying plaster to the walls is only the initial stage of finishing the wall surface. In order to give it maximum evenness for subsequent painting or wallpapering, after applying plaster mixtures, proceed to priming and puttying. And only then can you move on to the final work of decorating wall surfaces with wallpaper for painting.

What to do after plastering the walls? If the surfaces have completely dried after the plaster has been applied to it, you can proceed to priming the walls. To do this you will need to purchase a special tool. It is offered in a wide range by modern manufacturers of building materials.

Primer after plastering does not require special skills from a person. It is enough to purchase a convenient tool and be patient if a person performs this work for the first time in his life.

But if the priming stage has been completed, you can safely move on to puttying the wall surfaces.

The putty mixture used at this stage of finishing the room fits perfectly on a flat wall. However, not many can boast of the ideal geometry of their city apartment. That is why uneven surfaces must first be covered with plaster and primed. And you can do this with your own hands and without the involvement of professional builders.

Types and properties of putties

First you need to decide on the choice of finishing putty. Not all of its types are suitable for wallpaper, and, similarly, for painting. From the point of view of professionals, there are, in principle, no universal ones due to significant differences in composition. Recommendations from manufacturers regarding versatility of use are aimed at the average consumer without special requirements, but not for experienced painters.

The difference is this.

To adjust and trim wallpaper, you need a durable surface that does not get wet from glue, which is obtained by applying gypsum putties. But due to the heterogeneity of gypsum grains, noticeable after grinding in characteristic areas of “stains”, they are not recommended for painting.

For painting, the main thing is “fine grain”, the uniformity of the putty layer, which after sanding and painting gives the effect of a perfectly smooth canvas. Polymer (vinyl) based compositions are indispensable here. However, the latter have a fragile structure and are an order of magnitude inferior in density to their gypsum counterparts. Therefore, it is not advisable to use polymer putties if wallpaper is planned.

It should be said about the role of acrylic primers (primers), supposedly strengthening weak putty layers. Yes, they strengthen, but only slightly. The primer film is not a serious barrier to moisture from wallpaper glue, and accordingly, it is not capable of increasing the strength of the putty. The main purpose of all types of primers is to remove dust from surfaces for strong “adhesion” (adhesion) to solutions, increasing the productivity of work.

Preparatory work

Deep scratches and other rough spots are puttied in advance before applying the general layer. After drying, the designated areas are sanded with sandpaper fixed on a block. The photo shows a working fragment of preparing plastered walls for putty.

Next, the walls are primed. Dust removal of plaster is carried out with Glims primer, which is popular in the field of repair and finishing due to its good performance and versatility of use. In our case, as a finishing putty for wallpaper, we used a dry mixture based on the “Prospectors” gypsum.

The putty is mixed with water to a thick sour cream using an electric drill and a mixer attachment. You should knead in small portions (4 parts of the bucket), because Due to the gypsum content, you can work with the solution for no more than an hour.

DIY installation features

Important nuances when plastering the slopes of PVC windows that you should pay attention to in order to be prepared for the work and costs:

It is highly advisable to prime in 2 – 3 layers.- The price of the master is set for 1 linear meter, since work on slopes is much more complicated, including the installation of beacons and sealant (damping gasket), reinforcement, corner formation, leveling, particularly accurate calculations and markings, especially for the angle of dawn.

- Instead of paper mounting tape, you can use low-tack tape, as the former sometimes leaves traces of glue. Before each stage of work, such protection is changed - the tape must be removed immediately after completing a specific set of actions.

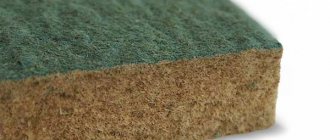

- Thermal insulation or damping gasket is required for the gaps (joints) between the opening and the window frame (frame). They use tow and felt. The ideal option is if the specified materials are used and there is complete insulation of the slope under the plaster: polystyrene foam (it will require high-quality waterproofing), expanded polystyrene or penoplex (considered the best), mineral wool (usually for external surfaces).

- Highly desirable corner strengthening:

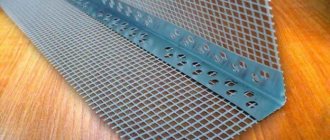

- internal (husks) - use a reinforcing mesh, which will protect against the formation of cracks;

- external ones (crests, jibs) - not reinforced, they are easily knocked off, for strengthening they use corner profiles - counter-shoulders (plastic or stainless steel);

- It is extremely important to install the beacons correctly and evenly; the angle of dawn and the absence of an uneven slope of the final finish depend on this.

This video will show you how to properly plaster slopes on windows with your own hands:

How to putty correctly?

Applying putty to walls is not the most difficult job, however, it requires certain skills and experience that only come with practice. But let's look at the theoretical part in more detail.

Alignment of walls . They get rid of unevenness, height differences, depressions and all kinds of wall defects not only with the help of putty. Plaster is also used for the same purposes. How to understand: to putty or plaster?

The walls are plastered if there are really strong defects or if the walls in the room are so crooked that they look like they are “dancing.” We can say that plaster is the heavy artillery for leveling walls. Putty can level the surface only if its height differences are no more than 2 mm. If potholes or depressions on the wall are more than 2 mm, then additional plastering is necessary.

Before applying putty to the walls, the surface is primed and it is determined exactly what unevenness it has. To do this, take a rule and apply it to the surface in different directions (vertically, horizontally, diagonally). Where there are gaps between the rule and the wall, there will be unevenness. If they are located vertically, then the putty should be applied in the same direction so that the material fills all the voids and levels the surface. If the recesses go in a horizontal direction, then the putty is applied horizontally.

Note! The thickness of the layer should not exceed the norm indicated on the packaging of the putty used. It may differ from one manufacturer to another, usually it is 0.5-1.5 mm. A layer that is too thick can crack and crumble, ruining all the work.

Spatula and more . The main tools for leveling and preparing walls will be spatulas. Typically, two stainless steel metal spatulas with a wide and narrow blade are used. But not only this pair will be useful for repairs - it is always useful to have a rubber or plastic spatula for smoothing the wallpaper, which will be needed at the final stages of work.

- A narrow spatula is needed to apply putty from a container (plastic bucket, basin) onto a wide spatula and to remove its excess. A spatula with a wide spatula is used to spread the material over the wall in a thin layer.

- A narrow spatula, if you don’t have one at hand, can be easily replaced with a trowel or trowel. This tool will also cope with its task quite successfully.

- And instead of a wide spatula, you can use a smoothing iron. The main thing is that it does not have jagged edges. Usually, using a trowel, putty is applied in the form of a paste to already plastered walls that do not require additional leveling. The trowel allows you to make a layer of putty very thin.

- And you will definitely need a plastic bucket or other container for mixing the plaster.

Requirements

Slopes must meet the following standards:

- Before plastering, the alignment of the walls from the outside and inside must be done especially well, otherwise the waviness of the finish will be noticeable, even minimal unevenness will appear through it, and this is more typical of the material in question. There should be no deviations in width/verticality that exceed the standards established in SNiP (see tables below).

- You need to make a bevel from the frame to the surface of the walls - it creates the so-called dawn of the window slopes. The angle of all such geometric shapes inside a building or at least a room should be the same.

- The surface of the base for painting coatings should be as smooth as possible, without roughness, the height/depth of which exceeds 1 mm. There should not be more than two such defects per 4 square meters. m area.

Dawn angle

In SNiPs and GOSTs there are no standards for the angles of dawn and slope reversal - there are only maximum permissible deviations, so this issue needs to be discussed in detail with the foreman or decided for yourself before work. The angles can be made different, for example, 90 or 45 degrees .

The angle of rotation of the window slope can be straight or turned, but if the opening serves for the penetration of light or this property needs to be increased, then it is better to choose the latter.

If the window acts as an element of the interior or is located between two rooms, then a direct option is more appropriate. When the angle is turned, in addition to improving the penetration of light, the doors will open more widely, reducing the risk of them hitting the walls.

Rules for dawn angles:

- usually make a turn of 90° or more;

- the amount of slope deployment is proportional to the thickness of the wall - the wider it is, the greater the value, the norm is 1:10, for example, with an edge (edge) width of 60 cm, they retreat 6 cm from the perpendicular to the bottom line of the frame;

- For the edge on top, for technical reasons, it is allowed to make the opening angle smaller than on the sides.

putty

Next we move on to leveling the walls, for which we use putty. Putty exists in both gypsum and cement. Which one should you use in your case? Remember a simple rule: if the room is dry and stable in temperature parameters, use gypsum putty, because it is more convenient to work with. If there is excess moisture in your room and the temperature varies periodically, for example in the kitchen or bathroom, then use cement putty.

Putties come in the following types:

- Cement based. It resists moisture well, but exhibits significant shrinkage.

- On a gypsum basis. The best option, but this putty is susceptible to moisture absorption, so it should only be used indoors.

- Polymer based. The most expensive putty that does not shrink and is not afraid of moisture.

If you plan to carry out renovations in the bedrooms, then gypsum putty will do just fine. However, if the renovation is being done in the kitchen or bathroom, then you should consider a more expensive option.

Leveling the surface

After plastering the walls, you can consider that you have gone halfway before finishing. But before further actions, it is necessary to give the plaster time to dry thoroughly. The drying time is usually indicated on the mixtures; we recommend from 15 to 28 days. The drying time depends on the humidity in the apartment and temperature. The best option is to ventilate the room, but at the same time make sure that the temperature remains at the same level of 20–21 degrees. After plastering the walls, we’ll find out what to do next by reading the article to the end.

Primer

The work after plastering consists of leveling. But the surface is first treated with an antiseptic and coated with a primer. You can purchase a two-in-one composition, but the price is higher. To treat a plastered surface, you can purchase a ready-made starting mixture, which is suitable for all types of coatings and will give greater adhesion. The primer is applied in 1–2 layers, pay attention to what the manufacturer advises.

Photos are enlarged, click!

Puttying

After the primer layer has dried, which will take 8–10 hours, you can begin leveling. To level the walls, putty is selected. Based on their composition, putty mixtures are divided into types:

In an apartment, putty is selected depending on the room. An inexpensive gypsum option is suitable for the living room and bedrooms; for the kitchen, toilet and bathroom it is better to use expensive polymer-based ones.

You cannot use gypsum plaster on the street side, for example, on a balcony or loggia. It is afraid not only of moisture, but also of temperature changes and quickly crumbles. On sale you can find ready-made wet putties and dry mixtures in bags. The first option is mixed at the factory and is considered better, but the composition must be used immediately after opening; the wet mixture does not last long when opened. Dry ones are inferior in quality, since when mixing at home it is difficult to maintain exact proportions, but it is more convenient to store the powder.

Choosing putty for walls after plastering

While the primer dries, you need to choose what to putty on the walls after plastering, since they need to be leveled before further finishing. For this purpose, it is better to purchase a starting mixture: it is designed specifically for treating walls after plastering, and is suitable for eliminating significant differences in height.

Also, when the primer dries after plastering the walls, you can treat their surface with universal or finishing putty. The latter, in comparison with the starting mixture, have comparatively worse consumer characteristics, and are usually used in cases where the plaster layer does not have significant flaws.

Based on the material, putty bases are divided into three categories:

- cement - resistant to moisture, but have a high degree of shrinkage;

- gypsum - cheap, does not shrink, is pliable when applied, but is sensitive to humidity levels;

- polymer ones are expensive, do not shrink, and are resistant to moisture.

Most often, gypsum-based putties are used; however, their scope of use is limited; they are not recommended for use in very wet areas where there is contact with water in the bathroom or swimming pool. Otherwise, why putty the walls after plastering if, due to high humidity, the gypsum-based coating will quickly become unusable.

It is strictly forbidden to use gypsum plasters outdoors since moisture and frost destroy the Rodband mixture and other similar ones.

According to the sales form, putties are presented in two categories:

- ready-made - an already diluted solution that can be used immediately after opening the container;

- dry - mixtures intended for self-preparation, but having a much lower cost than ready-made mixtures.

Thus, the cheapest option is dry gypsum powder, but it also has the lowest quality. Gypsum mixtures are excellent for sealing cracks in walls. The most expensive are ready-made polymer-based putties; these materials are best used for making the finishing layer.

Technology for processing plastered walls

Often, before starting putty work, the question arises as to whether the beacons need to be pulled out after plastering, or whether they can be left in the walls. It is recommended to do this without fail. The beacons are made from metal, and if left, they will corrode over time. This, in turn, will reduce the strength of the plaster layer, and ultimately lead to its crumbling. Cracks and other damage will appear on the surface of the walls.

After the decision has been made whether it is necessary to choose beacons after plastering, you can begin to putty the surface. The bottom, coarsest layer of material is applied. Using mixtures for starting putty, holes and grooves are filled in and large differences in height are eliminated. The thickness of one starting layer can sometimes reach 15-20 mm.

You can put a painting mesh under the putty layer, stretching it over the entire surface of the wall being treated. This will make it possible to achieve a more even laying of the material and improve the strength of the starting layer of putty.

When the starting coating has dried, the finishing process begins, which is carried out using finishing mixtures. Unlike the starting one, it is applied in a very thin layer so that it completely repeats the resulting wall relief. In some cases, the question arises whether it is necessary to putty the walls after plastering with Rotband in order for the surface to be perfectly flat. If you follow the technology, there is no need to apply additional finishing layers, the walls will already be level.

Preparing walls for painting or wallpapering

After completing the putty work, you should wait until the walls are completely dry, and only then prepare them for painting or wallpapering. The technology for performing both types of finishing is the same; the difference lies only in the nuances when choosing finishing materials. You can spend as much time choosing the appropriate finishing method as it takes for the walls to dry after plastering - about a month.

Putty

Puttying walls after plastering is a serious area of work, so it is better to separate it into a separate section. Before you start making a topcoat, you need to choose the type of material that is ideal for your conditions. There are three types of mixture in total.

Cement

This material is used for work after plastering and has the following advantages:

All these advantages have led to the fact that this mixture is often used after applying plaster to make the final layer. The main reason that the material has not received an overwhelming advantage in the market is a number of disadvantages, including:

Cement putty is used when work needs to be done in rooms with high humidity. Moreover, it perfectly tolerates harmful environments. It is also often used when, after the construction of a house, it is necessary to finish the facade.

Plaster

Gypsum putty is also used quite often when work needs to be done after plastering walls. It has the following advantages:

This material is easy to apply. Moreover, it is easy to level it after completing the main work on plastering the walls. But, of course, there were some downsides:

If you decide to putty with gypsum, you must take into account that you need to wash such walls extremely carefully, otherwise you will have to make new putty, and possibly plaster.

Polymer

In recent years, more and more companies have decided to make putty based on polymers. This decision is easily explained by a number of advantages that this material gives to builders after treating the walls with plaster and primer, namely:

Polymer putty, which is used to create the final layer of wall finishing after plastering, has a long service life. Moreover, it has high ductility, it does not crack or dry out.

Despite all the apparent advantages, before you start putting putty on the walls using gypsum, you need to learn about the negative aspects of this substance. Fortunately, there are only two of them. This is high cost and difficult to apply.

Most often, polymer mixtures are used when it is necessary to putty walls indoors. Some varieties are even used for external work. Such widespread use is explained by the high quality of the substance.

Packaging

To start making walls, you need not only to choose the type of putty, but also the packaging form. The fact is that there are dry mixtures on sale. After purchasing, you just need to dilute them with water.

You can also buy the substance in buckets. In this case, you won't have to do anything else. The putty can be immediately applied to walls that already have plaster. The first option is best suited for professional builders, and the second for beginners.

Application

For everything to go as expected, all operations must be done in the exact sequence. First apply a starting coat to the walls. This is best done with a thick spatula. Movements come from the corners. You can work in any direction convenient for you.

When the mixture has dried, it’s time to check the evenness of the coating. You will also need to sand the surface again. For this purpose, skin with a fine fraction is best suited. After this comes the finishing layer. Now you can safely glue wallpaper or paint the walls.

Grinding process and rules

How to sand putty correctly? In order for the sanding of walls after putty to go flawlessly, you need to follow some rules:

- Proceed with sanding only when the surface is completely dry. As a rule, it takes a day for the walls to dry.

- Before starting work, protect all furniture from dust with plastic wrap. If this is not done, subsequent cleaning may take a long time.

- Find the most visible defects. How to identify them? It’s very simple - take a bright lamp, place it as close to the surface as possible, and direct the light along the wall: a shadow will appear from obvious bumps. These irregularities can be marked with a pencil.

Content:

- The structure of plaster, its features and the main errors that occur during drying

- How to dry plaster or putty in the room being treated?

- Drying plaster and walls with a dehumidifier - a real example

- conclusions

Everyone finds a certain method for solving the issue, but we will discuss all possible methods and decide how to dry the walls correctly and in what sequence to do it. But first you need to understand the main thing - it is possible, and even necessary, to dry the walls during repairs, and it is advisable to do this at every stage of construction or finishing.

Plastering walls in a new building

The basis of almost any renovation in a new building is work related to preparing the surface of the partitions for applying finishing layers - ceramic tiles, paint, wallpaper. For this reason, plastering walls in a new building is an important stage: the longevity of the operational properties of the room and the overall result of wall finishing depend on the high-quality implementation of this work.

By the way, our craftsmen have the highest qualifications of professional plasterers. You can place a request for individual plastering work or entire repairs in the apartment on this page or by calling 8(495)662-48-33.

What is wall plaster?

Plastering the surface of walls and partitions in a new apartment is a process of applying special solutions and their subsequent leveling. This is the most important element of wall decoration. As a result, the surfaces of vertical structures become smooth and suitable for a fine finish. In this case, both planar (sinks, potholes, bumps) and angular irregularities are eliminated. In the latter case, deviations of walls and partitions from the vertical and horizontal are minimized or eliminated. In this regard, it is customary to talk about aligning angles at 90 degrees. Creating a room geometry that is close to ideal becomes especially important when using ceramic tiles as cladding or when installing built-in furniture, such as a kitchen. The lack of correct “geometry” of the room manifests itself when joining corner furniture elements (for example, when installing kitchen cabinets in an L-shaped line). Taking into account the purpose of the room after renovation, its equipment and the type of finishing, you can make an appropriate decision when looking for an answer to the question of whether it is necessary to plaster the walls in a new panel building. It should be remembered that ideal evenness of walls and partitions is not always required. In some cases, this leads to unreasonable wastefulness in the use of materials, as well as an increase in the duration of repairs due to the additional time required for thicker finishing layers to dry.

Why do walls need to be leveled in a new building?

Once again I would like to emphasize: applying a layer of plaster is not an end in itself. In addition to the insulating properties of this layer, its main purpose should be considered, as was said, to create a flat surface suitable for the installation of finishing layers and installation of attachments. This is the main (not the only) reason for plastering walls in a new building. Here are some examples when you should “bring out the corners”: L-shaped kitchen - if you neglect to match the perpendicular partitions on which the kitchen cabinets are mounted at an angle of 90 degrees, it will become impossible to align the furniture smoothly (a gap and “distortions” will form). Another example is wallpaper with a vertical stripe: the absence of right angles will become obvious when the stripes are brought together in the corners of the room. Once again I would like to write: in the issue of leveling walls in a new building, planning and a reasonable approach should prevail, based, among other things, on the judicious use of finishing materials and compliance with technological requirements regarding the maximum thickness of plaster systems.

During a preliminary discussion of the nature and scope of work with the foreman, it should be directly stated that plastering work should be carried out at “angles of 90 degrees.” In addition, the following should be established as contractual obligations:

- maximum tolerances for wall alignment; for this you can use the term “high-quality plaster” as provided for by SNiPs for plastering work; Please note that these rules are not binding; The exception is cases when their use is directly determined by agreement of the parties;

- the use of “beacons” - special guides that facilitate the creation of smooth surfaces and generally improve the quality of work on plastering walls in a new building;

- reinforcement of plaster layers with a special polymer mesh; as a general rule, such strengthening of plaster is not mandatory; however, it can be recommended both for the entire surface and for places that are most susceptible to the formation of cracks (junctions of building structures, window and door openings).

Please note that the beacons must be removed after the plaster has dried. The exception is galvanized profiles, which do not rust. Otherwise, over time, rust may appear on the surface of the walls.

What is the best way to plaster walls in a new building?

For indoor work, we recommend using mixtures based on gypsum binder. Gypsum dries quickly, provides the necessary strength, has low shrinkage compared to cement binders (has a positive effect on crack resistance), and allows you to regulate the microclimate in the room during subsequent operation. Thanks to its natural properties, it can absorb excess moisture and release it when the level of humidity in the air drops. Special additives increase the viability of a freshly prepared solution and increase its plasticity. The main mistake that finishing craftsmen make is failure to comply with the instructions that determine the amount of water that is needed to mix the solution. Exceeding this amount leads to the occurrence of internal stresses at the stage of drying and strength gain, which manifests itself in the form of cracks. There should be exactly as much water as indicated in the instructions.

The Rotband plaster mixture, produced by the Knauf company, has become very popular. This mixture has high adhesion - greater adhesion to the base, which allows it to be used on smooth surfaces.

The average thickness of the gypsum plaster layer is 20 mm. As a rule, it is applied in one layer. When constructing multilayer systems, the second layer is applied “wet on wet” (it is also possible after the first has completely dried). The general requirement is that the base for applying plaster must be dust-free, free from efflorescence, and dry. Its humidity should not be more than 8%. In the case of leveling the surface of the walls in several layers, it should be remembered that each subsequent layer should be softer (or equal to the previous ones in compressive strength). To increase adhesion to the base, especially in the case of smooth walls and partitions, their surface is pre-treated with concrete contact.

If the unevenness of the walls in a new building is large, then the possibility of leveling them with plasterboard sheets followed by putty should be discussed. This will save time and money, as well as ensure better quality work.

What plaster to use in the bathroom?

With the proliferation of gypsum plasters, the question arose as to whether they could be used in bathrooms . The fact is that gypsum, as already noted, has the ability to absorb moisture. There is a danger of soaking the finishing layers and their subsequent destruction. For this reason, we advise you to pay attention to the recommendations of the mixture manufacturers and the presence of restrictions regarding their use in finishing rooms with high humidity and especially bathrooms. The fact is that European building regulations do not classify kitchens and bathrooms as rooms with high levels of humidity. Materials produced in accordance with these provisions may be limited only in certain areas (for example, saunas) and still remain suitable for plastering systems in bathrooms and kitchens. Therefore, pay attention to the restrictions as they are indicated in the technical documentation published for the specific mixture.

For finishing in the bathroom or kitchen, it is better to use latex paints.

How much does it cost to plaster walls?

The price for plastering work depends on the quality of the work performed, as well as additional services directly related to leveling the walls. The cost of plastering on beacons with a high-quality finish will be higher than the cost of leveling with a lath (such work provides less planar and angular preparation). You should not always strive for ideal room geometry. Eliminating it and creating visually smooth surfaces allows you to save on apartment renovations. Additional services include: dust removal, application of concrete contact, reinforcement and priming. The cost of installing beacons is often indicated separately. All these issues must be worked out before collaborating with a team of craftsmen, i.e. get a cost estimate for all the work in its entirety.

You can always contact us for services related to the alignment of walls and partitions in new buildings. Long-term experience, well-functioning mechanization of processes make our offer profitable both in terms of price and timing.

Author: Attractive Repair Studio.

Links

There is currently no reference in the article on this topic.

Read

Very soon we will supplement this article with indications of third-party sources.

Notes

No notes found for this article. We regularly edit dictionary entries. It is possible that additional materials will be posted at this location soon.

The materials on this site are not a public offer. Any calculations using online calculators are indicative only. Their results cannot be used in the preparation of any project documentation (see also - rules for using the site).

Details

Preparatory stage

Before applying the paint and varnish material, the surface must be smooth, which is difficult to achieve with simple plaster. For this reason, when the plaster dries, the walls are puttied. But it is not applied to the plaster right away, and first the surface should be primed. Why do they do this? There are several options:

Remove all dust from walls prior to application.

What to do after plastering

What to do after plastering the walls? These are the following steps:

Let's look at all the stages in more detail.

Lighthouses

Primer and leveling

If after plastering work there are smudges and frozen mortar splashes on the walls, as well as all sorts of protruding irregularities, they need to be removed. Before starting work, the evenness of the surface must be checked using a rule. All plaster defects must be eliminated before filling. To do this, all defects must be primed and then covered with starting putty. In order for the solution to penetrate deeper, the cracks need to be expanded. After this, cover all dents and cracks with a primer, and then with a layer of putty (if the cracks are large, use a reinforcing mesh). After the walls have dried and leveled, it needs to be sanded using sandpaper or paper, and you can also use a grinder with a grinding wheel. After this, the walls will be covered with dust, which is important to remove with a vacuum cleaner or wash off with a damp cloth. After a day, prime. In order for the finishing quality to be at its best, apply the primer in two passes, allowing each layer to dry daily. Select the type of primer composition according to the type of plaster and place of use (indoor or outdoor). For application, brushes or a roller are used, and the composition itself is applied crosswise - first vertically, and then horizontally.

Selecting material for walls after plastering

The consistency of the composition is a paste-like mass, the purpose of which is to level the walls after plastering until the finish, which requires special evenness. Based on their structure, putty compositions can be divided into:

When choosing a material, pay attention to the basis of the composition, which can be significant for use. Acrylic products are applied in an extremely thin layer, which is not permissible for leveling. They have a narrowed range of application temperature conditions (at least +100 degrees), and they are not used in rooms where coatings must breathe. Popular putties are made from polymer binders, with cement or gypsum. Let's look at everything in detail.

Cement putty

After plastering, the walls are sealed with putty. Like the cement composition, cement putty is the most popular for finishing facade and interior surfaces. The popularity is deserved by the fact that the coating created is very durable, accessible for mass consumption and has many other advantages. It is suitable for damp rooms and unheated buildings. Putty is used to level surfaces and “treat” potholes and cracks. Manufacturers divide such compositions with cement into:

Various types of cement serve as a binder, for example, in expensive white cement putties. In addition to cement, the composition contains polymer additives and mineral fillers. The coatings will be smooth, durable, and the finishing and starting paste will be made according to their intended purpose. The latter, with quartz sand in its composition, is used for single-layer leveling of walls with a difference of up to 2 cm. In the composition of the finishing type mixture, the sand is much finer, which gives a smooth surface. You can find two types on sale - ready-made compositions in buckets and dry mixtures.

Gypsum putty

Even a high quality finishing cement paste will not give such a smooth surface as a gypsum composition. In addition to gypsum, it contains additives and modifiers (mineral and polymer). It is the filler fraction, for example, marble flour or sand, that will determine the purpose of the gypsum composition:

The material for dry rooms can be easily sanded and laid, it is lighter, creates a breathable coating, and does not create shrinkage cracks. A noticeable drawback is instability to water. There is a mixture in ready and dry form.

Polymer putty

These are polycement, latex and acrylic products. There are a lot of differences with gypsum and cement “classics”. They form elastic coatings, and therefore are in demand in seismically hazardous regions and in areas that lie near railway tracks. Such compositions are not afraid of even shrinkage of the building. All polymer compounds are highly adhesive and create breathable, durable finishes. For beginners, it will be attractive that such compositions have a long service life of up to ½ day. The main disadvantage was the high cost. A new product in the range of polymer compounds is polymer cement, which is a universal finish that can be applied in a layer of up to 0.3 meters, that is, curved surfaces can be leveled with each pass.

Putty for “wet” rooms

If you use simple putty in “wet” rooms, which is afraid of water, then repairs will soon be required. For this reason, for puttying bathrooms and other wet rooms, they choose moisture-resistant compounds. Such products are specially made for extreme conditions, for example, constant humidification when water gets in or condensation occurs. Paint applied to moisture-resistant putty will remain smooth and will not lose color, and pockets of mold will not appear under ceramic tiles. Such compositions are very expensive, but everything quickly pays off. Among the compositions of the mixture there are oil-adhesive, polymer and cement based ones. Moisture-resistant putties gain strength after a day. There are two types - hydrophobic (which are able to repel water) and waterproofing (they do not allow moisture to pass through due to their density). The first ones are always applied not in one, but in two layers.

Painting

After the last layer of putty has been applied, count the day and inspect the walls under oblique lighting, and then sand with sandpaper (zero). Clean the walls from dust using a vacuum cleaner with a hair brush, and if acrylic putty is not used for the finish, then check everything for moisture absorption - run over the surface with a damp sponge. If the surface begins to darken and absorb moisture, then a primer is required. The primer composition is selected according to the paint manufacturer's recommendations, and painting is carried out according to the manufacturer's instructions.

Wallpapering

Starting putty is often left under the wallpaper. This fact can be checked by gluing a piece of wallpaper to the surface and seeing if yellow spots begin to appear. If everything is fine, then sand the walls, wash them, remove dust, apply a layer of wallpaper adhesive, dry (you can apply additional paint while drying). Afterwards the wallpaper is glued using the simplest method. By the way, applying a snow-white primer to the putty gives a good result.

Source

Control of the process of sanding the wall and ceiling after puttying

This is perhaps the most important rule for an employee. The control process consists of the following points.

- Do not change the location of the light source to avoid refraction of light rays.

- Perform operations in small areas, moving from top to bottom.

- If work defects are detected (for example, an area that has been cleaned too much), you should re-plaster the area, wait until the material dries, and sand it again.

- Use a quality tool and follow the instructions carefully.

- Check the evenness of the cleaned (polished) surface with a building level or a ruler under a light source: if the shadow does not fall, then the ruler is absolutely adjacent, i.e. It turned out to be a perfectly flat plane.

vote

Article rating

What tools and consumables will be required?

The following materials and tools will be required:

To apply plaster:- spatula, trowel, trowel (trowel);

- falcon, corner leveler;

- rule;

- grater, grater for finishing smoothing.

- Tools required to prepare and strengthen the surface:

- polyurethane foam will be required if the window cracks were poorly sealed;

- materials for expansion and other seams, joints: sealant (silicone), special sealants, in extreme cases, tow, felt;

- reinforcing mesh for leveling if the surface is slightly curved, and for holding the mixture if necessary;

- beacons;

- corners: T-shaped for fixing beacons; perforated corner-forming, the option with reinforcing mesh will be the best; if cladding is planned, then a decorative corner for tiles will be required.

- For marking and calculations:

- a regular (bubble) level, but a laser level is better - for installing beacons and checking the evenness of surfaces;

- square with a movable bar for marking the slope and angle of dawn;

- pencil, tape measure;

- for the angle of dawn, wooden guides may be needed (shown in the diagrams above in the section “Angle of Dawn”).

- Goat, stepladder, you can use a table;

- Thick rubber gloves for hands;

- Knife for cutting foam;

- Containers for mixing the solution;

- Mixer (separate, attachment for drill/screwdriver) or tool for manual mixing (stick, iron rod);

- Polyethylene for protecting floors and surfaces;

- Mounting tape.

Materials:

moisture-resistant, antiseptic, antifungal primer - if the wall (base) is porous and weak, then use substances with enhanced penetrating and strengthening properties;- putty;

- plaster;

- paint, if the decoration will be decorated with it.

To prepare and mix the solution:

- a mixer, an electric drill with an attachment, or, as a last resort, a similar tool (stick, rod);

- measuring container for water;

- a bucket for pouring powder into it and a steelyard for weighing it

- basin, mixing bucket.

Beacons must be made of stainless, non-darkening metal or plastic.

Plaster beacons

Another very important point that is often neglected during repair work. The fact is that all lighthouses are made of steel, and sooner or later corrosion begins to spread on their surface, which is quite capable of leading to cracking, or even destruction of the plaster layer. Experts always advise removing beacons and sealing the grooves formed in their place with putty.

Important! Even galvanized beacons do not guarantee that corrosion will not begin. Of course, an additional layer of zinc will significantly increase the service life, but sooner or later rust will eat away the protective layer.

Beacons should be removed very carefully, and even before the plaster has completely dried. Of course, it will not be possible to avoid chipping, but the more carefully the removal is performed, the less effort will have to be spent on removing the formed grooves.

Puttying under wallpaper

For the purpose of further wallpapering, the putty is initially carried out with a wide spatula, covering with each subsequent layer up to ¼ of the previous one. The resulting “sausages” are not ground. Holding the spatula at an angle of 21-30°, maintain constant pressure, which will help distribute the material in an even layer of 2 to 4 mm. The smaller the angle of inclination, the more it leads to the formation of a thick layer, the more it leads to the formation of a thin layer. However, the dependence is typical for variations in the specified degree interval; when going beyond its limits, bumps and breaks form on the surface.

The next step is drying the layer, removing beads with a jointer and abrasive and checking the smoothness using a building code and a torch. The resulting defects are eliminated: protrusions - with abrasive, recesses - with additional lubrication. It is possible that an inexperienced master can approach the wall up to 5 times until the surface becomes perfect.

At the end of the manipulations and long hardening, they go over the wall with a jointer with a mesh size range of 80-120 (with an increase in the number, the abrasive grain decreases). Initially, the entire surface is worked with circular movements, after which, loosening the grip, movements are criss-cross in order to remove the contours of circular manipulations.

Then the wall is again checked according to the building rules with the lantern. If there are no lingering reflections from the rule, the surface is ready, after a day the walls are primed and you can start gluing.

Composition of putty mixtures

Based on their composition, putties are divided into three groups:

Plaster

Gypsum gives the solution increased plasticity. Thanks to this property, it is possible to achieve a very even plane of the walls. When making the next batch of gypsum putty, you need the correct measure of the volume of the solution. The liquid solution hardens quickly, so it is necessary to balance the volume of the finished mixture with the time of its production.

On the packaging of the powder, the manufacturer indicates the time for producing a certain volume of the finished mixture. Gypsum putty is used only for interior work.

Cement

Cement plaster is used in rooms with high humidity. In bathrooms, toilets and kitchens, the walls are leveled using cement putty. Tiles are laid over the cement finish.

With cement putty after plastering, you can immediately treat large areas of walls with your own hands in one batch. It takes much longer to harden than the gypsum composition requires.

Polymer

Polymer-based putties are called universal compounds. The main advantage is the virtual absence of shrinkage. Among putty mixtures, universal is the most expensive material.

All of the above is presented in this table:

Table of properties of basic putty compositions

Work progress

Finishing after plastering the walls is carried out in the following steps:

- Before applying the putty, the beacons are carefully removed from the wall. Some self-taught people write that they can be left and puttied, but this is a big mistake. The metal from which the beacons are made is susceptible to corrosion over time and this will reduce the strength of the wall. In the area of the lighthouse, the plaster will begin to crumble.

- A molar mesh is glued at the joints of gypsum board or gypsum board and in the corners. In places where there are large differences, you can also glue the mesh, it will give greater strength.

- Starting puttying is carried out. It can be applied roughly as it will serve as a base. It is important at this step to close all the fines, rub out holes and irregularities. The starting layer can be up to 20 mm thick.

- The starting layer is allowed to dry. It is important not to create drafts and monitor the temperature. The layer should dry evenly and not crack.

- After drying, a finishing layer of the mixture is applied. Its thickness should not exceed 2–5 mm. The finishing is done slowly, repeating all the reliefs and angles.

- The wall should stand for 2-3 days until it dries completely.

- Grouting is carried out using abrasive sandpaper of the smallest caliber.

- A layer of primer is applied for wallpaper or painting.

In this article we answered the question of what to do after plastering the walls.

Important! If you do all the work correctly and give each layer time to dry, then cracks will not appear on the walls. Haste when putting putty is your worst enemy!

Types of putties

Putty is a paste-like mass. It can be used to level walls and ceilings before final finishing of surfaces.

Based on the quality of formation of the putty surface, leveling materials are divided into three groups: starting, finishing and universal:

- Starting solutions are intended for sealing gross defects of treated surfaces. The name of the product indicates that the putty mixture is used for the initial treatment of plastered surfaces. Unlike the finishing coating, the starting solution has a coarser grain size of the solid filler (usually quartz sand). The starting composition is applied to the cement surface in those places where there is curvature of the coating, there are cracks and holes.

- The finishing putty is applied over the starting coating. It is intended to be the final finish before painting or wallpapering the walls. If the worker is sufficiently qualified and the material is of high quality, the finishing coating is completed in one go. The thickness of the finishing layer on plaster is made in the range from 0.5 to 2 mm. The finishing coating has plasticity, so the dried layer can be easily sanded with abrasives, thereby achieving a glossy effect.

- The universal mixture is used as a starting and finishing coating simultaneously. Like all universal products, putty is the most expensive compared to its analogues. The universal product is applied in one layer at once and forms the final finish of the walls before the final coating.