The contemplation of living fire is mesmerizing. A well-known proverb states that you can do this endlessly. The dance of the flame calms and pacifies, helps to collect thoughts. Unfortunately, such luxury is practically unavailable to those living in apartment buildings.

Setting up a wood-burning fireplace is not affordable for everyone. A good solution is to assemble a biofireplace with your own hands, while saving on the purchase of a ready-made structure. If you have never done this kind of work, our article will be a good help - here we looked at the structure and operating principle of a biofireplace, the main types of design, which will help you decide on the optimal scheme for assembling a homemade product.

They also provided detailed instructions for making a fireplace with your own hands, illustrating it with step-by-step photos and supplementing it with useful video recommendations. Thanks to a step-by-step analysis of each stage, even a novice master can assemble a biofireplace.

What is a biofireplace and its functions in the interior of an apartment and house

A bio-fireplace (eco-fireplace) is a device designed to heat a room and runs on environmentally friendly fuel. Does not require installation of a chimney or hood. It can be installed in an apartment with any interior style and will bring a note of comfort, tranquility and harmony to it. You can make your own eco-fireplaces from inexpensive scrap materials.

When installing a biofireplace, it is not necessary to install a chimney and hood

Designs for decorating and heating a room can be small or large-sized

With their help, they design recreation and relaxation areas, focus attention on some element of the interior, and are often used as attributes of a romantic evening. No permits or approvals are required for their installation in city apartments

Manufacturers of eco-fireplaces offer a wide range of models. There are designs that are remotely controlled and equipped with a fuel consumption system.

Advantages of eco-fireplaces:

- when heating the room, they do not reduce the level of air humidity;

- do not require complex installation;

- 100% heat transfer, since heat loss when passing through the chimney is eliminated.

Let's look at the working principle

The biofireplace owes its existence to devices created long ago - an ordinary alcohol burner and an oil lamp. The working principle is as follows: a component made of finely porous material - a wick - is immersed in a container with liquid fuel. Fuel, obeying the physical law of capillary rise of liquid, saturates it to the very top and evaporates through the open opening. If these vapors are set on fire, we get an even, persistent flame, as shown in the photo.

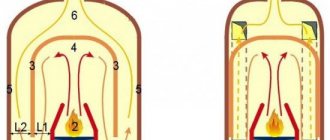

The heart of a biofireplace, made from innovative materials, is a round or elongated fuel block. It includes the following important elements (shown in the diagram below):

- a stainless steel container with a filling neck, equipped with an open opening on top - a burner;

- a damper or lid that blocks air access and is intended for extinguishing a fireplace;

- fireproof ceramic filler with a large number of very small pores;

- the side system does not allow fuel to splash out;

- Small portable structures are equipped with fire protection if they tip over.

In much inexpensive variations, non-flammable fiber can be used instead of ceramics

Reference. The price of cheap models available for sale starts from 80 USD. e. A large share of this cost is due to the stainless combustion chamber housing and ceramic filler.

Corner version of a wall biofireplace

According to the design method, eco-fireplaces are divided into the following types:

- Tabletop. They stand out for their small size and mobility, but require care during use. The product must not be installed or lit under flammable interior objects (for example, shelves).

- Floor models are equipped with both a point and an oblong burner. They can be carried, but installed only on the floor.

- Wall options have a quadrangular shape and can be equipped with several burners.

- Built-in type. Designed for installation in a niche or in the middle of a finished fireplace portal.

Tabletop models (left) and built-in type (right side)

How the combustion chamber of a commercially manufactured biofireplace functions, pay attention to the video:

Fuel for biofireplace

In terms of its basic technical characteristics, the biofuel used in special biofireplaces is very different from those liquids that are used in classic wood-burning heating devices.

Denatured ethanol, which is safe for the environment, is used to produce fireplace fuel.

Such fuel is advantageously distinguished by the formation of very beautiful and even flames without the release of by-products such as soot, soot, smoke or fumes. As practice shows, the efficiency of high-quality biofuel exceeds 90-95%.

The best proven biofuels are those produced by manufacturers in Germany, Holland and France. Their products fully comply with all quality standards, are completely safe to use and allow you to achieve a high level of room heating at minimal cost.

Depending on the design features of the fireplace device, biogas can be used as fuel, as well as bioethanol and biodiesel liquid obtained by processing vegetable and animal fats.

Biofuel is sold packaged in special containers of different volumes.

Many modern manufacturers bottle fireplace fuel in containers that have a very convenient scale for flammable liquid consumption.

Some domestic and foreign manufacturers specially add sea salt to fireplace fuel, which creates the crackling effect of stove logs, as well as special additives that guarantee an attractive and absolutely even orange color of the burner flame.

Adviсe

It is worth remembering that all safety requirements must be strictly observed:

- A fireplace is not a toy for children. When using it, you should make sure that there are no children near the fire.

- Storing biofuels near a fire source and in the public domain is prohibited.

- Do not add fuel while the fireplace is operating. It is worth waiting until the equipment cools down.

- Ignition is carried out only with the help of a special lighter.

The bio-fireplace serves as an excellent interior decor, and at the same time, it can also be improved. For example, place ceramic logs on the grill that imitate real firewood. This fire source can be used not only indoors, but also outdoors. For example, decorate a gazebo with a corner homemade eco-fireplace.

Instructions for making a bio-fireplace with your own hands

In this section we will look at how to make a bio-fireplace with your own hands.

The entire process of self-manufacturing a tabletop heating fireplace powered by biofuel is represented by several stages, including the assembly of the fuel block and glass chamber, as well as the final design and decor of the completely finished structure:

- At the first stage, it is necessary to build a fuel block based on a ready-made or self-made metal box, which must be painted from the front with high-quality metal paint.

- The inside of the fuel tank must be thoroughly cleaned of dust, rust or welding deposits, but painting it with paint is strictly prohibited, since otherwise there will be an active release of toxic components during combustion.

- At the next stage, all pre-prepared glass blanks are combined. High-quality silicone sealant is used for connection. After the adhesive is applied to the ends, supports are used, which allows you to obtain the most durable and reliable fastening of the parts.

- As a rule, the layer of sealant hardens completely within 24 hours, after which you need to carefully remove all excess and sagging using a regular blade, stationery or thin penknife;

- At the next stage, it is necessary to properly prepare fireplace biofuel, which, for the purpose of safe operation of the heating device, must be poured into a metal container and installed in the bottom of the metal fuel block. A wick cord is required. As necessary, the fuel container is replaced with a new portion of liquid for burning the tabletop fireplace.

At the final stage of manufacturing, you need to make a cover for the heating box yourself. It is best to use a fine-mesh construction metal mesh for this purpose, which should be cut in accordance with the dimensions of the box.

Design of a homemade biofireplace

A mesh with a large mesh can be laid in two layers, after which the lid is fixed with thick wire. In this case, adding biological fuel is carried out using a conventional medical syringe.

To give a tabletop heating device a finished look and improve its external characteristics, all kinds of decorative elements, represented by decorative stones or pebbles, are used.

Laying such natural stones on top of the mesh not only creates an attractive design, but also helps to achieve the most efficient and uniform distribution of thermal energy.

general characteristics

A mini-fireplace has many advantages, due to which it has rapidly gained popularity. It is easy to use and compact in size. This useful thing will come in handy during a power outage, especially if you don’t have a flashlight, candles or other mobile lamp at hand in the house.

Some models of tabletop fireplaces are a smaller copy of a standard fireplace. This is the same open fire, only in a more compact variation. A small home will instantly transform the atmosphere, making it more soulful and peaceful. The element will fit into both classical and modern decorative trends.

A fireplace placed on a table has a positive effect on a person’s psychological state. It can not only relax and get rid of anxious thoughts, but also set you up for fruitful work and inspire, giving an outlet to your creative nature. After a hard day at work, it is useful to relax with a cup of tea at the table on which the fireplace is located.

And if you want a large bio-fireplace?

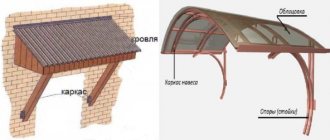

With large fireplaces, of course, there is more hassle. First you need to place the wall and cut out what you need from the drywall. If the wall is not made of plaster, then hollow out the millet. Next, you need to make a frame for the fireplace - it can be the same drywall (do not forget to secure the frame).

To assemble large fireplaces, still purchase a specialized fireproof box. This miracle is sold in special stores. We must not forget that between the frame and the box it is necessary to lay out a fire-resistant material, at least mineral wool. And it’s better to buy a special, large burner. This option will still be cheaper than buying a solid fireplace. We cover it with fireproof tiles or stone. You can look on the Internet for photos of a bio-fireplace and how to decorate it.

As you can see, making a bio-fireplace with your own hands is not that difficult, the only thing is that now it’s always worth purchasing oil for bio-fireplaces. Other oils are obviously unhealthy or leave behind soot.

How to assemble the structure?

The surface of the case is often decorated, but you can leave it in its original form. Next, you need to install a container with fuel. It is recommended to buy a special liquid as fuel. It is intended for bio-fireplaces and costs about 250 rubles per liter.

If it is not possible to make an exclusive product, you can use a metal can. If the container is made of thick tin, that will also work.

Is the fuel container installed? This means it’s time to lay the grating on its surface. After that, put the wick in it. It is better to use products made from natural materials. It will be good if it is not too thin cotton rope. Now place the stones on the grate. Consider your bio fireplace ready for use!

How to make a bio-fireplace with your own hands - step-by-step instructions

In appearance, a floor-mounted biofireplace can be indistinguishable from a real one, made of brick and having a chimney. The design of the housing can be different:

- with columns;

- with projections;

- have the shape of a bowl or cabinet with legs.

The base of a biofireplace is easier and cheaper to build from plasterboard and metal profiles. From these materials you can make a geometrically regular, semicircular or wavy body. Instead of gypsum board, you can use wood, durable plastic or metal.

Design and drawings

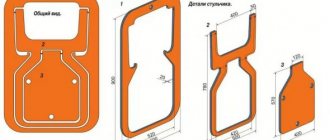

At the design stage of the biofireplace, its dimensions and installation location are determined. Floor structures are stationary, so you need to choose a place so that the fireplace fits harmoniously into the interior after changing the design of the room or purchasing new furniture. For small-sized apartments, medium-sized floor structures indicated in the drawing are suitable.

The drawing will help you quickly produce all the necessary parts for the fireplace.

Case manufacturing

To install the biofireplace body you will need:

- plasterboard 9 mm thick;

- metal profile PP 60/27;

- self-tapping screws;

- screwdriver;

- serpyanka;

- primer;

- putty;

- spatula with a narrow metal blade;

- roulette;

- ruler;

- bubble level at least 80 cm long;

- pencil or marker.

Suitable for decorating the case:

- fake diamond;

- ceramic tile;

- plastic panels “brick-like” or “stone-like”.

Housing installation steps

- Marking the wall and floor. Based on the previously drawn up drawing, mark the corner points of the back wall of the fireplace on the wall and connect them with straight lines. Mark the location of the front wall of the cabinet on the floor.

- Frame installation. Build a structure frame from a metal profile. Keep in mind that the planks should not be in close contact with each other. There should be a gap of 2–3 mm wide between them. This will prevent the structure from distorting during heating and cooling.

- Frame covering. Using a jigsaw or a utility knife, cut the gypsum board sheets to the required sizes. Attach them to the metal profile frame. “Down” the caps of the self-tapping screws into the gypsum board by 1–2 mm.

- Preparing drywall for finishing. Cover the joints of the gypsum board sheets with glass-woven mesh tape - serpyanka. Apply putty in the places where the screws are installed and cover with a thin layer of serpyanka. After the putty has dried, start sanding it. To do this, use a special trowel with a sanding mesh.

- Housing cladding. Cover the body of the bio-fireplace with the previously selected facing materials.

Installing the fuel block and burner

You can make a metal container for the fuel block yourself from stainless steel 2 mm thick. It is necessary to make a rectangular structure with a bottom and low sides. The dimensions of the block must correspond to the dimensions of the housing.

The burner is a metal cartridge that is installed in a container. Together they form the fuel block. An important element of the burner is the perforated damper, which is used to extinguish the flame and regulate its intensity.

When making your own, consider the following:

- the burner must fit freely into the metal container;

- the top panel of the burner may be a metal plate with slots;

- The internal cavity of the burner can be filled with mineral wool insulation or medical wool.

Operating principle of the fuel unit:

- Eco-fuel is poured into a metal container;

- The burner filler absorbs liquid;

- ignite fuel with a lighter.

Fireplace decoration

A protective screen made of ordinary window glass with polished edges is installed on the front wall of the biofireplace. The fuel block is decorated with ceramic firewood or stones.

False fireplace made of foam plastic

Basically, it's a simple box that you cut and fold yourself. Take several sheets 10 cm thick, cut them into parts and glue them together, and use self-tapping screws for a more reliable fixation. By the way, packaging foam from household appliances is usually denser than finishing foam - and therefore stronger.

To cut sheets, you will need a small hacksaw for metal - this way the foam will not crumble. Take your time and cut the lines completely so as not to break anything. For connection there are special adhesive solutions for foam plastic - other glue will not work on impermeable material.

First, mark the floor for the future foundation, and begin to gradually put together the parts. Immediately check all surfaces with a level until the adhesive solution sets. Puttying smooth foam is problematic, so place a painting mesh on top. Ready-made elements are suitable for the design of the portal - columns and half-columns, stucco molding, shelves, moldings.

Photo: m.2gis.ru Photo: interior-experts.ru

What it is?

The biofireplace is a bladeless design that burns not wood, but liquid fuel. The history of biofireplaces dates back to ancient times; the prototype was oil lamps or special vats of oil.

In order to please yourself with a bio-fireplace, you do not need to build a chimney, but only periodically ventilate the room. After all, this is fire, and it still takes oxygen. Moreover, biofireplaces come in several modifications, which will allow you to make your dreams come true:

- large floor fireplaces, the same size as regular ones;

- lightweight fireplaces that effortlessly cling to a wall or ceiling, but only the fireplace will be enclosed with special glass for safety purposes.

- small bio-fireplaces that easily fit on a table or cabinet and harmonize perfectly with the interior.

This type of fireplace has a simple design, but is quite expensive. You can find a way out of the situation and how to make a fireplace with your own hands, especially since the materials for it are sold in every hardware store. To do this you need the following list:

1. Glass. To do this, you just need to go to a regular glass workshop. Of course, the volume and dimensions will depend on your idea.

2. Silicone sealant, which is sold in every hardware store.

3. Metal box or can for flammable liquid. In most cases, such a device is available on the farm.

4. Finishing materials: decorative stone, decorative brick, etc.

e41dbbc8cbcac979c99be0c7ea3ee4d4.jpe

5. Wick cord.

Before you take on a bio-fireplace, you need to make at least a rough drawing or search on the Internet.

The most important part for a biofireplace is the burner. If something is done incorrectly, the consequences can be disastrous. So, here are some tips for making:

- if the fireplace is opaque, then you need to paint the narrow fuel outlet from the outside;

- a fine mesh is carefully cut to size and laid out at the top of the container. This is necessary for a more even distribution of fire and for decoration. You must watch carefully so that this mesh does not fall inside the fuel container.

False fireplace made of polyurethane

It is impossible to make a real fireplace from polyurethane, but a good decorative imitation is quite possible. This is a modern material that bends easily and takes on absolutely any shape. It is used to make ready-made portals with imitation of wood or stone carvings - you just need to glue them to the wall.

In stores you sometimes find ready-made kits for false fireplaces. Essentially, this is a kind of 3D puzzle that you just need to unpack and assemble according to the instructions. All that remains is to color it to match your interior.

Photo: pech-kamin.ru

Photo: womanadvice.ru Photo: pinterest.ru

Required materials and tools

The main element of the design is the fuel tank; it is better to make it from a sheet of stainless steel. You can purchase it on the construction market or order it from craftsmen if you plan to construct a large structure.

If there is no need for large volumes, then you can use metal mugs by breaking off their handles. They must be installed in a fireproof tank.

The body itself can be made of almost any transparent material that can withstand high temperatures, for example, smoky special glass. The device can be installed on a coffee table instead of a smoking candle.

If you need an imitation of a real fireplace, you will have to make a decent base from the following materials:

- Plasterboard sheets;

- Self-tapping screws;

- Metal corners;

- The refractory material used to insulate the structure can be, for example, isover.

False fireplace made of cardboard

To shop around for artificial fireplaces and have fun with your kids, your first test model can even be made from unwanted cardboard boxes. Large boxes of equipment are ideal - from one - a podium, from the other - the fireplace itself.

Mark the doors for the future firebox, carefully cut them and fold them inward. To connect the parts, only wide tape will be enough. Cover the fireplace with beautiful wrapping paper or leftover wallpaper and decorate it with ready-made polyurethane elements.

Photo: odstroy.ru Photo: 1000sovetov.ru

Simple tabletop biofireplace

Such fireplaces will serve as an ideal addition to any room design, and in the evening they will provide the opportunity to admire a live fire in all its glory. One of the main advantages of tabletop fireplaces is their simplicity. Let's take a closer look at how to make one of these bio-fireplaces.

To create such a fireplace with your own hands we will need:

- 4 glasses.

- A base box made of metal or other fire-resistant material.

- Glass cutter.

- Sealant for glass bonding.

- Steel mesh.

- Fireproof stones for decoration.

- Fuel container.

Step-by-step instructions for making a desktop biofireplace:

- We calculate the dimensions of the future structure. For one burner, the minimum distance between the glasses is 15 cm.

- We adjust the glass to the dimensions of the box. If they fit true to size, great. Otherwise, you need to cut off the excess with a glass cutter. The glass box after connection will be installed on the base.

- We connect the glass with sealant. To do this, apply sealant to the end of the glass and connect it at right angles to the other glass. It will take at least a day for the sealant to dry completely. To do this, stands are installed under each side.

- A glass box without a top or bottom is installed on a base. If the calculations were done correctly, then he should definitely be on the edge. To fasten the glass and the base, we again use sealant.

- We place a burner with biofuel in the center of the base and cover it with a steel mesh. It must be cut so that its edges lie on the edge of the base. It is recommended to lay the mesh in several layers so that it does not collapse under the weight of decorative stones.

- Place the stones in an even layer on the mesh. If you use natural stones collected with your own hands, they must be washed. In this case, when heated, they will not emit an unpleasant odor.

- If necessary, light the burner and check the result.

Important! This design is very easy to assemble, but has a number of disadvantages. First of all, it is impossible to replenish fuel without disassembling part of the fireplace

The second disadvantage is the lack of a combustion regulator. As a result, neither the flame intensity nor the fuel consumption can be changed.

False fireplace made of wood

If you prefer eco-style and natural materials, then a false fireplace can even be made from wood. Sheets of plywood with a thickness of 8 mm or more are best suited for this - they are easy to cut and join. For the frame, use beams measuring approximately 4x4 cm, and for fastening - self-tapping screws and liquid nails.

Keep in mind that the wooden structure on a frame made of beams is quite heavy, so you will need a podium for stability. Sew the base with plywood, cover the seams with corners and putty all the joints. You can leave additional niches, shelves or other elements, and only the decor will remain.

Photo: pinterest.es Photo: homemania.ru Photo: odstroy.ru

Biofireplace manufacturing process

Biofireplaces can easily replace an electric fireplace or fireplace stove. This accessory brings a pleasant feeling of warmth and comfort. Of course, there is the option to buy a small potbelly stove, but this is not a very cheap product. The main process of making a home biofuel fireplace will involve selecting the necessary materials.

- The bio-stove is assembled from simple elements: a fuel tank and a frame.

- All work begins with drawing a diagram of the desired decor item on paper.

- When it is ready, you can evaluate your capabilities and start purchasing materials. If you find it difficult to develop a product plan, find photos of biofireplaces on the Internet and create your own version based on them.

- Then you should take on the drawing, where you should indicate all the exact dimensions. With its help, you will never get confused and will get the desired result in the end.

Advantages and disadvantages of products

The main and undeniable advantage of eco-fireplaces is that visually they can replace a natural fireplace and create a feeling of coziness and comfort in an apartment or privatized house. Other advantages look like this:

- the design is simple and reliable, there is nothing to break in it, which means there will be no need for repairs;

- due to the smokeless combustion of a minimum amount of fuel in the room, there is no need to install a chimney;

- hot coals do not fly out of the combustion chamber and, in general, the device is considered fireproof if the manufacturer’s instructions are followed;

- ease of use.

Elite and prestigious models of biofireplaces are equipped with electronic control units, which make it possible to check the operation and remaining fuel on the monitor, automatically ignite and extinguish the flame, and also control the device from a distance using a mobile phone. They also have safety systems installed - protection from children and animals living at home, from tipping over, and so on. But the prices of such products start from 3000 USD. e.

Now about the disadvantages of biofireplaces:

- The burner hardly heats the room. The flame is real, but very little heat is released due to the slow burning of a small volume of fuel.

- Fuel supplied to order and sold at points of sale is quite expensive. Very inexpensive bioethanol in a liter container costs from 7 USD. e., and a branded one with the smell of coffee from the Kratki brand - 16 USD. e.

- No matter how little combustion products are released, supply and exhaust ventilation is first necessary to remove them.

What is a biofireplace

The biofireplace, which is becoming fashionable, is a decorative source of open fire that runs on so-called biofuel. For safe operation, the device is framed by a portal that traps the flame inside.

Structurally, a biofireplace is a burner that runs on alcohol fuel. A mandatory element of the device is a fuel tank, which contains a sufficient supply of flammable liquid for operation.

A wick is inserted into the tank, along the fibers of which the fuel rises to the place of combustion. The combustion itself takes place in a special bowl, which can have a variety of shapes. The sizes of biofireplaces vary significantly.

Installing a bio-fireplace is a great way to decorate your interior, make it unusual and attractive. Depending on the type of device and model, the fire can be completely open or closed on several sides by the walls of the portal, transparent and opaque

In addition, some burners are equipped with nozzles. This makes the flames as similar as possible to those formed when burning wood in a fire or fireplace.

The devices are very convenient to use. First of all, they don't need a chimney. During combustion, biofuels are oxidized to carbon dioxide and water vapor. The absence of heavy impurities in the flammable liquid allows it to burn completely, without the formation of soot, soot and volatile toxic substances.

Therefore, smoke removal (which does not form) is not required. Thanks to this, the biofireplace can be installed anywhere in the room.

It does not need a heat-resistant floor frame or a separate foundation. Special permission for its installation is also not required. The only thing that needs to be taken into account when choosing a place to install a bio-fireplace is the possibility of ventilating the room or the presence of effective ventilation. This is necessary because combustion uses oxygen, the amount of which must be constantly replenished.

To ensure that the bio-fireplace does not differ from the real one, it can be decorated with firewood made from fire-resistant ceramics. They are produced in the form of whole or half-burnt logs

Biofireplaces are not only decorative, but also functional. Unlike traditional fireplaces, where most of the heat “goes” into the chimney, the devices completely transfer their heat into the room. Of course, you won’t be able to use such a device as a heating device, but it will be able to heat some area in the room. Biofireplaces are completely safe if used correctly.

The industry produces models that are most comfortable to use, equipped with electronic controls. They can be controlled from a remote control or via Wi-Fi. In the latter case, it is quite possible to integrate the device into the Smart Home system and remotely control it from a phone or tablet. It is clear that the cost of automatic biofireplaces is an order of magnitude higher than that of conventional ones.

At the same time, standard models can be considered “eternal”, since they are structurally extremely simple and there is nothing to break in them, while devices stuffed with electronics may well fail.

Composition and features of biofuel

The “bio” part of the word “biofuel” explains that only natural, renewable raw materials are used to produce this substance. Therefore, it is completely environmentally friendly and biodegradable.

The main components used to produce such fuel are grasses and grains containing large amounts of starch and sugar. Thus, corn and cane are considered the best raw materials.

You can find various brands of biofuels on sale. Preference should be given to certified products, otherwise you may face serious troubles

They produce bioethanol, or a type of alcohol. It is a colorless liquid and has no odor. If necessary, it can replace gasoline, however, the cost of such a substitute is much higher. When burned, pure bioethanol decomposes into water in the form of vapor and carbon dioxide.

In this way, it is even possible to humidify the air in the room where the bio-fireplace is installed. The substance burns with the formation of a blue “gas” flame.

This is a purely aesthetic drawback that prevents you from still enjoying the sight of an open fire. A traditional fireplace produces a yellow-orange flame, which is a kind of standard. To eliminate this drawback, additives are introduced into biofuels that change the color of the flame.

Thus, the traditional composition of a flammable liquid is as follows:

- bioethanol – about 95%;

- methyl ethyl ketone, denaturing substance – about 1%;

- distilled water - about 4%.

In addition, crystalline bitrex is added to the fuel composition. This powder has an extremely bitter taste and is intended to prevent alcohol biofuels from being consumed as alcohol. Biofuel is produced in different brands, its composition may vary somewhat, but in general does not change. It is clear that the cost of such fuel is quite high.

It is not recommended to use homemade fuel for biofireplaces, but if you still decide to try, to make it you need to use only high-purity gasoline “Galosha”

Fuel consumption depends on the number of burners and the power of the biofireplace. On average, a 2-3 hour operation of a heating unit with a power of about 4 kW per hour consumes about a liter of flammable liquid. In general, operating a biofireplace turns out to be quite expensive, so home craftsmen are trying to find a cheaper alternative to fuel. There is such an option and it is viable.

To avoid trouble, you need to purchase only high-quality components for homemade fuel. We must not forget that the bio-fireplace does not have a smoke exhaust, and all combustion products immediately enter directly into the room.

If toxic substances are present in the fuel, and this is not uncommon for low-quality alcohol-containing compounds, they will end up in the room. This threatens with the most unpleasant consequences. We recommend that you familiarize yourself with the best biofuel brands.

Therefore, it is not recommended to make fuel for a biofireplace yourself. However, if you really want to experiment, this is the safest recipe. Take pure medical alcohol. It must be purchased at a pharmacy.

To color the flame, highly purified gasoline is added to it, which is used to refill lighters (“Galoshes”).

Filling the fuel tank must be done very carefully. If liquid is spilled, you must immediately wipe it with a dry cloth, otherwise an accidental fire may occur.

Liquids are measured and mixed. Alcohol should be present in a volume of 90 to 94% of the total amount of fuel, gasoline can account for 6 to 10%. The optimal proportion is determined empirically, but you should not go beyond the recommended values. Detailed instructions for the production and use of biofuel are given here.

It is important to remember that the resulting fuel cannot be stored, since the mixture of gasoline and alcohol will separate. It should be prepared before use and shaken well for better mixing.

Disadvantages of a biofireplace

Along with its advantages, this product has its own disadvantages, which are a tribute to convenience, safety and environmental friendliness.

Dependence on one type of fuel. The burner runs only on alcohol, while a regular fireplace can be lit with any solid flammable substance.

The relative high cost of fuel. A medium-sized heating unit (burner) consumes 0.3–0.4 liters per hour. The cost of 1 liter of fuel is on average 200–250 rubles*. Burning a fireplace for one hour will cost about 100 rubles.

We are talking about factory fuel for biofireplaces.

Minimum room area. The room in which the fireplace is installed must be at least 25 square meters. m.

| Name | Dimensions, mm | Characteristics | price, rub. |

| Floor-standing | |||

| DirectCheminee Universal, France/Russia | 760x335x800 | 1 TB* 2.5 l, hearth walls included, classic look | 75 000 |

| DirectCheminee Universal Х2, France/Russia | 980x345x1100 | 2 TB 2.5 l, hearth walls included, classic look | 95 000 |

| Planika CALVADOS Cherry/Ivory, Poland | 860x870x365 | 1 TB 2.8 l, wooden portal, classic look | 120 000 |

| DirectCheminee Baroque Italiano, France/Russia | 1300x400x1100 | 1 TB 3 l, portal and tabletop made of cast marble, sophisticated look | 145 000 |

| BERLONI Turin, Italy | 1100x1100x320 | 2 TB 2.2 l, MDF portal and painted steel | 58 000 |

| Horus Freedom Wall, Italy | 950x400x870 | 1 TB 2.9 l, portal made of steel and glass | 160 000 |

| Horus Tetris, Italy | 1000x1000x450 | 1 TB, stainless and painted steel, tempered glass, independent location | 177 000 |

| Wall mounted | |||

| Planika Wallfire, Poland | 360x810x210 | thermostat, fan heater, stainless steel/glass, 2.5–3.7 kW | 191 000 |

| Horus ZEN, Italy | 1200x340x450 | steel/glass, 2.1–2.8 kW | 140 000 |

| Horus Closer inox Frame, Italy | 640x640x220 | steel/glass, 1.8–2.2 kW | 110 000 |

| DirectCheminee Premier, France/Russia | 800x250x500 | Any finishing option from any material, 1.8–2.6 kW | 42 000 |

| DirectCheminee Autofire 146 electronic, France/Russia | 1460x290x620 | Fully electronic control system, flow rate 1 l/hour, 6.2 kW | 300 000 |

| DirectCheminee Monumentale Huge for 5 fireboxes, France/Russia | 2000x300x790 | 5 TB, painted steel, 5.8 kW | 220 000 |

| Tabletop (small) | |||

| DirectCheminee Biocandle Reed 3, France/Russia | — | Interior element, stainless steel steel | 16 000 |

| DirectCheminee Biocandle “Classic” on a marble base (Modern collection), France/Russia | — | Interior element, stainless steel steel, marble | 9 000 |

| DirectCheminee Block box 2.5 l (Artificial stone), France/Russia | 440x340x105 | Stainless steel steel, artificial stone to choose from (200 types) | 28 000 |

| DirectCheminee Block box INOX 5 l, France/Russia | 550x510x350 | Stainless steel steel, surface finish - mirror, metal, wood | 50 000 |

| Planika Simple Commerce, Poland | height 420, diameter 380 | Glass flask - Italy, burner - 1.5 l (7 hours) | 48 500 |

| Planika Stone, Poland | height 410, diameter 450 | Glass flask - Italy, Scandinavian field stone at the base, burner - 0.6 l (up to 2 hours) | 82 000 |

| Planika VERANDA GF-07 Table, Poland | height 597, diameter 700 | Glass - Italy, wood legs - teak, burner 1 l (3.5 hours) | 95 000 |

* TB - fuel block.

Sketch

Before the “creation” stage, you should draw a picture of the appearance of the bio-fireplace and indicate the main dimensions. Based on the results obtained, you can evaluate the possibility of self-production and calculate the required amount of materials.

Making your own fuel tank is difficult. It is better to purchase it at a hardware store. It will be much safer and more cost-effective.

For a complex design design, drawings of each part are made with dimensions. All components must fit together perfectly. Otherwise, you will need to redo the work again. The drawings show what materials need to be purchased and how many parts should be made.

Advantages of a biofireplace

Biofireplace is a new product on the market that is rapidly gaining popularity. This is not only a tribute to fashion, but also a lot of beneficial advantages.

Convenience. The purity of combustion emissions allows the use of a biofireplace without a chimney. This decisive advantage makes it an exceptionally technological product - the fireplace can be placed in any location that meets the installation requirements. It does not require a separate foundation and heat-resistant floor lining. Approximately 50% of these products are made in a portable version, the rest are mounted on the floor, walls and even suspended from the ceiling.

Manufacturability. The alcohol burner hearth can be purchased separately, without a portal. It can then be installed into the firebox of an existing traditional fireplace. This will preserve the functions and appearance of the interior and eliminate the need to prepare solid fuel and the risk of smoke. Due to the simplicity and low cost of their design, full-fledged biofireplaces are available in a sufficient range of sizes. The portal can also be made to order from any material.

Safety. Factory-made fireplaces are supplied complete with protective panels and casings, so the biofireplace portal can be made of plasterboard or wood without fear of ignition from overheating. Ignition and combustion of fuel occurs without sparks or flame fluctuations (when using a special lighter). When burned, fuel breaks down into water vapor and CO2. The concentration of carbon dioxide is insignificant and does not affect air quality if there is standard ventilation of the premises.

Functionality. In a conventional fireplace, most of the heat is removed along with toxic waste gases through the chimney. In a biofireplace, the entire combustion temperature is transferred to the surrounding air. A medium-sized device is equivalent in power to a 3 kW electric heater.

Reliability, simplicity of the device. Basic models of alcohol fireplaces do not have mechanisms, moving parts, or wearable parts. When used correctly, these are “eternal” devices (service life is unlimited). “Biocombustion” does not form carbon deposits, which reduces maintenance of the fireplace to wiping along with other interior elements. More complex and expensive models have electronic control - from a panel, remote control or Wi-Fi from a tablet or phone. Like any electronic devices, they can fail, but not more often than others.

Originality and beauty. The new bio-fireplace can be matched to absolutely any design - from minimalist cold high-tech to luxurious baroque. The portal can be ordered in any workshop, from any material. Such an open fire in the middle of the room will become the emotional center of the entire house, intuitively reminiscent of distant ancestors relaxing at night around the fire. Always even and stable flames are a “living” piece of furniture that can be moved at your discretion.

Price. The price of the device itself, together with the portal, does not exceed the price of a fireplace of the same format with a traditional or electric layout.

Some distinctive features

In terms of its design, a small fireplace has a number of differences that are not limited only to size.

- Its diagram is simplified as much as possible, and if real fireplaces use certain technologies to increase heat transfer, remove smoke, enhance and regulate draft, then here the device can be described in literally a couple of phrases: ash pan, firebox, chimney.

- Despite the fact that small dimensions mean low productivity, such a fireplace still copes with the task of local heating of the room, but most importantly, it gives everyone the opportunity to create a small cozy corner for themselves.

When talking about miniature fireplaces, one cannot fail to mention ready-made options that can be used not only in private homes, but also where the construction of a brick fireplace would be prohibited. We are talking about steel free-standing structures. They can be finished on the outside in different styles, imitating the brickwork of a classic fireplace.

- Gas, as an inexpensive type of fuel, has sufficient combustion heat, so such models can be used for heating.

- Compact electric fireplaces are stand-alone devices that can be built into a wall, furniture or a ready-made portal. They do not require a chimney, so in terms of space saving, these options have become unsurpassed.

- A real flame, enclosed in small dimensions, is realized in a biofireplace. In the furnace of such a device, fuel is burned, which leaves virtually no harmful substances. This fireplace also does not require a chimney and serves as a portable option.

However, when it comes to the hearth, everyone involuntarily imagines the light smell of smoke, the crackling of logs in the firebox and the coziness that only a brick wood-burning fireplace can create.

DIY bio-fireplace made from plasterboard

The chosen location determines the shape in which the biofireplace will be made - corner or straight, along the wall. Anyone who sets out to create a fireplace at home must prepare or find a sketch with instructions on how to make a biofireplace yourself, and purchase the necessary materials:

- Drywall and profiles for it.

- Self-tapping screws.

- Materials for interior decoration, for example, ceramic tiles and heat-resistant adhesive for them.

- Exterior finishing material, such as stone.

- Cotton wool, grout and finishing putty.

We recommend reading in more detail on our website how to make a tabletop biofireplace yourself.

Drawings of finished bio-fireplaces contain information on how to make bio-fireplaces, namely, determine the dimensions. However, the design of the structure can be absolutely anything - you just need to use your imagination.

3cb4dd33d05ffdea50addfaf5977d759.jpeWhen everything is ready to start working, you can begin to perform the following steps sequentially:

According to the instructions, marking lines are drawn on the wall, to which the formed guides for the body of the bio-fireplace are subsequently attached. Using self-tapping screws, rack profiles and frames are installed.

Using a plumb line, you need to check the correct location of all elements

Next, during the construction of a biofireplace, the frame is covered with plasterboard. The optimal distance at which it should be fastened is from 10 to 15 cm. When performing this work, you also need to lay a layer of mineral wool about 5 cm thick in the firebox area.

The direction of the fibers - vertical or random - of mineral wool affects the properties that it best provides. Thus, for bio-fireplaces, a material with a chaotic direction is suitable, which better provides thermal insulation properties.

A recess is left at the bottom of the firebox, into which the burner will be installed in the future. Then, using non-combustible materials, the bottom of the bio-fireplace is formed. On the outside, the drywall is puttied and lined with the selected material.

For cladding, a material more suitable for the interior and price parameters is selected. The main thing is that it is fireproof.

The remaining seams are rubbed down, the surface is wiped with a damp and dry cloth. After this, when building a bio-fireplace with your own hands, you can start decorating - add a burner, lay out decorative elements. You can also take additional protective measures, such as installing fire-resistant glass on the front wall.

The burner allows you to reproduce the fire evenly, with a bright color, without flashes. Some burner models contain protection against fuel spillage when tipped over.

How to choose cardboard

To assemble it, you need to select materials and allocate approximately 5-6 hours for work. It is not at all necessary to do this yourself, it is not so difficult to do it yourself, so the whole family can take part in the process.

Make a fireplace with your whole family

The quality and appearance will depend on the material and type of cardboard boxes. If you take the packaging from under the TV, the “false fireplace” will be narrow without much of a recess in the place where the burning wood is located. Therefore, wide boxes are most often used, at least 50 centimeters deep. It is also advisable to use the most durable cardboard, in which case you can make a wooden stand on top.

Choose durable cardboard

If you want to make a more complex design, it is recommended to prepare 2 more boxes of different sizes. This will expand the scope for creative ideas. It is also worth making sure that the drawings are easily applied to the paper. They must be clearly visible, since in case of an error, you will have to look for new material.

Complex design of several boxes

3 types of “false fireplaces” are often used, namely:

1Christmas with New Year decorations.

2 Corner hearth.

3Standard wall-mounted.

For each of them it is necessary to select a certain amount of materials and types of cardboard boxes. To make the structure more stable and reliable, you can place a wooden frame inside. This will be relevant in a family with small children.

Christmas wall fireplace

Step-by-step assembly instructions in detail

There are a lot of ways to make a fireplace for apartments. For example, there are step-by-step instructions for assembling a decorative stove that will fit perfectly into any home.

To create it you will need the following parts:

- fuel block with a valve, a stand for it (made of metal);

- fire-resistant ceramic glass for both walls;

- bolts, washers and pads;

- rubber gaskets and metal legs;

- black paint that protects from fire, or a special material used for the panel design (stone, aluminum).

Regular assembly:

First of all, make a part for the tank.

- According to the drawings, make 2 beams. They will act as fastening for the plywood part. You only need to cut out the top and bottom halves. A glass frame will be attached to the bottom.

- Make a rectangular hole at the top for the fuel container.

- Drill holes for the bolts. Bolts that have silicone gaskets will pass through them. All actions must be carried out carefully so that the structure does not break.

- When the structure is ready, a fuel container is installed in its upper half (in the cut hole).

Design and principle of operation

In its traditional design, a biofireplace consists of the following elements:

- Burner - made of heat-resistant metal and natural or artificial stones. To control the intensity of combustion, the design may include a special adjustable damper.

- Fuel block - has the form of a container intended for filling fuel.

- Protective shield - placed on the sides or all sides of the device to ensure safety and prevent the possibility of sparks.

- Case - some devices do not have one. In miniature models, its function can be performed by the fuel sector.

Types of biofireplaces

Depending on the dimensions of the structure and the location of its installation, there are several types of biofireplaces.

There are several types of biofireplaces

Floor-standing

The advantage of such a fireplace is its mobility

Massive and solid structures that can be installed next to a wall or anywhere in the room. The design solutions of the case are very different. There are eco-fireplaces made in the shape of a tree trunk, forged, decorated with carved metal sheets, decorated with colored glass inserts.

a53da261ccb611fe793540376b572e56.jpe

Ceramic firewood is purchased for floor-standing devices; outwardly it is almost indistinguishable from the real thing. Imitations of coniferous and deciduous trees are possible. These accessories bring the appearance of the bio-fireplace as close as possible to the natural one. The burner is decorated with chipped or rounded stones. They are necessary to create the effect of a more “living”, natural flame.

Wall-mounted (mounted)

A hanging biofireplace can be placed at any height

Wall-mounted biofireplaces are lightweight and light-weight devices, equipped with protective fire-resistant and transparent screens on 1, 2 or 3 sides. All models are flat, equipped with a back wall made of heat-resistant material. The advantages of this type of biofireplaces include:

- a light weight;

- Possibility of installation at any height;

- modern style solution.

To prevent the possibility of falling, the hanging devices are securely fastened to the walls.

Tabletop

A tabletop fireplace will become a stylish piece of furniture

Tabletop biofireplaces are miniature, eye-catching products that can decorate any interior. Most often they consist of a metal body filled with small stones. They are equipped with transparent glass around the perimeter or on both sides. The main advantage of these models is low fuel consumption. Miniature eco-fireplaces will decorate the holiday table and create a calm and peaceful atmosphere.

Built-in

Built-in biofireplaces are produced in the form of metal modules with a front protective screen.

Biofireplaces of this type can be built into walls or special niches

Installed in niches built of brick, concrete or plasterboard. There are models designed to be built into furniture. The fuel block and burner are decorated with ceramic firewood or stones.

Built-in eco-fireplaces have their advantages:

- allow you to save space and are the best choice for small apartments;

- provide modern room design;

- equipped with a height-adjustable screen.

Steam models

Modern manufacturers produce steam fireplaces that are very difficult to distinguish from designs with an open fire. Special devices are used to create a spectacular illusion. The movement of steam follows the changing flames. The image never repeats itself, as happens with electric fireplaces where video is projected. The volumetric visual effect can be viewed from all sides from various angles.

Principle of operation

The steam fireplace is equipped with special miniature lighting devices (LED or halogen lamps), as well as a steam generator.

The device is very simple and understandable. The steam generator makes light and fine steam from water. As a result, water mist appears inside the structure. Small particles of water frozen in the air are illuminated with colored filters. Yellow, red and orange lighting is used. The combination of all these elements creates the effect of a burning fire.

The result is surprising and amazing. At the bottom, the steam is painted in a bright and rich color, imitating a real flame, and towards the top the color saturation is lost. The tips of the fire smoothly turn into gray smoke.

To complement the composition and make it more realistic, imitation coals or firewood are added to the fire. There is a separate projection on them. The combination of all elements creates a unique picture. The fire is very similar to real fire.

Advantages and disadvantages

Steam fireplaces are much safer than alcohol-based fireplaces, as they do not generate a flame, but only create the illusion of one.

Besides this, there are other advantages:

- There is no need to spend money on fuel.

- You can use the fireplace indoors. No need for ventilation.

Among the disadvantages are operation from the mains:

- Placement options are limited by the length of the cord and the availability of an outlet.

- It is worth considering aesthetic functions; even the most skillful imitation remains only an illusion. Natural fire has a special charm and expressiveness.

A tabletop fireplace is a practical, stylish, fashionable, reliable and profitable way to transform your interior. Such an element will look great in almost all rooms of a residential building: kitchen, living room, bedroom, hall, study. Steam models can be used to decorate teenagers' rooms.