After the introduction of a new standard for the thermal protection of buildings, insulation has become relevant even for those houses that were previously considered “safe”. Owners of older buildings don't have to do anything, but they must be prepared to pay rising energy bills. And designs for new houses will not be approved if they do not meet the requirements of SNiP 02/23/2003. There are several technologies that make it possible to ensure standard indicators for buildings made of any materials. The main thing is to choose the right insulation for the exterior walls of a house in each case.

The house must be kept warm Source prolesa.com.ua

Why external insulation and not internal

The most understandable argument for a non-specialist sounds very convincing, although this is a secondary factor - insulation from the inside “takes away” the useful volume of residential and office premises.

Builders are guided by the standard according to which insulation must be external (SP 23-101-2004). Insulation from the inside is not directly prohibited, but it can only be carried out in exceptional cases. For example, when work on the outside cannot be carried out due to the design features or the facade “belongs” to a house that is classified as an architectural monument.

Video description

The result of proper internal insulation of a house in the video:

Even such protection from the inside will not provide a 100% guarantee against the wall getting wet - water vapor will find its way into the film joints and fastening points Source domvpavlino.ru

That is, when deciding how to properly insulate a house, in the vast majority of cases, the answer will be based on clear regulatory recommendations - from the outside.

But there are exceptions! Insulation from plant materials.

Environmentally friendly insulation made from flax and hemp fibers have unique properties and, using them, you can deviate from generally accepted rules. Thermal insulation made from plant materials does not require the use of vapor barrier. Such thermal insulation can be used both internally and externally in almost any structure. If additional wall insulation is performed, then vapor barrier is not used at all. This is especially important when insulating wooden walls. This method of insulation allows you to maintain a favorable microclimate for a person in a wooden house, while significantly improving the heat-saving characteristics of the structure. If a frame house or roof is insulated with flax insulation or hemp insulation, then instead of a vapor barrier, special vapor barrier cardboard is used. Flax and hemp are natural antiseptics, they are not afraid of moisture and can remove moisture from the structure through their capillary fibers; this is their main difference from other non-organic insulation materials. Linen and hemp insulation are absolutely safe for humans, are not afraid of rodents, are durable and will last more than 70 years.

Stone wool: application

This material is universal, due to its technical characteristics.

In construction, stone wool is used for:

- installation of ventilated facades of buildings for various purposes;

- insulation of building structures both inside and outside buildings;

- insulation of utilities and building elements made of various materials;

- for isolating fire hazardous areas and objects that normally operate at high temperatures;

- for soundproofing objects and buildings for various purposes.

Video description

Which insulation is better? Watch the test of mineral wool, polystyrene and NPE Tepofol in this video:

Tepofol

This is a new type of thermal insulation made of polyethylene foam with a heat-reflecting layer. Made from LDPE - high-density polyethylene. This raw material is widely used in the food industry, which confirms its safety. Surely you have already come across similar material. Previously, it was used in conjunction with other types of thermal insulation only as a vapor barrier. This was due to the production of small thickness - up to 10 mm. The Tepofol company has developed and patented a system of interlocking connections and has the ability to produce insulation up to 150 mm thick. Despite this possibility, in the central region for year-round use, the optimal thickness is 60-80 mm. This allows it to be used as the main thermal insulation without the use of other types of insulation. Tepofol does not absorb moisture and does not lose its properties; it is no longer necessary to use vapor barrier and wind protection. With traditional insulation technology, thermal insulation is laid between the frame. But since the thermal conductivity of wood is higher than that of any thermal insulation, in this case the frame itself will act as a cold bridge. In the case of insulation with Tepofol, the rolls are rolled out along the structure itself, after which the locking joints located on the top and bottom of the roll are soldered together with a construction hairdryer. This allows you to achieve a solid, sealed fabric, without cracks and without cold bridges, without resorting to the use of foam and sealants.

External insulation of the house Source tepofol.ru

Example of internal roof insulation Source tepofol.ru

Expanded polystyrene

Better known as "foam". To be precise, in addition to slabs, this material is also used in granular form as bulk thermal insulation.

Its thermal conductivity varies with density, but on average it is one of the lowest in its class. Thermal insulation properties are provided by a cellular structure filled with air. Its popularity is explained by its availability, ease of installation, good compressive strength, and low water absorption. That is, it is cheap, quite durable (as part of the structure) and is not afraid of water.

Polystyrene foam is considered low-flammable, and those marked PSB-S are self-extinguishing (does not support combustion). But during a fire, it emits toxic gases, and this is one of the main reasons why it cannot be used for insulation from the inside. Its second drawback is low vapor permeability, which imposes restrictions on the use of “breathable” materials when insulating walls.

Extruded polystyrene foam

Insulating the outside of a house with polystyrene foam Source makemone.ru

See also: Catalog of companies that specialize in insulating country houses.

It differs from polystyrene foam by a fundamentally different manufacturing technology, although the raw material is the same polystyrene granules. In some respects it is superior to its “relative”. It has the same percentage of water absorption (no more than 2%), on average, thermal conductivity is 20-30% lower (Table D.1 SP 23-101-2004), vapor permeability is several times lower and compressive strength is higher. Thanks to this set of qualities, it is the best material for insulating the foundation and basement, that is, the walls of the basement and the “zero” floor. The disadvantages of EPS are the same as those of polystyrene foam, and it costs more.

EPPS is usually made “colored” Source footing.ru

Stone, also known as basalt, cotton wool

This is a subtype of mineral wool, the raw materials of which are rocks of stone (most often basalt). A completely different type of thermal insulation material, the low thermal conductivity of which is ensured due to its fibrous structure and low density. It is inferior to foam plastic and EPPS in terms of thermal conductivity (on average 1.5 times higher), but unlike them, it does not burn or smolder (flammability class NG). Refers to “breathable” materials - according to the new standard this sounds like low “breathing resistance”.

Mineral wool mats for wall insulation must be “hard” Source konveyt.ru

But there are other materials for insulating a house outside, which, although used less frequently, have their own advantages.

Advantages and disadvantages

Mineral wool has its own advantages and disadvantages that are worth considering. Therefore, you need to familiarize yourself with them. Let's start with the advantages:

- No harmful impurities. In production, practically no harmful substances are used: resins, phenols, so they are not released during operation.

- Low thermal conductivity, good heat retention.

- High sound absorption.

- It does not ignite or burn. At temperatures up to 600 degrees, the structure remains virtually unchanged.

- Service life up to 50 years.

- Resistance to biological, physical, chemical factors.

- Easy to install.

Disadvantages include:

- Ability to absorb moisture. This characteristic is common to all fibrous materials. You can get rid of it by installing vapor barrier membranes.

- High mass. This will require additional calculations about the ability of the supporting structure to withstand the insulation.

- The price is slightly higher than other, less traditional insulation materials. However, the quality of insulation is better.

Based on the listed features, you can choose cotton wool or another heat insulator.

Thermal insulation materials - new products on the market

Additionally, you can always consider new options - they are a little more expensive, but often somewhat more effective than traditional ones.

Foamed polyurethane

A common polymer material for “household use”. Also well known as foam rubber for furniture (in the form of “soft” mats) or as polyurethane foam for sealing cracks. When insulating, it is also used in the form of slabs or sprayed insulation.

Polyurethane foam slabs have low tear-off holding properties, so they are not used in “wet façade” systems.

But this is a common thermal insulation material for making sandwich panels. The same technology underlies the production of thermal panels for facade cladding. Such a panel is a heat-insulating board with a decorative layer (clinker tiles or stone chips) already applied at the factory. Two types of insulation: polystyrene foam and polyurethane foam. In the first case, the thermal panel is two-layer, in the second – three-layer (OSB or moisture-resistant plywood is used as the supporting base). Two mounting options: on dowels/anchors (open method) or on your own hidden fastening system.

Three-layer thermal panel Source zafasad.ru

Sprayed polyurethane foam is in demand if it is necessary to create a seamless layer of thermal insulation on complex surfaces. Until recently, there was only one technology for applying such a layer - using professional installations working with a two-component composition (mixing occurs during spraying).

Spraying polyurethane foam onto the base of a house Source nauka-i-religia.ru

Now in Russia, for household use, the production of one-component polyurethane foam has been launched, which is produced in an aerosol can with a capacity of 1 liter. As the manufacturers assure (there are two competing companies), insulating 1 m2 with your own hands is much cheaper than concluding an agreement with specialized enterprises that use professional equipment. And this option for insulating a house from the outside is quite attractive if literally 2-3 cm of the thermal insulation layer is missing.

Insulation using sprayed polyurethane foam "Teplis" Source m.2gis.kz

Ecowool

Rockwool is a world leader

Rockwool was founded in 1909 and is still headquartered in Denmark. For almost 110 years of its existence, the company has become a leader not only in the European, but also in the global thermal insulation market. It now has 28 factories in North America, Europe and Asia. In Russia there are three enterprises in the Moscow, Chelyabinsk and Leningrad regions. Another plant operates in Tatarstan. The total number of employees of the company reaches 10,000 people.

The product range contains materials for insulation and fire protection, as well as sound insulation in domestic and industrial premises, ships, and oil rigs. This company was the first in the world to be awarded the Eco Material Green environmental safety mark, so its products are very popular for insulating bedrooms and children's rooms.

Rockwool stone wool for private houses and apartments

For private housing construction, the manufacturer has a whole line of stone wool insulation. The most popular among them are insulation materials such as:

- LIGHT BUTTS

- SAUNA BUTTS

- ACOUSTIC BUTTS

LIGHT BATTS are lightweight mineral wool slabs designed for thermal insulation of non-load-bearing structures in the insulation system of a house or apartment. The thermal conductivity of this insulation is 0.036 W/(m K). It can be used to insulate a large number of objects: attic rooms (pitched roofs), partitions, joist floors, walls lined with siding, frame walls, balconies, baths, saunas

SAUNA BATTS are basalt slabs with a density of 40 kg/m3 and can be used both on the ceiling and on the walls. A special feature of the insulation is its one-sided coating with aluminum foil, which does not allow steam and water to pass through. This protects the fibers from getting wet and shrinking, and also completely blocks the escape of heat from the room. Using such cotton wool in a bath or sauna will ensure the preservation of temperature and the integrity of the partitions. In this case, installation of a vapor barrier is not required, which reduces construction costs. The material can withstand up to 200 degrees without loss of properties.

ACOUSTIC BATTS stone wool has a pronounced sound absorption effect, therefore it is optimal for insulating walls and ceilings in an apartment, which ensures comfort and increases fire safety. Suitable for all types of residential and non-residential premises, installation in suspended ceilings is permitted. The sound absorption index with a layer of 50 mm is 0.8 according to GOST 23499-2009. A thickness of 200 mm provides sound absorption class A with an index of 1.0. The density of such basalt slabs varies from 35 to 45 kg/m3.

Rockwool LIGHT BUTTS.

Rockwool stone wool for facades

Insulation of facades requires durable slabs that will interact well with subsequent finishing materials. For this purpose, Rockwool produces VENTI BATTS N OPTIMA, with the function of repelling water thanks to synthetic binders. The main material is fibers from basalt rocks, which provide high insulation and strength.

In terms of density, VENTI BATTS N OPTIMA stone wool has an indicator of 32 kg/m3 and is not prone to destruction under the influence of its own weight and emphasis on attachment points. Thermal conductivity is 0.036 W/(m*K). The material does not burn at all, which protects the building when trying to set fire to the facade. The thickness of the slabs varies from 50 to 200 mm and is selected according to insulation needs.

Rockwool VENTI BUTTS N OPTIMA.

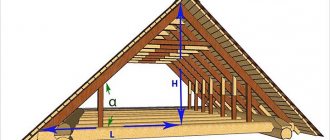

Stone wool for roof insulation

Roof insulation must withstand the heavy weight of subsequent layers and precipitation, so increased demands are placed on them.

The manufacturer Rockwool has a wide range of products for roof insulation, both flat and complex shapes:

- ROOF BATTS N LAMELLA - as the name implies, it is produced in the form of lamellas or strips, which is convenient for installation on roofs of various shapes. Installation with dowels or glue is allowed. Produced only with a thickness of 200 mm. It has a high density of 115 kg/m3, so it can withstand up to 5500 kg of pressure per square meter.

- ROOF BATTS D OPTIMA - made with two layers (hard outer and regular), which increases strength and reduces weight. Thicknesses range from 60 to 200 mm. The hard layer is always 15 mm. The density of the outer side reaches 205 kg/m3, and the inner one 120 kg/m3.

- ROOF BATTS N OPTIMA - designed for organizing the lower layer of the roof with subsequent laying of more durable materials. The density is 100 kg/m3, and the thermal conductivity is 0.036 W/(m*K). Thickness ranges from 40 to 200 mm.

- ROOF BUTTS IN OPTIMA are especially durable slabs with a density of 160 kg/m3 (full thickness), intended for laying as the last layer before the main roofing material. The plates are hydrophobic and insulate not only from freezing temperatures, but also from moisture penetration.

- SANDWICH BUTTS K - designed for use as a middle layer in sandwich panels. They can be located immediately behind the metal shell. Rigidity allows you to withstand the pressure of atmospheric precipitation. Density is 140-155 kg/m3. Compression can withstand forces up to 10,000 kg/m2.

- ROOF BUTTS IN EXTRA - slabs are produced with a thickness of 40-50 mm and serve as the top layer in the construction of the roof. The density of the entire material is 190 kg/m3.

Rockwool ROOF BUTTS.

The better way to insulate a house from the outside - standards for the number of layers

If you follow the regulatory documents, there are two options for how to insulate a house from the outside in terms of the number of structural and thermal insulation layers: two-layer and three-layer. Moreover, in the second case, the external paneling or plaster is not considered an independent layer, although their thermal insulation properties are taken into account. In three-layer walls, the outer (third) layer is the structural material.

Brick cladding with insulation Source pinterest.ru

In addition to this classification, there is also a division based on the presence of a ventilated and non-ventilated layer.

Total: four recommended types of technical solutions for thermal protection of walls. The standards already indicate insulation options depending on the wall materials and thermal insulation:

- brickwork, reinforced concrete (with flexible connections), expanded clay concrete - all types of solutions;

- wooden houses - enclosing structures with two-layer, three-layer walls and a ventilated air gap;

- frame houses with thin-sheet cladding - three-layer walls with thermal insulation in the middle, as well as with a ventilated and unventilated air gap;

- cellular concrete blocks - two-layer walls with brick cladding, as well as with a ventilated or non-ventilated layer.

In practice, for insulating low-rise buildings, such a variety of solutions comes down to the choice between a “wet” or a curtain wall. Although, it is those recommended by the standard that are considered as thermal insulation materials - mineral wool or expanded polystyrene (EPS as an alternative).

But each case has its own preferences.

The better way to insulate a house from the outside, depending on the wall material

For insulating a brick house, there are no restrictions when choosing technology. Different options can be considered only depending on the chosen method of finishing the facade:

- Facing brick. This is a classic three-layer wall construction with flexible ties. Even when using polystyrene foam, a ventilated air layer is provided to ventilate water vapor and prevent the wall materials from getting wet.

- Wet facade. You can use mineral wool and polystyrene foam. The first option is preferable - ceramic bricks have higher vapor permeability than foam plastic. And according to clause 8.5 of SP 23-101-2004, the arrangement of layers should facilitate the weathering of water vapor to prevent moisture accumulation.

Scheme of a “wet facade” Source deskgram.net

- Ventilated facade. With cladding with wall panels or large-format porcelain tiles on the sheathing. The insulation is traditional for all suspended facades - mineral wool.

Scheme of a ventilated facade Source sk-optimus.com.ua

Wooden houses (logs or beams) are insulated exclusively with mineral wool using curtain facade technology.

For them, you can find examples of using polystyrene foam and plaster using the “wet facade” method. In this case, a ventilated gap is created between the wall and the foam boards using spacer sheathing. Although in this case the main advantage of the “wet facade” is lost - simplicity of design and installation.

Is there any harm to health during installation?

Work rules and safety equipment, as well as possible negative impacts on human health when working with stone wool, are regulated by the Interstate Standard “GOST 9573-2012 Thermal insulating mineral wool slabs with a synthetic binder.

Technical conditions". The very basis of the insulation (the natural species used) are safe substances, but resins containing phenol and formaldehyde in their composition are potential sources of danger to human health, while different researchers give completely contradictory conclusions on this matter. It is believed that thanks to a special production technology that ensures the neutralization of harmful substances, as well as their insignificant content per unit volume of insulation, stone wool is an environmentally friendly material.

Stone dust formed on the surface of the insulation has a negative impact on human health if it enters the respiratory tract. In this regard, when working with stone wool, it is necessary to use personal protective equipment - respirators, masks and protective gloves.

Work with stone wool is carried out in a respirator

How to calculate the thickness of insulation

If you look through SP23-101-2004 or a similar but later set of rules SP 50.13330.2012, you can see that calculating the thickness of the insulation is not so easy.

Each building is “individual”. When developing a project and approving it, such thermal calculations are made by specialists. And here a whole range of parameters are taken into account - the characteristics of the region (temperatures, length of the heating season, average number of sunny days), the type and area of glazing of the house, the thermal capacity of the floor covering, the thermal insulation of the roof and basement. Even the number of metal connections between the wall and the cladding matters.

But if the owner of a previously built house decides to insulate it (and the new standards introduced in 2003 are much stricter than the old ones), then he will have to choose between three parameters of the “standard thickness” of insulation - 50, 100 and 150 mm. And here the accuracy of calculations is not needed. There is a diagram that shows the equivalent dimensions of the thickness of different materials (in average form), the wall of which will meet the new requirements for thermal protection.

Only a house made of aerated concrete blocks with a thickness of 45 cm does not need insulation Source legkovmeste.ru

And then it’s simple. They take the thickness of a wall made of a certain material and see how much is missing from the standard. And then they calculate in proportion what thickness of the insulation layer of the outside wall of the house should be added. Taking into account that a wet façade also has a layer of plaster, and a ventilated façade has an air gap, plus the interior finishing of the façade walls, you can be sure of sufficient thermal protection.

And the issue of insulating the roof, floors and choosing good windows is decided separately.

It’s even easier to use one of the many online calculators. The figure here, of course, is approximate, but rounded up to the nearest standard insulation thickness, it will give the required result.

Features of the process of insulating a building from the outside

The materials from which the walls of permanent structures are erected can be different: brick, concrete, slag or aerated concrete blocks, wood, sandwich panels - these are just their main types.

Some of them do not require insulation at all: for example, sandwich panels. But other options need it to varying degrees.

Why do you need to insulate from the outside? Many people attribute this to the fact that if an insulating layer is installed inside a building, useful spatial volume is stolen from the interior.

This is partly true, but this is not the main reason. A critical parameter is where the dew falls.

A dew point forms on a surface where there is a temperature difference when pressure changes.

And if you install thermal insulation inside the room, it means that the walls of the building themselves will be cold, since the insulation will save heat inside the space and prevent it from reaching the enclosing structures.

Insulation from the inside is fraught with the fact that the dew point will form inside the building, most likely on the inner surface of the main wall, which is insulated with insulation

How to properly install insulation on a facade

Before installation, the facade must be prepared: cleaned of old finishes, removed dirt and dust, dismantled hanging elements of engineering systems, removed ebbs and canopies (you will still have to replace them with wider ones), remove signs, plates and façade lamps. Then the surface of the wall must be strengthened - cracks and chips must be repaired, crumbling areas must be cleaned, and a deep penetration primer must be applied.

Application of primer composition Source rmnt.ru

For reliable fastening of polystyrene foam or rigid mineral wool mats in a wet façade system, the wall surface must be as smooth as the unevenness can be smoothed out with an adhesive solution. If the height difference is up to 5 mm, the solution is applied over the entire insulation slab, with unevenness from 5 to 20 mm - along the perimeter and in the form of “cakes” on 40% of the slab surface.

The first row of slabs is mounted with emphasis on the starting bar, which also sets the horizontal level. The second and subsequent rows are placed with a vertical seam shift (at least 200 mm), leveling the surface of the insulation in the area of the joints so that the height difference is no more than 3 mm. When insulating the walls around the openings, make sure that the seams of the slabs do not intersect in their corners. Each slab is additionally secured with umbrella dowels at the rate of 5 pcs. per 1 m2.

Before applying plaster, the surface of the slabs is reinforced with fiberglass, fixed in the middle of a layer of adhesive solution with a total thickness of 5-6 mm.

The density of polystyrene foam is chosen to be 25-35 kg/m3.

Stages of work

First of all, before insulating the walls of a house internally, it is important to know that the dew point will change - the place where moist air turns into condensation.

Consequently, if you choose the wrong material or its thickness, then such insulation can worsen the condition of the walls: mold, mildew, or destruction of the partition will appear.

It is important! In order to avoid irreparable mistakes, it is better to entrust all calculations for choosing insulation, as well as installation work, to specialists from a trusted construction company.

Before starting work on wall insulation, certain rules must be followed:

- Remove old coatings to the base of the surface, clean, remove possible formations of mold or mildew.

- Treat the wall with an antiseptic and primer solution. At the same time, give each coating a chance to dry.

- When using polystyrene foam, plaster the surfaces with the placement of beacons, which will allow for a more even plane. Allow to dry for at least two days.

- Laying the material.

- Finishing the wall.

Video description

Visually about mineral wool insulation in the video:

Attention. In the “wet facade” system, the insulation is installed in only one (!) layer. A vertical surface made of two layers of “soft” slabs loaded with plaster behaves unpredictably, especially with changes in temperature and humidity conditions. Do not be fooled by arguments that the second layer of slabs overlaps the seams of the first and eliminates “cold bridges”.

The ventilated facade uses rigid mineral wool mats with a density of 80 kg/m3. If the surface of the mats is not laminated, then after attaching them to the sheathing, the surface is covered with either fiberglass or a vapor-permeable membrane.

The spacing of the lathing is chosen 2-3 cm less than the width of the mats. In addition to fastening to the sheathing, the insulation is additionally fixed to the wall with umbrella dowels.

The size of the air gap between the insulation and the cladding should be in the range of 60-150 mm.

Important. The size of 40 mm is standardized for non-ventilated air spaces.

To ventilate the layer in the cladding, inlet openings are installed in the base area and outlet openings are installed under the roof eaves. The total area of the holes must be at least 75 cm2 per 20 m2 of wall.

Ventilation grilles in the wall Source tproekt.com