Home » Building a house

Vladimir 03/28/2020

6374 Views

Most holiday villages, especially in the outback, far from large cities, are still not supplied with gas. Therefore, a gas cylinder at the dacha is a necessary thing. Especially where there are power outages. In this article we will try to figure out how to choose and correctly connect a gas cylinder. And also in what cases it makes sense to use it, and in what cases it is better to look for a cheaper alternative to gas.

Do-it-yourself cabinet for a gas cylinder - we make and install

Many people have to use gas cylinders for domestic needs, for example, owners of private houses or summer cottages. Cylinders are selected according to individual parameters - volume from 5 to 50 liters. This equipment is subject to a high level of danger, therefore it is necessary to comply with its storage standards. This material presents one of the safest ways to store and use reduced gas cylinders - a gas cylinder cabinet. We recommend that you pay attention to the cabinets that are presented in our catalog. They are inexpensive, impact-resistant, and meet all safety requirements: cabinets for gas cylinders

Turning on the oven

The procedure for igniting the burner inside the oven is more complicated than on the surface of the stove.

Often the view is blocked by a massive tray, and it is suggested to use only a small hole with access to the burner. This not only makes it difficult to start, but also makes it difficult to see whether the torches in the holes in the round base are fully lit. The safest way is the auto-ignition built in by the manufacturer, which provides a stable spark for the flame. The second highest risk are electric or pneumatic lighters with an elongated bell for supplying a spark. They protect the owner's hands from accidental burns in case of fire. The most dangerous methods include outdated wooden matches or a piece of paper rolled up into a ball.

You can light the oven with matches or a lighter, but it is safer to use automatic ignition.

Before turning on a new oven, it must be wiped and dried.

If the stove has already been used, it is important to completely clean the internal surfaces of burnt food residues so that additional combustion of carcinogenic substances does not occur when heat is supplied.

Why do you need a closet?

It is strictly forbidden to keep a container with compressed gas in the house, due to the low level of ventilation in rooms with low ceilings (2.3-2.5 meters). Therefore, the best option for installing the cylinder is the street. However, the container must be protected from sunlight, exposure to bad weather, various damage, as well as from possible theft. For this purpose, you can build a special cabinet for a gas cylinder, which will also eliminate the negative consequences if the cylinder explodes.

Precautionary measures

Household gas is very dangerous. The main threats posed by propane are:

Reminder about domestic gas

- Fire hazard.

- Unsuitable for breathing.

- Explosion hazard when the maximum concentration of propane in the air is reached, as well as when the temperature in a closed volume rises sharply.

- During a gas leak, the temperature drops sharply and frostbite is possible.

To preserve the life and health of people and their property, precautions should be taken:

Rules for using gas

- Avoid proximity to open flames and heat sources.

- Avoid the presence of other flammable materials in the work area.

- Eliminate the presence of nitrates and perchlorates near gas equipment due to their chemical activity.

- Do not use the reducer for a propane cylinder if it is damaged or leaking.

Do-it-yourself cabinet equipment

Before you start designing, you need to decide on the model:

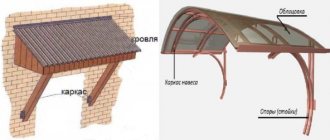

A double-cylinder cabinet is especially convenient because it allows you to easily switch the main container to a spare one and ensure a constant supply of gas. Construction work begins with determining the required dimensions, after which a frame is equipped from metal corners, and then wrapped in sheet metal. A hole is cut in the side or back of the cabinet for the hose that supplies fuel to the room. The hole is made in the direction of the highway.

The structure must be equipped with holes for ventilation and a lock. It is best to place ventilation holes at the top and bottom, but you can also place them on the sides. The diameter of the hole for ventilation is also very important - if you drill with a 10 mm drill, then the distance between them should be 7-8 cm, with a 20 mm drill - 10 cm. Another method of ventilation is a unique roof structure – “on legs”. It looks like this: using a grinder, cut out longitudinal strips or leave a small gap of 20 cm.

The bottom of the cabinet is made of slats for greater ventilation. The cylinder can be secured using chains, which ensure a stable position of the container. Door hinges are welded from the inside, and lugs are made on the door itself for a padlock.

Cabinet legs are made from high-strength corners or metal profiles. The height of this part should be 10-15 cm. All types of work can be done using several devices:

Standard dimensions of the finished product: height 1m 25 cm, depth 40 cm, width 1m 25 cm.

Jet

Liquefied gas is different from natural gas. Therefore, jets installed on gas stoves for apartments or private houses will not work normally. Because bottled gas reaches the stove at higher pressure. And the injectors (nozzles) for it should have a much smaller passage hole.

You can purchase a jet with a smaller nozzle diameter for liquefied gas in a specialized store. And replacing them is easy. It is necessary to unscrew the old nozzles from the burners and install new ones in their place. The problem can only arise with the plate, the design of which requires removing the top panel from it in order to get to the jets.

Materials for making a gas cabinet

Since the cabinet should not be made of flammable materials, sheet metal 0.8-1 mm thick is used for this purpose.

To avoid corrosive processes, the structure is coated with powder paint based on polymers and polyesters; ordinary paint for metal products is also often used. Installation parameters for gas cylinders and cabinet

The fuel container should not be located on the sunny side of the building, so the cabinet is installed on the north side to prevent the structure from overheating. It is best to set the distance between the stove and the cabinet to a minimum; for this, the box itself should be located near the kitchen wall. It is better to choose a supply hose that is metallized, of high quality and made specifically for gas equipment. It is better to remove the location from window and door openings by about 5 m. A prerequisite for the design is a foundation, and the base must be at least 1 m.

Source

Norms

Fuel containers should not be stored on the sunny side of the house. Therefore, the cabinet is placed from the north. This way the structure will not overheat.

Other standards for storing gas cylinders in cabinets are as follows:

- The cabinet is separated from the stove at a minimum distance. The box stands against the kitchen wall.

- Gas hose – high quality, metallized.

- The distance of the cabinet from the openings is 5 m.

- Availability of foundation. The minimum base parameter is 1 m.

- The distance between cabinets for storing gas cylinders is 5 m.

Item 5 is usually applicable for large sites, for example in industry.

Connecting a gas cylinder to a kitchen stove

Before performing work with gas equipment, it is necessary to thoroughly study the regulatory literature on this issue, as our regular author Andrei Dachnik did. Otherwise, such work should be entrusted to a certified specialist or contact the gas service.

Hob installation

The panel was placed in the center of the ventilation duct laid in the wall, to which the kitchen hood will be connected. It was planned to install an independent oven under the countertop. The opening for the panel was cut out by first drilling holes in the corners into which it was easy to insert an electric jigsaw blade. Since our kitchen has a chipboard countertop, we protected the edge of the opening from water and swelling by applying a layer of sanitary silicone sealant to it. Sealing tape was glued to the edges of the opening under the slab.

The gas injectors on the panel needed to be replaced as it was set to mains gas. Modern manufacturers include a set of nozzles with holes of various diameters in the delivery package of their products.

Correct placement of the gas cylinder

There are also a number of requirements for placing gas cylinders on the street.

Thus, they must be located in a steel cabinet, grounded and protected from corrosion, closed from entry by unauthorized persons, rigidly fixed in a vertical position, with ventilation holes at the top and bottom. Gas cylinders must be placed on a solid base that prevents them from tipping over, or must be secured vertically.

Cylinder cabinet #8211 installation

The cabinet for cylinders should not be located on the main facade of the building, but in a place where heating of gas cylinders above +45 C is excluded.

We purchased a ready-made steel cabinet for two 50-liter gas cylinders. It must be said that the commercially available samples are made of thin metal and have poor quality painting. We had to completely repaint the cabinet we bought.

To install the cabinet, we prepared a reinforced concrete foundation with grounding. They did this at a blank wall on the north side of the house, at the opposite wall from the entrance and the main facade. We secured the cabinet to the foundation using dowel nails, and then connected the grounding. Additionally, the cabinet was attached to the wall of the house to prevent it from being deliberately tipped over or stolen.

Bellows pipe connection

All we have to do is lay a gas pipeline from the cylinder to the gas hob. We used a Kofulso non-breaking steel bellows gas pipe in a polymer shell for the gas pipeline. It is protected by thermal insulation and a polymer corrugated sleeve, laid underground before entering the house. Underground installation will protect our gas pipeline from excessive cooling in winter. They introduced the pipe into the house directly in the kitchen - next to the hob.

The bellows pipe is connected using a special fitting with a dielectric gasket, which is required to protect against accidental occurrence of an electric arc. The second reason for its use is protection against the transfer of static electricity to gas cylinders.

When laying a gas pipeline externally in a room, a shut-off valve must be installed in front of the gas stove. Also, to increase safety, you can install a thermally activated valve and a valve that shuts off the gas supply when the critical concentration of carbon monoxide is exceeded. We installed them in a gas cabinet using Kofulso fittings with dielectric gaskets. Our gas panel is also equipped with a system for automatically shutting off the gas supply when there is no flame in the burners.

General recommendations

- Check the condition of the supply devices (flexible hoses), which should not be twisted, stretched, or have direct contact with household electrical appliances;

- Keep any gas equipment clean;

- In houses on the ground floors, it is prohibited to wall up or otherwise close the gas riser taps;

- Do not prohibit gas service workers from inspecting and repairing gas appliances and gas pipelines at any time of the day;

- Ensure good ventilation of the room where gas equipment is used;

- It is prohibited to use gas appliances for purposes other than their intended purpose;

- Changes in the layout, in the places where gas appliances are installed, are not allowed without agreement with the relevant organizations;

- Turn off automatic safety and regulation, use gas if gas appliances, automation, fittings and gas cylinders are faulty, especially when a gas leak is detected;

- Use gas when the density of masonry, plaster (cracks) in gasified stoves and chimneys is damaged. Use heating stoves with ovens and open burners for cooking. Unauthorized installation of additional dampers in chimneys and on flue pipes from water heaters;

- Use gas after the expiration of the certificate for checking and cleaning smoke and ventilation ducts.

IMPORTANT: the use of liquefied gas cylinders in apartments can lead to an explosion, fire, and in the worst case, destruction of the house

Household gas and causes of explosion

REMEMBER: the design, installation, and commissioning of gas equipment must be carried out by specialized organizations that have a license for this type of activity.

It is strictly PROHIBITED to independently install and put gas equipment into operation.

What can you do with a gas cylinder?

Section: Useful devices

Gasification of the population is making itself felt, so many 50-liter propane cylinders turned out to be unnecessary. To prevent good things from going to waste, we offer a selection of devices to make life easier. What can be done with a gas cylinder - see below.

Before you make anything from a cylinder, you must follow safety precautions, since propane gas is very dangerous.

Open the tap and release the gas. This is done away from an open source of fire. Then, we put the empty cylinder on the ground, hit the tap with a sledgehammer, it breaks off at the place where it is screwed into the cylinder. Next, pour water through the resulting opening. Water fills the balloon and displaces the remaining gas. To prevent the smell of the mercaptan odorant, it is necessary to fill it with bleach or wash it with a solution of bleach. A very good result for weathering the smell of gas is obtained by calcining the cut cylinder over a fire until the paint burns.

Homemade products from a gas cylinder

Mobile compressor station - there are more than fifty rubber wheels scattered around the farm, which need air pumping from time to time. In order not to carry a cable and a compressor, it is easier to bring a cylinder of pressurized air.

The stationary compressor station is equipped with a gearbox for a maximum pressure of 2 atm - even children can easily pump up the wheels without fear of over-inflating.

With such a stove it is easy to heat the workshop in winter; it is also possible to dry and fry nuts and seeds. Maximum temperature +140 degrees above the burner, works around the clock with an external chimney.

It’s a pleasure to cook porridge for various animals on such a stove. This stove took two cylinders. Capacity 75 liters. Heating outdoors with wood in summer, gas indoors in winter.

Roller for gardening and compacting paths.

A compressor made from a refrigeration unit compressor and a gas cylinder as a receiver. It works silently. Produces a maximum of 4 atm. Stable at 1.2. It is quite enough to work with a spray bottle.

The most common thing made from a gas cylinder is a barbecue. Using several cylinders you can make a captilla. Learn more about how to make a barbecue from a gas cylinder. look on our website.

A large 50-liter cylinder gave birth to a small women's autoclave for 14 half-liter jars. Half-liter cans are placed in three rows of seven or eight cans per row, depending on the size of the cans themselves. Liter - five pieces in two rows. Good owners place fabric at the bottom of the jars and do not use partitions between the rows - the jars practically float in an autoclave filled with water.

Boilers that are connected to the heating system are in great demand among the thrifty population. How to make a boiler or heated shower from a gas cylinder, see more details on our website.

It is easy and simple to transfer the gas cylinder to the potbelly stove. There are two designs of such potbelly stoves, when the cylinder is located horizontally and, accordingly, vertically.

Feed cutter from half a gas cylinder with an overhead engine. You can also combine a feed cutter with a corn cob sheller.

A collar from small cylinders will also come in handy. The protection for the sharpener is also from the collar of the cylinder.

Construction of a summer house in SNT. Part 30 - Installing a gas cabinet on two large cylinders on the street

Previously, I already described the process of replacing the jets in the Darina gas stove so that the stove could be used with bottled gas.

An empty cylinder weighs 15-16 kg. Filled - about 35 kg.

Dimensions - 1100x800x400 mm (HxWxD) 1.0 mm stainless steel

The box for gas cylinders was sold disassembled in a packed cardboard box.

— gas rubber hose 4 m (240 rubles) — GOST 9356-75 category III

— gas reducer — RDSG 1 (250 rubles)

- clamps - 12-20mm (30 rubles per piece)

— adapters from 1/2 thread to 9mm fitting

- 1/2 paronite gaskets

When I started assembling a cabinet for bottled gas, I really didn’t like the thickness of the material - it felt like tin.

Also, short centimeter screws with a flat head and a 5mm thread and simple nuts for it were used as fasteners for assembling this miracle.

There were no washers. I'm not even talking about locking and engraving washers.

The doors of this shield for gas cylinders are also hung on the sides with 5mm bolts - there are no hinges in sight.

The doors can be hung in any way: on any of the sides - for this purpose, corresponding holes are made in the doors.

The bottom of the box is solid, and there are ventilation holes on the side walls, on the doors and above the doors.

I also placed a small aluminum corner along the front edge of the resulting shelf to give the structure greater rigidity.

It turned out quite well.

A 6m corner was bought at the market and cut there into 3 meters - so I took it to the dacha in a sedan - inside the car from the front window to the trunk with the rear seats folded down is just over 3 meters.

These pins were driven into the ground (loam) using a previously made “stray” for hammering in corners with a hammer drill - I already wrote about this earlier.

There was no welding at hand, so I made all the fastenings with 5mm bolts.

The design is removable and can be disassembled if necessary.

— I drilled through holes in the protruding corners along with the 5mm cabinet and secured the drawer to the corners themselves.

— I cut a vertical hole in the back wall of the box with a margin for introducing the pipe from the cabinet directly into the house, so that possible soil movements would not bend the gas supply into the house.

— in the shelf that I additionally made in the box, I also drilled a hole so that the gas hose could easily pass to the cylinders.

The introduction of gas from a box with cylinders into the house will be written below.

How to check traction

A sufficient amount of air is required for complete combustion of gas. Draft is the directed movement of gas combustion products into a smoke or ventilation duct. Craving can be natural or forced. Natural draft occurs due to the difference in the specific gravity of gas combustion products and colder atmospheric air. You can check the draft in the smoke and ventilation ducts using a sheet of thin paper. 1. Place a piece of paper on the ventilation grille. If the paper is attracted, there is traction.

2. To check the draft in the smoke channels of boilers, attach a thin sheet of paper to the inspection window of the boiler or column. If the paper is attracted, there is traction.

Boxes for gas cylinders: why install?

Boxes or cabinets for cylinders are available in different capacities: from 5 liters in the minimum version, to 50-100 liters. Their main task is protection from the sun (direct rays that heat the cylinder) and precipitation, which can cause corrosion processes. It is also worth buying a box for an outdoor gas cylinder in order to regulate the ambient temperature, since for containers with propane, for example, it should not exceed 45 °C. Due to safety precautions, gas cylinders with a capacity of 50 liters or more are allowed to be installed only outside the house, so you can’t do without a cabinet.

Bellows hose for gas, advantages:

- The gas hose is manufactured in accordance with technical specifications and satisfies GOST regulations;

- The only one approved for use by government services;

- Component PVC coating provides the product with reliable protection. Polymers are highly resistant to aggressive environments and mechanical shocks.

- The gas supply line often remains undamaged, subjected to significant and sometimes critical loads;

- Manufacturers set a long service life for the product, more than 25 years;

- PVC protects against electrical influences of 1000 V or more.

- There are no regulations regarding restrictions during operation.

Boxes for gas cylinders: production and subsequent storage techniques

Box for outdoor gas cylinder 27 liters - most often used for installations in the country. Its shape and dimensions are strictly determined by production standards; it is painted, like other options, with powder coating and equipped with a straight or inclined lid. The lower part is made from a square pipe and gives it the shape of a lattice. It is mandatory that the doors of the cylinder box have special lugs for a padlock, and there is a hole for the gas hose on the back wall.

An outdoor gas cylinder box for transportation is most often packaged in a cardboard base, thick paper or film, so as not to

damage materials. First of all, it is important not to forget that it is better to store the gas cylinder directly outside any room, including a residential building, therefore, the box is installed outside. It has a fairly modern and aesthetically pleasing appearance, so it will not spoil the overall appearance, and thanks to its compact size, it will not take up much space and will not take up precious space, but will be able to save the house from damage if the gas cylinder does explode. The most important and indispensable condition that must be met when installing a gas box is to place it in that part of the site or building that needs to be gasified, where the rays of the sun are least likely to reach, that is, in the shade.

Making a box for an outdoor gas cylinder with your own hands is not difficult, since the design is based on a container made of sheet steel with a polymer powder coating applied to it. It is equipped with special eyes for installing a padlock; holes should be made in the side walls for ventilation. Assembling the box is very simple, it can be handled by a person who does not have special knowledge, both in the gas sector and in the installation and training of a builder, in just a few minutes.

The main tasks of the gas cylinder box:

Many residents of private houses that do not have a gas supply use two cylinders at once, one is used immediately, and the other is in reserve. Therefore, an outdoor gas cylinder box is not just another outbuilding, but an important part of safety that must be observed when working with gas and its mixtures.

Acquisition

The first question that arises is which cylinder is best to use.

Some people still use old Soviet-style steel tanks. Either because they were inherited from my grandmother, or because you can buy such a cylinder for pennies or even exchange it with your neighbor Uncle Vasya. But you shouldn’t keep such a monster in the house.

And not only for aesthetic reasons. Any metal, as you know, is susceptible to corrosion, and if the cylinder is already thirty or forty years old, you understand, no one can vouch for its reliability.

Such rarities belong in a landfill or in a museum, and not in a house where people live

In some states of the former USSR, for example, in Latvia, their use is generally prohibited or allowed after mandatory testing and certification. Therefore, we advise you to stop using such cylinders and replace them with modern, safer analogues.

Manufacturing materials

The manufacturing material used is sheet steel with a thickness of 1 to 1.5 mm. This may be a large thickness, but it leads to a significant weighting of the structure. To prevent corrosion, as well as to give the cabinet for gas cylinders a more aesthetic appearance, it is painted with polyester (or powder) paint. This painting provides good resistance to all atmospheric factors: temperature and humidity.

Propane cylinders are painted red, cylinders with other gases are painted in “their” colors; for example, oxygen is blue, helium is brown, and so on. Sometimes the cabinet is painted the same color as the cylinders in it. Warning signs are placed on cabinets with hazardous gases, and their names are written on cabinets with inert gases.

Gas for a generator: cheaper than gasoline, but still expensive

The same applies to the use of gas for electricity supply. Of course, a gas generator is cheaper to operate than a gasoline generator, but it still consumes a lot of fuel. When you connect a generator to a gas pipeline, that’s one thing, but when you use it with a cylinder, the gas again won’t last long.

Those who have used gas generators say that at a load of up to a kilowatt, the generator consumes 1.2-1.5 kg of gas per hour. That is, a 50 liter tank is most likely not enough for a day of continuous operation.

If you have a gas generator, you won’t be able to get by with just one cylinder either.

Therefore, this option can be considered as a forced short-term measure - the light has gone out, and you urgently need to charge the battery, turn on the refrigerator, etc. Constantly using a gas generator using liquefied gas is expensive, as is the case with heating devices. However, if you already have a need to purchase a generator (frequent power outages in your village), then it makes sense to get a gas one instead of a gasoline or diesel one.

Shape and dimensions

Existing cabinet models differ, first of all, in the height of the cylinders stored in them. Cabinet heights of 1 and 1.5 meters are considered standard, since a standard gas cylinder has a height of 0.96 or 1.37 meters. However, manufacturers do not adhere to such standards and the size of cabinets can vary widely: from 1 to 1.3 meters for low-height cylinders and from 1.4 to 1.5 meters for high cylinders. As a rule, additional space in cabinets is used to accommodate gearboxes and other equipment.

But as for width and depth, the requirements are more stringent. For one cylinder the dimensions of the “floor” are 0.43 by 0.4 meters, the cabinet for two gas cylinders has dimensions of 0.43 by 0.8 meters.

Thus, the design is a parallelepiped with dimensions ranging from 1x0.4x0.43 meters for one low cylinder to 1.5x0.8x0.43 meters for two high ones. A single cabinet can weigh up to 50 kg, and the difference in weight between a single and double product of the same model can reach up to 30 kg.

Scope of application

The technical and operational characteristics of polymer-composite gas cylinders provide them with great potential and an almost unlimited scope of application. This is an autonomous source of one of the most popular energy carriers in a variety of situations.

Cooking - both at a seasonal dacha or in a capital country house (kitchen gas stoves), and on a picnic or while traveling (gas grills and barbecues, mobile stoves).

In heating systems - a variety of home gas heaters, sauna stoves, outdoor heaters (trips to nature).

In construction and finishing - welding machines, heat guns.

In autonomous power supply systems - generators.

The ease of use of compact and presentable composite cylinders in almost all conditions is undeniable.

What to look for when choosing

Like any functional product, a cabinet for gas cylinders requires a comprehensive analysis from the point of view of consumer properties. Therefore, when choosing, you should be guided by the following rules.

Checking compliance with requirements for volume and number of storage locations

It is necessary to make sure that the declared characteristics of the cabinet for storing gas cylinders correspond to reality. This applies, first of all, to its capacity and also dimensions.

The volume itself may not mean anything, since there are several standard sizes of cylinders that differ in height. Therefore, for example, two cabinets of the same volume can be used to store different numbers of different gas containers. If you need a cabinet for two gas cylinders, you must immediately discuss this with the manufacturer or seller.

Compliance with required security features

The main purpose of the cabinet is to increase safety during cylinder operation. Therefore, it is necessary to make sure that the strength of the structure, in particular the wall thickness, meets the required standards (at least 1.0 mm). The hinges on which the door goes must be strong enough and not have any play or bending inward or outward.

The design of the moving parts (door and lock) must be such that it is difficult to break the door using a crowbar or crowbar or to “push” it inside the structure. This allows you to immediately test it not only for its strength during an explosion, but also for its resistance to hacking by intruders.

It would be a good idea to have additional safety features inside. For example, a special chain holding gas containers. The design of the lock should be simple and at the same time reliable. It should be difficult to open it without the use of special technical means.

Maintaining cylinders in working condition

The cabinet must protect the contents not only from intruders, but also from adverse environmental conditions. Therefore, it is necessary to make sure that these functions are performed in full and that the manufacturer has taken care of this.

Since almost all products are supplied disassembled (they are called: ShGR - collapsible gas cylinder cabinet), it is necessary to make sure that after assembly the functions of dust, dirt and moisture protection will be fulfilled. In this case, you need to check the quality of assembly of the cabinet for the gas cylinder, the degree of fit of its structural elements and the absence of possible cracks. An additional advantage will be the presence of rubber or silicone seals that prevent rattling in windy weather.

You should definitely make sure that the structure has a stand, that is, the level of the bottom wall does not lie on the surface, but is raised above it by several centimeters. A mandatory requirement is the presence of ventilation holes located in the floor or at the bottom of the side walls, but their location may vary: sometimes holes in the bottom are preferable to the side ones.

Durability and aesthetic issues

Since the cabinet is made of iron alloys, protecting it from corrosion is an important issue. Therefore, when choosing it, you should pay attention to the quality of the product’s painting. The metal surface must be covered with an even layer of paint, without any foaming or chipping. There should be no scratches or rust on it.

The cabinet is a rather bulky structural element; sometimes it may not fit well into the interior of a garden or cottage. This is especially true if the dacha has a cabinet for two gas cylinders. In this case, painting it in some color acceptable to the customer can help.

Source

Which gearbox to choose?

Gas stoves have built-in jets designed for constant gas pressure, while the pressure in the cylinder decreases with consumption. To normalize combustion, the cylinder is connected to the stove not directly, but through a reducer. Gearboxes for liquefied household gas are called propane and, as a rule, have a red or metallic body color.

The main characteristics of the gearbox - outlet pressure and throughput - must be selected to match the parameters of a single plate. If it is not possible to set the nominal pressure value, you should purchase an adjustable type reducer and set it manually. Also, adjustable reducers are directly indicated when using cylinders with a capacity of 20 liters or more, where the pressure drop is more pronounced.

For the use of propane for domestic purposes, gearboxes of the reverse operating principle are recommended. Due to the low pressure values of liquefied gas and the low difference at the inlet and outlet, the use of multi-stage gearboxes is economically unjustified. The only requirement is to use reducers provided for by their technical standard in conjunction with composite cylinders.

A separate nuance in choosing a reducer may be the temperature regime of the cylinders’ operation. The fact is that when liquid gas evaporates, an intense decrease in its temperature is observed. So, if initially the propane-butane mixture is at a temperature of -5...-10 °C, in the reducer itself its temperature can drop to the condensation mark, due to which the gas becomes liquid again and the reducer stops working. One way out of this specific situation is to use gearboxes with a built-in heating system.