If you decide to build a frame house for yourself, then its insulation is a very important aspect. It is necessary to decide on the material and methods of insulation. In order for the home to be warm and cozy during the cold season, in addition to the walls, the floor insulation in the frame house is required. In this article we will try to reveal some of the nuances and advantages of this or that material, as well as methods of laying and thermal insulation of the floor in the building being built.

What materials to install the floor from?

Before you carry out thermal insulation of the floor in the frame on your own, you need to find out what materials the floor sandwich in the proposed structure will be made from. Before deciding on the insulation material, you need to take into account the region in which the structure will be built, as well as calculate the expected load on the structure, in addition, determine the purpose of certain rooms inside the room.

The generally accepted material for making logs is coniferous wood, which is characterized by its low cost, long service life, and most importantly, reliability. Although if you use oak wood for logs, the service life will be much longer, but the material is also an order of magnitude more expensive.

Proper floor insulation involves the use of high-quality material for a frame house. Before purchasing lumber, it is imperative to make sure that the wood is properly dried; it is better that this is done in production, since if the material is damp, it can twist during operation, which will significantly affect the quality of the entire structure.

Laying floors in a frame house

Any construction begins with the need to carry out all the preparatory work. All lumber that will be used in the construction of the structure must be impregnated with the required antiseptics and fire retardants. This will help protect the structure from possible fire, and will also repel parasites and rodents.

In the case of using a columnar foundation, the preparatory work involves preparing the pillars on which construction will be carried out.

If the choice fell on screw piles as a foundation, then the preparatory work will begin with the very screwing of these same piles.

Use of logs in frame construction

Insulation of the floor in a frame house on a pile-screw foundation begins with the fact that it is necessary to tie this very foundation. This will allow the floor and foundation to be connected into one; such a structure will be much stronger and more reliable. Tying is done in the following order:

- A board for the bottom trim is laid out on a pile-screw base;

- The strapping beams are attached to each other at the corners of the building and are additionally fixed with staples;

- The timber is secured to the ends of the pile-screw foundation using bolts;

- After all this is done, you can immediately begin installing the logs. As a rule, a board with a section of 100x50 mm is used for this. The size is determined by the expected load on the floor covering. The logs are mounted using nails on the foundation frame. The logs must be impregnated with fire-fighting and antiseptic solutions.

Conventional frame construction involves installing a subfloor at the initial stage. Only after this can you begin installing partitions and walls. There is no need to carry out these works, and they are carried out only at the request of the owner or in accordance with architectural drawings.

Thermal insulation of the base of the strip foundation

According to experts, up to 15% of the heat leaves the house through the foundation. Reinforced concrete structures have high thermal conductivity.

In such a case, it is recommended to use EPS for insulation of panel houses, or rather the base, because It is quite difficult to protect mineral wool from ground moisture.

Extruded polystyrene foam has a fairly low water absorption coefficient. This material can simultaneously perform waterproofing functions.

How to insulate a panel house using the “wet facade” method, the sequence of installation work:

- The surface of the base is first cleaned of all contaminants, then, if necessary, leveled with concrete mortar and treated with a deep penetration primer mixture (specially designed for concrete surfaces);

- The slabs are fixed using construction adhesive and additionally mechanical fasteners;

- An adhesive composition is applied to the surface, reinforced with a metal mesh, which is pressed into the solution, and the base is leveled;

- The finishing cladding of the base is carried out. To do this, you can use tile material made from natural or artificial stone.

Rough floor

Insulating the floor in a frame house involves stuffing wooden slats in the spaces between the joists, onto which sheets of plywood or specialized moisture-resistant chipboards will subsequently be mounted. In order to maintain the height of the joists, which is necessary in order to place insulation of sufficient thickness between them, the rough covering can be mounted directly on the underside of the joists, in which case support slats are not required. When installing a subfloor in a frame frame, you should remember some nuances:

- Sheets of the rough coating are mounted in a checkerboard pattern;

- The thickness of the slabs or plywood to be used is determined depending on the spacing between the joists;

- The sheets are installed using specialized glue and self-tapping screws, this will prevent the floor from creaking when walking on it during operation;

- Fastening is carried out in the central part and along the edges, screws are screwed in at a distance of 150 mm from each other;

- When installing plywood, it is necessary to leave a gap not exceeding 3 mm between the sheets. To ensure that this gap is the same everywhere, you can use nails or screws of the required diameter. Upon completion of installation, they must be carefully removed.

How to insulate the floor in a house on stilts

In order for insulation to be carried out according to all the rules, you need to know exactly what the floor sandwich in the frame will consist of. The floor in a frame house usually consists of:

- Wood flooring;

- Vapor barrier layer;

- Insulation layer;

- Windproof membranes or films;

- Subfloor.

The entire structure of the frame structure is installed on floor joists, which, in turn, are installed on the foundation and on the frame. Usually the logs are equal in height to the floor sandwich, frame on stilts.

In harsh climatic conditions in a house on stilts, an additional layer of insulation is required; it must be installed even if the height of the logs does not allow for its installation.

The subfloor serves as a base, a kind of support for the installation of subsequent layers of the frame floor panel sandwich. This measure makes it possible to install the floor both from wooden boards and from other sheet material. The scheme for insulating the subfloor of a frame house involves fixing it to the underside of the joists, thus creating unique wooden containers, which, for the purpose of insulation, will be filled with heat-insulating material.

In order to prevent hot or cold air from entering the structure, a wind protection layer is located in the niches between the logs. It is also necessary to install a vapor barrier layer; it is better, of course, to use materials that prevent the penetration of steam, but do not interfere with air circulation, these include diffuse membranes.

The vapor barrier layer must be laid overlapping, with a covering of the lower layer of at least 100 mm. If a film is used for vapor barrier purposes, its thickness should be more than 300 microns; reinforced film is better suited for this. After this, the floor in the frame house is insulated by laying insulation.

After the insulation, we again lay a layer of vapor barrier. The need to lay this layer is very obvious; as a rule, with high humidity indoors, steam, in any case, will reach the sandwich floor of the frame, which will significantly affect the quality characteristics for the worse.

Installation of wooden flooring is the final process in installing the floor of a frame building. In addition to the base for decorative covering, such flooring will protect the elements of the floor sandwich from mechanical damage.

A few words about waterproofing and vapor barrier

Vapor barrier is a certain film that does not allow moisture to accumulate in the layer with insulation . In this way, the penetration of any vapor from the room into the various layers of insulation and back is blocked. Often used in conjunction with waterproofing.

Vapor barrier

Waterproofing helps to minimize the phenomenon of dew point . Blocks moisture from entering the insulation, usually used on the outside of the wall.

Waterproofing

We insulate the floor in the frame

Insulation is an integral material when installing the floor of a frame house, which, in turn, will allow you to establish an optimal microclimate indoors. If insulation is carried out using foam plastic or mineral wool, then it is more constructive to use cross-laying of the heat insulator.

Insulation with mineral wool

Mineral wool is a more versatile insulation material than others, since in addition to the fact that this material provides unique thermal insulation, this element also copes excellently with soundproofing tasks.

This material, as insulation, excellently resists the formation of fungus and is not susceptible to fire. In addition, mineral wool prevents rodents from forming nests in walls and floors, since the sharp fibers of the insulation repel them.

A frame house and floor insulation in it can be viewed in a training video in which this process is shown step by step from start to finish. Installation of mineral wool as insulation is carried out in protective clothing; compliance with this condition is mandatory, since mineral wool fibers negatively affect the human respiratory system, as well as the skin.

Mineral wool must be properly dried, since when the material is damp, the performance characteristics are much lower.

Polystyrene foam as insulation

The use of expanded polystyrene as insulation for a frame house is not entirely advisable for environmental reasons. This material contains a large number of harmful impurities. Among the positive characteristics, excellent sound and moisture insulation data should be noted.

In addition to environmental disadvantages, one should also note the predilection of rodents for building their nests in wall cavities insulated with foam plastic, and at high temperatures the material melts and releases toxic substances.

Benefits of mineral wool

In order for the house to be warm, it must be properly insulated with special wool or polystyrene foam.

Insulation of a frame building can be done with various materials, but mineral wool is a universal remedy.

It has the best qualities, is easy to install with your own hands and has an affordable price.

Insulation of a frame house with mineral wool

Use of sawdust and expanded clay for insulation

First you need to understand what expanded clay is. This is a raw material created by burning shale, subsequently forming pellets with low weight. This type of insulation also has excellent sound and heat insulation properties.

Insulating the walls, floor and ceiling of a frame house with expanded clay is the simplest method of thermal insulation; to do this, simply pour a layer of expanded clay on top of the windproof layer and level it well, aligning the lag along the edge. This type of insulation does not need to be adjusted to size, this material does not require any additional fastening, and also copes excellently with minor unexpected gaps and cracks.

When using sawdust as insulation, all work is carried out according to the same principle as with expanded clay, with one minor but very important difference - the raw materials for the insulation must be treated with protective solutions that prevent the occurrence of fungi, rodents and possible fire.

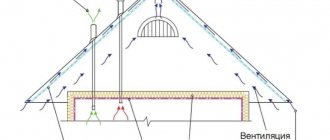

Thermal insulation of the attic room

Insulation of a panel house with an attic requires thermal insulation of the second floor. This can be done in two ways:

- Perform insulation along the contour of the attic room itself;

- Insulate the roof.

In any case, the entire plane of the truss structure from the roofing side, in front of the continuous decking or sheathing, is covered with waterproofing material (membrane). If the roof covering is metal, a technical gap must be left between it and the waterproofing layer to remove moisture from under the roof and allow condensation to drain onto the drip line.

Using penofol for insulation

How to efficiently insulate the floor in a frame house using an inexpensive material that meets all the requirements? Penofol is a heat-insulating material made of polyethylene, foamed in a special way, which is subsequently covered with aluminum foil on one or both sides. This type of insulation is manufactured in rolls with a thickness from 0.5 mm to 10 mm. Penofol is fireproof, hydrophobic and environmentally friendly material, which makes it very attractive among consumers.

It is recommended to use it in combination with other materials that provide hydro-, wind- and vapor barrier.