Choosing a cesspool as a storage tank for sewage allows you to significantly save on construction, but can lead to many serious problems. This includes an unpleasant odor on the site, contamination of groundwater, and clashes with neighbors. Therefore, before making a cesspool in a private house with your own hands, it is worth carefully studying this issue and understanding how justified such a decision will be.

Concrete drainage pit on the site Source domvdom.com

Choosing a location for a cesspool

Any, even a completely sealed cesspool, according to regulatory requirements, must be located at a distance from a source of drinking water (25-50 meters), as well as from garden plants and fruit trees (at least 3 meters). It is better to increase the distance if you choose a cesspool without pumping with a drainage layer instead of a bottom, and to intensify the process of decomposition of inclusions, not biological compounds, but chemicals are used. A distance from the house (at least 5 meters) is required not only for sanitary and hygienic reasons, but also to prevent soil shedding.

Location of sewerage on the site

Don’t forget that the structure will still need cleaning at least once every few years, so you should place it so that a sewage disposal truck can drive up to it. At the same time, according to established standards, the distance from the main road must be at least 2 meters.

Another important nuance: If the terrain of the site is not level, the cesspool should be installed in the lowest place.

Video description

Video about how an overflow septic tank works and works:

- The distance between the 1st and 2nd chambers is maintained at about 1 meter.

- At the site where the receiver is installed, a sand and gravel cushion is poured. Finally, a waterproofing layer is laid.

- At the location of the filtration well, the same bedding is performed, only instead of waterproofing, a thick layer of gravel is laid.

- The first chamber is being installed - a reinforced concrete slab is installed, and reinforced concrete rings are laid on top of it. The outer surface of the structure is covered with a layer of waterproofing, and the rings themselves are fastened with mortar and resin.

- Rings for the 2nd tank are installed in a similar way - only without a bottom.

- An overflow pipe is installed at the top of the tanks at a given slope.

- Finally, slabs with hatches are installed on both chambers, and the pits are buried with soil.

Note! Each tank, regardless of its purpose - both storage and overflow - must be equipped with convenient hatches. Since during operation the system must be periodically serviced.

Calculation of volume and selection of materials

Sanitary standards require that a cesspool without pumping have a volume of no less than the three-day water consumption rate for all inhabitants of the house. It is generally accepted that a person needs 200 liters of water per day, including consumption for drinking and cooking, washing hands, showering, etc. Thus, the three-day norm will be 600 liters. To calculate the minimum permissible capacity of the treatment tank, it remains to multiply this number by the number of people living in the house.

It remains to be clarified that this refers to the total volume of all chambers during multi-stage cleaning, although the first tank in this case should be larger than the others - approximately 2/3 of the total capacity.

When installing a treatment system in a country house where people do not live permanently, the volume of the pit may be less than the standard, since there is no constant flow of wastewater.

A do-it-yourself cesspool without pumping for a summer residence can be made of various materials:

- bricks,

- monolithic concrete (the solution is poured into the formwork),

- concrete rings,

- plastic eurocubes, etc.

Septic tanks of our own production

Quite often, a cesspool is built with one’s own hands for a summer residence, as well as for a private house. The strength of this rather complex system is the ability to carry out deep waste treatment. At the same time, they are processed into fertilizer, which is then used to enrich the soil. The complex most often consists of two or three chambers. The first of them is intended for liquid accumulation and primary mechanical cleaning. After this, special bacteria come into play, which leads to complete recycling of hazardous waste.

Using the overflow principle in constructing a drainage pit in a private home allows you to achieve outstanding results. The water inside the system is purified so well that in the future it can be used for economic and technical purposes - watering the garden, washing surfaces and cleaning areas. Arranging a drainage pit with an overflow will require considerable financial and physical costs. Old car tires are often used for this (the main thing is that they do not have holes). Given the light weight of the rubber, the construction of a solid foundation in this case is not required. Usually a compacted cushion of crushed stone and sand 30-40 cm thick and a cement screed 10 cm high are installed.

Recommendations on how to equip a cesspool from homemade septic tanks:

- A good way to increase the volume of a tank constructed from tires is to cut off their sidewalls.

- A concrete pipe is installed inside the finished tire trunk in a strictly vertical position. A building level is used for this. It is desirable that it be 2 times smaller in diameter than the tire size.

- The pipe is mounted so that its upper cut is 10 cm below the mouth of the rubber well.

- Concrete is used to fill the bottom of the pipe. As a result, you need to get a monolithic concrete cylinder. It is equipped with a hole at the top for infiltration and for an overflow pipe.

- The sewer pipe is inserted into the container. Areas where the vertical and sewer pipes are connected to each other must be sealed.

Installation of a cesspool made of monolithic concrete

As an example, we can consider how a drainage pit is built without pumping from monolithic concrete. Such structures are strong and durable, and when the walls are treated with special compounds, they become waterproof. The installation of such a structure is somewhat longer than when using concrete rings, since it takes time for gradual hardening, but it has certain advantages:

- easier transportation of materials,

- no need to use lifting equipment (it is impossible to lower heavy rings into the pit manually).

Advice: It is better to build such structures on light soils to allow purified water to drain through the bottom of the second chamber.

Once the optimal volume of the structure has been determined, the issue of its depth, which determines the capacity along with the surface area, must be decided. There are some restrictions in this regard. The sewer pipe is located at a depth of at least 1 meter underground in order to avoid freezing during the cold season. Taking into account the diameter of the pipe itself, the need for an indentation from the upper edge of the container to the point of its entry and the reserve for installing the lid and backfilling the structure with soil, the depth of the pit can be up to 3 meters, but no more.

A two-chamber septic tank is much more efficient than a single-chamber one. When installing a cesspool, the chambers are made adjacent, that is, the pit is divided into two parts, and the partition is also made of monolithic concrete.

Sequence of construction work

Concrete cesspool without pumping - the device diagram assumes the presence of formwork for pouring cement

In essence, a cesspool without pumping is more of a septic tank than a simple cesspool. The operating principle of a septic tank is described in detail in a separate article.

Read about the construction of a septic tank using reinforced concrete rings on this page of the site.

You can find out where and how a vacuum sewer pump is used by following the link https://okanalizacii.ru/sistemy/elem-i-oborud/vakuumnyj-nasos-dlya-otkachki-kanalizacii.html

There are various ways to improve the performance of a structure during construction.

- Covering the inside of the cesspool walls with a waterproofing layer (homemade bitumen composition, special mastic or primer) will increase its sanitary safety. Concrete in its “pure” form is not a completely moisture-proof material. The coating can be done on both sides, however, to be able to apply it to the external surface, it will be necessary to dig a pit, which will have an area much larger than necessary, which will significantly increase the labor intensity of the work. For external waterproofing, a polymer film is often used, lining the pit with it before installing the walls and partitions.

- The strength of floors and vertical structures can be increased using the principle of reinforcement. Ready-made metal reinforcing mesh, broken brick or scrap metal can be used as reinforcing elements.

Typical reinforced concrete sewer well

A standard design of reinforced concrete sewer wells, depending on their purpose, was developed back in 1984 by the Central Scientific Research Institute for Standard and Experimental Design.

It is the last album that is of interest to us. It presents calculated data for most types of wells that are of interest to owners of suburban areas.

Such information is truly invaluable for a master who has decided to independently build both a septic tank from reinforced concrete rings and an ordinary well responsible for the water supply of the site.

Components

The struggle for the unification and manufacturability of manufactured products has led to the fact that the “assembled” reinforced concrete well has at least five structural elements:

- concrete rings, the main ones, making up the frame of the entire structure;

- rings are dimensional, additional, with a height of 10 to 30 centimeters. Used to accurately select the required well height;

- concrete base or bottom. Depending on the manufacturer, it can be either reinforced concrete or simply concrete. Such liberties in manufacturing are allowed, since this element does not bear significant mechanical loads;

- well neck with hatch. It is used when using reinforced concrete rings with a diameter of two meters and above;

- reinforced concrete slab, with a hatch, for wells of “normal” sizes.

The combination of the above elements makes it possible to bring to life the most daring plans of a novice “homemade artist”.

Assembly of well elements

As a rule, it takes place in a pre-prepared pit and begins with preparing the base for the first ring. Reinforced concrete structures are installed one on top of the other and fastened together with a Euro-lock (grooves of a certain shape) or brackets made of steel reinforcement, with a diameter of 10-20 millimeters.

This operation is necessary to increase the stability of the well shaft to possible displacements of soil layers, the so-called “quicksands”. The concrete bottom, with a diameter slightly smaller than the reinforced concrete ring, is laid in the next line.

All that remains is to seal the seams using special mortars.

How often should a septic tank be pumped out?

The use of a septic tank is considered the optimal solution when arranging an autonomous sewage system for a country house. Such a treatment facility can easily cope with the collection and processing of liquid waste. At the same time, insoluble compounds gradually accumulate in the sedimentation tank, which have to be removed from time to time.

Independent removal of liquid waste is used quite rarely, given the complexity and danger of this activity, as well as the need to dispose of pumped out wastewater. Therefore, in this situation, it is more advisable to use the services of professional vacuum cleaners. On average, a car is called 1-2 times a year. In this case, the frequency of pumping depends on factors such as:

- volume and model of septic tank;

- number of permanent residents;

- intensity of sewerage operation;

- composition of household waste.

Local sewerage system with wastewater treatment

In this case, ready-made septic tanks are used. They are installed in prepared pits. The main function of such structures is to collect and purify contaminated water.

Septic tanks can be one-, two- and three-chamber. Each of the compartments solves different problems.

The wastewater passing through them is first purified naturally (sediment sinks to the bottom), then goes through the stage of biological treatment, then ends up in a drainage well or filtration fields (equipped according to the principle of drainage). Here the water is purified to 90-97% and can be reused.

Operating principle of a sewage disposal machine ↑

The main elements of any sewage disposal machine are: a reservoir (tank) for transporting liquid, a vacuum pump, a pipe for pumping water from septic tanks, sewer wells, drainage systems of car washes, natural reservoirs, etc. The operating principle of such equipment is as follows:

- One end of the pipe is connected to the machine, and the other is lowered directly into a container of liquid.

- Using a vacuum pump, water mixed with sludge is pumped into the tank. The process continues until the septic tank is completely empty or until the tank is full.

- Disposal of reinforced waste products is carried out in strictly designated areas, taking into account environmental standards.

Theoretically, the transport tank and pumping equipment can be installed on any vehicle chassis that meets the technical requirements. In Russia, as a rule, GAZ, KamAZ or ZIL are used for such purposes.

The maximum distance within which water can be drawn depends on the length of the pipe (hose). The standard length, regulated by the manufacturer, usually varies between 6-15 m. By individual order, this parameter can be increased to 25 m. Some sewer trucks use additional hoses, which allow increasing the length by another 5-10 m. However, even this is sometimes not possible enough to clean a septic tank located at a great distance from the roadway. In this case, additional measures will be required from the owners of the site.

Cost of construction work

When determining costs, it is necessary to understand that installing a small drainage pit is not economically feasible. When calculating the cost, it is best to consider a size of at least 3,000 liters. It is recommended to analyze the parameters:

- costs for the selected device type;

- prices for employee services.

For a better understanding, you should look at the situation using an example. The calculations include work:

- A complete set of components required for construction (including the preparation of concrete mixture, waterproofing and hatch).

- Delivery (taking into account the distance to the destination).

- Digging a pit and then backfilling it.

- Concreting the bottom.

- Installation work.

The approximate cost of the work will be 30,000 rubles.

Installation of a pipe for pumping water from a septic tank ↑

In order not to depend on the length of the sewage hose, a pipeline is laid from the treatment plant to allow the removal of wastewater. In this case, the pipe for pumping out of the septic tank must correspond to a certain type and technical parameters.

Why you can’t use pipes for internal sewage ↑

During the process of pumping out liquid, a negative pressure or, in other words, a vacuum is created inside the pipe. At high vacuum, the pipeline tends to compress, and in this situation, the reliability of the system will depend on the strength of the material used and its suitability for working in such conditions.

Conventional gray sewer pipes, which are used for indoor installation, have a wall thickness of 2.2 mm, which is insufficient to work under pressure or vacuum conditions. Therefore, such a pipeline is used exclusively for non-pressure systems.

So, what kind of pipe is needed for pumping out a septic tank? For such purposes, you should use special pressure pipes with increased wall thickness or an orange PVC pipeline, which is intended for outdoor placement.

Correct pipe diameter for pumping concrete waste ↑

The diameter of the pipeline must correspond to the size of the suction pump hose. Theoretically, the size of the pipe for pumping water from the septic tank can be smaller. However, it should be borne in mind that in this case the pump will need more effort to create the required pressure, and it will work with increased load.

Since the diameter of the suction machine hose is usually 100-104 mm, it is advisable to use a 110 mm PVC pipe. The interpipe space can be covered with a wet rag or an adapter can be used to seal the pipeline and hose.

Installation technology ↑

Pipe laying must be carried out taking into account the following rules:

- The pipeline is laid at a shallow depth from the septic tank to the roadway. The slope is towards the septic tank.

- The pipe cuts into the septic tank at a depth of about 1 m and, using an angle, turns down, resting with an oblique cut (45°) on the bottom.

- Exit to the street is realized using a 90° corner, which is located in a small pit near the intended entrance of the sewer truck.

Such a system will make it possible to remove concrete waste even when the septic tank is significantly removed from the roadway. In this case, the pipeline does not need to be buried below the soil freezing level. Firstly, it is filled with liquid only during the pumping process, and secondly, pipes for external sewage can easily withstand low temperatures.

This article provides general recommendations for installing pipes for removing liquid waste. If there are specific operating conditions for an autonomous sewer system, it is better to additionally consult with specialists.

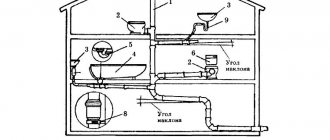

Construction of an independent sewer system

Diagram of a homemade brick septic tank.

To speed up the work, the option of installing a ready-made storage tank, for example a septic tank made from Eurocubes, is often chosen. However, a structure built with your own hands from brick will be cheaper.

A diagram of such a design:

- digging a hole in the ground;

- the walls and bottom are reinforced with bricks;

- a sewer pipe is installed on the side under the soil layer, it is located at a slight angle to speed up the movement of wastewater;

- the structure is closed with a lid and a hatch is provided for maintenance;

- in the upper part of the pit (in the side wall) there is a hole for connecting the ventilation duct.

A structure with a filter base is built according to the same scheme. However, in this case, a crushed stone cushion is formed at the bottom. There should not be a hard bottom that ensures tightness, as in the first case.

When choosing a finishing material to protect walls from wastewater, you need to take into account the properties and degree of strength of the products.

For example, it is not recommended to use silicate or porous bricks. Such material will absorb moisture, which will not only lead to its destruction, but will also cause the contaminated liquid to spread outside the storage tank.

The best option for a sewer structure is baked brick. It is durable and therefore can withstand the forces of soil heaving. In addition, baked clay brick is not a material with a porous structure. For this reason, it is better resistant to moisture.

If you plan to install drainage at the bottom of the pit, use a multi-layer structure: a layer of soil, sand, gravel or crushed stone. The recommended distance of the filter base from groundwater during the rainy season, when its level rises to its maximum, is 1 m. Sometimes holes are left in the walls of the well during laying, which will improve the filtration properties of the structure.

Digging a pit

Excavation of soil on the site is carried out in accordance with previously made calculations. Moreover, between the outer surface of the brick structure, which will be erected in the future, and the walls of the pit, a gap of up to 50 cm is left on each side.

If this is not done, the storage volume will decrease, since brick walls will have to be moved.

This measure allows for waterproofing on the outer sides of the structure. Even if baked brick is used, the structure is protected from prolonged contact with moisture. This helps to increase its service life.

Preparing the base of the container

The foundation of a sealed structure must be strong. For this reason, reinforcement is performed, and drainage is additionally arranged. If you skip one of the stages, the strength of the cesspool will decrease.

Instructions for making the base:

Installation diagram of a septic tank with a sand and gravel filter.

- A sand and gravel cushion is formed at the bottom of the pit. The total layer thickness is 200 mm. The sand is carefully compacted, which reduces the risk of subsidence of the base during the process of pouring and drying concrete. Gravel should also be compacted whenever possible (it consists of large fractions, so such material is more difficult to compact).

- The base is waterproofed. To do this, roll durable material, such as roofing felt, is placed at the bottom of the pit. It is laid with an overlap. Thanks to this, cement laitance will not get into the ground when filling the hole with mortar.

- A pre-prepared frame of steel rods with a diameter of 8-10 mm is laid on top of the roofing felt. It is recommended to use flexible strong wire for fastening. Welding will cause a deterioration in the properties of the material, resulting in a decrease in the strength of the structure. The cell dimensions of the reinforcing mesh are 100x150 mm.

Concrete bottom casting

To prepare the solution, use cement grade M300 and higher. Due to this, the strength of the structure increases. The prepared multilayer base is poured with a layer of concrete up to 150 mm thick. This is enough for the cesspool to withstand the impact of a large volume of wastewater.

Installation work can continue when the concrete has dried. If there is no time to wait 28 days, they move on to brickwork after 7-10 days.

During this time, the solution will set and harden enough to withstand a significant load without the risk of loss of properties.

Walling

In most cases, load-bearing structures are constructed using half-brick technology. For large pits, more reliable walls are erected: 1 or 1.5 bricks. To strengthen the structure, after completing the construction of the vertical partitions, the space between the storage tank and the walls of the pit is backfilled. A mixture of sand and cement is used.

There is no need to prepare the solution. It is enough to wait until sedimentary moisture begins to release, helping to strengthen the cesspool. The desired result is achieved when the cement-sand mixture is completely moistened. The result is a monolithic structure that will withstand the load exerted by wastewater even when the storage tank is full.

Application of waterproofing

Work to protect brick partitions from moisture is carried out as the masonry is completed. It will not be possible to protect the surfaces after construction is completed due to the small distance between the storage tank and the walls of the pit.

Coating and roll materials are used for waterproofing. Bitumen-based insulation is the most common. They use mastics and roofing felt.

It is recommended to cover the cesspool with coating-type materials. Roofing felt will not last long in direct contact with monolithic walls made of a moistened mixture of cement and sand. It is permissible to combine waterproofing materials, but this will lead to an increase in the cost of the structure. The sand and cement mixture used for backfill does not need protection. On the contrary, it is necessary to ensure access of moisture to this layer of material. Only under such conditions is it possible for the composition to harden.

Finishing the walls of the cesspool from the inside

Waterproofing a brick septic tank must be done using water-repellent materials.

It is recommended to use plaster compositions made from materials with suitable properties. Thus, preference should be given to mixtures with moisture-resistant properties.

But this waterproofing method is not reliable enough, given that the plaster layer will be affected by water in the existing storage tank around the clock.

For this reason, liquid glass is added to the mixture at the preparation stage. A potassium or sodium composition is suitable. This component improves the properties of the plaster.

However, all possible methods should be used to protect the internal walls due to the high humidity inside the drive. For this reason, the surfaces of the structure are additionally ironed with cement.

Covering the drain pit

From above, the pit and brick structure are closed in different ways:

- concrete slab with a hole for a sewer hatch;

- a wooden shield, to protect it from water, it is covered with roofing felt, the surfaces are pre-tarred.

A layer of thermal insulation material helps to reduce the outflow of heat from a structure in the winter season. It is recommended to use polystyrene foam for this purpose.

However, such measures do not always help prevent freezing. It is necessary to additionally use a layer of soil as a thermal insulation material. Soil is laid on top of a concrete slab or wooden panel. The layer thickness should be 150-500 mm.

How does a cesspool work?

A cesspool is a one- or two-chamber tank. The device is designed to facilitate the removal of particles heavier than water; heavy waste settles to the bottom, thereby creating a layer of sediment. The sump is also designed to hold particles lighter than water, which float to the surface and are stored in the container, creating a sump layer. In addition, for approximately two to three days, the effluent sits in a pit where the organic elements biodegrade in the absence of oxygen into less complex compounds. This decomposition process is slow and largely inefficient because the pits are so cold and the anaerobic bacteria need higher temperatures to effectively decompose the runoff's organic material, thereby reducing the need for biological oxygen.

Anaerobically treated wastewater exits the cesspool and is sent to additional treatment facilities or distributed to a soil absorption zone. The retention of heavy (dissipated) and light (floating) solids slowly fills the pit with heavy sediments from bottom to top and top to bottom. When there is no longer room inside to store these trapped particles, they begin to come out as runoff and clog the earth's absorption area.

In pits equipped with an outlet filter, the device will help protect the absorption area, but it will increase the volume of particles captured and stored in the sump. Therefore, it is important to periodically pump the tank to remove partially decomposed organic matter.

Since the wastewater disposal system is used, waste continues to accumulate in the cesspool. Properly sized pits are large enough to safely store up to three years of waste. As the volume filled with sludge increases, wastewater is retained in the tank for less time and the waste disposal process becomes less efficient. If too many particles accumulate, large amounts of solids will enter the soil absorption field, causing system failure (especially older systems that do not have outlet filters). To prevent this from happening, the pit must be pumped out periodically.

Options for improving drainage

After installing the receiver, protruding edges of the necks with covers remain above the ground surface. Currently, many garden design solutions have been found that will help disguise a cesspool.

Ready solutions

Suitable for pits that require constant pumping. The main rule is a bright camouflage with many decorative elements. The cover requires weekly removal, so you can take advantage of design solutions and lightweight acrylic stone structures.

Lids are produced in standard sizes. Materials used in production:

- metal;

- plastic;

- rubber.

The advantages of using ready-made solutions in the garden:

- variety of materials;

- weigh no more than 10 kg;

- fit perfectly into any style.

This method is suitable for a hatch whose neck is located near the yard next to a path made of tiles or stone.

Unusual decor

An ordinary rubber hatch can be turned into a unique design work. The main condition is that the top part must be absolutely smooth. These lids are also made of plastic.

If your drawing skills have not achieved the desired result, then you can use stickers. How to make an unusual decor:

- You will need to choose a sticker that is protected from moisture, otherwise the decor will look unattractive.

- Carefully stick the film and smooth it over the surface so that no air remains inside.

Another solution is to decorate with regular vinyl film.

Pros:

- a budget option;

- There are many options for designer decor;

- you can easily do it yourself.

Instead of stickers, also use stencils to apply patterns. You will also need spray paint or markers to mask scratches on the car.

Fake diamond

Necks can be decorated with voluminous lids made of non-standard materials. For example, artificial stone made from acrylic resins with the addition of crumbs or quartz.

What are the advantages of a decorative item:

- the stone does not react to exposure to sunlight and withstands temperature changes;

- lasts for decades;

- products of any shape and volume are created;

- wide range of color solutions.

You can put artificial lizards, cats, etc. on top of the decorative item.

Mini sculptures

Instead of covers, if your budget allows, you can put plaster or acrylic decorations for the garden. The newest material is polystone, which is a liquid acrylic stone with the addition of crumbs. It is poured into ready-made molds and painted after hardening.

Pros of use:

- light weight - no more than 20 kg;

- resistance to frost and ultraviolet radiation.

To decorate sewers on lawns, bright covers with shapes are suitable.

To provide a home with sewerage, you must choose a location taking into account all the rules specified in SNiP and SanPin. Also decide on the volume, calculate costs for materials and additional services, and then follow the work technology. In this case, the cesspool will last for decades.

How often is the cesspool pumped out?

The period depends on several factors:

- Capacity;

- Daily wastewater volume;

- The amount of heavy waste in the waste stream.

It should be noted that there are several classes of solids that typically end up in a pit. These include:

- biodegradable "organic" elements such as feces; - slowly degradable particles such as toilet paper and cellulose compounds, which take a long time to biodegrade in the pit;

- Non-biodegradable solids such as pet bedding, plastics and other materials that do not decompose and quickly fill the container.

Reducing the amount of slowly biodegradable organic matter and non-biodegradable waste entering the pit will significantly reduce the rate at which waste accumulates in the tank.

Another contribution to how quickly a septic tank fills with solids is lifestyle. The two most important problems in life associated with septic tanks are:

- Using water at home;

- Age of residents.

Homes with growing families, including young children and teenagers, tend to use more water and receive enormous amounts of heavy rainfall into the pit. Older people tend to use much less water and send little waste to the pit. Thus, the frequency of pumping out the pit depends on the residents of the house.

Another important factor regarding how often to pump a hole is time. As the sump fills with heavy waste, these substances are transferred from the container to the absorption zone, especially from devices that do not have outlet filters. As more sediment mass accumulates in the hole, this waste begins to clog and restrict the movement of liquid into the ground. The absorption area will be clogged with nearly impervious biomass and flooded because the soil is no longer able to absorb the liquid produced daily.

Removing biomass from a septic tank is usually expensive and time consuming. The pit pump does not pump out biomass. To do this, it is necessary to pump out wastewater located in the soil absorption zone. The pump access hole in the absorption zone should remain open for several days. Once the absorption area is free of water and becomes aerated, the biomass usually decomposes within a few days.

Drainage sewer complex

Distribution wells are being installed. Their height does not exceed 400 mm, the diameter varies from 400 to 700 mm depending on the type of material used to construct the walls. To protect the structure from water, the same techniques are used: coating insulation of external surfaces, plaster inside, as well as the ironing method.

The wells are covered with concrete slabs or wooden panels and thermal insulation is provided. It is recommended to equip them with bends. A concrete tray is created at the bottom of the wells; its height corresponds to the diameter of the pipes. Such wells are located away from the septic tank. Communications are diverted from them.

How to determine the method of pumping out a cesspool

Tanks that receive large quantities of non-biodegradable elements and slowly biodegradable organic substances must be pumped out more often using sewer trucks or home pumping equipment. The sump must be pumped out before the accumulated solids accumulate to the point that they begin to flow out of the settled water tank.

There are two relatively safe approaches to solving pit pumping. One is to have the tank pumped out every two or three years. Another is to open the tank hatch once a year and insert a long beacon into the bottom and remove it. It will show the depth of the sediment. If the sediment is more than a third of the depth of the hole, it is time to pump out.

Sump pumps can remove all the liquid. To extract all the material from the tank, the scum layer must be destroyed and the sludge layer mixed with the liquid part of the pit. This is usually done by alternately pumping the liquid out of the pit and reinjecting it into the bottom of the tank. The sump should be pumped through two large central access ports (manholes) rather than through the small inlet or outlet inspection holes located above each baffle.

The use of chemical additives to reduce sludge volume or as an alternative to pumping out the pit is not recommended. In fact, relying on chemicals rather than conventional septic tank pumping can cause the entire septic system to fail, damaging the tank materials.

To facilitate future cleaning and inspection of cesspools, install risers from central access ports and inspection holes to the ground surface. Also mark the location of the reservoir so that it can be easily found for future pumping.

Features of the design of overflow septic tanks

If we consider the design of overflow septic tanks in general form, then these are two wells, the first of which serves for

settling solid fractions and carrying out the rotting process. It has a concrete bottom to prevent unwanted liquid drainage. The second of them, which has a bottom made of crushed stone, is filtering and absorbent. The liquid, which has already been pre-cleansed of large solid particles at the previous stage, undergoes resorption. The first well must be periodically cleaned, removing excess silt from there. This cannot be done manually; it is simply impossible to do without calling a special sewage disposal machine. However, in order to resort to its services as little as possible, biological products are added to the first well to help break down solid particles to the greatest extent possible.

Pit pumping time

Homeowners should get used to pumping septic tanks and plan how to spend the day away from home. In order for the pit to be pumped on a regular basis, the efficiency of the entire wastewater disposal system at the sites could be further increased by increasing the pumping time by a couple of days. Research has shown that a soil absorption system will benefit from periodic rest (a period during which wastewater is not added to the absorption zone).

To get the maximum benefit from pumping, it is recommended that the septic tank be pumped every two to three years on a day while the family is away on summer holidays. This means that the entire system, especially the soil absorption area, will have the opportunity to dry out, and any partially decomposed organic waste (biomass) that may have developed in the absorption area will quickly decompose in the absence of water.

The cesspool is only part of the on-site wastewater system. It is designed to remove solid masses before the flow entering the absorption zone expires, ensure the digestion of part of the waste and store the remaining elements. Biological and chemical additives are not needed to accelerate decomposition. Sewage trucks place additional load on the solid phase of the system. Sediment must be periodically removed so that it does not fall into the soil absorption zone. The cesspool should be pumped and inspected every two to three years.

Advantages and disadvantages

The advantages of the design include:

- a simple way to organize a waste collection container;

- financial accessibility;

- possibility of independent creation.

The disadvantages include:

- the design requires periodic cleaning using a sewer machine;

- the container smells bad, so you will have to spend extra money on biological or chemical agents;

- if the established standards are neglected during the location, then there is a high risk of contamination of the site and wastewater;

- the pit stands out on the site, so it needs to be further improved, increasing the amount of costs.

If all norms, rules and advice are followed correctly, the identified shortcomings will be avoided.

general information

Before dealing with ventilation, you need to clarify how the autonomous sewage system works. Autonomous sewerage system is a pipeline system for removing waste from a building, ending in a cesspool. Cesspools can be of several types:

- A pit with an earthen bottom, absorbent type.

- The pit is hermetically sealed.

- Septic tank.

The simplest and most common version of a cesspool is a design with an earthen bottom. The earth provides natural absorption and purification of water. Such “economical” sewerage is harmful to the environment, as it does not provide the proper level of purification from fecal and other wastewater from the house.

The sealed pit is equipped with concrete rings and slabs. The joints of the cesspool made of concrete rings are sealed. Such sewerage is safe for the environment, but requires frequent cleaning and pumping out of waste.

A septic tank is the most effective system. It can be homemade or industrially produced. A homemade septic tank provides reliable wastewater treatment and removal of purified liquid into the soil by arranging the bottom with filtering materials from several layers (gravel, broken bricks, stones, cinder concrete). The walls of the septic tank can be made of concrete rings, bricks or other available materials.

Any type of cesspool requires a ventilation system. Industrial septic tanks can be equipped with an additional biological treatment system and a built-in ventilation system, which will effectively eliminate all odors and gases. When constructing a cesspool or septic tank yourself, ventilation is designed taking into account the characteristics of the wastewater tank, its characteristics and location.

Problems solved by ventilation in the autonomous sewer system of a private house:

- Removing unpleasant odors.

- Removing organic decomposition products (methane and other compounds), large volumes of which can lead to poisoning, fire and even explosion.

- Maintaining optimal pressure in the pipeline.

When draining waste, a space of rarefied air or vacuum is formed in the pipe. After the passage of waste, the discharged space, according to the natural laws of physics, is filled with air. If there is ventilation, filling occurs due to the intake of fresh air through special pipelines.

If there is no special air exchange design, the freed-up space will be filled from openings in the house (sink, bathtub), and this will lead to disruption of the sewer system.

The ventilation system can be of two types:

Natural ventilation works due to temperature differences in different parts of the system.

Temperature affects pressure, the difference of which ensures the movement of air masses. In a forced system, air exchange is ensured thanks to the installation of additional ventilation equipment that pumps air.

Forced ventilation in a private house consists of connecting an exhaust fan to the drain pipe, which will remove the unpleasant odor from the room outside the building. The fan is carefully mounted in the exhaust duct and connected to the power supply.

Tips from professionals for construction

When doing all the work with your own hands, professional builders recommend:

- Backfilling a three-cube tank requires at least 1.5 m³ of soil.

- After concreting the bottom, the mixture must stand for at least 10 days to achieve the required strength.

- For brickwork, errors are acceptable. Because the main function is to keep the soil from crumbling, and slightly uneven rows do not affect the quality of the task performed.

- For formwork, corrugated sheets or boards are best suited.

- Compact and level the soil around the entire perimeter and on top of the well.

A large selection of designs allows you to make a device that will correspond to your financial capabilities, and using the above tips, each owner will be able to independently build a reliable cesspool.

Sewage ventilation at home

An important element of the general sewage system of a house is the drain pipe. This structure is located at the upper end of the riser and goes out onto the roof. It solves the problem of supplying fresh air and filling the vacuum when draining waste.

Roof drains are installed from standard PVC sewer pipes. The standard diameter of 110 mm is used, but a smaller size of 50 mm is also suitable. When installing a drain pipe, the following requirements must be met:

- The fan pipe should rise 50-80 cm above the roof ridge so that air circulation is maintained at the required level.

- At high loads, the cross-section of the drain pipe must coincide with the cross-section of the sewer pipe. In small private houses, the cross-section of the drain pipe may be smaller than the cross-section of the sewer lines, but it is recommended that the diameters be consistent.

- The structure can be positioned vertically or at a certain angle (taking into account the design features of the roof).

- The upper end is covered with a deflector, which will protect against dirt and improve air circulation.

- The distance from the outlet to the nearest window is at least 400 cm.

- Ventilation outlets to the roof are prohibited from being connected to chimneys and air ventilation of the building.

If in an already built house there is no ventilation outlet to the roof and it is impossible to install it, a suitable option is to install a special aerator - a vacuum valve.

When the wastewater is drained and the air is discharged, the valve will draw air from the atmosphere, filling the vacuum. Such additional equipment can be installed in any convenient place in the house. The plastic pipe fitting system allows you to easily install a vacuum valve in the right place.

A vacuum valve is an excellent alternative to installing a drain pipe that goes out onto the roof. This device has a number of advantages:

- does an excellent job of eliminating unpleasant odors;

- allows you to fill the vacuum when draining;

- easy to install and maintain;

- does not spoil the appearance of the building, does not require access to the roof.

Vacuum valve installation requirements:

- There is one device per toilet.

- The valve can only be mounted vertically.

- The device can be installed next to the toilet, sink, bathtub or in another convenient place.

- The room where the aerator is located must be well ventilated.

- The valve must be installed at a point located above the connection between the sewer branch leading to the plumbing fixture and the riser.

- Free access to the device for inspection is provided.

Self-installation of the tank

If you want to install a similar cesspool on your property, be sure to follow the basic installation steps.

- First of all, you need to prepare the place. The best option would be a site that meets all the requirements for shambo.

- You should dig a pit 3–4 m deep and 2 m in diameter. It is important to take into account the need for subsequent finishing. So, the inside of the tank is filled with concrete or lined with bricks.

- The last stage involves connecting the pipe coming from the riser with the pipe responsible for the removal of sewage water.

In some dacha areas, the groundwater level is quite high. In this case, reinforced concrete rings will be required to install the shambo.

- First of all, you need to select a site for the cesspool.

- Next, a pit with a maximum depth of 3 m is prepared.

- Then the reinforced concrete rings are installed. They are carefully connected and the resulting seams are sealed.

- The final stage is laying the waterproofing layer.

Ventilation of waste container

Not only the sewage system in the house, but also the cesspool or septic tank itself must be equipped with a ventilation system.

To solve this problem, a hole for an air exchange pipe is provided in the design of the container for collecting and filtering waste. This hole is located on the roof. The diameter should not be less than 100 mm. The material used is standard sewer plastic pipes. Rules for installing a septic tank ventilation pipe:

- A pipe of smaller diameter (50 mm) is inserted into a 100 mm pipe.

- The structure must rise above the ground by at least 50 cm. Melt and rainwater should not fall into the pit or septic tank. It is better to “extend” the pipe to a height of at least 150-200 cm (above human height) so that the emanating odors do not bother people.

- The end of the hood is equipped with a deflector, which improves the circulation of air masses and protects the pipe from dirt, snow, and leaves.

- The pipe can be insulated to prevent it from becoming clogged with ice in the winter.

If the septic tank is deeply buried in the ground, a special inspection hole is equipped for maintenance work. To facilitate inspection and operation, the ventilation pipe is mounted in this inspection hole.

In many private houses and cottages (especially old ones), the cesspool is located directly under the toilet. The toilet may look like a separate stall or be part of a common building. It doesn't matter for ventilation. In such a situation, the ventilation pipe is mounted in the roof of the cesspool and is installed next to the toilet at a level of at least 200-250 cm. The pipe is located vertically.

When planning a private house or cottage, you should avoid building a toilet over a cesspool. It is better to equip the wastewater tank separately and connect sewer lines from the toilet and other objects to it using pipes.

The location of the cesspool at a distance allows you to install additional ventilation pipes using tees in a convenient place in the fresh air. But it is worth remembering that the installation of such additional structures is acceptable only if there is a flush in the toilet.

If the house has a basement or cellar, the sewer ventilation pipe should not be routed into these rooms. For obvious reasons, the unpleasant odor will be concentrated in the basement. Basement ventilation should also not be connected to the air supply system to the sewer or cesspool.

Installation of ready-made blocks

The easiest to install system for accumulating and processing wastewater is considered to be a ready-made complex, offered for sale in disassembled form. Individual elements of factory-made septic tanks for a drainage pit in a private house are manufactured exactly to size, which allows them to be assembled as quickly as possible. The only weak point of these systems is the fact that they have a fixed volume specified by the manufacturer. As a rule, container parameters are designed for average consumption. To select the optimal system option, it is recommended to make approximate calculations of the load on the septic tank in advance.

The installation of cesspools of this type usually does not cause any difficulties:

- Dig a pit. The work is carried out according to the standard scheme for all pits. The bottom is equipped with a cushion made of a mixture of concrete and crushed stone.

- After pouring the solution, pause work until the concrete has completely hardened. From time to time it is sprayed with water.

- In the meantime, in a specialized store you can choose a waste accumulation and treatment unit of suitable volume. As a rule, its kit includes septic tanks, lids and rings.

- The assembly of individual elements must be carried out in strict accordance with the instructions. It contains an installation diagram and recommendations for arranging individual components. Thus, to increase the tightness of the joint sections of the underwater pipe and the main tank, it is recommended to use an acid-resistant sealant.

- Before filling the finished structure with soil, it is recommended to test it. To do this, process water is allowed into the system. As the procedure progresses, it is necessary to check the correct angle of laying the sewer pipe and the tightness of the connections. If no leaks are found, the complex can be backfilled.

Device, circuit, principle of operation

An effective sewerage ventilation system in a private house consists of two key blocks:

- A ventilation duct from a cesspool or septic tank.

- Fan pipe in the house.

The principle of operation of ventilation with a cesspool:

- the pipe above the cesspool works as a supply system, air is drawn through it into the sewer system;

- through the drain pipe of the house, the unpleasant odor is released into the air space above the roof;

- when draining waste, excess air masses with an unpleasant odor are discharged through a pipe above the pit;

- the vacuum is filled by the exhaust pipe.

For such an autonomous system to work, it is important that the cesspool does not overflow and the ventilation pipe does not block the drains. The channel above the septic tank and the drain pipe must not be allowed to become clogged. For preventive purposes, the system should be equipped with inspection compartments and inspection pits. They will help remove blockages, carry out repairs and restore ventilation if necessary.

Construction materials

In order to equip a high-quality sewer system with an overflow cesspool, it is necessary to prepare the necessary tools and materials in advance. Only at first glance it seems that it is impossible to build such a structure with your own hands.

In fact, there is nothing complicated about how to make a cesspool with an overflow; it is important to use good materials and follow the recommendations for arrangement

During the construction process, you can use both materials that you can find at home, as well as those purchased in advance. Often, overflow cesspools are made from car tires, red bricks or concrete rings. Since the pit consists of two chambers, they can be made of different materials.

You will also need crushed stone and sand to lay drainage at the bottom of the second tank; the first is filled with concrete. You should also stock up on tools that may be needed during the work process. This is a shovel, rope, bucket, hammer, chisel and other items that you probably have in your garage.

Simplified waste removal

An autonomous sewer system with a drainless septic tank (sealed cesspool) has a fairly simple device that does not require large financial investments. The frequency of calling a cesspool truck will depend on the number of people living in the house and the capacity of the septic tank. Vacuum trucks demand that they have convenient access to the site. To do this, the owners are forced to set aside part of the territory for the entrance area, and also make a gate. This option has many inconveniences. Firstly, the useful area of the site is lost due to the installation of a rarely used sewage disposal site. Secondly, after calling a car, you need to wait for its arrival, which is not always possible. Thirdly, emptying the septic tank through the hatch is accompanied by unpleasant odors, which are more noticeable the closer the cesspool is to the house.

If you move the pit close to the concrete foundation of the fence, behind which there is a roadway, then the entrance gate and sewage disposal area become unnecessary. In addition, to pump out wastewater from a septic tank, the presence of the owners becomes completely unnecessary. Vacuum cleaners can do this themselves, because... there is no need to enter the site.

It is best to provide a hole in the foundation of the fence for the pipe leading outside from the septic tank in advance. But in any case, getting it out won’t be too difficult. The diameter of the passage hole must be such that a PVC sewer pipe with an internal diameter of 200 mm can be passed through it. The pipe is laid at an angle of approximately 45° so that the hose of the sewer truck descends along it almost under its own weight.

The outer outlet of the sewer pipe section must be securely secured. From the street side, a tight lid is put on it so that the hole does not become clogged and to avoid the spread of unpleasant odors. The easiest way is to use a standard plug to which you can attach a handle.

The described solution is suitable for any type of drainless septic tank - both plastic and concrete. However, plastic containers are still more convenient, since they often have special places for making additional technological holes.

If the septic tank on the site is already located close to the fence, then a device for simplified pumping of wastewater is not difficult to implement. The only difficulty in this case is that the work is very dirty. And again, a plastic septic tank turns out to be more convenient: making a hole in it is not difficult. If the septic tank is concrete, then it is better to make the hole in the direction from the outside to the inside. To do this, you need to dig a pit half a meter deep. This is just enough to tilt the sewer pipe to pump out wastewater at the required angle.

The entrance of the pipe to the tank must be sealed to prevent groundwater from entering the septic tank. The seal must be strong enough to withstand half a meter of water pressure. The quality of sealing must be checked at least once a year.

The end of the pipe, located on the other side of the fence, allows sewage trucks to pump out wastewater without disturbing the owners. Even if they are not at home, the waste will be removed on time. This eliminates many problems and allows you to get comfort almost the same as in the case of using a centralized sewer system.

The diameter of the pipe leading to the septic tank is selected in such a way that the hose of the sewer truck fits in it with a minimum gap. This allows you to get rid of sewer odors from escaping from the septic tank. If its ventilation is done correctly, then odors should not appear at all. The septic tank must have an outlet - a pipe that is discharged above the surface of the earth. Some, due to a misunderstanding of how sewer ventilation works, do not make an vent for fear of unpleasant odors in the area. However, this pipe serves to intake air, and not to remove gases from the septic tank. These gases are discharged through the outlet of the sewer riser, which rises above the roof. The vent pipe serves to compensate for the exhausted gas volume. If this is not provided, the septic tank will not be ventilated. As a result, methane will accumulate in the septic tank, which is extremely explosive when mixed with air.

How to choose a hose for a sewage pump

Using specially made hoses, accumulated liquid can be pumped out of wells, septic tanks and other containers. Suction hoses are classified according to their design and quality characteristics. Drainage pumps have certain differences from other types of devices. To choose a suitable hose for pumping wastewater out of the sewer, you will need to familiarize yourself with the information presented in this article. This is a very responsible and significant choice for any private homeowner who has installed an autonomous drainage system on their property.

Content

Materials for simplified sewage removal device

The only thing you will need to implement this project, if you have an operating septic tank in a suitable location, is a piece of PVC pipe with a diameter of 200 mm and a certain amount of sealant. In plastic containers, sealing is done using rubber cuffs that fit the diameter of their technological holes. To seal the passage in concrete septic tanks, you can use a cement mortar with tow, which is covered with several layers of liquid glass or bitumen sealant. A more technologically advanced method is to use ready-made sealing compounds for concrete, which can be purchased at hardware stores. Polyurethane foam cannot be used as a sealant, because... it is not intended for these purposes. Foam can only be used to fix the pipe in the passage, but the outside and inside must be finished with a sealing compound, otherwise groundwater and flood water will penetrate into the septic tank, forcing it to be emptied more often than usual.

In order not to look into the septic tank hatch every time, it is better to equip it with a level sensor. When the septic tank is 75% full, the float sensor will close the circuit and the light on the septic tank hatch (or in another place) will light up. This is a signal to the owners: call the sanitation workers in the coming days.

The normal frequency of waste removal is once a quarter. To adhere to such a schedule, a family of three will need a septic tank with a volume of about 27 m³. For clarity, you can imagine a cube tank with a side of 3 m. The required volume is obtained based on the calculation of 100 l/day. per person. If we proceed from accepted sanitary and hygienic standards, then this volume must be doubled. However, in reality, a family of 3 people on average uses only 150 liters per day. If you save water by using jet aerators, economical flushing of the toilet, and taking a shower instead of a bath, then the volume of water consumed can be reduced by another third. Thus, the capacity of a septic tank, which will be emptied once every 3 months, for a family of three people can be only 9 m³. This will allow you to install an inexpensive and sealed plastic drainless septic tank.

Source

Design options

The sewer system is a depression in the ground, the walls of which are reinforced with different materials depending on the expected time of use. Based on this, we can distinguish 2 main types of structures:

- permanent - concrete or brick;

- temporary - wooden or from old tires.

Permanent

A concrete pit can be made from a solid screed or rings. The bottom of the ring structure must be filled with concrete mortar and only after that the main part is installed. The second option is convenient because you can do it completely yourself. The big disadvantage is the frequent cleaning of the structure, which depends on the number of people in the family.

A solid screed design requires more money and time to implement. Reinforcement is placed at the base of the floor, and then filled with concrete mixture. Next, a form is erected, which is filled with the same solution. This sedimentation tank will last for many decades, sewage will not be able to penetrate into the ground and the volume will not decrease during operation.

A concrete septic tank consisting of two sections is less expensive than previous options. A large hole is dug to divide it into two parts. Each of the finished compartments will be connected by a duct. All wastewater ends up in a larger container with precipitation, and in a smaller container without precipitation.

Note! If the second section is reinforced with a drainage well, then wastewater flows into the ground without insoluble sediment.

The most complex septic tank design consists of 3 parts. It will require the use of additional equipment - a compressor with a timer is placed in the second compartment and a drainage pump in the third.

The most modern option available is plastic containers of different sizes. They are sealed, so wastewater will not get into the ground, but it will require constant pumping of waste.

Temporary pits are made from wood or used tires. When using boards in construction, the material is treated with a protective solution. The walls are made in the same way as for the formwork. Such sedimentation tanks are good because of their low cost, quick construction and high degree of isolation of the soil from possible ingress of wastewater. Service life – no more than 10 years.

The tire construction option does not require finishing or high costs and can last up to 25 years. But the big disadvantage is the high level of throughput, due to which sewage will go into the ground, thereby polluting it.

Design principles

Some owners of private houses believe that it is not worth spending time and resources on design, because... It is possible to install a cesspool with your own hands without it. This is a common misconception. This stage is as important as the installation work itself.

Before starting installation, it is important to choose the right location for the structure, study its structure and calculate the capacity of the tank. If this is not done, several problems may arise at once:

- if placed incorrectly, the owner will bear administrative responsibility, and the building will have to be destroyed and rebuilt in another location;

- the system will not function correctly;

- Frequent pumping of the contents will be required (using a sewer pump) or using special equipment to carry out sewage disposal. Thus, it will lead to significant financial or time losses;

- Improper preparation for installation work can lead to ineffective functioning of the cesspool.

Therefore, it is advisable to immediately pay special attention to the design stage of the future system.

Location

To select a location, you must follow certain requirements and standards that are regulated by current legislation.

Note! If this is not done, the inspection may require moving the structure, and a fine will be imposed on the owner of the site.

It is advisable to pay special attention to the design and selection of location.

The structure must be located at a certain distance from the walls of houses, other buildings and objects:

- 3 m from trees and vegetable gardens;

- 4-5 m from the road;

- 10 m from various rivers, streams and foundations;

- 30 m from the reservoir;

- 50 m from the well where drinking water is obtained. If the soil is clayey, then a distance of 20 meters is allowed.

It is recommended to avoid constructing a cesspool at the lowest point of the site. Otherwise, such a location can lead to flooding due to heavy rains. It is also undesirable to place the structure on the site if the groundwater level is less than 4 meters.

When choosing a location, you should definitely take into account the possibility of unhindered access for special equipment for sewage disposal.

It is worth noting that the above requirements apply for the most part to drainage cesspools built with your own hands. If you plan to install sealed containers for a private home, then the exact distances to objects may not be observed.

Another factor on the basis of which the location is determined is the slope of the site. It is recommended to independently install a cesspool for a private house below the drain point. This is required to ensure gravity flow. When laying the pipeline, the slope should be 3 cm for each meter of pipes so that the drain liquids independently fall into the tank.

Device

After determining the place where the cesspool for a private house will be installed with your own hands, you can plan the installation procedure. There are certain subtleties that are important to know before starting the process.

If you plan to use the pit exclusively in the summer, then the depth of the pit can be approximately 1-1.5 meters. If the structure will be used in winter or all year round, then when calculating the depth it is important to take into account the characteristics of the soil.

For example, in winter the volume of soil will increase due to freezing, and during the season of heavy rains the soil will become wet. The minimum permissible tank depth is 0.5 meters.

During installation, be sure to provide for a ventilation pipe, as well as a drainage system. Ventilation should be located at a distance of approximately 40-70 cm from the surface.

When building a cesspool with your own hands for a country house or a private house, it is recommended to choose not a sealed model, but one whose tank has a filtration bottom.

However, it is advisable to take into account that the total volume of waste water and waste should be less than 1 cubic meter per day. Such a sewer system is the best choice for sandy soil types, if the depth of groundwater is more than 2.5 meters.

The problem of how to properly make a cesspool worries all owners of a private house who are planning this procedure. It is advisable to know about certain features of mounting and choosing a sealed model:

- The scope of application and design of tanks made of concrete and plastic containers are somewhat different;

- wells have worse tightness compared to plastic containers;

- The best ratio of quality and cost is a Eurocube as a container. It is completely sealed, can store up to 1000 liters of waste, is sold in many hardware stores and has an affordable price;

- the cross-section of the ventilation pipe should be approximately 10 cm, and the distance from the surface should be more than 40 cm;

- The pipeline should be laid taking into account the possible need for future repairs or replacement. Therefore, it is recommended to design it in such a way that various bushes, roots and trees do not interfere.

Scheme for creating a cesspool in a private house, built with your own hands:

- A pit of the required size is dug.

- The walls are being constructed and a pipe is being laid through which waste liquids will flow into the tank. It is important not to forget about maintaining the slope to ensure immediate gravity flow of waste and the absence of blockages.

- An outgoing pipe is connected to a special hole in the tank, through which wastewater leaves the tank.

- The installation of sewerage components is carried out directly.

- Hatches are being installed.

- When installing a brick cesspool yourself, an additional 30-centimeter excavation is made on top, on which a concrete slab is then placed.

- The slab is covered with earth and the surface is leveled. The hatch, as a rule, remains open.

Dimensions

One of the most important design stages is calculating the required volume of a self-built cesspool for a private home. Basically, a general rule is used: the container should hold the approximate amount of liquid drained in 2 days.

That is, you will need to find out how much water is drained on average per day (kitchen, bathhouse, bathroom or shower, sinks, etc.). If a heating tank is used to supply hot water, its volume is multiplied by 2, resulting in the required tank size.

However, it is important to note that the above calculation can only be used if you plan to operate the filtration cesspool in the warm season.

If it is necessary to use year-round or use a sealed model in winter, you will need to calculate the required liquid capacity using the formula: Volume = N * X * V.

Where:

- N – how many days the tank must be filled before pumping is carried out;

- X – the number of people who live in the house;

- V – how much liquid does 1 family member use (measured in liters).

For example, 4 people live in a private house, each of whom drains approximately 200 liters per day. If you plan to pump out wastewater once every 30 days, then you can substitute this data into the formula.

It turns out that Capacity = 30*4*200 = 24 cubic meters.

It is advisable to analyze from your own experience how much water is consumed per day, but if this is not possible, then you can use the average value - 150-200 cubic meters. meters per person. This parameter is largely based on the habits and lifestyle of those living in the house. Statistics say that, for example, city residents use more water than people living in villages.

Sanitary standards

To avoid problems later, it is necessary to comply with sanitary standards:

- The drainage pit must be located at least 35 meters from the well.

- You cannot use a storage system without a bottom if there is excess waste (more than 1 cubic meter).

- The lid should cover the pit tightly, especially in winter, to avoid freezing of the tank. And it’s best if the lid has additional insulation.

Design and types of drainage pits

A cesspool for a country house is considered a fairly simple method of eliminating sewage. In most cases, it is installed in dachas where there are no permanent residents, so there is no need to install complex septic tanks or connect to a centralized sewer system.

Installing a cesspool in a private house is not particularly difficult. This structure consists of the following components:

- dug pit;

- a special container that will contain waste liquids;

- pipeline;

- a system of fasteners and anchors to prevent the container from floating;

- filters for wastewater purification;

- sealants and other installation compounds.

The advantage for a private home of a self-made cesspool is financial savings and the ability to select the type of device, depending on the characteristics of the site (soil, proximity to the groundwater surface, etc.).

Which manufacturing method to choose also depends on the regularity of use, required service life and financial capabilities. To make the right choice, it is recommended to carefully study the options offered on the market and make a list of the features of your own sewer system.

If the wrong variety is chosen or there are errors in the arrangement of the cesspool, the owner of the site is highly likely to encounter some unpleasant moments. These include the release of sewage into the environment (deterioration of the ecological situation in the area), damage to property, the appearance of an unpleasant odor, etc.

Types of cesspools and septic tanks

Structures are classified according to the material used for their manufacture:

- car tires of various diameters;

- wood (this includes chipboard, plywood, boards, fiberboard, etc.);

- brick;

- concrete rings and slabs;

- plastic, metal-plastic, MDF, plastic.

The above materials are affordable and easy to find. It is worth noting that it is permissible to use not new products, but used high quality ones. Models are also divided according to the period of application:

- all seasonal;

- summer models.

Based on the principle of operation, structures are divided into sealed and filtration. In the first case, regular waste disposal will be required, because... wastewater is not treated, but simply accumulated.

In the second case, waste liquids are processed due to the proliferation of bacteria. The waste is not only cleaned, but also goes into the soil, which means there is no need for constant pumping. It will be necessary to call the sewage disposal equipment quite rarely and only to remove inorganic waste.

The main disadvantage of filtration cesspools is their low environmental friendliness. Poorly treated wastewater entering the ground can directly contribute to the pollution of nearby reservoirs, wells, etc. However, if such objects are located at a distance from the site, then the best solution would be to construct a filtration type structure.

The advantage of sealed pits is that there are no too strict requirements for choosing the location of the system. However, the main disadvantage is the need for regular pumping of wastewater. If about 5 people live in a house, then waste removal from the pit will need to be done every 1-2 weeks.