For each heating system, pipe sizes and their technical parameters have been developed and individually selected. In accordance with practical skills, selecting the required diameter prevents the occurrence of various technical problems and increases the safety and reliability of the entire heating system. It is necessary to take this into account and not neglect this condition. Let's look at where and what diameter is best to use.

The diameter of the pipes for each heating system was selected practically. The choice of diameter should be taken as seriously as possible, since a high-quality selection will allow you to fill the screed if necessary, provide passage through the walls, will not complicate the installation of circulation pumps, etc.

Difficulties in choosing pipeline diameter

When choosing pipes, the internal and external diameters, as well as the material of manufacture, are taken into account.

The main difficulty in selecting the diameter lies in the peculiarities of planning the highway. Taken into account:

- external indicator (copper and plastic) - the surface of the fittings can transfer heat flows into the room;

- internal diameter (steel and cast iron) – allows you to calculate the throughput characteristics of a separate section;

- conditional parameters - rounded value in inches, needed for theoretical calculations.

To determine the cross-section, it is taken into account that 100 W of energy is consumed per 1 m2 of room.

Dependence of size on coolant speed

The choice of diameter indicator will determine the throughput of the highway, taking into account the recommended speed of 0.4-0.6 m/sec. It is taken into account that at a speed of less than 0.2 m/sec, air pockets are formed, and at a speed of more than 0.7 m/sec there is a risk of an increase in coolant pressure.

To eliminate heat loss and increase the speed of the coolant, a pump is installed

How evenly the thermal energy is distributed along the circuit determines the diameter of the pipes. The smaller it is, the faster the water moves, but speed indicators have a limitation:

- up to 0.25 m/sec - otherwise there is a risk of air pockets and the impossibility of removing them with drains, heat loss in the room;

- no more than 1.5 m/sec - the coolant will make noise during circulation;

- 0.36-0.7 m/sec is the reference value for coolant velocity.

To control the intensity of circulation without increasing the diameter of the pipes, a circulation pump is used.

Coolant volume parameters

For systems with natural circulation, it is better to choose fittings with an increased diameter. This will reduce heat loss during friction of water against the inner surface. When using this technique, it should be taken into account that as the volume of water increases, the energy costs for heating it increase.

Hydraulic losses

The phenomenon occurs if the pipeline is made of plastic products of different diameters. The reason is the difference in pressure at the joints and an increase in hydraulic losses.

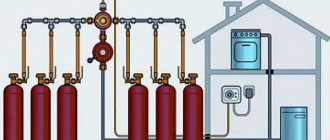

Boiler power

In a country house, rooms are heated using gas or electric equipment, less often - solid fuel models. Based on the size of the heated space, the power is calculated. For high-quality home heating you need 0.1 kW of thermal energy per square. Parameters may change due to climatic conditions or gentle regime up to 1.3.

The power of the boiler is affected by the material from which the walls are made and the presence of thermal insulation. Increased thermal conductivity, combined with the thinness of the partitions, increases the heat loss of a country house. Even the most efficient model will not cope with heating the building.

What to look for Source eco-kotly.ru

The quality of heating is affected by the presence of a second circuit in the boiler. When hot water is turned on for domestic needs, the performance in the utility system decreases. Designs with this option should have higher parameters than their single-circuit counterparts.

The boiler power depends on the type of fuel. Gas equipment is considered the most practical. The most expensive are electric, the most inconvenient are solid fuel. Pumps are used to optimize coolant circulation and solve the problem of air locks.

Formula for calculating the diameter of the line

The correct determination of the diameter of the pipe used for the heating main of an apartment building or private building is made on the basis of a table and formula. When working with the table, you need to focus on the green cells - they indicate the optimal coolant pressure rate.

The calculation is made using the formula D= √(354*(0.86*Q/∆t)/V), where:

- V – fluid velocity in the pipe (m/s);

- Q – required amount of heat for heating (kW);

- ∆t – difference between reverse and forward feed (C);

- D – pipe diameter (mm).

In a system with natural circulation, the diameter of the pipes is chosen larger.

As an example, we can consider a two-story house with four wings (2 per floor), connected to a two-pipe system with a total heat loss of 36 kW, 20 kW of which is for heating the 1st floor, 16 kW - second. Polypropylene was used for communications; they operate in 80/60 mode at a temperature of 10 degrees.

Counting algorithm:

- The entire volume of water falls on the area where the first branch connects to the boiler. This is a total heat amount of 38 kW.

- Using the table, you need to find this line and the corresponding green cells. With these parameters, the required diameter is 40 and 50 mm. The choice is made in favor of less.

- The fork shows the amount of heat on the first (20 kW) and second (16 kW) floors. The cross-section of pipe fittings according to the table is 32 mm.

- Since there are 2 wings on each floor, the circuit is divided into two branches. For the first floor 20/2=10 kW per wing, for the second - 16/2=8 kW per wing.

- The table determines the diameter - 25 mm, used until the load drops to 5 kW, then - 20 mm.

Calculations for the return are not needed - pipes with similar parameters are used.

Calculation of wastewater volume

In order for the water drainage system to operate as efficiently as possible, it is necessary to accurately calculate the average amount of precipitation falling in a particular area during the month.

To do this, you can use the formula taken from SNiP 2.04.03-85: Q = q20 x F x Ψ

Here the indicators are the following data:

- Q - average volume of rain or melt water that will need to be drained from the site;

- q20 is the intensity of rain or snow precipitation in a specific region of Russia. The data is recorded in SNiP tables for each specific area;

- F is the total area of all roofs and platforms from which storm or snow wastewater will be drained;

- Ψ is the correction factor, which allows you to achieve the most accurate calculations of the average volume of water for disposal. This indicator completely depends on the type of coating from which the liquid will be drained.

The coefficient indicators are also specified in the tables of SNiP 2.04.03-85 and have the following wording:

- Roofs of any type - coefficient is 1;

- Asphalt platforms and paths - coefficient 0.95;

- For sites and objects made of concrete - the coefficient is 0.85;

- For crushed stone with bitumen admixture - coefficient 0.6;

- And for simple crushed stone in its pure form - 0.4.

Thanks to the use of this formula, it is possible to calculate as accurately as possible the volumes of rain or melted snow water that will “attack” the object in each season.

Important technical characteristics of pipes

High-quality heating of a room is impossible without taking into account the technical characteristics of the equipment. They can be considered using standard polypropylene products of grades PN 20 and 30 as an example.

| Outside diameter, mm | PN 20 | PN 30 | ||

| Diameter inside | Wall thickness | Diameter inside | Wall thickness | |

| 16 | 10,6 | 2,7 | ||

| 20 | 13,2 | 3,4 | 13,2 | 3,4 |

| 25 | 16,6 | 4,2 | 16,6 | 4,2 |

| 32 | 21,2 | 5,4 | 21,2 | 3 |

| 40 | 26,6 | 6,7 | 26,6 | 3,7 |

When the coolant flows at a speed of 0.4 m/sec, it is necessary to take into account the thermal power of products of different diameters. With external parameters of 20 mm, 4.1 kW is generated, with 25 mm – 6.3 kW, with 32 mm – 11.5 kW, with 40 mm – 17 kW.

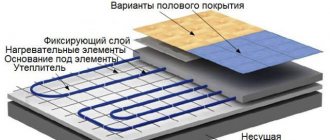

The procedure for calculating the heating manifold and mounting sleeves

The sleeves are installed on the heating manifold after choosing the diameter of the pipes.

An apartment or private house is equipped with a heating manifold. The device provides distribution of coolant through several branches. The calculation of the collector is carried out together with the cross-section of the pipes according to the external or internal dimensions based on the principle of “three diameters” - the pipes along the route are removed from each other by 6 radii each. The diameter of the collector is also equal to this value.

The parameters of the sleeves are calculated after establishing the cross-section of the line. Elements are selected taking into account the material of the wall and reinforcement, the degree of expansion when heated. For example, the diameter of a plastic pipe is 20 mm, the sleeve is 24 mm.

Peculiarities

Pipe structures made of polyvinyl chloride are often used to equip wastewater drains, displacing cast iron and steel ones. Plastic sewer pipes are made from regular and unplasticized PVC. The material contains vinyl chloride and additional additives. High strength properties make it possible to use unplasticized PVC for organizing pressure pipelines.

Sewage pipes are designed for draining wastewater from a water drain, for installing a drainage channel, and installing indoor and outdoor sewage systems. The use of PVC products for sewerage installations is justified due to the technical characteristics of the material. The long service life of sewer pipelines will allow the system to operate for up to 50 years. The tensile strength reaches 50 MPa, so the street section of the sewer can withstand installation to the depth of soil freezing. The pipeline is capable of operating at pressures from 6 to 16 bar.

The use of polyvinyl chloride pipes for sewerage has the following advantages:

- A variety of sizes and shapes of pipes and fittings will allow you to assemble sewer systems of any complexity.

- Smooth internal walls do not allow sewage to settle, preventing the formation of blockages in small diameters and preventing the pipe passage from becoming clogged with sediment.

- The low weight of the products and ease of cutting mean quick and easy installation and dismantling without additional tools.

- Inert to chemicals and corrosive effects.

- Affordable price of pipeline elements.

The sequence of calculating the cross-section of heating lines

For communications with circulation pumps, you will need to take into account the volume of coolant in the system, the total length of the heating main, the reference flow rate, heating heat transfer, equipment power, resistance value and pressure without a pump.

To find out the size of the products, you will need to make an adjustment for a decrease in efficiency - resistance to turns, bends and fittings. Calculations can be carried out using the formula H = λ(L/D)(V2/2g), where:

- H – height of zero pressure without pressure in m;

- λ – pipe resistance coefficient;

- L – line length;

- D – internal diameter of the pipe in mm;

- V – flow velocity in m/s;

- g – gravitational acceleration equal to 9.81 m/s2.

In the process of calculating the minimum heat loss, you need to check several diameter options for minimum resistance.

Diameters of steel pipes and their wall thickness in mm. Dependence of one parameter on another

Steel pipes are actively used in various industries and agriculture. Their reliability has been tested by time.

Of course, such products have their drawbacks, in particular, a tendency to corrosion. But everyone is already quite well informed about these shortcomings.

Timely preventive and repair activities make it possible to maintain engineering systems based on metal pipes in perfect order.

The main characteristic of steel pipes is their diameter. We can say that, based on the diameter of the pipe, a decision is made about its use in a particular engineering system, in a particular section of the system.

Features of steel products

In the building materials markets you can find pipes of two main designs:

- welded, having a seam;

- seamless - obtained, for example, by casting.

Characteristics of materials for making pipes

Table of diameters of plastic pipes for heating

Manufacturers produce pipelines from several types of materials.

Polymer

Products for which plastic material is used - cross-linked or regular polyethylene. After calculations, you can determine what diameter of propylene pipes is needed for heating a private house, depending on the type of equipment:

- one or two batteries – 16 mm;

- radiator or group of radiators with a power of 1-2 kW (standard), up to 5 batteries with a power of up to 7 kW - 20 mm;

- dead-end wiring arm (house wing), radiators up to 8 pcs. total power up to 11 kW - for heating it is better to use propylene pipes with a diameter of 25 mm;

- one floor (up to 12 radiators with a total power of up to 19 kW) – 32 mm;

- line of 20 radiators up to 30 kW with a power of 40 mm.

The wall thickness of polymer products is selected according to the pressure parameters in the network and can be 1.8-3 mm.

Steel

They are durable and have good heat dissipation, but are difficult to install. The surface of stainless steel fittings is not subject to corrosion and is characterized by smoothness. Steel heating fittings according to GOST 3262-75 are classified according to their outer diameter, on which the wall thickness depends. The data is shown in the table.

| Outside diameter | Wall thickness | ||

| Lungs | Standard | Reinforced | |

| 21,3 | 2,5 | 2,8 | 3,2 |

| 26,8 | 2,5 | 2,8 | 3,2 |

| 33,5 | 2,8 | 3,2 | 4 |

| 42,3 | 2,8 | 3,2 | 4 |

| 48 | 3 | 3,5 | 4 |

Standard and light modifications are used for organizing apartment or home heating.

Copper

The material has good thermal conductivity, corrosion resistance, and stretchability. When the coolant freezes, the system can operate while maintaining tightness. Features of the sizes of copper fittings are indicated in the table.

| Diameter, mm | Wall thickness, mm | Weight m.p., g |

| 15 | 1,5 | 391 |

| 18 | 2 | 480 |

| 22 | 2 | 590 |

| 28 | 2,5 | 1420 |

| 42 | 3 | 1700 |

To carry out heating, it is worth using copper fittings with walls of 1.5-2 mm.

If there are 5-8 radiators in an apartment and 2-3 forks in a private house, you can independently calculate the diameter of the pipe for the heating main. For this purpose, it is allowed to work with formulas and tables. The organization of a complex system with several levels involves the use of special online programs.

Where can I get the tables?

Everything is simple here. Usually, all detailed tables with all the necessary data can be viewed (or downloaded) on the websites of pipe manufacturers. But it happens that there are still no tables.

You can get out of this situation as follows. If there are no tables for the outer diameter, then take the one for the inner diameter and calculate according to it. Yes, there will be inaccuracies, but, as experience shows, for forced circulation they are completely insignificant and acceptable.

Having analyzed a huge number of already installed and perfectly working systems, experts noticed a certain pattern in the choice of pipe cross-section. It is mainly suitable for small-sized autonomous systems.

In private houses, the pipes that come out of the boiler are most often one-half and three-quarters in size. This diameter of the pipe for heating a house is used until the first fork, and at each subsequent fork the cross-section is reduced by exactly one step.

But this method is applicable only for apartments and one-story houses; for high-rise buildings, alas, everything will have to be calculated very carefully.

If we have a private house or apartment, autonomous heating for no more than 5-8 radiators and 2-3 forks, we can easily calculate everything ourselves. We need to know how powerful each heating point is, the heat loss in the room and a good table for selecting the pipe diameter.

However, as has already become clear, trust experienced specialists to calculate a complex multi-level system with numerous junctions and forks. Well, if you still decide to do everything yourself, then at least read articles like ours and consult with experts.

Source: eurosantehnik.ru/kak-vybrat-diametr-truby-dlya-otopleniya-doma.html