The Fakro attic access ladder is made of pine wood and has three or four sections. With the help of such structures you can quickly and easily climb into the attic. The appearance is not spoiled by the staircase, since it can be stored at the top, under the ceiling. In addition to the fact that the aesthetic appearance will not deteriorate, it can be argued that the staircase saves space. And the fact that it is durable, functional and comfortable only reinforces the fact that the use of fakro stairs is the right decision.

Typically, folding structures have three or four sections, depending on the height of the ceiling and the compartment for lifting into the attic. When folded, the design is similar and works on the principle of a nesting doll, when smaller parts are inserted into larger ones and pushed into even larger sizes. This is very convenient as it saves space.

Most often, the lifting structure is made of light types of wood, but there are also metal structures. Price and operational capabilities have their differences. The height of the stairs ranges from two meters and seventy centimeters to three meters and twenty centimeters. The maximum possible weight that the structure can support is no more than one hundred and sixty kilograms.

The structure will not spoil the interior, since the cover of the structure is made attractive in appearance and does not require camouflage or additional decoration. Such structures are considered simple to install.

The cover of the product is about 40 millimeters thick, lined on both sides, and insulated in the middle with special materials. The outer side of the cover shows no traces of installation work. The metal rod makes it possible to close and open the hatch, and the structural elements do not make it difficult to lower or rise with a load.

The staircase structure is stable and of high quality; the fastening methods, thanks to which the connecting elements are held, are called dovetail.

Do-it-yourself fakro staircase equipment

In private homes there is a room that is located under the roof and serves, most often, as a kind of warehouse. You can use the free space in different ways, but in any case, you need to think about how to access the room under the roof. You need a staircase that is comfortable, reliable and compact enough so that everyone living in the house can use it without difficulty. A similar access option can be made with your own hands.

When thinking about installing a folding system for lifting into an attic space, you need to carefully analyze some points:

- it should be understood that the attic space is limited and there cannot be a large selection of designs;

- it is necessary to think over the purpose of the stairs, it must be safe, with convenient descent and ascent;

- it is necessary to take into account all the dimensions of the structure and think through the nuances.

Advantages and disadvantages

Fakro attic stairs from the Polish manufacturer have some distinctive parameters. But a characteristic feature of the products is that they can be equipped with a universal insulated hatch. Due to this, stairs can be installed between rooms with different temperature conditions. An insulated hatch will prevent the appearance of drafts and a decrease in temperature in the heated part of the house or apartment.

Experts note that each model has both strengths and weaknesses, but with high-quality products, the positive aspects always prevail over the negative parameters. The main advantages include:

- Simple and affordable installation that even home craftsmen can do.

- High degree of design reliability.

- Absolute safety of stairs, as they are connected to the floor of the building.

- Wide color segment.

- Huge selection of models.

- Saving free space due to compact design.

- Increased thermal insulation qualities.

- The product copes well with loads from 150 to 250 kg.

- The staircase can be equipped with various accessories.

- The presence of a powerful lock prevents intruders from entering.

The only disadvantages include the heaviness of the hatch, as well as the lack of a protective paint coating on wooden models, which is why they are exposed to various adverse factors.

Attic staircase options

There are many variations of lifts that allow you to climb into the attic space.

Variety of models

Today there is a huge variety of products on sale. Each model differs not only in design, material of manufacture, but also in a good dimensional grid. The experts themselves note that Fakro stairs have the following technical characteristics:

- When disassembled, the maximum height of the structure is 3 meters.

- Wood, metal and plastic can be used as the main material.

- The design can consist of 3-4 sections.

- Insulated models prevent cold air from entering the room.

- Additional steps are 25 cm high.

- Some models have handrails.

- The lowest sections are equipped with universal rubberized tips.

The huge advantage is that when assembled the staircase does not take up much space. The universal scissor folding mechanism can be used by a person as a handrail. In addition, such products perfectly resist open fire, as they are coated with special agents.

Fakro company experts note that since their appearance on sale, the following staircase models have gained enormous popularity:

- Comfort. The length of the product ranges from 1.2 to 1.4 meters, but the width is 60-70 cm. This is an excellent option for those rooms where the ceiling height does not exceed three meters. The hatch cover is painted white. The presence of special grooves prevents slipping on the steps. The model has rubberized tips on the lower section, as well as comfortable handrails. Manufacturers produce products from this line in 5 different sizes.

- Smart. The width of the structure is 70 cm, length 1.5 m. Ideal for ceilings with a height of 2.80 to 3.25 meters. The thickness of the insulated hatch cover is 4 cm, there is additional insulation. The product is painted in the color of natural wood. The steps are provided with universal anti-slip grooves. The model range includes 7 different sizes of Smart stairs.

- LST. This is a multifunctional energy-saving design, which is made of durable metal. The width of the product varies from 50 to 70 cm, and the length is a maximum of 1.2 m. The opening mechanism is foot-operated. There are comfortable handrails, the lid is insulated with high-quality material. The ladder can easily withstand loads of up to 200 kg. The design is intended for those rooms where the final ceiling height does not exceed 280 cm. The product can be extended by installing an additional step.

Variety of folding stairs

There are several popular options for stairs that are assembled:

Choosing the type of staircase

Attic stairs are selected according to the frequency and intensity of use, location in the room and insulation requirements.

Main types of staircase structures:

- portable - ladders, stepladders that can be removed to another place;

- folding - the mechanism is activated manually or by levers;

- stationary - all stairs that cannot be hidden or carried away.

Residential attics, where people climb several times a day, are equipped with stationary stairs made of wood, metal, and concrete. For straight marches you need a lot of space. Screw designs are more compact, but often not convenient.

Finished products are practical and durable. They are offered by manufacturers FAKRO, Oman, Unikma, JAP. You can make an insulated or regular attic ladder yourself using calculations and step-by-step instructions.

Stationary

Stationary structures are reliable and durable; they are installed for a long time. They can be located in the center of the room, on the side, along the walls or in a separate room. The staircase to the attic rests on a supporting frame made of metal, wood or reinforced concrete. It could be:

- kosour or bowstring for marches;

- central post for screw types;

- cables for suspended steps;

- Bolts for stairs mounted by sequential twisting of steps and supports using special bolts.

Original options include cantilever steps mounted in the wall, or the “goose step” type.

In the space under the stairs you can organize a children's corner, equip a pantry for storing things, and shelves for books.

This is interesting: how to arrange a storage room under the stairs?

Fences are made of wood, plastic, steel or glass. Sometimes they are completely absent, or they are replaced with a handrail on the adjacent wall. The structures are made to the required dimensions and adjusted to the installation site.

Portable

Portable ladders are compact and multifunctional. They are made from aluminum - a durable light metal that is not subject to corrosion, or wood. They consist of 1-3 sections, the steps can be standard or wide. There are usually no railings.

There are several types of similar stairs

Common types of portable devices:

- Attached - a single-plane structure in the shape of a rectangle or trapezoid. Consist of 6-12 steps. In everyday life, non-removable, retractable and folding versions of stairs to the attic are used.

- Stepladder - A- or L-shaped metal structure with steps located on one or both sides. An additional retractable section in some types helps transform the stepladder into an extension ladder.

- Hinged - made of sections, the position of which can be changed. One staircase structure can be transformed into a U-, L-shaped or attached one. Indispensable when used on uneven surfaces.

Folding

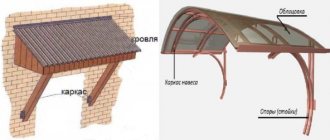

The optimal solution for private houses, where there is nowhere to place a stationary ladder, and nowhere to put a portable one, are folding structures with a hatch. Thanks to special mechanisms, they are easy to get ready.

In the group of folding stairs to the attic:

- telescopic – structures, the size of which is regulated by moving sections along the length and securing them with clamps;

- sliding – sections change position relative to each other in space;

- folding - a flight of stairs pressed against the wall is brought into the desired position by turning it in card loops and fixing it with a stop;

- scissor - an assembled accordion of steps, which is straightened by pulling the lower element.

The folding mechanisms are activated manually or remotely using a control panel. Telescopic, sliding and scissor structures are completely hidden behind the hatch cover, while the folding ladder is attached to the wall and is always visible.

How to install an attic ladder

Depending on the size of the opening, the staircase option is selected. The box is usually several centimeters smaller. Having found out the height of the room, they plan and calculate the length of the stairs to access the attic, taking into account the angle of inclination and height. Before starting installation work, it is necessary to temporarily secure the staircase equipment. For this, two boards are used, which are nailed into the opening so that it is possible to lay the box.

To carry out such work, it is recommended to hire an assistant so that the work is carried out by two workers.

To carry out the work you need to stock up on the following tools:

Sizing and preparation for installation

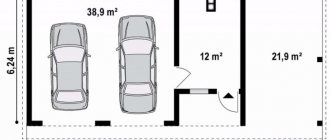

The production of stationary marches begins with design - taking measurements and creating a drawing in three projections (front, side, top), linked to the floor plan. For an accurate calculation, you need to measure the length and width of the attic opening, the height from the floor of the first floor to the floor of the second floor, and the thickness of the ceiling. Based on this, a drawing is constructed, focusing on the optimal dimensions of general construction standards and GOSTs:

- span width - 0.6-1.0 m;

- tread depth - from 17 cm;

- step thickness - at least 2 cm;

- tilt angle - maximum 75°.

The calculation can be done using the online calculator, which is available on our website. After creating the project, they purchase the necessary materials and prepare the tools. An alternative is to buy ready-made staircase elements from the manufacturer for further installation.

To purchase a folding model, just measure:

- Distance between the floor and the attic opening. Manufacturers produce ladders with lengths from 280 to 350 cm. The height can be adjusted during installation (the bottom is filed or cut with a hacksaw), so we recommend choosing structures that are longer than the required size. If the length is not enough, additional segments can be supplied.

- The size of the opening in the ceiling. Look at the product label. For example, “Fakro” on the label indicates the width/length of the attic opening (50-70/80-140 cm) into which the staircase will fit; other companies - the dimensions of the box (in this case the opening should be 2-3 cm larger).

- The thickness of the floor slab where the box will be mounted. If the walls of the box do not completely cover the stove, you will have to install an additional board or finish the open part with other available materials.

If there are rooms at the attic level, it is better to close the entrance with a door; in non-residential premises, install a hatch. To prevent heat loss, the lid must be insulated.

Important details:

- the optimal width of the attic opening is 60-100 cm;

- The recommended lifting angle is a maximum of 75°;

- thickness of steps - 2 cm;

- The maximum length of the attic ladder is 3 m.

When determining the size of the opening, we recommend taking into account the dimensions of the users and the possibility of moving bulky objects into the attic. When walking up the steps, a person should not hit his head on the ceiling.

Metal stairs and models with insulation are best installed in unheated rooms.

If you plan to make the folding structure removable (independent of the ceiling), before installation you need to complete all ceiling work, prepare the opening, for example, reinforce it with a CD profile, or cover it with plasterboard.

How to make an attic ladder yourself

For home craftsmen who are not afraid to make items with their own hands or who are accustomed to protecting the family budget, you can make an attic staircase on your own. Those who know how to work with wood or at least roughly know how to work with carpentry tools can make their own wooden attic ladder. It will turn out to be simple and without frills, but durable, functional and inexpensive. Fragments of the structure can be prepared using metal rods and pipes. In this case, the structure will be even stronger. To make your own structure, you will need the following material:

It is worth calculating in advance the required number of hinges, hinges and similar material. Practitioners recommend purchasing ready-made complete sets of fasteners and accessories; the cost will be a little more expensive, but no important part is guaranteed to be left out.

You need to stock up on the necessary tools:

It is necessary to work only with dry wood. Considering the functional features of the staircase, this is extremely important: wet wood can deform the structure and it will not fold. It is also worth taking care in advance to treat the surface of the future staircase from insects and with a fire-fighting agent.

Short description

Since their inception, the design of attic stairs has not changed significantly.

Only the parts themselves underwent minor modernization, which became more accessible, lighter and thinner. Experts are accustomed to separating such products depending on the main material. The modern Fakro attic ladder can be made not only from wood and metal, but also from reinforced plastic. Products made from natural wood are in greatest demand. The design turns out to be quite light, and in the event of a breakdown, the failed part can be repaired with your own hands. With minimal skills, a home craftsman can easily replace a problematic section of a bowstring or a step. Birch and pine are most often used as the main material.

In some models, a bowstring or steps may be made of metal. If the sections have increased rigidity, then silumin, aluminum, duralumin or other alloys can be used for their production. The solid folding section is most often made of high-quality steel.

According to their design, Farko stairs can be insulated or not. The first option is most suitable for cold attics. The cover itself is made of plywood with polystyrene foam. The non-insulated model is intended for heated attics. The lid is made of the same plywood, but without insulation. Consumers should note the fact that the appearance and types of designs of standard stairs are almost identical for all manufacturers.

Fakro attic ladder installation, fakro ladder installation instructions

In order to install the structure, it is necessary to perform a number of sequential actions:

Stairs to the attic. We build it ourselves

When choosing a design, it is important to consider the type of hatch. A vertical entrance in the wall is made when one of the rooms does not have an attic ceiling and is combined with the roof; an attic entrance is combined with an exit to the roof. To install folding ladders, the attic hatch must be horizontal. It is cut into the ceiling so that the lid opens upward.

It’s not difficult to make a folding bed in a horizontal opening yourself. The simplest option is to cut a high stepladder into 3 equal parts, which are connected with a hinge. We fix the first section on the hatch cover, fold the rest so that they end up in the attic.

If there is no stepladder:

- We measure the thickness of the ceiling, the height between the floor and the ceiling.

- We draw a diagram of the hatch with the required dimensions.

- We make an opening 5-6 cm larger than the hatch itself (take into account the thickness of the material from which you will make the box). We cut a hole in the wooden floor and reinforce it with beams. In a concrete floor, we make the entrance to the attic at the junction of the slabs, otherwise the floor will lose strength. Concrete tool - grinder with diamond-coated discs (diameter no less than 220 mm). For even corners, you need a hammer drill with a drill whose length is greater than the thickness of the ceiling. The hole for the hatch is reinforced with iron corners.

- We assemble the box frame from a board (20-30 mm). Maintain right angles.

- We install the box in the opening.

- We make a cover from fiberboard/chipboard or from the remains of the ceiling.

- We lay insulation (extruded polystyrene foam). Insulation depends on the level of thermal insulation of the attic. We reinforce it with a cross member and attach it to the frame of the box with hinges, as in the photo (for smooth opening, you can install closers).

- Making stairs. For load-bearing beams, we cut beams with a diameter of at least 50 mm. For the steps you need a board at least 2 cm thick.

- We connect the sections with loops and install steps.

- We attach the upper section to the ceiling with anchors (or to the hatch cover).

- To prevent the structure from lowering arbitrarily, we install a hook and loop on the wall and place another hook on the back wall of one of the steps.

Instructions for assembling an attic ladder with a detachable hatch cover

All types of ladders that have a detachable hatch cover have an easier permanent installation system. Speaking about the sequence of actions, it is necessary to adhere to a certain sequence:

Self-installation

Experts note that all parts of Fakro stairs are universal. The frame itself has precise parameters that are suitable for a specific opening. Only after careful preparation of all the edges of the hole can you begin the installation itself. To do the job well, you will need at least two people. The tools you need to prepare are regular screwdrivers, a screwdriver, and a 10-mm open-end wrench. All joints can be insulated with mineral wool or polyurethane foam.

The installation itself consists of several main stages:

- Unpack the purchased product, check the contents, and also study the attached instructions.

- Install a suitable frame for the outer part of the frame. Of course, this can be done at the end of installation, but at the initial stage it is much easier to level the purchased structure.

- At all internal corners of the frame there are special fastenings made of high-quality metal. Manufacturers have provided them for temporary hanging of the product. You need to install nuts in them, into which threaded pins must be screwed.

- Insert the hatch into the prepared frame and mount the back stops on the pins.

- Use powerful screw rods to level the product in all directions.

- To avoid possible deformation of the structure, it is necessary to secure the frame itself to the slope through a rigid lining. To implement this idea, you can use dowels or screws.

- The most important point is to check the diagonal. All indicators should be as even as possible. You need to make sure that the frame is not too pinched by the screws.

- At this stage, the final unfastening is carried out. All gaps can be filled with non-expanding foam. The technician can remove pins and temporary hangers.

- Sections must be adjusted. To do this, the craftsman needs to unfold the structure itself and bend the lowest section onto the support. It is necessary to measure the distance from the end of the previous section to the stop. Place the resulting value on the lower section and cut it with a hacksaw. Rubberized pads are placed on the support points.

Additions and clarifications

The auxiliary boards can be beams that are placed on top of the attic opening. The box is tied to them with ropes and hangs in the opening. The person in the attic must untie it from the beams. There are also options from the manufacturer - corners with special fasteners.

The final fastening of the box in the opening must be very reliable. For heavy metal structures, manufacturers provide special fasteners. If it is not provided, and the staircase is quite massive, then when installing the box with your own hands, you just need to use more screws. If the ceiling is decorated with plastic panels, then it is still advisable to place the box flush with the ceiling (and not with the surface of the panels). By leaving the correct gap, you can make the attic hatch invisible by finishing it with the same panels as the ceiling.

When purchasing an attic ladder, you should ask the seller whether installation work is included in its price. You may not have to do anything with your own hands. It happens that manufacturers indicate the dimensions of the opening, and not the box, in the product characteristics. To avoid misunderstandings, this point needs to be clarified.

Making your own ceiling hatch

Opening design

The first stage of our work is the design of the hatch itself

It is important to consider the following points:

- If the opening in the ceiling is laid at the construction stage, then the issue of choosing a location is not relevant. If we can choose for ourselves, then the hatch should be placed so that the ceiling above the stairs is at its maximum height. This will provide us with a comfortable climb and protect us from hitting our heads on the rafters.

- The opening itself must be reinforced around the perimeter with wooden beams. If the ceiling is made of concrete slabs, then the edges of the opening should be additionally reinforced with steel corners.

We reinforce the perimeter of the hatch with beams

- To make a hatch cover, you can use thick (10 mm or more) plywood or a wooden panel. The perimeter of the cover should be reinforced with wooden beams.

- You can mount the lid on factory hinges, but finding suitable ones is quite difficult. As an alternative, it is worth making brackets from sheet steel, connecting them with bolts with a diameter of at least 10 mm.

Cover with a locking mechanism and lever We attach the hatch cover to beams or corners around the perimeter of the opening. We install the latch on the far part of the lid so that the handle is directed towards the living room.

Assembly of segments

After the hatch itself is secured, you can begin manufacturing the ladder segments:

Most designs involve assembling the lifting part from three segments: this way, the length of each part is relatively short, and not so many hinges need to be made.

Dimensions of segments

- The easiest way is to buy a ready-made metal (steel or aluminum) ladder. But if you want to save money, then it is quite possible to make a wooden structure.

- We cut out side bowstrings for each segment from 40x100 mm timber. We file the corners of the beam so that the structure can fold.

- We cut an edged board with a cross-section of 40x80 mm into step blanks. We form spikes at the ends of the blanks.

Preparation before installation

- On the inner surfaces of the bowstrings, using a router or chisel, we select grooves for installing steps.

- Lubricate the spikes on the steps with glue and drive them into the grooves. We strengthen the structure with self-tapping screws.

- We sand all wooden parts with sandpaper, after which we treat them with varnish for interior work. Instead of varnish, you can paint the steps and bowstrings with interior wood paint - the main thing is that it is sufficiently resistant to abrasion.

- We assemble the individual segments into a single structure using folding hinges.

Installation of the structure

Next, we proceed to the most important part of our work - assembling the hatch with the ladder:

- We attach the first segment of the lifting part to the inside of the hatch cover. Fastening must be done at several points, since it is this node that will experience the maximum load.

- We connect the side beams along the edges of the opening to the fixed staircase with metal brackets. These brackets will make it easier for us to open and close the hatch, in addition, they will prevent it from swinging open too wide.

- To facilitate assembly and disassembly of the folding structure, you can install springs connecting the brackets to the hatch edging. These springs will take on part of the load.

Installed brackets, springs and handrails At the same time, the design features, which allow you to literally bring the ladder into working position in just a few seconds, make it almost indispensable in everyday life.

In the video presented in this article you will find additional information on this topic.

First installation method

Today you can find Fakro products in relevant stores. The attic ladder is one of the products of this manufacturer. If you decide to acquire such a mechanism, then you need to become more familiar with the technology of installation work. This requires the presence of an opening, which must have the three dimensions indicated on the packaging. In order to choose a place for installation work, it is necessary to take into account the length of the ladder when it is disassembled. Auxiliary boards are installed at the bottom of the opening; they will support the structure during the installation process.

By visiting the store, you can get acquainted with the products of the Fakro brand; the attic ladder is an excellent example of this. It must be installed by two people. Before starting work, it is necessary to prepare a set of necessary tools, namely: screws, a screwdriver, a protractor, a 10mm wrench. One of the craftsmen must climb into the attic using a stepladder, and then the ladder is lifted up and laid on the installed boards. In those places where screws are supposed to be screwed in, spacers must be installed between the edges of the opening and the frame so that right angles on the sides of the frame are maintained. After this, the stair box is strengthened with two screws, two of which are installed at the back, while the remaining two are installed at the front.

Kinds

All types of attic stairs can be divided into portable and stationary. Portable options are ordinary stepladders that are attached to the attic hatch and used for their intended purpose. Constantly going up and down them will not provide much comfort, especially for children or the elderly, and they are also unsafe. Their advantage is that they are easy to make, do not take up much space in the room, and if they are not in demand, they can simply be put away in any free space.

The folding structure is usually made of aluminum as it is strong and lightweight. At the bottom there are support beams to provide stability, the width can reach 65 cm. The step pitch is usually 10–20 cm, there can be one or more sections. The longest is the 4-section model, but such a height is usually not required; for a floor height of 2.5–3 m, two sections are sufficient.

According to the mechanism of its disassembly, a folding attic ladder can be:

- retractable;

- scissor;

- lever;

- folding

A sliding attic ladder made of aluminum is good because it easily unfolds to the desired length and is securely fixed, and when folded it takes up very little space; it can be leaned against a wall or placed in the attic. All such structures can be easily found in construction stores, so you don’t even have to do anything yourself.

Another option is to mount a homemade ladder with a folding part. It can be mounted on a ceiling door or hatch, then easily folded back and unfolded. There can be 2–3 sections; when unfolded, it turns out rigid and stationary. Hardwood is used to install its frame and steps, and metal parts are used for fastening and folding mechanism. With proper design and careful work, such a design can be automatic, very convenient and completely safe.

An interesting option for compact structures that are attached from the inside to the attic hatch are scissor ladders. They are most often made entirely of metal, and when the damper is opened in the attic, they are laid out like an accordion or a tram current collector. The frame is very light and can be easily attached to a wooden hatch using bolts. The disadvantage is that after some time of intensive use, the metal parts begin to creak. Therefore, we must not forget to lubricate them periodically.

A type of retractable ladder is the telescopic attic ladder. It consists of many aluminum tubes that are folded one into another. When folded, it takes up little space and is easily attached to the attic hatch. In order to unfold it, a special handle is provided. But such models are not particularly popular.

A very common option is monolithic stairs, that is, not folding or portable. Although such lifting structures take up more space, they are strong, do not require moving parts, and can last for decades. They can be made from high-quality wood, equipped with railings, and the space under the stairs can be used to maximum benefit.

A single-span monolithic staircase is the easiest to manufacture, but it may have too steep a rise, which will cause inconvenience during regular use. The most convenient design may be one with two spans located perpendicular or parallel to each other. The only problem is that it will take up maximum space. To save space, many craftsmen build a spiral staircase in a small room.

Monolithic stairs to the attic or attic with one or two spans are made of wood, but there are also models with a metal frame and wooden steps. Most often they are done in a secluded, most unclaimed place in the room. A good solution would be to place them against the wall or in the corner of the room.

Choosing a suitable design

All attic ladders are divided into stationary and folding of various modifications: two-section folding, three and four-section sliding attic ladders, as well as electric ladders. The choice of stairs depends on a number of factors that need to be taken into account when choosing.

Free space

If the area of the room allows, then you can install a staircase to the attic the same as other stairs in the house - from the same material, in the same style, the same size

In this case, the harmonious unity of the design and interior of the house will not be disrupted, which is very important for many owners, and especially landladies.

A staircase that matches the overall design of the house looks good, but takes up quite a lot of space

If there is not so much free space and you want to free up space for something more important than a staircase, then you can use more affordable options, for example, installing attic folding stairs. They are sometimes no less reliable and safe, and in some cases they are the optimal solution, for example, if there are small children in the house who have nothing to do in the attic for their own safety

Features of residents

Consider who will use the stairs most often. If these are elderly people, the requirements for the convenience and safety of the stairs automatically increase. In addition, it should give the impression of being durable and reliable even upon superficial inspection. If there are children in the house, then care should be taken to limit the possibility of their unauthorized access to both the stairs and the attic, since the safety rules usually observed in the house are often unwittingly violated in those rooms that are used from time to time.

A do-it-yourself folding attic ladder is a completely doable task if you have certain construction and engineering skills. However, many manufacturers offer such designs in ready-made form and the prices are quite affordable, so the choice depends only on the owner of the house.

Retractable stairs to the attic have their own advantage - they do not disturb the interior of the house at all, because they are hidden in the attic behind a hatch cover. This wonderful feature was immediately appreciated by designers, who freed themselves from the problem of decorating and finishing this detail of the interior of the house.

This staircase may not decorate the room, but it will hide in the attic hatch after use.

One of the modifications of folding stairs is a sliding staircase to the attic, which makes sense to use where there is not enough space even for a compact folding one. If ordinary folding stairs consist of 3-4 sections, then the sliding one consists of only two and, therefore, is even more compact. At the same time, manufacturers claim that this does not in any way affect its quality, strength, reliability and safety. Such stairs are ideal for summer cottages and for cases where there is no need for constant access to the attic.

In modern homes, an attic door is rarely used as an entrance to the attic. More convenient and practical is an attic hatch with a ladder secured in such a way that the ladder folds and is hidden in the ceiling.

The ladder attached to the attic hatch cover is compact and disappears into the ceiling after use.