Even before the advent of high-strength insulation materials, solid slab foundations were considered an effective means of compensating for seasonal (frost heaving) and non-seasonal soil movements. Being “floating”, they maintained the relative position of all elements of building structures relative to each other, even when houses fell into areas of small landslides. An original engineering innovation that combined the solution to energy efficiency problems was the so-called USP foundation, the technology of which came to us from Sweden and Germany. This article describes the design and operational features of the insulated Swedish stove (as the abbreviation “USHP” stands for).

Technology of insulated Swedish stove using the example of Dorocell

About 10 years ago, the first domestic enthusiasts, developers, used standard projects from this particular company. According to Dorocell, the optimal energy-efficient foundation for low-rise housing construction is a high-quality monolithic concrete slab with stiffeners, external thermal insulation and built-in heating.

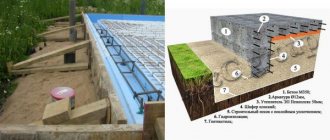

Scheme of the technology for installing an insulated Swedish USHP plate using TechnoNIKOL materials

Thermal insulation, representing a kind of “trough” for pouring concrete, serves as a natural permanent formwork.

Schematic diagram of USP in section

Here is a detailed overview of the foundation of an insulated Swedish slab:

- Formwork made of polystyrene PSB-S is assembled on a compacted sand and crushed stone bedding. At the bottom of the backfill bed, slopes were made and a drainage pipe was installed.

- Formwork 400 mm high consists of slabs 100 mm thick and forms rectangular grooves with a cross-section of 400×200 along the perimeter to form stiffeners and a bed for pouring the main slab 100 mm thick.

- Reinforcement of the ribs is carried out in two belts with a profile of variable section with a diameter of 8 - 12 mm. Reinforcement of the floor slab is carried out using a welded mesh 150x150 mm.

- The heating system pipelines are embedded in the floor slab. The floor slab is reinforced using a 150×150 mm welded mesh laid on top of the heated floor pipes.

- In addition to the heated floor, other communications are also poured with concrete - water supply, sewerage, electrical wiring in the rooms.

- Insulation of the blind area is carried out along the perimeter of the foundation with 70 mm PSB-S slabs adjacent to the polystyrene formwork from the outside at the depth of its contact with the bedding.

Thermal insulation skirt around the foundation slab protects against freezing

The described scheme corresponds to the load generated by a two-story house with load-bearing walls made of cellular concrete, as well as climatic conditions with a frost index of 4000 - 8000. An increase in load requires an increase in the cross-section of the stiffeners, and a more severe temperature regime requires the addition of one or two additional layers of insulation.

Video description

The video below will show an insulated Swedish stove - pillow preparation technology:

Laying insulation and formwork

After the pillows are ready, they proceed to installing the insulation and begin with the walls of the pit. If standard EPS boards are used, they subsequently become formwork for concreting. But the Scandinavians came up with special blocks and their use significantly simplifies the work. It also makes it much easier to control the correct placement of the material.

L-modules have a locking system that allows them to be connected correctly. Therefore, the desired transition from the vertical to the horizontal plane is immediately formed. And to avoid even the slightest displacement, there is a groove in the upper part of the blocks into which the rod fits. It connects adjacent modules to each other. For horizontal slabs, a steel plate with spikes is provided.

Laid insulation for USHP Source tn.ru

Pros and cons of the Swedish stove

The most important thing is that as a result of installing the foundation according to the warm Swedish stove scheme, the developer receives a solution to a whole range of issues:

- effective drainage,

- anti-frost protection,

- energy saving,

- heating,

- comfortable microclimate,

- laying communications,

- as well as obtaining a floor surface for finishing coatings.

Other benefits of the scheme include:

- For frame houses, USHP compensates for their main drawback - the low heat capacity of the walls. A massive insulated foundation takes on the function of a backup heat accumulator.

- Price. Despite the fact that the Swedish scheme is not a cheap pleasure, it includes not only the zero cycle, but a whole set of stages. Performing these works separately costs significantly more in total.

- Deadlines. When the work is carried out by a team of qualified specialists, everything will take, on average, about a week.

- Versatility. The technology is suitable for most soils and climatic zones of the Russian Federation.

- Indispensable in the construction of “passive house” class buildings.

TECHNONICOL CARBON ECO SP insulation

Disadvantages of a foundation based on a warm Swedish stove:

- Conditional (psychological) disadvantage: low base. In houses with a regular foundation, a high base is necessary to ensure normal humidity in the rooms. Until now, many of our compatriots tend to consider the height of the basement as one of the guarantees of housing quality.

- Maintainability of communications. Since the floor slab is a stressed structure, it is extremely undesirable to violate its integrity to repair bricked up pipelines. On the other hand, there are other installation methods and technical solutions that compensate for the shortcomings of the circuit. But all these measures lead to an increase in costs.

- Requires highly qualified performers. Not every team will take on the turnkey delivery of the USP.

- It requires significant one-time capital expenditures, therefore it is not suitable for developers who expect construction in small (in terms of money) stages.

- Not suitable for peaty soils and other soils with low bearing capacity, as well as areas with large slopes.

Calculation

The basis is taken from the geometric data of the future foundation: total area of the base; foundation perimeter; height of the building. During survey work the following is determined:

- soil characteristics, bearing capacity;

- groundwater level;

- soil freezing height.

Then the thickness of the sand cushion and the volume of concrete to be poured are calculated.

The cost of installing a stove depends on the features of life support systems, the method of supplying electricity and water.

It is important to immediately think through all the nuances to avoid mistakes.

Technology development: methods, materials, components

To date, more than 1.5 million houses have been built using the USP scheme in Germany and the Scandinavian countries. In Northern Europe, the insulated monolithic slab foundation technology has received generally accepted status and is reflected in EU building standards. In the USA, complete external insulation of slab foundations is not widespread, since 90% of the country has a frost index of no more than 3000. However, USP has also found application there: first of all, in the construction of “passive houses”.

Over the past 10 years, project developers have given greater preference to extruded polystyrene foam (EPS) as a material that provides more uniform shrinkage of foundations and maintains thermal insulation properties regardless of time and operating conditions. The stresses in concrete arising during the operation of shallow slab foundations were studied in detail. Based on their results, builders abandoned the idea of using insulation materials with different ultimate strengths (previously it was assumed that in order to equalize shrinkage under the floor slab, it was necessary to use less strong slabs than under the stiffeners). It has been proven that the most dangerous stress concentrators in a slab can occur at the junction of different types of heat insulation.

Manufacturers of extruded polystyrene foam began to produce materials and components specialized for the installation of USP.

For example, Dorocell itself currently produces a complete set of “designer” parts for permanent formwork made of EPS. The company's calling card is blocks with built-in guides for fittings. Some brands pay increased attention to the aesthetic properties of the components: the sides of the formwork are molded in the form of plinths of a traditional variable section.

Formwork for USP

If we talk about the domestic market, then there are 2 brands on the market: TechnoNIKOL and Penoplex. Both companies produce EPS of European quality level for slab foundations built using USHP technology. I would like to dwell in more detail on the specialized series TECHNONICOL CARBON ECO SP. In addition to the basic slab formats, it includes L-shaped profiles for quick installation of sides. In addition to the cross-section, these elements are interesting because CSP (cement-bonded particle boards) are fixed to their base parts on the outside. DSPs allow you to apply decorative plaster without additional preparatory stages. Thus, installation of USP using TechnoNIKOL components is currently the most convenient.

USP device using PENOPLEX boards

Video description

The following video shows an insulated Swedish stove, the technology for constructing the external insulation contour and examples of laying L-modules:

Armored belt and “warm floor”

Upon completion of the placement of the second layer of insulation, they proceed to reinforcement. First, separate structures are knitted for the stiffening ribs, which are placed inside on special supports. Then they proceed to installing the grating for the entire area.

Reinforcement of the USP occurs strictly according to the approved design and for this purpose rods and stands of the required sizes are selected so that the necessary gaps remain everywhere. And then they move on to laying out the circuits to create heating.

To do this, a distribution manifold is installed in a pre-agreed location. And pipes are laid from it throughout all the rooms where the “warm Swedish floor” is planned. Moreover, it should be recalled that saving on materials is strictly prohibited. This requires quality that is ready for long-term service. It is also necessary to conduct a full pressure test of the system in order to eliminate defects in a timely manner (while possible).

Reinforcement of stiffeners in USHP Source rmnt.ru

Concreting

The final operation should ideally be carried out in one go. Therefore, you will need a concrete pump and a team to level the solution. But simply distributing the concrete mixture will not be enough. It will be necessary to work with a deep vibrator to fill all possible voids.

After which it is useful to use a vibrating screed to reach the desired level and level the surface. But, since the resulting plane is already the floor in the room, minor modifications are necessary. It is necessary to wait for the solution to incompletely harden and, using a special device (helicopter), carry out the final grouting of the surface while simultaneously adding powder topping. And after this, the floor in the house is considered ready.

Developer reviews and cost of USHP type foundations

The vast majority of developers who used thermally insulated slab foundations are satisfied with their choice.

Houses built using the USP method are never damp. The settlement is uniform and very insignificant in absolute terms, so it is practically not recorded. Cracks and other troubles occur during the implementation of projects in which gross engineering errors were made (incorrect strength calculations, or incorrect determination of soil characteristics).

USP, on average, is more expensive than conventional foundations, but somewhat cheaper than UFF (insulated Finnish foundation). The approximate cost of a thermally insulated monolithic slab is 100 - 115 $/m. sq. If the area of the house is small (less than 80 sq. m.), then the unit price can increase to 130 - 140 $/m. sq. Some organizations provide USP prices in the form of a specific value per linear length of a stiffener. Such estimates are less accurate than area estimates. However, in any case, you should compare contractors not by their stated prices, but by the calculation of the estimate for the project you provided.

Step-by-step installation steps

During the preparation of project documentation, specialists determine the composition of the soil, measure the groundwater level and find out how much the layers of the earth can move due to rain or melted snow. Based on this data, calculations are made, which include the required pit depth and drainage system parameters.

The thicknesses of the bedding, insulation layers and concrete for the USHP device are calculated. Find the required diameter of the rod for reinforcement and the pitch of its laying. All utility networks and the piping system for floor heating are calculated. After the project is approved, excavation work begins.

Pit for a monolithic slab Source peredelka.tv

Pit

Work begins with clearing the area and carefully marking it. Moreover, you need to immediately outline everything that is specified in the project. From the septic tank pit to every utility line. Due to the shallow depth of the pit, the excavation work itself can be done manually. But the area of the object involves unloading a large volume of earth, so it is reasonable to connect the equipment.

And after refining the walls of the pit and leveling the bottom, another additional marking is carried out for drainage, sewer and water pipes. As well as a power cable, if it is planned to bring it into the house underground.

Field of application of UVF

Studying the technical characteristics of an insulated foundation made of Finnish slabs, we can confidently say that such a structure can be used in areas with different climatic conditions, is suitable for any soil composition, and can withstand loads of up to three tons per linear meter of strip foundation.

Each of the given characteristics corresponds to the majority of frame-type structures under construction, the height of which reaches two floors.

By increasing the supporting base of the foundation strip, it is possible to add the mass of the building structure at the rate of four to five tons. But in this case, it is necessary to perform a mandatory verification calculation using the strip foundation method.

Base reinforcement

Reinforcement of stiffeners is done according to the design.

Important:

In order not to damage the laid XPS, the working reinforcement must be tied into spatial frames on the ground, and only then the finished frames must be installed on the reinforcement clamps and tied.

The rest of the foundation, as a rule, is reinforced with one row of reinforcement bars with a cross-section of 6-10 mm. They are placed in increments and tied into a 150x150 mm mesh. The longitudinal joining of the rods is done with an overlap of at least 24 cm.

Important:

the lower protective layer of the reinforcement must be at least 30 mm thick - for this, the rods and frames are installed on special PVC clamps for the reinforcement.

Strengthening the slope of the USHP pillow

Let's return to our pillow on the slope. The dump of the cushion soil turned out to be quite steep, so not only were the geotextiles on the soil slope additionally provided with soil anchors, but measures to additionally strengthen the slope would also be required.

But since literally a couple of days after concreting, frosts hit and snow began to fall, it was decided to postpone the work on additional strengthening of the slope, in agreement with the customer, until the spring.

So the article will be updated in the spring of 2022.

At the same time, we’ll see how the pillow “overwinters.” (Visited 4,202 times, 1 visits today)

Insulation of the blind area

To further protect the house from frost heaving, you need to carry out a simple procedure for installing an insulated blind area for the USHP.

There are three stages of blind area insulation:

- The fertile layer is removed, at least 10 cm of sand is poured and compacted.

- XPS boards are laid on the compacted pad - no mechanical fixation is needed.

- Lay out the PLANTER geo drainage membrane. It is covered with crushed stone on top, or covered with sand with a tamper and paving slabs are laid, or a green blind area is made.

Important:

when installing a sand cushion under the blind area, a slope from the foundation of at least 1.5% is required.

Area of possible application of UVF

When considering the technical characteristics of the foundation of a Finnish slab of insulated construction, we can talk about its acceptable use in all climatic zones of Russia, for any type of soil during the construction of buildings with a weight load of up to 3 tons per 1 linear meter of strip foundation.

This characteristic will correspond to the majority of frame-type buildings being erected with a height of up to 2 floors.

When increasing the support cushion of a strip foundation, it is allowed to increase the weight of building structures to 4-5 tons, but in this case, a mandatory verification calculation is required using the method of strip foundations.

Briefly about the main thing

Installing a Swedish stove is a serious and complex project. Its development and subsequent implementation can only be entrusted to professionals. Carrying out soil analysis and all calculations on your own, without experience in this area, will lead to fatal errors that are not always possible to correct.

Since the resulting foundation can no longer be redone, it is necessary to use only the highest quality materials for its laying. The entire pipeline hidden inside the slab must have channels leading to the surface to allow clearing of blockages. And only those that have a certificate for long-term operation can become materials for heated floors.

Warm floor

The diameter of the pipes used to install heated floors is 16-20mm. In this case, a smaller diameter is used in cases where the total length of the created loop does not exceed 70 meters. If its length is longer, then a transition to wider pipes is required.

In places where load-bearing wall structures will be located in the future, pipes are placed in special sleeves with a length of about 400-500mm.

At the same time, preparations are being made for the installation of collectors in accordance with the existing house-building plan. To do this, reinforcement with a diameter of 12 mm (2-4 rods) is driven into the right place, released on the surface at a distance of 1.5 meters. A board is attached to the reinforcement for subsequent installation work. The joints with supply pipelines require additional installation of protective corrugation.

After forming the heated floor contour, it is necessary to fill it with water and conduct a full test. If no defects are found and the heated floor is operating normally, it is pressure tested.