Appearing for the first time in the capital and large cities of France, in our country houses with an attic floor are most widely used in suburban construction. The debate about whether it is advisable to build an attic or choose a full floor does not subside. And it is unlikely that the parties will ever come to a common opinion. Each specific case has its own advantages and disadvantages, so we will not enter into a useless argument, but will take a closer look at these designs.

DETAILED CONSTRUCTION INSTRUCTIONS

1. Development of drawings.

The main element in the whole work is the roof and its unusual structure. A common occurrence is the installation of skylights. The uniqueness lies in the fact that it is located at a certain angle. To build a roof, you will have to completely rebuild everything.

2. Designing the shape for the roof.

Already at the initial stage, you need to clearly know what the future roof will be like and how it will be located. There are several options: broken, classic and lean-to. Carry out careful work on the drawings, from all sides, clearly describe every detail.

3. Construction process.

It is the largest in volume. You'll have to ask someone for help; you can't do this job with your own hands. A mauerlat is laid across the entire upper area of the house. After which the side posts are attached to them using corners. We make a jumper in the upper area of the racks.

4. Arch.

We stretch the cord, when an arch is formed, an internal frame will be created. We carefully compare the sizes. Fastening with brackets and corners. We install the sloping part of the roof at an angle. We nail down slats and boards on the outside, but don’t forget to leave space for the future window.

5. Insulation.

An important element in the construction process is the use of insulation for the attic. The best option would be to use a membrane-type film, mineral wool. It covers the sheathing and is attached from the inside of the entire structure. We lay it so that no gaps appear.

6. Roof decking.

There is a huge selection of roofing materials , everyone chooses to their taste.

7. Window and interior decoration.

The final stage is the installation of the window frame and finishing on the inside.

Using the above recommendations, you can easily build an attic with your own hands.

Rafter system

Tilt angle

The classic version of roof slope angles

The angle of the slopes affects not only the height of the ridge. The degree of snow and wind load depends on its size. The lower this indicator, the greater the load the snow cover has on the supporting structures of the building. As the angle of inclination increases, the snow load decreases, but the wind load increases.

Types of rafter systems for sloping roofs

There are two main types of truss system design.

Hanging structure

Types of hanging rafters of an attic roof

When the rafter leg rests only on the mauerlat (in the lower part), and the upper part is joined to the mirror paired rafters. To give the structure additional rigidity, such a system is fixed and expanded with special elements: fillets, spigots, headstocks, and puffs.

Layered system

In a layered system, the rafter legs have two supports: at the bottom - a mauerlet or logs, at the top - a ridge girder.

How to calculate a sloping roof

The principle of calculating a sloping roof is no different from the above calculation of a gable roof. The only additional step in this case is breaking down complex links into simple components.

To determine the height of the ridge in the “triangle” formed by the hanging rafters and the attic floor, we will use the same formula as in the first case. Let's convert the angle value into a relative value, according to the Bradis table, and multiply the resulting number by a value equal to ½ of the attic base (half the distance between the posts).

We calculate the length of the rafter leg using the Pythagorean formula.

A2 + B2 = C2

Where A and B are the height at the ridge and half the distance between the posts, respectively, and C is the length of the rafter leg.

We calculate the layered rafters either by the angle and height of the rack, or by the Pythagorean formula.

Just as in the first case, by selecting options, we will choose the optimal dimensions of the attic and calculate the area of each slope.

What section of rafters are required?

To determine the cross-section of the rafter legs and the distance between them, in addition to the constant load, consisting of the weight of the structure itself (the mass of roofing materials, thermal insulation layer, steam and water barrier, rafter legs and sheathing), you will need to calculate the magnitude of the temporary load (snow, wind, people).

To do this, use the map to determine in which zone the building is located.

Using the table, the estimated weight of snow cover for a specific area is found.

Using the formula, the snow load is calculated.

S = Sg × μ

Where:

- Sg calculated weight of snow cover (according to the table);

- Μ – coefficient depending on the angle of inclination of the roof.

If the slope of the slopes is more than 60 degrees, then the correction factor is not taken into account. It is believed that snow does not linger on such roofs.

- If the roof slope is less than 250, the correction factor is 1;

- For a roof slope from 250 to 600, the correction factor is 0.7.

To calculate the wind load, a special map and tables are also used:

| No. | Building height in meters | Zone A | Zone B | Zone B |

| 1 | Up to 5 | 0.75 | 0.5 | 0.4 |

| 2 | From 5 to 10 | 1 | 0.65 | 0.4 |

| 3 | From 10 to 20 | 1.25 | 0.85 | 0.55 |

- zone A – open area (steppes, forest-steppes, deserts, tundra or forest-tundra, coastal areas);

- zone B – urban areas with buildings, forests, artificial and natural high-altitude obstacles;

- zone B – urban areas with densely located multi-storey buildings.

Using the formula Wp = W × k × c determine the wind load for a particular case.

For buildings located in difficult climatic zones (with a lot of precipitation and strong gusty winds), the calculation of snow and wind loads should be carried out more carefully. To familiarize yourself with the basic rules, watch the thematic training video.

Tools

To carry out the work you will need the following tools:

- Electric drill;

- Screwdriver;

- Saw;

- Jigsaw;

- Grinder with a disc for wood;

- Chisel;

- Axe;

- Building level;

- Plumb;

- Measuring instruments and pencil.

WHAT MATERIALS TO USE

The following may be required during the construction process:

- Wooden slats.

- Wooden beams.

- Wooden boards.

- Metal corners.

- Elements for fastening.

- Metal brackets.

- Mineralized wool.

- Waterproofing material.

- Window frame.

- Ladder.

In addition to this list, you will need the basic tools that are used for construction.

What are the components of the price of adding an attic to an old house?

In order to correctly calculate the cost of building an attic, it is important to consider what building materials will be used and what dimensions the building will have.

The first step is to take accurate measurements, after which the following is calculated:

- length and width of the rafter system;

- attic height;

- skate length;

- rafter section;

- number of rafters;

- area of the attic room;

- the total number of rows of sheathing, the number of boards required for it;

- the amount of roofing materials, such as waterproofing and vapor barrier;

- roofing material area;

- volume of insulation material;

- the number of square meters of gable cladding material;

- the length of the boards that will be laid on the attic floor;

- window size.

This is a list of the main materials that will be used for the construction. Depending on the situation, other building materials may be required.

INSULATION OF THE ATTIC

In a residential building, heat losses are absolutely inevitable: heat evaporates through the outer walls, through the roof, and through floors, windows, and doors. All surfaces in the room are heated by the heating system and immediately begin to exchange heat with the external environment. If in a city apartment heat loss occurs mainly due to the cooling of the walls, then in a private house, along with the walls, the roof also cools down. Its area is sometimes comparable to the area of the walls, so you can imagine how important the task of high-quality roof insulation is. And you cannot save on this, otherwise the purchase of cheap thermal insulation materials or a frivolous approach to insulation will subsequently lead to increased heating costs. Thermal insulation of the roof with your own hands or with the help of specialists is necessary if you have a used (living and heated attic). The roof of a non-residential attic does not require insulation, but in this case it is necessary to insulate the floor, which is also the ceiling of the room below. When insulating a used attic, in addition to thermal insulation, several layers are used - vapor barrier, waterproofing, and an air gap. This design of the roofing “pie” allows the insulation to remain dry. This is especially important for mineral wool and glass wool. If mineral wool gets wet, it will no longer cope with its functions.

Regardless of climatic conditions, time of year and operating characteristics of the building, it is necessary to create such a structure in the under-roof space so that moisture has the opportunity to be removed outside on its own. If the humidity of the insulation increases by at least 5%, its thermal insulation capacity will decrease by half. In addition, when wet, mineral wool begins to lose its shape - cracks form between the plates of this insulation and the seal is broken. When installed correctly, mineral wool should last a long time. She is not afraid of temperature fluctuations, rodents, or chemical exposure. The only thing you need to be wary of is the penetration of steam rising from the living space into the thickness of the insulation. For this purpose, after installing the mineral wool slabs, a vapor barrier film is installed. On the upper side the material is protected by a waterproofing layer.

First you need to dwell on the issue of wall insulation of the attic floor. Initially, in order to protect the attic from moisture entering and accumulating in it, waterproofing must be placed along the roof slopes and gables. Rolled waterproofing is attached overlapping and over the mounted insulation using a stapler or slats. Mineral wool is considered the best option. The first type of wall placement involves strengthening the insulation with a thick layer between the rafters with a gap for air circulation. The result is that attic insulation consists of waterproofing, insulation and waterproofing on top of them. In the second option, the installation of the insulating layer varies depending on the material of the partition. Brick requires installation of insulation on both sides. A vapor barrier is added from the inside. Only waterproofing is attached to the slopes.

Floor insulation involves the use of thermal insulation (glass wool, mineral wool) with a thickness of at least 100 mm. Waterproofing is placed on top and under thermal insulation. The best insulation for ceilings in the form of a monolithic slab is screed.

Professional builders, when choosing materials for insulating an attic from the inside or outside, usually give preference to mineral wool, ecowool, polyurethane foam, polystyrene foam and expanded polystyrene.

The final decision largely depends on the priorities and budget of the cottage owner. We will consider the properties, advantages and disadvantages of each of these insulation materials.

Dormer windows

Attic window with a combined opening system

According to the requirements of SNiP, the glazing area in attic-type rooms must be at least 10% of the total surface area of the walls and roof of the house. But if the installation of ordinary double-glazed windows is allowed in gables and cubby houses, then only special dormer windows are suitable for installation in the roof.

Types of dormer windows

- Windows balconies;

- Hinged windows;

- Cornice windows;

- Panoramic double doors;

- With a combined opening system;

- Mid-turn.

MINERAL WOOL AND ECO WOOL

Mineral wool and ecowool are good insulation materials. They are quite lightweight, environmentally friendly, fireproof, sold in a convenient form - exactly what you need. Mineral wool is less susceptible to shrinkage, but it is much more expensive than glass wool. In turn, glass wool does not like to be crushed or wrinkled and can significantly reduce its thermal insulation properties when wet.

A common drawback of both materials is difficulty in installation. When laying the insulating layer, joints and cracks are formed that require high-quality sealing. In addition, both glass wool and mineral wool need additional waterproofing or vapor barrier.

POLYURETHANE FOAM

Polyurethane foam is an excellent modern material; in fact, it is a plastic foam that must be sprayed onto the insulated surface from a cylinder. It is very easy to use, moisture resistant, has a very low weight and high noise insulation and vapor barrier properties. In addition, polyurethane foam forms a continuous coating and fits tightly to the sheathing, which completely eliminates the appearance of seams and heat leakage. An important advantage of polyurethane foam is that it does not rot and provides an unfavorable environment for the development of bacteria and fungus. Polyurethane foam has high strength characteristics and a high degree of penetration into wood. There is no need to use any fastening devices when “laying” it.

" Important. Perhaps the only drawback of polyurethane foam is its high cost.

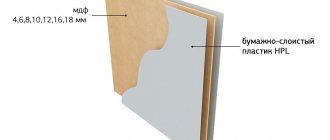

Particle boards (MDF, OSB, chipboard)

How can you decorate the attic cheaper? It will be less expensive to use particle boards, which are made from wood processing waste. This material is a mixture of chips or shavings with a binder. All these elements are connected to each other passing through the press. But it is worth keeping in mind that compared to solid wood, such slabs are more susceptible to loads, especially bending ones.

How to decorate the walls in the attic? Chipboard is also suitable for this. This is a domestic version of the slabs. They have a chaotic arrangement of chips. By finishing the attic with chipboards, the owners have an excellent opportunity to save money.

In OSB, chips or shavings are arranged in three layers, and sometimes more. In each of them it is only in one direction. In adjacent layers, the arrangement of shavings or chips is perpendicular. That is why this material was called OSB, which means “oriented strand board”. This design allows it to more resistantly withstand bending forces. That is why when home owners are wondering how to decorate an attic ceiling that has a complex structure, they should pay attention to OSB boards.

But it is worth keeping in mind that in the manufacture of the wood-based materials described above, phenol-formaldehyde resin is used. And it is a substance that emits harmful fumes. That is why for residential premises it is necessary to purchase slabs that correspond to a certain emission class of toxic elements. These are E0 and also E1. In this case, the material must be covered, for example, with ordinary wallpaper.

MDF boards are also made from shavings. However, they differ from previous materials in that:

- binders are paraffin and lignin, harmless to health;

- During its production, a decorative cladding (melamine film or veneer) is applied on one side of the slab.

MDF boards are environmentally friendly. That is why they can be used directly for finishing. The wood-based material OSB and chipboard is rough and needs to be covered with a decorative layer.

Expanded polystyrene (PENOPLEX)

Expanded polystyrene is an improved and more expensive version of polystyrene foam. This material is characterized by high strength and moisture resistance. Typically, in construction stores, polystyrene foam is offered in the form of slabs with grooves for tight joining, which allows you to create light thermal insulation without gaps. Like polystyrene foam, penoplex is a flammable material that emits dangerous toxic compounds when burned.

SAWDUST

Sometimes, when insulating yourself, they use the “old-fashioned” method - sawdust. This is an environmentally friendly and very cheap material - sometimes you can get it absolutely free. However, sawdust is susceptible to getting wet and rotting. In addition, they are highly flammable and are a favorite habitat for rodents. If you use a sawdust-cement mixture rather than pure sawdust as insulation, many disadvantages can be avoided - such insulation does not burn, does not rot, and does not attract mice and insects. However, the sawdust-cement mixture is heavy enough to be used to insulate an attic space in a wooden house, and can overload the supporting structure and floors.

PVC panels

How to decorate the attic inside (see photo below)?

For this you can use PVC panels. This material consists of two plates, which are separated from each other by stiffening ribs. Such panels, as a rule, are produced with a structural element, with the help of which one part can be connected to another. Construction stores offer this material in a wide range of colors. A huge range of panels allows you to use them to implement a wide variety of design solutions.

How to decorate an attic inexpensively? To do this, you should pay attention to plastic panels. In addition to the low price, they also have a number of other advantages, namely:

- waterproof;

- smooth surface that is easy to care for;

- softness, which makes it easy to handle the panels when installing them;

- ease of installation, which you can easily do yourself.

However, in addition to the impressive list of advantages, this material also has some disadvantages. Among them:

- the likelihood of releasing harmful substances hazardous to health, which is especially important in the case of panels made of cheap plastic;

- fire hazard and the release of toxic smoke during combustion;

- low strength under mechanical stress;

- lack of comfort in a room decorated with plastic.

PVC panels are a budget material for interior decoration. But most often they are used for rooms where permanent occupancy is not expected and hygiene and moisture resistance are required. That is why such panels are in demand in bathrooms, on balconies and in hallways. It is still undesirable to use them for finishing residential attics.

HOW TO CORRECTLY INSULATE AN ATTIC

If you do not plan to subsequently turn the attic into a residential attic, you can limit yourself to only insulating the floors. In any case, it will be possible to properly insulate the roof at another time.

To independently insulate the roof from the inside in a wooden house, it is recommended to adhere to the following sequence: 1. Empty the attic space from things and debris. 2. Treat the floor and beams for sheathing and joists with an antiseptic. 3. Inspect the floor for cracks, if necessary, coat the cracks with clay or caulk. 4. Cover the floor with waterproofing material with good vapor permeability properties. Otherwise, moisture will condense on the ceiling, causing it to rot. 5. Strengthen the logs and sheathing for laying the thermal insulation layer (if necessary). 6. Lay thermal insulation material. All joints and gaps must be sealed. 7. Cover the insulation with waterproofing material (this time vapor-tight). 8. Perform final flooring. The recommended thickness of the gap between the vapor barrier and the finishing flooring is 20-30 millimeters.

Insulating the roof of a wooden house is not a whim, but a necessary measure. Most Russian regions are characterized by cold winters, so it would be very imprudent not to take care of the comprehensive insulation of a private home.

How and with what to insulate is up to you. Choose what suits your budget and your goals.

What is a mansard roof

According to SNiP 2.08.01-89, an attic is a floor in the attic space, the facade of which is fully or partially formed by the surface (surfaces) of a sloping or sloping roof.

Note. A wooden attic is considered a floor, and by adding it to an existing private house, you automatically transfer it from a one-story building to a multi-story one. Therefore, we are required to document these changes.

The attic roof, unlike other types, is both a flat roof and a wall of a living room located in the attic. Often it has the shape of a sloping roof, consisting of two planes, but other architectural solutions are possible.

FINISHING THE ATTIC

Finishing work in the attic of a wooden house is not an easy task, requiring an integrated approach. To make rooms cozy and attractive, you will need high-quality materials and the experienced hands of professionals.

You can cover the walls with clapboard, imitation timber, or a block house made of larch, pine, or spruce. This is a budget and simple option.

First, preparatory work is carried out - several days are needed to acclimatize the wooden panels. Then the surfaces of the walls must be treated with an antiseptic to protect against fungus and insects. After this, the sheathing is installed, the heat-insulating material is mounted, its thickness must be at least 50 mm. Next, you need to install a vapor barrier film.

INSTALLATION OF PARTITIONS

To place partitions, boards with a width of 20 to 100 mm are lowered from the outer beam of the ceiling base to the floor, serving as the base of the partition. Then additional bars are placed horizontally. The space for the doors is arranged in the same way. The reverse side is covered with horizontal boards with a gap of 0.5 mm. Next, waterproofing is attached inside and finishing material is installed.

A house with an attic involves placing in it an interior partition 10-15 cm wide, which can be made of wood or channels. The channel is attached to the wall on all sides with self-tapping screws. Inside the installation, a channel descends from the ceiling to the floor with a running start. Wooden beams are screwed to the channels with self-tapping screws, drywall - with self-tapping screws to a metal structure, lining - with nails to horizontal bars.

WALL FINISHING

Various materials can be used for interior upholstery: lining, block house, imitation timber, plywood, plasterboard, plastic or hardboard. If you use drywall, then after covering it you can only cover it with wallpaper or paint it with water-based emulsion, so choosing wood for decoration may be the most convenient and attractive option.

Projects of houses with an attic often involve dividing the attic floor into rooms using partitions or adding built-in wardrobes. Initially, you need to sheathe the roof slopes and gables, then the ceiling. When decorating the slopes, the bars are horizontally fixed to the rafters with a difference of 1 m, and plasterboard is attached on top and all the cracks are filled with putty. The lining is installed on a wooden base with nails in the joint areas, and then varnished. When covering, you need to constantly check the correct placement using a level.

Block house

How to decorate the attic from the inside? Another type of wooden cladding is a block house. What is this material? Many people are familiar with croakers. They represent the sidewall of a rounded log. This part is cut off when turning the trunk into timber or when dissolving the tree trunk into an unedged board. Croaker is a waste product from such production, which is why it is sold inexpensively.

Another thing is a block house. This material is a calibrated slab made specifically for interior decoration. The block house boards are the same width, and they all have a smooth edge. There are grooves cut into the back of this material. Their presence allows you to relieve the internal stress of the cladding, which prevents it from cracking.

How to decorate the attic walls? Owners who want their premises to look like they were made of logs are recommended to purchase a block house.

In this case, how to finish the inside of the attic (photo below)?

It is worth keeping in mind that narrower boards are used for such work. Due to their slight convexity, they will not take up much space. Wide boards should not be used in this case. They are usually used for cladding the outside of buildings.

FLOORING

The base of the floor is a coniferous plank flooring at least 4 cm thick on joists with beams laid on top. There must be a gap between the boards and the insulation, and between the boards - no more than 2 mm, from the wall - at least 1 cm. To make it convenient, it is better to number the boards and lay them in order; installation is carried out using self-tapping screws.

" Important. Dry boards are treated on the back side with antiseptics against rot, fungus, insects, and in order to increase fire resistance.

Plank flooring has many advantages. Among them are excellent strength and elasticity. It is cheap, durable, if installed correctly, and can be easily repaired.

It is recommended to lay a plank floor in the attic room only after all planned construction work has been completed. When the windows are installed, the doors are installed, the plastering and painting work is completed, you can start working on the floor.

The flooring is made from boards made from various types of wood - pine, spruce, fir, cedar, birch, and larch. Their standard sizes are: 28-45 mm in thickness and 119-135 in width. The dimensions of the logs depend on how they are laid; as a rule, their width is 70-100 mm, and their thickness is from 40 to 70 mm. The thickness of the lining should be 20-50 mm.

Next, joists are supports for floors and platforms. They can be metal beams, logs or beams located horizontally.

Before you start laying the floor, all materials used for this are subject to mandatory treatment with antiseptic agents, and the boards are only on the bottom edges, and the lining and joists are completely on all sides. Nails are used to attach boards to the joists. But for convenience during further repairs, it is better to use self-tapping screws.

Carefully carried out preparatory work will greatly facilitate the installation of the floor. First of all, you need to get rid of the old floor, if there is any. Then proceed to leveling and cleaning the surface, sealing the gaps between the floor slabs and walls well, without leaving any gaps. And, of course, remove construction waste.

Despite the fact that wooden floors themselves are very warm, you can use foam insulation if desired. It is placed in a layer on waterproofing material.

Finally, the final operation is the actual installation of the floorboard. Having finally removed the construction debris, they begin laying the boards on the joists - with ridges in one direction in one layer. The boards should fit snugly against each other. The ridges are driven into the grooves using a hammer. Nails or screws are attached to the base of the ridge so that they do not protrude. At the end, you need to check the floor again for unevenness and protruding nails.

And one more detail. When laying floors along the entire perimeter of the room, a small gap, about a centimeter, is made between the walls for laying sound insulation. Aesthetics will not suffer - the baseboard will help. But in the future, with thermal expansion of the base, curvature of the floors can be avoided.

Varieties

All mansard roofs can be classified into 4 categories, each with different designs. Moreover, such attics can be single-level or two-level. It is easier to build a one-level attic. As a rule, this design involves the construction of a conventional gable or sloping roof.

Two-level attics are more difficult to construct. This design involves the construction of 2 rooms at different levels. In this case, the method of combining supports is used.

In the photo of the attic roof you can clearly see the design options for such structures. Additionally, a balcony can be provided. It is constructed by analogy with a window opening.

But this possibility depends on the load-bearing capacity of the walls. If it is not enough, a balcony can be built using additional supports.

FINISHING THE ATTIC CEILING

The desired ceiling height is from 2.2 m. To do this, a measurement is made from the flooring to the rafter ridge, and a mark must be made at the point with the achieved height. A block is placed between the opposite rafters, attached only on one side, and the other (unfastened) is installed to the mark and secured with self-tapping screws. After placing all the rafters, the base of the ceiling can be considered ready. It will be more reliable if you additionally attach cross beams. Sometimes it is also allowed to place vertical bars from the outermost to the floor, which serve as the basis. The finished structure is sheathed with boards with a gap of 0.1 mm or plasterboard. Waterproofing is nailed on top of the boards and a thick insulating layer is laid. The decoration of the ceiling depends on your own desire.

Drywall

How to finish an attic? You can also use drywall for this room. It is a cheap sheet material used for rough cladding. It is plaster covered with cardboard. The material can be:

- ordinary;

- fire resistant;

- moisture resistant;

- moisture- and fire-resistant.

You can decorate an attic with plasterboard in a very original way.

Elements of rather complex and bizarre shapes can be constructed from this material without much difficulty. If you make perforations in a layer of cardboard using a needle roller, and then moisten the sheet with water, it will become flexible. This will allow you to make an arch, a multi-level ceiling with curved outlines and other complex structures.

STAIRWAY TO THE ATTIC

To access the attic, the best option is a staircase. If space allows, you can install a full-fledged structure, but you can also choose an option with a retractable attic ladder and hatch. Another option is a staircase outside.

Initially, you need to plan the staircase, but it is worth considering that its width varies from 80 to 100 cm, balusters and handrails are placed in mandatory steps. The railings are installed at a height of 90 cm, the step should be 19-26 cm in height.

Four-slope

It differs from a gable roof in that instead of vertical gables, two inclined planes with a roof are installed. A complex truss system for an attic roof, requiring precise calculations and experience. The usable area is small.

The positive aspects are an attractive appearance and the least exposure to wind. Air masses simply flow around such a structure.