Stove maker.. +375 (29) 127-50-30

If you call a stove maker and start asking him what size the stove should be in your house, you can believe that each stove maker will give you his own estimate. It’s good if you come across a competent and decent specialist and correctly calculate the optimal size of the stove, based on the characteristics of your home or premises. But this doesn't always happen. You must understand that the work of a stove maker depends on the amount of brick that will be used to lay the stove, and therefore it is important for many stove makers to include a larger size than necessary in the stove design. In this case, you may receive a stove with too high thermal characteristics, which will lead to unnecessary costs on your part for its construction and operation.

It must be said that quite often there are cases when the Customer, due to his financial condition, asks to build a small or small stove. In this case, a situation may arise that this stove will not be able to warm up the room in the house and will simply be ineffective. You will simply heat it for wear and tear and significantly increase the consumption of firewood.

The stove in the house must have optimal dimensions, calculated on the basis of the characteristics of the premises of the house, which include such as the area of the heated room, insulation of the house, the type of stove and its shape, and some others.

Before looking for a stove maker, calculate what size your stove should be. Knowing this data, you can have a reasoned conversation with any Stove Man and convincingly appeal to him.

Payment service tarexi.by © 2020

Calculation of the number of bricks

Regardless of the type of brick block, they all have the same standard dimensions.

This makes it possible to use several varieties at once in one masonry, without having to rack your brains trying to align the rows. Bricks have the following dimensions:

- single (standard) - 250x120x65 millimeters;

- one and a half - 250x120x88 millimeters;

- double - 250x120x138 millimeters.

There are also other options, but these are, as a rule, European standards that are not applied in our country.

For kiln construction, as a rule, single bricks are used, sometimes one-and-a-half bricks. Double is not suitable in this case. The fact is that it is usually hollow, that is, it has a large number of holes in the structure. This is done in order to reduce its weight.

We only need solid blocks. Hollow ones accumulate heat much worse and are destroyed more quickly under the influence of various aggressive factors.

Let's move on directly to the calculations. For them, we need only two indicators: the number of bricks from which the lowest continuous row is laid, that is, the base, and also the number of rows. All this is easy to calculate if you know the dimensions of the blocks you are going to use.

Having calculated the amount of material in the base, multiply it by the number of rows of which the oven will consist. In this case, only those departments that go up to the chimney are taken into account. Subtract a third from the resulting product, and you will have the required number of bricks.

We carry out calculations for the chimney separately. There you take the number of bricks in one row, multiply by the number of rows and do not subtract anything.

That's all. All that remains is to add up the results. Now you know how many bricks you will need to build a fireplace. Don't forget to add about 5% in case of replacing blocks broken during construction. Good luck and warmth in your home!

Recommendations for selection

The model and dimensions of the stove are selected depending on the assigned functions.

Hearth stoves for heating a home are selected taking into account their location. You need to calculate in advance what dimensions the device should have. You must also ensure that the chimney pipe is at least 1 meter in length. An equally important indicator is power. The higher it is, the better the oven heats. But a powerful device will require more fuel.

Popular models for residential premises:

- Fireplace stoves WGO. Manufactured in Germany and made from fireproof fireclay HBO+.

- ECO+ oven. It has a simple design and low cost. Made from fireproof materials.

To heat non-residential premises (bathhouse, garage), you also need to select a model based on power and size. Externally, such hearth sauna stoves look less attractive, but their cost is lower. It is recommended to take stoves of the KIV, PKO-40 series. They are able to heat a room to the desired level without significant fuel costs.

Features of stove masonry

In order for a stove in the country, laid with your own hands, to serve for a long time, each row should be checked for right angles and horizontal surface. The laying sequence is visible in the order drawing.

The cast iron doors of the blower and combustion chamber are secured using steel wire, which is embedded in the masonry. The cuts are made with a grinder. As a last resort, you can do it the old fashioned way - with a mason's hammer, but in this case there may be a lot of waste for scrap. The area for the grate should be slightly larger than the size of the grate itself. Then, when heated, the metal will not move the brick.

The solution is applied to the wet brick. Experienced stove makers do this not with a trowel, but with their hands. A good solution spreads as easily as soft butter spreads on bread.

Important Note

If during laying the brick sank lower than necessary, it should be removed, the mortar cleaned and laid on a fresh one. Otherwise, the new stove at the dacha will smoke heavily and leak soot. Unlike cement mortar, bricks cannot be moved in clay mortar!

When building a stove for your dacha, try to make the inner walls as smooth as possible. Then soot will not linger on them, and it will be easier and less likely to need to be cleaned. The outside of the country stove should also be neat and beautiful. External seams should be carefully embroidered with a needle or finger. There should also be no gaps in the places where arches and horizontal partitions are formed. It is better to lay such rows slowly, one per day, so that the lower rows have time to set, and the upper rows do not creep.

Chimney device

When it comes to heating equipment that runs on solid fuel, it is imperative to install a chimney. In this case, the chimney is made from a pipe with a diameter of 100 mm.

At a distance of 50–100 mm from the upper edge of the stove, a chimney pipe is cut in. This is a length of steel pipe into which the chimney will fit tightly. The smoke channel is made with a small horizontal section - 50 - 60 cm of a straight pipe is enough to weaken the draft. A large number of knees before leaving the premises is not allowed.

A chimney made of several sections is easy to use. This way you can clean it without any problems.

Brick stove shapes for home

In addition to the specific functions, other parameters can be used to classify brick kilns.

The following types of stoves for brick houses are found in shape:

- Rectangular. It is easiest to build such structures.

- Square. They have the most compact sizes.

- Angular. An excellent option for small spaces and rooms with complex configurations.

- Round. A very exotic and beautiful option.

- T-shaped. The most traditional type of brick stoves for the home.

The shape of the stove is usually chosen based on the specific installation location and the preferences of the home owners.

There are also varieties of home stoves based on the firebox model, where the main parameter is the wall thickness:

- Thick-walled. They are characterized by the highest efficiency.

- Thin-walled. They are equipped only with cooking types of brick stoves.

- Combined. Typically used in heating and cooking stoves for home use.

As a rule, the finished brick furnace structure is additionally finished in one way or another.

For these purposes the following can be used:

- Plaster.

- Decorative brick.

- Tiles or stove tiles.

- Special metal case.

The choice of finishing option mainly depends on the overall interior of the home and the type of brick stove. The first three options will require the use of a special heat-resistant solution based on high-quality clay. In principle, for this you can use the same mixture on which the masonry was carried out. Factory-packed dry powders are especially good in this regard: to prepare the finished solution, they must be diluted in water in the proportions indicated on the packaging. In the case of plaster, an additional reinforcing mesh made of steel is usually used, which is fixed to the brick walls. Plastering work is permitted only after the masonry has completely dried.

As for cladding with decorative bricks or tiles, only special heat-resistant samples that can withstand significant temperature fluctuations can be used for these purposes. In some cases, brick walls are left without any finishing, but for this the masonry must be done to the highest possible quality. This is also allowed in cases where there are no special requirements for the external design of the furnace. This happens, for example, if the heating structure is built somewhere in a garage, barn or greenhouse.

Conclusion

A simple stove for a summer house or private home can have a different design. There are many models of heating devices made of brick, which differ in both appearance and functional characteristics.

When choosing a type, you should take into account the purpose of the unit, the size of the room and the period of operation. One of the main steps is choosing the location of the stove: it should be installed near a wall with an adjacent room. This way you will achieve the most optimal temperature for the whole house.

Laying and lining of the firebox and furnace wells

The laying and lining of the furnace should be carried out only according to accurate, pre-made calculations. Fireboxes up to 42 cm wide should be covered with a simplified triangular vault, placing the brick flat, followed by continuation of the masonry walls, which will firmly press the heels to the underlying rows of masonry. If such a vault is erected without continuing the masonry, this may cause the heels to shift due to the thrust of the vault, and then lead to its collapse.

To avoid this, the heels laid under the arch for laying the firebox must be tightened using pieces of square, rectangular, corner or T-steel connected with a wire harness. A wire bundle consists of several wires twisted together using a nail.

The harness should be located inside the masonry, in the seam. If the harness is open, it will quickly burn out. Instead of wire, you can use strip steel, firmly fixing it to the bars. In some designs, the ends of the bars may extend outward. In this case, they should be tied together with strands or round steel rods with threads and nuts at the ends, for which holes should be drilled in the ends of the bars.

Fireboxes with spans up to 38 cm can be covered by releasing bricks from the side walls of the masonry. To firmly fix the overhanging supporting bricks, the side walls of the masonry must be located at least four rows of masonry above the row to be overlapped. The more rows are laid out, the better the laying of the furnace fireboxes, this way you can avoid the ceiling tipping over inside the furnace.

In the process of laying furnace wells, it is recommended to block the combustion openings with various jumpers.

It is forbidden to rest bricks on the door frame. If the width of the combustion hole is less than 250 mm, it is blocked into a lock by cutting off the brick. If the opening width is more than a brick, it is necessary to make a brick lintel. Date: September 25, 2022

Type of fuel

Stoves in country houses can be heated in two different ways.

- Solid fuel;

- Universal.

Solid fuels include coal and firewood. They are superior to electric and gas.

Heating with gas or solid fuel can be considered universal. In this case, when one fuel runs out, you can switch to another. From gas to wood or coal and vice versa.

The first method or boiler No. 1

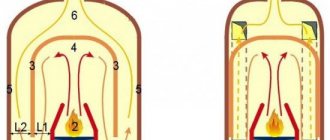

The natural vortex is replaced by forced pressurization, and pyrolysis is divided into two stages in space: a pyrolysis chamber, a nozzle (nozzle) that forms a flow of pyrolysis gases, and a combustion chamber. The nozzle is made so that there are no parasitic turbulence behind the mass of fuel. To ensure complete control over the process, through blowing is necessary.

Features of direct-flow and heat-storing pyrolysis boilers:

The temperature in the combustion chamber is a parameter necessary to control the process. Optimization of heat dissipation is directly proportional to the intensity of the boost. The system is insensitive to the temperature of the walls of the combustion chamber, so the water heater can be installed in a technically convenient way. Additional loading is possible at any stage and in any acceptable quantity.

Note: the rate of pyrolysis and the composition of gases is affected by the type of fuel. These factors are taken into account by regulating the back pressure at the outlet by throttling the chimney. Regulators for industrial solid fuel boilers are equipped with marks indicating the recommended type of fuel.

The efficiency of once-through boilers can be above 90%. They require power to operate. When switching off, to further start the system, it is necessary to remove the sintered mass and make a new filling in the firebox.

Steam-assisted solid fuel boilers use different types of fuel

Technical nuances

- The oven should not be placed close to walls, objects, etc. Leave enough space around it.

- The oven gets very hot - do not keep flammable materials, fuel, or anything that can catch fire, dry out or melt near it.

- When making a chimney, think about how to clean it in the future. The best option is to make it collapsible.

- If the chimney pipe is prefabricated, install the elements so that the joints are located in the opposite direction in relation to the moving gases.

When cleaning out ash, leave some of it behind each time. If the combustion takes place on an ash bed, the bottom of the stove will not burn out longer.

Principle of operation

A bottom combustion furnace allows you to achieve high efficiency with minimal fuel consumption. The device allows for “top” combustion, evenly distributed from the top layers of firewood to the bottom. The air supplied through the combustion door ensures good oxidation of the fuel, which improves the quality of its combustion and increases the intensity of heat release.

The body of the stove is made of a polished stainless steel alloy, and the firebox is lined with fireclay bricks or other refractory material. This allows you to achieve a heating temperature of up to 420 degrees. The bricks heat up to 700 degrees, which guarantees stable combustion of the fuel even in difficult conditions (for example, with high humidity in the room where the stove is located).

Caring for a Russian stove

It is important to know not only how to heat a Russian stove, but also how to properly care for it. All furnace passages and working chambers should be cleaned in a timely manner.

The ash compartment is cleaned of accumulated ash every time the firebox is completed. First, its remains in the hearth are swept into the ash pit to be completely removed, for which they use a shuffle - a special metal scoop attached to a long handle.

Typically, major cleaning is carried out once a year on the eve of the heating season. When carrying out cleaning, openings are used that are closed by doors that are provided in the design. This procedure is performed with a poker. It is used to remove the remaining ash and soot accumulated on the inner surfaces of the walls through open holes.

You can remove plaque more thoroughly with a broom made of hard rods. After cleaning, the doors of the openings are tightly closed. The chimney is cleaned of soot, condensation or foreign objects once a year with a special hose or rope with a weight at the end. But in this case it is better to use the help of specialists.