To provide water to every consumer, the entire land under the city is riddled with pipes.

Cities are settlements in which, in addition to a large number of domestic water consumers, there are also industrial facilities that also require its continuous supply. Therefore, the city water supply system is classified as large. This is a complex mechanism, the stable operation of which depends on many interrelated factors.

Types of water supply sources

First you need to decide which source of water supply for a private home is best suited for your case. Before choosing a system, you need to understand that the water consumption rate per person is 200 liters per day. This figure was not taken out of thin air, but from regulatory documentation - SNiP 2.04.01-85 * “Internal water supply and sewerage of buildings.”

Please note that if you have a vegetable garden or green spaces, then the consumption rate should be even higher. For these purposes, it is recommended to take into account at least 5 liters of water per square meter of land area.

If we take as an example an average family of two adults and children who live in a house with flower plants and flower beds measuring 20 m2, the following formula is obtained: V = 4 people × 200 liters + 5 liters × 20 m2 = 800 l + 100 l = 900 liters per day.

As you can see, the estimated water consumption for a home is quite high, so the choice of source for the water supply system must be well reasoned. Otherwise, problems with water supply may occur.

Currently, there are only two options for such systems available to us: main water pipelines or private water sources. We will talk about them in more detail below.

Connection to the main water supply

This option can also be called stationary - it is simple in terms of technical measures, which is why it is in greatest demand among homeowners. The water supply system is designed in such a way that its basis is the main pipe. Branches go from it and distribution networks are laid, from which, in turn, intra-block networks are formed. The last sections are where the consumer facilities are connected. The documentation that regulates all these activities is SNiP 2.04.02-84* “Water supply, external networks and structures.”

In order to use this method, the property owner must contact a company that provides network maintenance. After reviewing the request, she makes a decision about the possibility of connection in your particular case. If the answer is positive, all necessary documents are drawn up and a permit is issued. It indicates the connection conditions, as well as the recommended water supply scheme. After this, the owner has the right to lay the necessary communications to connect to the network. This can be done on your own or with the help of contractors.

Main water supply

Autonomous water supply

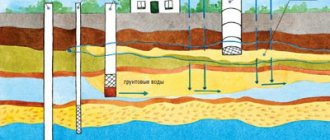

Autonomous water supply is considered the most optimal option for people who do not have the opportunity to connect to the main water supply. For example, in country houses where there are no communications nearby. Water can be used from a well, river, well and other sources. Remember that the distance of the water source from the septic tank and cesspool must be at least 20 meters. This is a necessary condition for safety reasons so that wastewater does not get into drinking water.

Experts advise drilling a well or digging a well near the house so that the costs of excavation work and pipeline installation can be minimized. Before starting work, you must make sure that water will flow in sufficient quantity.

If we are talking about a house where you live permanently, the ideal option would be to install a well for drinking water and a well for technical water, which will be used for watering the garden.

Problems with wells and methods for solving them

The most common problems with artesian wells are:

- flow rate reduction;

- deterioration of water quality;

- increase in sand content.

Before you can solve a problem, you need to determine its cause. The reasons may be different:

- a hydraulic connection may occur between the aquifer and the layers of rock located above;

- the pipe wall may be damaged;

- The casing plug may be depressurized;

- the production casing filter may be destroyed;

- connections between sections of the production string or casing may be broken;

- The number of wells in the area may simply increase.

In order to find out the reasons for the deterioration of the well's performance, a television inspection is carried out. For television inspection, a special camera is used that is lowered into the water. This camera films and records on tape the condition in which the internal walls of the water-lifting pipe are located along the entire length of the water pipe. This operation is also called well telelogging.

Although the procedure is not very cheap - about $3 per meter, it allows you to quickly find out the causes of malfunctions and make a decision on the advisability of restoration work or the need to drill a new well. In addition, by accurately determining the location of the problem, the cost of repairing the water supply system is reduced.

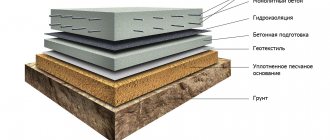

Plumbing structure

The water supply system in a private house is made up of two parts: internal and external. The latter ensures the connection of the water source with the building. Depending on the type of external part, its configuration and design may differ slightly.

The simplest way is to connect to the distribution network. In this case, the outer part of the system will look like a regular section of pipeline. The parameters of the working environment in it will be determined by the characteristics of the central pipeline after the pumping station.

If you are planning to connect to an autonomous water source, in addition to external pipelines, you need to pay attention to:

- Pumping equipment

, which is responsible for transporting water to water collection points. Depending on the conditions, submersible or surface type pumps can be used. - Automation systems

that are responsible for quality work and regulate pressure in the internal network. - Filters.

Usually two filters are installed, which are responsible for coarse and fine water purification. - Water tanks.

They are necessary to create a small supply of water. From the water tank, water flows to consumers. It should be understood that the pressure of the container decreases after a person opens the tap. The automation reacts to this and turns on the pumping equipment, which replenishes the volume to a predetermined level.

The water supply system in an individual private house can use a water tank or a pumping station. The latter option is more preferable, since it eliminates the need to install the container at a high height (up to 4 meters). But it should be noted that the pumping station is more expensive.

Correct installation of external water supply is a prerequisite in order to ensure high-quality and uninterrupted operation of the system at any time of the year. It must be installed below the freezing point of the soil. Please note that this setting differs by region. You can find it out from the table SNiP 2.01.01-82 “Construction climatology and geophysics”. For the southern regions of Russia, this parameter is usually from 60 cm and gradually increases towards the north and east.

Installation of external water supply

Quite often, our compatriots who live in cold regions of Russia have a question about how to bring water into the house from the central water supply when the soil freezes to a depth of more than 1.5 m. In this case, excavation work will be very expensive. But the laying of pipelines is allowed below the required parameter if thermal insulation materials are used.

As for the internal plumbing, it consists of certain components that can be replaced depending on actual conditions. Typically, a water supply scheme includes the following elements:

- Pipelines with different sections.

- Water meters (when connected to a central water supply).

- Boilers, which are responsible for heating water.

- Shut-off valves. It is necessary to shut off the supply of the working medium and carry out repair or inspection work.

Current requirements

The quality of drinking water is regulated by SanPiN 2.1.4.1074-01. The main requirement of sanitary standards is that water should not pose a danger in epidemiological and radiation terms. It should be harmless in chemical composition and have pleasant organoleptic characteristics. The quality of the water environment must comply with hygienic standards before being supplied to distributors and at water distribution points in the water supply network.

With regard to technical standards for aquifer pipelines, SNiPs and TKP impose the following requirements:

- supplying specified volumes of liquid to water consumption points under the required pressure;

- high level of reliability and uninterrupted water supply;

- accessibility of utilities for water consumers;

- cost-effectiveness of water supply systems projects, involving a minimum of costs for arrangement and operation.

Fulfillment of the requirements is achieved by competent selection of the configuration of the water supply system and pipe material, as well as the correct determination of the technological and economic characteristics of all parts of the pipeline.

Development of a water supply scheme

Before starting work, you need to pay special attention to the design stage. It is best to create a sketch of the future system, determine the diameter and select equipment. This will help calculate the required lengths of pipes for purchase, and will also simplify the installation of water supply in a private house.

You also need to consider:

- Pipe routing option.

- The need to use collectors and their quantity.

- Pumping equipment power.

- The need to use filters.

- Number of water points.

Ideally, a sketch of the water supply system in a private house should be developed based on the building plan, indicating the required distances and dimensions.

Daisy chain wiring

This type of wiring has a main vertical riser, from which branches are laid for each point of water consumption. The peculiarity of this scheme is that it is almost impossible to achieve the same pressure at all distribution points. The more turns, tees and pipe sections, the weaker the pressure.

Despite this drawback, there is a significant advantage of sequential wiring - efficiency due to minimal consumption of materials. This option will be best for a small 1-2 storey building with a small number of water points. The diameter of riser pipes for water supply in a private house must be at least 32 mm. For branches, inch and half-inch pipe sections can be used.

Collector wiring

The main feature of this scheme is the presence of so-called collectors. This system can be called a distribution node, i.e. supply from a centralized network. If the water supply in a private house is from a well, then water from it first of all enters the collector. Then water is supplied to risers, which are mounted directly into the collector. Each individual riser rises upward and can supply consumers with the same operating environment parameters. The disadvantage of such a system is its cost, since the construction of the collector wiring requires a large number of pipes.

When supplying water to a private home from a well, you need to take care of additional filters. Models with coarse cleaning should be quite sufficient. In order to ensure proper operation of the hot water supply system, a branch is made in front of the first collector, from which the water supply will go to the boiler. It is necessary to make an exit from the boiler in the collector, and then install the risers.

Note! Please note that the fewer turns and tees in your system, the stronger the pressure will be. Such elements increase hydraulic resistance when water passes through them and, thus, require a more powerful pump. This will increase both the construction budget and the operating cost because energy costs will increase significantly.

The laying of pipelines can be carried out using an open or hidden method. In the latter case, all elements of the water supply system of a private house are installed in grooves or ventilation shafts. The advantage of this method is that the pipes will not spoil the aesthetic appearance of the premises, unlike the open method.

Installation of pipes in grooves

Cavitation and its elimination

As practice shows, cavitation is the most common problem faced by owners of household plots with an autonomous water supply system.

The cause of cavitation is incorrectly selected pumping equipment. Water devices are selected taking into account the diameter of the well. For sizes less than 100 mm, plunger or circular models are suitable, 100 mm and more - submersible.

Cavitation is a violation of the density of the water column, in other words, the filling of the pipeline with air bubbles. Formed in areas with reduced pressure at a critical level. The phenomenon is accompanied by the formation of voids in the pipeline, bubble formations formed as a result of the interaction of gases and vapors released by well water.

It is not always possible to determine the faulty area yourself, since special equipment is required. It is also worth adding that this area may be unstable. If measures are not taken, the consequences will hit the pocket hard - dynamic effects on flow and vibration will lead to breakdown of pumping equipment.

To reduce the likelihood of a problem developing, you need to choose the right water pumps, taking into account the volumes of water consumed and the technical characteristics of the well.

To get rid of such an unpleasant phenomenon as the appearance of air in water, you need to consider the main ways to solve the problem:

Replace the small diameter pipe with a larger diameter pipe. Install pumping equipment closer to the storage tank

When transporting the pump, it is important to take into account the established standards: the interval between the container and the pump must be no less than 5 diameters of the suction pipe. Replace the valve with a gate type and remove the check valve. To reduce the pressure in the pipeline, the pipe is replaced with a smooth one. There should not be many turns in the suction pipe

To solve the problem, you need to replace small radius bends with large ones or simply reduce them. At the design stage of an autonomous water supply system, it is recommended to place all outlets in the same plane and use flexible pipes rather than rigid ones.

Selection of pipes for water supply

Thanks to the development of new technologies, the building materials market offers a wide variety of pipes. If 20-30 years ago metal pipes were considered to have no alternative, today they have been replaced by metal-plastic, polypropylene and polyethylene models. They surpass their predecessors not only in quality and duration of use, but also in labor costs during installation and cost. Let's look at what types of pipes are best used in a private home.

Polyethylene pipes

It should be noted that this is the most popular type among homeowners. Polyethylene pipes are used to create utility networks not only for private homes, but also for administrative, commercial and even industrial facilities. There are two types of such pipes.

PE grade polyethylene pipes

Such pipes are never used for hot water supply to a private home. The fact is that at water temperatures above 400C they lose their properties and become deformed. However, they have a number of advantages:

- They cope excellently with negative temperatures, so you can install water supply even in winter.

- High plasticity. Even if the PE polyethylene pipe was bent during transportation, this is not a big problem, because it will restore its previous shape.

- Quick and easy installation using fittings or soldering.

- Long service life.

PEX grade cross-linked polyethylene pipes

Pipes made of cross-linked polyethylene have improved production technology compared to the previous type. Thanks to it, they are characterized by increased temperature resistance and are able to withstand coolant up to 950C. This allows them to be used not only for hot water supply systems, but also for heating.

Since polyethylene has high oxygen permeability, which has a negative effect on the metal components of networks (shut-off devices, regulators, etc.), the pipes are additionally shielded with aluminum foil. Installation is carried out in the same way as in the previous case - with fittings and soldering.

Advantages of cross-linked polyethylene pipes:

- Thermal resistance.

- High strength.

- Corrosion resistance.

- Excellent elasticity.

- They do not overgrow from the inside.

- Environmentally friendly.

- Light weight, which facilitates the process of transportation and installation.

Note! Please note that polyethylene can be destroyed by ultraviolet rays. Therefore, pipes of this type must be installed in a hidden way or have additional protection.

Polyethylene pipes

Polypropylene pipes

It should be noted that polypropylene pipes are also in great demand among Russian citizens. The fact is that they are quite easy to work with, and all you need is a special soldering iron. Pipeline sections are connected using couplings. It must be said that this connection is not inferior in reliability to a welding seam. Installation of water supply can be carried out using two types of polypropylene pipes:

- Single layer.

Such pipes are made purely from polypropylene and are considered the most economical option. - Multilayer.

This is a more reliable analogue, because its design contains several reinforcing layers. Aluminum or fiberglass can be used as reinforcement material.

Advantages of polypropylene pipes:

- Chemical resistance.

- Resistance to high pressure – up to 2.5 MPa.

- Ecological cleanliness.

- Reliability.

- Durability.

- Low hydraulic resistance.

- Fast and convenient installation.

- Resistance to temperature expansion.

Polypropylene pipes

Metal-plastic pipes

Metal-plastic pipes are often used to construct water supply systems. They can be used not only for the construction of new networks of private houses, but also for the reconstruction of existing ones, even in apartment buildings. Installation of elements is carried out using fittings that have a collet connection. Thanks to this solution, it is possible to create an effective water supply system for both cold and hot water in a short time (withstand coolant temperatures up to 950C).

There are cases when metal-plastic pipes are used even for intra-house heating systems. This allows you to save significantly without purchasing polypropylene analogues. As for the structure of a metal-plastic pipe, it has several layers of plastic and aluminum. They are attached to each other using a special adhesive composition, which turns the structure into a monolith.

The advantages of metal-plastic pipes include:

- Possibility of installing a water supply system with your own hands - installation does not require significant effort.

- Resistance to any mechanical damage.

- Light weight, which facilitates the transportation process.

- No problems with internal fouling and corrosion.

- Airtight design due to several screen layers.

- Resistance to freezing of the transported medium and water hammer.

- The service life is about 20 years.

- Acceptable price.

Before purchasing metal-plastic pipes, you should pay attention to their disadvantages:

- They may lose their properties when exposed to ultraviolet rays. Therefore, it is necessary to use a hidden installation method.

- They are not resistant to sudden temperature changes.

- May accumulate static electricity.

Other recommendations

The installation of a water supply system must be preceded by a detailed development of its diagram, taking into account all possible changes. In case of changes, special reserves must be left so that an increase in the number of consumers or the length of the water supply system does not lead to a violation of the permissible pressure values in the pipes.

It is necessary to take into account that it is possible to obtain a guarantee for the fittings that are supplied with the water supply system, i.e. collet or compression clamps, valves, water level limiters or fittings, only if it is provided by the installation organization itself.

To properly cool the motor of a submersible pump, a water flow rate of at least 0.15 m/s is required. To maintain such a speed when the well's flow rate is insufficient, it will be necessary to artificially increase the water speed at the suction point, so the pump is equipped with a water receiving chamber.

If the concentration of sand in water from a well exceeds 15 mg/l, then this leads to rapid wear of the pipes and the need to frequently backwash the filters, without which the life of the well itself is reduced. Therefore, it is necessary to find out the cause of such a problem, if it occurs, as soon as possible, using telelogging.

Installation features

Installation of the water supply can be carried out from the consumer to the collector or vice versa. But let's consider a situation in which the installation is performed from the consumer down. Let's take a two-story cottage as an example:

- A pipe is installed on the second floor (it will be a riser), and a 900C outlet is attached to its upper part. This section of the pipe is attached to the ventilation shaft using special clips.

- A small section of the pipeline is connected to the outlet, to which a ball valve and, if necessary, a water meter will be attached.

- After the water meter, it is necessary to leave a threaded connection. The hoses from your mixer will then be connected to it.

- A pipe of a size sufficient to connect to the future water collection point on the ground floor is installed at the bottom of the riser. Then a tee is attached to it, from which a section of the pipeline will go to the mixer.

- A section of pipe is connected to the tee to connect the riser to the manifold. In the future, it will be connected to the central water supply entrance in a private house.

Note! There must be sufficient distance between the cold and hot water risers for their maintenance. Sleeves should be used to pass through floors and walls. Fastening with clips should be done every 1-2 meters. In order to be able to perform quality maintenance in the future, it is recommended to install shut-off valves before connecting the riser to the collector. In this case, during repairs, it will be possible to turn off only the necessary riser, and not the entire house.

As for the diameters of pipelines for the water supply of a private house, it should be noted that their parameters depend on the number of water points. If you are using a collector circuit, and the height of the house is no more than 5 floors, then a cross-section of 100 mm will be sufficient for the collector, and 32 mm for the risers. For room-to-room wiring, the optimal diameter is considered to be 20mm.

Note! After completing the construction of intra-house water supply networks, it is necessary to conduct a test run. During this process, the installers (or you directly, if you installed the water supply yourself) with a flashlight must go around all the connections and visually check them for leaks. If no drips have formed within 20-30 minutes, then the work has been done efficiently.

A private house

Is an air vent needed in the domestic hot water system of a private home?

The answer is pretty obvious. An air vent is required if your hot water system uses recirculation and there are no plumbing fixtures at its highest point through which air can escape.

Please note: the presence of a high-pressure circulation pump, coupled with the low height of the circuit, means that you do not have to worry about stopping the circulation. However, air in the DHW system often causes annoying hydraulic noise.

If there are water draw-off points in the upper part of the DHW circuit, it can do without vents

Pumping station

If the water supply to a private home is from a well or borehole, then an indispensable attribute of such systems is a pumping station or pressure tank. Since the tank must be installed in the attic, and this requires quite a lot of effort, pumping stations are in greatest demand among homeowners.

This system perfectly performs the functions of transporting water both from the well and from the well, so its scope is quite wide. Particular attention should be paid to the fact that such mechanisms are quite sensitive to low temperatures. Thus, they must be installed in heated rooms, for example, on the basement or living floors.

When choosing a location for installing the pump, keep in mind that it makes noise during operation. If you plan to place the pump on a residential floor, it is recommended to allocate a separate small room or storage room for it.

When building a water supply system with your own hands, in particular installing a pumping station, take into account the fact that a check valve must be installed in the area from the water source to the station. It is installed to ensure the necessary conditions so that water from the pipeline does not return back to the well in the event of a regulator failure. It is recommended to install a filter in front of it for additional cleaning. Also, the pipelines that surround the pumping station must have shut-off elements on both sides. They are necessary for carrying out repair work.

The pumping station is installed using fittings. For this, two threads are used, which are located on the system body (at the inlet and outlet).

Note! Some models of pumping stations have a pressure switch and a damper tank in their design. These are compact devices with low productivity, which will be quite enough for 1-2 storey cottages. If we are talking about a large private house - for 2 or more families, the installation of more powerful pumping stations will be required. High-performance models are available in separate forms, i.e. the pump, relay and tank are located separately. Installing pumping stations of this type is a more complex process.

Pumping station

Removing air from the system with a circulation pump in the boiler

Modern boilers used in heating systems are equipped with circulation pumps to force the movement of liquid. Standard methods are used to ventilate circuits with these units. Certain differences exist for pumping units with a wet rotor. So, when performing the first startup of a heating system filled with coolant, you need to remove gas from the pump housing. This is done so that the sliding bearings do not fail and the rotor does not jam. The air can be released by unscrewing the screw located at the end of the pump with a screwdriver several turns. After liquid appears, tighten the screw and repeat the procedure with the pump running. If the heating has not been turned on for a long time, you need to turn the rotor manually. To do this, unscrew the mentioned screw completely and turn the rotor with a screwdriver. During this procedure, excess air is removed from the circuit.

Hydraulic accumulator

The hydraulic accumulator is not considered an essential element of the plumbing system, but recently it has become increasingly in demand. The purpose of such a vessel is to maintain a given pressure parameter in the system. As soon as the water flow increases, the accumulator begins to recharge the water supply. The fact is that experts distinguish between peak load in the morning and evening, i.e. when people are getting ready for work or taking a shower before going to bed.

During these periods, the peak load is distributed to the pumping group. And in order to reduce its negative consequences, a hydraulic accumulator is installed. It looks like a closed container, inside of which the space is divided by a rubber membrane. On one side there is water, and on the other there is air. As the flow rate increases, the pressure in the system drops, and part of the water from the accumulator goes to the consumer. As soon as the pressure decreases to a predetermined limit, the pump starts working and restores it to the required level.

The advantages of a hydraulic accumulator include:

- System tightness. The hydraulic accumulator prevents contact of the internal surfaces of the pipes with air, which increases their service life.

- Great pressure. Thanks to the rubber membrane inside the container, the pressure parameter is always maintained at the required level. Unlike storage tanks, which cannot provide the required pressure due to the fact that the water moves by gravity, the design of hydraulic accumulators allows you to create an automatic station.

Hydraulic accumulator

Main tasks of the device

To know how to choose a hydraulic accumulator, it is important to clearly understand what tasks it can solve. So, the hydraulic accumulator solves the following series of problems:

- the hydraulic accumulator is designed to maintain a given level of water pressure inside the system;

- the hydraulic accumulator-receiver should reduce the number of pump starts;

- hydraulic accumulators are designed to reduce the likelihood that there will be hydraulic shocks in the system;

- hydraulic accumulators retain a certain supply of water if there is no electricity for some reason.

It is very important that if there are any malfunctions of the hydraulic accumulator, they must be corrected immediately. This will help avoid serious consequences and accidents.

So, if you take a close look at the problems that hydraulic accumulators solve for water supply, you can come to the conclusion that they can extend the life of the pump for a long time. In addition, hydraulic accumulators for water supply are often necessary for backup water replenishment. It is very convenient and practical

It does not matter what kind of horizontal or vertical accumulator you have. Its operation will depend on the setting and application

If we take into account that the hydraulic accumulator (or rather its tank) has a usable volume of around forty percent, then we can find out how much “spare” water we get. The most optimal tank volume that is best to buy is one hundred liters. There is no need to try to buy a large tank if it will not be used at full capacity.

Important! If there are only two people living in the house, then it is enough for them to purchase a 24-liter hydraulic accumulator

The calculation is still simple. It is confirmed by practice. If three people live, you can purchase a 50-liter tank

Well, for four people you need to pay attention to tanks of 80 liters and above. There is probably no need to purchase a large tank for a family of two

This can be more expensive both during purchase and during operation.

Water purification systems

Water supply in a private home does not require a water treatment system, but if the water source is a well or well, we strongly recommend its installation. The fact is that such water can contain many impurities, and its quality, in most cases, does not meet the standards. And these are not only mechanical parts, but also an increased level of rigidity.

The best option would be to submit water from your source for special analysis. This will determine what kind of cleaning you need. Based on your results, you can choose the right cleaning equipment. This is the only way to achieve optimal results and quality. Installation of the water treatment system must be carried out immediately after installing the hydraulic accumulator. It looks like several filters that are installed in series. From time to time, filter cassettes need to be replaced as they have a certain lifespan.

Fine water purification systems are best installed directly at water points, for example, in kitchens. This way you can purify the volume of water that will be used for cooking.

Water after purification

Danger of air bubbles in the pipeline

Water hammer can rupture a pipe.

Bubbles, especially large ones, can destroy even strong elements of the pipeline. The main troubles they cause to owners of private houses:

- They accumulate in the same areas, leading to breakdowns of pipe sections and adapters. They also pose a risk for turning and twisting pipe sections where air is trapped.

- They break the water flow, which is inconvenient for the user. The taps “spit out” water all the time and vibrate.

- Causes water hammer.

Water hammer leads to the formation of longitudinal cracks, which causes the pipes to gradually collapse. As time passes, the pipe breaks at the point of cracking and the system stops functioning. Therefore, it is important to equip additional elements that allow you to quickly get rid of dangerous bubbles.