The efficiency (coefficient of performance) of a heating boiler is the ratio of the volume of fuel consumed to the volume of heat generated. The efficiency of even the most efficient modern models of hot water boilers cannot be 100% due to heat loss inside the boiler, insufficient thermal conductivity of metals, or imperfections in the operating principle. In addition, the efficiency of the same gas boiler model also depends on the load: the efficiency indicated in the passport is not real in the entire range of heating output.

In the article we will look at how to correctly calculate efficiency, what it depends on and how to increase the efficiency of an already purchased boiler on your own.

Gross efficiency and net efficiency

Not all the heat generated during fuel combustion is used to heat the coolant; a certain part is spent on the boiler unit’s own needs: turbine, fan or smoke exhauster, circulation pump, operation of automation and electronic display, operation of the electric drive (as you already understand, all types of energy received are used in the calculation , including electricity, if the boiler is volatile).

Taking this into account, it is customary to divide the boiler efficiency by the generated heat ( gross efficiency ) and the released heat ( net efficiency ).

This classification allows us to highlight the degree of technical perfection of the boiler - gross efficiency or efficiency of fuel and electricity consumption - net efficiency.

Underfloor heating circuits

Like the collector circuit, a water-heated floor is installed during the construction or renovation of a two-story house. There are 2 ways to install underfloor heating:

- embedding pipe coils in a cement-sand screed;

- layout of heating circuit pipes in heat-distributing metal plates without pouring screed.

The ends of pipes Ø16 x 2 mm, laid with a snake or snail, are connected to the comb, which was mentioned above and described in detail in a separate publication. A manifold with a mixing unit or RTL thermal heads ensures the supply of coolant to the circuits with a temperature not exceeding 50 °C.

The advantages of heated floors are obvious - real energy savings of 15-20% due to heating the surface to a temperature of 20-25 ° C and comfort for those living in the house. Now about the negative points:

- Installing a heated floor in a two-story home is not a cheap undertaking. In terms of the cost of materials and installation, this is the most expensive option for space heating.

- Heating circuits, especially in cement screeds, are very inert in terms of adjustment. Imagine, a cold monolith reaches operating mode within 24 hours. To prevent the room from overheating, a third of the required heating power should be supplied by batteries that quickly respond to changes in air temperature.

- In the event of a malfunction or water leak in the circuit, the concrete screed will have to be broken.

Method for installing heated floors without cement screed

Despite the problems listed above, heated floors are being used by homeowners more and more often - the heating is too comfortable and the fuel savings are noticeable. Unlike other heating systems, heating circuits do not spoil the interior of the premises at all.

How to calculate the efficiency of a heating boiler

Values can be calculated in several ways. In European countries, it is customary to calculate the efficiency of a heating boiler based on the temperature of the exhaust gases (direct balance method), that is, knowing the difference between the ambient temperature and the actual temperature of the gases exiting through the chimney. The formula is quite simple:

ηbr = (Q1/Qir) 100% , where

- ηbr (read “this”) – boiler efficiency “gross”;

- Q1 (MJ/kg) – the amount of heat that was accumulated, i.e. used for heating the house.

- Qir (MJ/kg) – the total amount of heat released during fuel combustion;

For example, if Q1 = 19 MJ/kg, Qir = 22 MJ/kg, then gross efficiency = (19/22)*100 = 86.3%. All measurements are carried out at an already established, standard boiler operating mode.

The direct balance method does not take into account the heat loss of the boiler itself, underburning of fuel, deviations in operation and other features, so a fundamentally different, more accurate calculation method was invented - the “reverse balance method”. The equation used is:

ηbr = 100 – (q2 + q3 + q4 + q5 + q6) , where

- q2 – heat loss with exhaust gases;

- q3 – heat loss due to chemical underburning of combustible gases (applicable to gas boilers);

- q4 – loss of thermal energy with mechanical underburning;

- q5 – heat loss from external cooling (through the heat exchanger and housing);

- q6 – heat loss with physical heat of slag removed from the furnace.

Net efficiency of the heating boiler according to the reverse balance method:

ηnet = ηbr - Qs.n , where

- Qс.н – total consumption of thermal and electrical energy for own needs in % expression.

The actual efficiency will almost always differ from that declared by the manufacturer, since it depends on the correct installation of the boiler and heating system, smoke removal system, quality of power supply, etc. It is measured, accordingly, already on the spot.

Other changes

Among other things, gas heating units equipped with modulating burners also have very good performance indicators. Modern boilers from the best European manufacturers are initially supplemented with similar two-level or fully modulated elements. Burners of this type are able to independently adapt to the actual operating parameters of the heating system installed in the house. Thus, the percentage of underburning in boilers of this design is reduced to a minimum.

In conventional heating units, home owners can, among other things, try changing the position of the burner. Installing this element closer to the water circuit allows you to increase the efficiency of the boiler by several percent. In this case, the heat balance of the unit increases significantly.

What determines the thermal efficiency of boiler units?

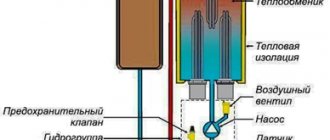

The operating principle of a classic floor-mounted gas atmosphere.

The efficiency of heating boilers is not equal at any power; there is a proportional dependence on the load: an increase in the thermal load (the amount of fuel burned) also increases heat loss through the body or chimney. Likewise, operation at minimum power does not always ensure complete combustion of fuel, which leads to a decrease in efficiency.

For example, the service instructions for gas boilers Protherm Wolf KSO with a power of 12.5 kW and 16.0 kW indicate that when operating at maximum power (12.8 kW and 16.3 kW, respectively), the efficiency is 92.5%, while time when operating with a minimum load (4.5 kW and 5.8 kW) - will decrease and amount to only 78.4%.

This is one of the main reasons why you should take a conscious approach to choosing the power of the boiler unit. The most optimal operation in most models is achieved at a load in the range of 60-90% of maximum power.

Otherwise, the efficiency depends solely on the technological excellence of the model, aimed at reducing the above-described q2-6 (reducing the temperature of exhaust gases, efficient combustion of fuel, modulating burners, thermal insulation, etc.), as well as on the quality of maintenance and operation of the boiler unit. Cleanliness of the coolant, regular cleaning and flushing - all this over time seriously affects the efficiency.

How to choose a room thermostat and save up to 30% per month on heating

The combustion chamber

The efficiency of a gas boiler is also affected by the type of combustion chamber, which can be open or closed. In an open chamber, air comes from the room, and in a closed chamber, air is forced from the street. A closed combustion chamber due to the coxial type of chimney, which increases the efficiency of the burned gas, is more economically advantageous.

Interesting material Gas boilers, rating of the best and what you should pay attention to when choosing heating equipment Good choice Gas boiler Bosch 6000

Values of modern boilers depending on the type of fuel

| Photo | Type of boiler depending on the fuel burned | Average efficiency, % |

| Gas | ||

| — Convection | 87-94 | |

| — Condensation | 104-116* | |

| Solid fuel | ||

| — Wood-burning | 75-87 | |

| — Coal | 80-88 | |

| — Pellet | 80-92 | |

| Liquid fuel | ||

| — On diesel fuel | 86-91 | |

| — On fuel oil | 85-88 | |

| Electric heating elements | 99-99,5 |

*From a physics point of view, efficiency cannot exceed 100%: it is impossible to obtain more thermal energy than is released when burning fuel. However, it all depends on how you count. There are two definitions:

- lower calorific value - the heat obtained during the combustion of fuel, when the combustion products are simply removed through the chimney;

- higher calorific value - heat, including the energy contained in water vapor - one of the products of combustion of flammable gases.

Gas condensing boilers additionally accumulate the thermal energy of condensate formed from gas combustion products and deposited on an additional heat exchanger. Thus, a significant part of the heat does not “fly out into the chimney”, and the temperature of the exhaust gases is almost equal to atmospheric.

Construction of a simple condensing single-circuit gas boiler.

According to current standards, both in Russia and in Europe, the efficiency of heating boilers is calculated based on the lowest specific calorific value, so taking into account the additional heat extracted from the condensate leads to values of more than 100%. When calculated based on the higher calorific value, the efficiency of condensing gas boilers is 96-98%, depending on the model and type of installation: wall-mounted boilers usually have higher efficiency than floor-standing boilers (this applies to all gas boilers).

Also from the table you can see that the average efficiency of solid fuel boilers also differs depending on the fuel used, this is due to the degree of fuel combustion, its heat transfer, combustion temperature and heat loss with physical heat of slag removed from the combustion chamber. Even the same solid fuel boiler can produce different efficiencies when operating on different types of fuel.

What to do with the chimney

The performance of boilers is greatly influenced by the condition of the combustion products discharge pipe. If the chimney becomes clogged with soot, this will reduce its diameter and, accordingly, draft. Experts recommend checking the condition of the pipe that discharges gas combustion products at least once a year.

To increase efficiency, it is best to connect a closed-type boiler to a coaxial chimney. In this case, the air will begin to enter the combustion chamber through the outer cavity of the two-cavity pipe, already slightly heated. This, in turn, will reduce the initial heat costs by several percent.

How to increase the efficiency of a gas boiler

It is almost impossible to increase the efficiency of fuel combustion by interfering with the technical structure of the boiler; it will not be possible to install the same layer of thermal insulation due to the banal failure of the manufacturer to provide a place for it. In addition, doing this yourself is prohibited. Nevertheless, there are ways to increase the efficiency of a gas boiler, especially if it is an imperfect old-style model:

- Ready-made economizer for chimney – replaces a certain section of the chimney and is designed to accumulate heat from gases exhausted through the chimney (some kind of imitation of condensing boilers). However, it is necessary to accurately calculate the parameters of the economizer and the requirements for the chimney in order to maintain the necessary draft and prevent reverse draft, for example, in strong winds. The issue price is 1,700-2,500 rubles.

Sandwich mesh economizer for chimney pipe. - A homemade economizer is almost identical to the finished products described above. We have already described how to make an effective economizer in one of the previous articles.

- Cleaning the boiler and flushing the heat exchanger are regular maintenance measures that are meaningless for new boiler units, but extremely effective for those that have been in use for at least several seasons. The fact is that during operation, scale and other salt deposits form inside the heat exchanger, and the external fins of the heat exchanger, burners and igniter become clogged. All this leads to an increase in gas consumption, a decrease in heating output, and, accordingly, a decrease in efficiency (often up to 20-30%). We have also already discussed how and how often it is necessary to clean a gas boiler.

- Gas filter - it is installed in front of the shut-off valve of the gas main and is designed to clean the gas from debris and impurities that are sometimes found in the composition. This not only helps reduce soot formation, but also, by improving the quality of the fuel, slightly reduces heat loss during underburning.

The remaining methods involve proper commissioning, which is carried out once, when the boiler is first started, exclusively by specialists. With correct initial settings, the efficiency guaranteed by the manufacturer is ensured. It is important to understand that it is impossible to increase this indicator by interfering with the technical structure of the boiler itself, and even more so, it is not safe.

Instructions BoilersEnergy-saving technologies

Operation of heat sensors

Turning the boiler on when it’s cold and off when it’s hot is not an economical idea, since it often turns out that the start is made earlier and the stop is made later than necessary. Fortunately, modern models include heat sensors that monitor the temperature in the room. When it drops to a certain limit, the heating boiler turns on, and when the air warms up, the power is interrupted.

The very presence of sensors increases the efficiency of the system, and incorrect configuration of devices or their incorrect placement reduces it.

In addition to monitoring the temperature, there are sensors for self-monitoring systems that monitor the condition of the boiler - for example, turn off the gas supply if the fire in the burner goes out.

Sensors of various types

Tips for choosing

The choice of radiator depends on the heating system installed in the house. For an autonomous design, it is recommended to use batteries made of cast iron, steel and aluminum. Such products can easily withstand circuit pressure.

In apartment buildings with central heating, cast iron or bimetallic products are installed. Such radiators will withstand increased circuit pressure and will last for many years.

The main criterion for choosing a battery is heat transfer. The temperature inside the room depends on this. Aluminum, steel and cast iron products have proven themselves well, so they are preferred by most users.

Operating rules for boiler devices, compliance with which affects the efficiency value

Any type of heating unit has its own optimal load parameters, which should be as useful as possible from a technological and economic point of view. The operation process of solid fuel boilers is designed in such a way that most of the time the equipment operates in optimal mode. This operation can be ensured by following the rules of operation of heating equipment operating on solid fuel. In this case, you must adhere to and follow the following points:

- it is necessary to observe acceptable modes of blowing and exhaust operation;

- constant control over the intensity of combustion and completeness of fuel combustion;

- control the amount of entrainment and failure;

- assessment of the condition of surfaces heated during fuel combustion;

- regular boiler cleaning.

The listed points are the necessary minimum that must be adhered to during the operation of boiler equipment during the heating season. Compliance with simple and understandable rules will allow you to obtain the efficiency of an autonomous boiler stated in the characteristics.

We can say that every little thing, every element of the design of a heating device affects the value of the efficiency factor. A properly designed chimney and ventilation system ensure optimal air flow into the combustion chamber, which significantly affects the quality of combustion of the fuel product. Ventilation performance is assessed by the excess air coefficient. An excessive increase in the volume of incoming air leads to excessive fuel consumption. Heat leaves more intensely through the pipe along with combustion products. When the coefficient decreases, the operation of boilers deteriorates significantly, and there is a high probability of oxygen-limited zones appearing in the furnace. In this situation, soot begins to form and accumulate in large quantities in the firebox.

The intensity and quality of combustion in solid fuel boilers require constant monitoring. The combustion chamber must be loaded evenly, avoiding focal fires.

During combustion, it is important to prevent failure of the fuel resource, otherwise you will have to face significant mechanical losses (underburning) of fuel. If you do not control the position of the fuel in the firebox, large fragments of coal or firewood falling into the ash box can lead to unauthorized combustion of the remaining fuel mass products. Soot and resin accumulated on the surface of the heat exchanger reduce the degree of heating of the heat exchanger

As a result of all of the above violations of operating conditions, the useful volume of thermal energy required for the normal operation of the heating system decreases. As a result, we can talk about a sharp decrease in the efficiency of heating boilers

Soot and resin accumulated on the surface of the heat exchanger reduce the degree of heating of the heat exchanger. As a result of all of the above violations of operating conditions, the useful volume of thermal energy required for the normal operation of the heating system decreases. As a result, we can talk about a sharp decrease in the efficiency of heating boilers.

Aluminum radiators

Aluminum batteries have many advantages. They do not require constant care. The low weight of the batteries will significantly reduce transportation costs. More resistant to water hammer than cast iron. The high flow of coolant prevents such a radiator from becoming contaminated from the inside. This is due to the flow area being less than or equal to the internal diameter of the riser.

You may hear a common myth that such batteries have low heat transfer due to their small cross-section. It's a lie. The cross section is compensated by the area of the radiator fins. Such batteries also have disadvantages - they often cannot withstand high pressure surges. Also, in the manufacture of aluminum batteries, alloys are often used, which greatly increases their destructibility.

Incorrect connection will cause the internal surface of the battery to oxidize. Also, the coolant in Russia contains many impurities, which will lead to corrosion, significantly reducing its service life. Therefore, you should not install them yourself.

Selecting a circulation pump for a heating system

In order to select a circulation pump for the heating system, it is necessary to make the appropriate calculations

Please note that within an hour, this element will drive three times more water than its total volume in the system. Thus, the total volume of a suitable amount of liquid is on average 10 liters per 1 kilowatt of heating boiler power

The required pump model for the heating system and its power are determined by pressure and flow parameters. The pressure must be equal to the hydraulic resistance of the heating system.

Typically, the fluid pressure velocity in systems with forced circulation is quite low, which gives the right to judge low losses of hydraulic resistance, which usually do not exceed 2 meters. It is quite difficult to calculate the exact resistance, so the performance of the circulation pump is determined by the midpoint. In order to calculate productivity, the size of the area of the heating object and the power of the electricity source are also taken into account. It should be remembered that a pump is only needed in a system with forced circulation; a system with natural circulation does not need it.

How to take into account the height of ceilings when calculating?

The formula below is suitable when the ceilings in the house are of standard height.

Those. do not exceed 2.6 - 3 meters. If the ceilings are higher, calculation by area will not work.

You need to use volume.

Knowing the volume of the room, you can calculate the predicted heat loss (HL) using the formula:

PT = V (volume) x Pt (difference t) x k: 860.

Pt – difference in average temperatures outside and indoors. Example: in winter the average temperature is -30 C, but in the house you want it to be 22 C. Pt = 52. The higher this indicator is, the more the building will lose heat.

k is the dispersion coefficient. It depends on the building materials from which the structure is made:

- Wood or corrugated iron, no insulation = 3–4.

- Single brickwork, regular windows and roof, average thermal insulation = 2 – 2.9.

- Double brickwork, good thermal insulation, few windows = 1 – 1.9.

- Excellent thermal insulation, plastic windows, well insulated floor and ceiling = 0.6 - 0.9.

Now that all the basic data is known, you can calculate the boiler power using the formula:

M = PT x kz.

Kz in these calculations is the safety factor. It is equal to 1.15 - 1.2 (that is, 15 - 20%)

Example. Brick house with good thermal insulation, area 60 m2. And the ceiling height is 3m.

- Let's calculate the volume. 60m2 x 3 = 180m3. Pt = 52, k = 1.5.

- We substitute the data into the formula: PT = 180 x 52 x 1.5: 860. PT = 16.32.

- We multiply this indicator by the safety factor: 16.32 x 1.2 = 19.58.

- We round up and get a boiler with a capacity of 20 kW.

How to increase the efficiency of heating equipment running on solid fuels

Today, many consumers, having at their disposal a solid fuel boiler, are trying to find the most convenient and practical way to increase the efficiency of heating equipment.

The technological parameters of heating devices set by the manufacturer lose their nominal values over time, so various methods and means are being sought to increase the efficiency of boiler equipment. Let's consider one of the most effective options, installing an additional heat exchanger. The task of the new equipment is to remove thermal energy from volatile combustion products.

In the video you can see how to make your own economizer (heat exchanger)

To do this, we first need to know what the temperature of the smoke at the outlet is. You can change it using a multimeter, which is placed directly in the middle of the chimney. Data on how much additional heat can be obtained from evaporating combustion products is necessary to calculate the area of the additional heat exchanger. We do the following:

- we send a certain amount of firewood into the firebox;

- We measure how long it takes for a certain amount of firewood to burn.

For example: firewood, in the amount of 14.2 kg. burn for 3.5 hours. The smoke temperature at the boiler outlet is 460 C.

In 1 hour we burned: 14.2/3.5 = 4.05 kg. firewood

To calculate the amount of smoke, we use the generally accepted value of 1 kg. firewood = 5.7 kg. flue gases. Next, we multiply the amount of wood burned in one hour by the amount of smoke produced by burning 1 kg. firewood As a result: 4.05 x 5.7 = 23.08 kg. volatile combustion products. This figure will become the starting point for subsequent calculations of the amount of thermal energy that can be additionally used to heat the second heat exchanger.

Knowing the value of the heat capacity of volatile hot gases as 1.1 kJ/kg, we make a further calculation of the heat flow power if we want to reduce the smoke temperature from 460C to 160 degrees.

Q = 23.08 x 1.1 (460-160) = 8124 kJ thermal energy.

As a result, we obtain the exact value of the additional power provided by volatile combustion products: q = 8124/3600 = 2.25 kW, a large figure that can have a significant impact on increasing the efficiency of heating equipment. Knowing how much energy is wasted, the desire to equip the boiler with an additional heat exchanger is completely justified. Due to the influx of additional thermal energy for heating the coolant, not only the efficiency of the entire heating system increases, but also the efficiency of the heating unit itself increases.

Incorrect air supply

The work of the flame greatly depends on how much oxygen enters the firebox. In order for fuel to burn normally and give off the maximum amount of heat, it needs a strictly defined amount of air - no more, no less. If there is not enough air, the hydrocarbons released during combustion will be poorly oxidized, which means less heat will be released. If a lot of air comes in, and it usually comes in cooled, the temperature of the released gases decreases and they do not have time to burn (again settling as soot on the pipes) and thereby release useful heat. It is worth noting that the air contains moisture, the evaporation of which also wastes heat (instead of heating the house).

Most solid fuel boilers offered on the market operate on the following principle. They have a thermostat installed that regulates the temperature of the water circulating through the heating system of the house to warm it. If the water becomes too hot, the thermostat reduces the air supply to the boiler (this is how the power of a solid fuel boiler is regulated). It turns out that at the moment when the fuel flared up and the efficiency with the power of the solid fuel boiler became maximum, which means the flame began to need more oxygen, the thermostat artificially reduces the efficiency, limiting the air supply.

After the temperature has dropped, the thermostat starts supplying air again. But by that time the fuel is already burning down and it doesn’t need as much oxygen. The heating efficiency is again reduced due to the cooling of the released gases, as mentioned earlier.

It turns out that the operating principle of most solid fuel boilers absolutely contradicts the concept of high efficiency.

Cast iron and steel structures - what are the differences?

Whatever material the boiler is made of, it is very important that it meets the basic operational characteristics. Let's look at them in more detail

First of all, you should pay attention to the material of the heat exchanger - cast iron or steel. If you want to use a ready-made solid fuel boiler circuit, it’s unlikely that you’ll be able to make a cast iron heat exchanger yourself

Such work requires both special equipment and special knowledge and skills. Therefore, you can purchase ready-made sectional structures, which are disassembled before transportation and reassembled on site.

Cast iron heat exchangers tend to become covered with dry rust - a special film that protects the walls of the unit from destruction. In addition, wet rust also forms much more slowly, which is due to the long service life of cast iron products - from 10 to 25 years. Other advantages of cast iron heat exchangers include the absence of the need for frequent and complex maintenance. Cleaning of such devices is rarely required, and carbon deposits practically do not reduce the efficiency of the boiler. If it is necessary to repair or increase the power of the unit, you only need to replace the defective sections or increase their number.

The disadvantages of cast iron products are:

- the large mass of the boiler requires a separate foundation;

- difficulties in the assembly process and high transportation costs;

- sensitivity to thermal shock - cast iron does not like temperature changes, so contact of a hot surface with cold firewood or cold water can be detrimental to it;

- high thermal inertia - it takes a long time to warm up the boiler, but its subsequent cooling occurs slowly.

As for steel products, they are less sensitive to temperature changes and are not afraid of contact with cold objects. This property allows, when assembling solid fuel heating boilers according to drawings, to equip them with sensitive automatic elements. And thanks to their low inertia, such units quickly warm up and cool down - this allows you to regulate the air temperature in the house. At the same time, you can make a drawing of a long-burning solid fuel boiler with your own hands, which will allow you to take into account all the nuances.

In appearance, steel boilers are solid welded units that are quite difficult to transport, although their sensitivity to mechanical damage is much lower than their cast iron counterparts.

The possibility of repairing steel boilers is, from the point of view of some experts, very doubtful. Repairing, as well as welding a boiler with your own hands according to a drawing at home, is quite difficult; over time, leaks may form at the seams in it. In fairness, we note that everything depends on the worker’s skills in working with a welding machine. But repairing a cast iron heat exchanger is still easier - you only need to replace the sections.

As a rule, boilers with cast iron heat exchangers are non-volatile and inexpensive, so they can be a worthy alternative to already installed heating equipment in the event of a power outage. Coolant circulation in such units occurs naturally, without the use of a pump. However, the batteries must be installed in such a way that when heated, water moves freely through the pipes under the influence of pressure in the boiler.