Various impurities may be present in the water supplied from the well. A well filter will help you achieve compliance with sanitary standards. The degree of purification may vary significantly. It all depends on how the device purifies the water. Let's look at the main stages of water purification and tips for choosing a filter, and pay attention to the main characteristics of water treatment systems.

The filter will ensure water purification from the well Source southforkpeaksavers.com

Is cleaning necessary?

A number of indirect signs indicate that well water needs to be purified. You may encounter:

- Sludge, indicating the accumulation of undesirable substances in the water, the appearance of which is caused by the processes of decay.

- A characteristic metallic taste that worsens the taste characteristics of the produced water. After installing the filter, the organoleptic properties of the liquid are significantly improved.

- Plumbing fixtures and dishes have a yellowish tint. Its appearance is facilitated by dissolved salts and a number of other substances deposited on the surface.

- Cloudy sediment with some silt due to the presence of harmful bacteria.

- Characteristic smell of “rotten eggs”.

Water should not have an unpleasant odor or impurities Source build-experts.ru

How to minimize pollution?

Sand and lime may appear in the water due to the initial properties of the aquifer or errors during drilling or use of the well.

You can minimize the likelihood of well contamination with sand grains using a set of measures:

When drilling, you need to monitor the condition of the casing pipe.- The new well should be thoroughly flushed.

- A caisson and a cap should be made on top around the outlet hole.

- In sandy soils, vibrating pumps should not be used for pumping.

- Long pauses in work should not be allowed.

Important. It is impossible to completely eliminate the ingress of sand, but it will be possible to delay the occurrence of problems and reduce the mass fraction of solid impurities in deep water using these methods.

In any case, for long-term safe operation of the well, filters will be required.

Cleaning steps

A well water purification system for a private home includes several stages:

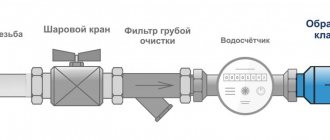

- Pre-cleaning. Allows you to get rid of coarse impurities: sand, clay residues, various mechanical particles. For this purpose, coarse filters or settling tanks are used. This stage is mandatory for any cleaning system, as it can significantly increase the service life of the installed equipment.

- Removal of dissolved chemical impurities and gases . Allows you to get rid of excess amounts of magnesium, iron and other components. The cleaning method and type of filter used are selected taking into account the composition and amount of chemical impurities.

- Softening . Using the ion exchange method, salts are removed from water. They precipitate and are then removed from the water in a subsequent purification step.

- Fine cleaning . A filter with a specific configuration helps to filter out the smallest particles. Their size is 5 microns.

- Disinfection . At the biological treatment stage, it is possible to get rid of unwanted bacteria and microorganisms.

- Drinking preparation . Reverse osmosis systems are mainly used. Relevant exclusively for the preparation of water intended for the preparation of water or drinking.

The degree of purification may vary depending on the filter device Source vodopodgotovka-vodi.ru

Water purification from a well for a private home may include various stages. A chemical analysis of the extracted liquid will help determine the number of stages. The result obtained will allow you to accurately understand which substances have exceeded their concentrations and in what quantities.

Main types of filtration equipment for pre-treatment

The design and operating principle of filters may differ significantly. Used to remove mechanical impurities with different fractional compositions. Some allow you to get rid of particles with a size of 20 - 100 mm, while others effectively cope with inclusions of 0.25 - 0.5 mm. The area of use and the achieved effect largely depend on the type of soil in a particular area.

Gravel

A simple and economical option. Allows you to get rid of large particles. Increases the life of the well. A gravel filter for water from a well has certain requirements for the installation procedure:

- The transverse dimensions of the pipe are smaller than the diameter of the well.

- The fractional composition of the gravel backfill should be on average 5 times greater than the size of small rock particles.

- The height of the sprinkling depends on the gravel layer. Usually 0.9 - 2 m. The more salts dissolved in the water, the higher the gravel layer is poured.

There are a number of requirements for the filter used. Source piccy.info

If the aquifer contains predominantly sand, the gravel system will not cope well with the task. It is advisable to use a mesh or wire type filter for a sand well.

The advantages of such equipment include:

- Simplicity of design.

- Prevent possible rock collapse.

- Reduce the likelihood of equipment corrosion.

- Safety of use. When using it, you don’t have to worry about the taste of the water.

See also: Companies specializing in utilities: water supply, heating and sewerage.

Reticulate

Filters for water wells of this type are made with cells of different shapes and sizes. This allows you to retain small particles of various rocks. They are widely used to purify water produced in areas with a clay-sand layer.

According to the configuration of the cells of the product, there are:

- Square.

- Keeper or multilayer.

- Galunny.

The size and type of cells are selected individually. The size and configuration of mechanical impurities contained in a test batch of water extracted from a well are taken into account. The area of square cells varies in the range of 0.12 – 3 mm2.

Various materials are used to make the strainer. Stainless steel products have proven themselves well. They are not afraid of prolonged exposure to water. If you follow the manufacturer's recommendations, their service life reaches 30 - 50 years.

The size and shape of the cells affects the functionality Source www.kai.by

The size of galloon and keeper mesh includes two numbers: the number of horizontal and vertical wires per unit area. Thus, the dimension 6/40 means that each square contains six vertical wires and 40 horizontal ones.

Mesh models are easy to install. Allows cleaning. Repairable. However, they can cause a decrease in water pressure due to the high resistance of the materials used. Not suitable for water with a high iron content: the resulting sediment clogs the cells, the product begins to wear out intensively and you have to look for a new one.

Slotted

Such filters for water purification in a private house from a well are suitable for a water supply system mounted on unstable soil prone to collapse:

- Sandy.

- Galechny.

- Shchebnev.

A thoughtful design allows you to retain particles of different fractional compositions inside the filter. Can be mounted on systems with low pressure. The basis of slotted models is a pipe with a characteristic perforation. The sufficient strength of the material used and the presence of a special stiffening belt allows the product to withstand high pressure. However, during operation there is a risk of clogging the cracks.

The slits are located at equal distances Source mozfiles.com

The number and size of slots are selected individually, taking into account water hardness. The higher this indicator, the larger the slots to be formed should be. To increase the versatility of the device, a combined hole shape is chosen.

Installation of a water filter for a house from a well

To choose the right filter for purifying water from a well, you need to get acquainted with the principle of its design and operation. Well equipment solves the following problems:

- retains solid impurities in front of the casing pipe entrance;

- keeps the well from collapsing.

Downhole equipment includes:

- filters;

- perforated supports;

- settling tank

Each element can be made in several versions for functioning in different aquifers. The basis of the filter for the well pipe is perforated metal. The holes in it are oblong or round, 1-2 cm in size. Slot-like holes allow more water to pass through, but weaken the structure.

The perforation area should be 20–30% of the entire circumference of the pipe. The filter base and the well line are made of the same material, because their coupling must be airtight.

When using metal operating parts, the base must also be made of stainless steel. If plastic elements are used, the base must be selected from plastic, because metal and plastic will not create a hermetically sealed connection.

The filter layer should not fit tightly to the perforated pipe. To do this, create a frame of vertical rods or loosely wound wire around the filter. Make a gap of several millimeters between the turns.

In filter configurations for water intakes, there are several options for the filter layer:

- mesh;

- wire;

- combined.

For the first, the filter part is made of mesh, for the second, a wedge-shaped wire is used, which is wrapped around the filter body.

The most convenient option is a mesh filter. If damage occurs, only part of the filter requires replacement. High-quality metal construction can last up to fifty years. If you prefer high-quality water purification, you should buy a mesh filter for a well. Plastic filters are not strong enough and cannot withstand heavy loads. Compared to stainless steel, they have a shorter service life.

A wire filter is more durable because the material is thicker than mesh. The cost of such equipment is accordingly higher. When using galvanized wire, the maximum service life of the filter will be 7 years.

This is interesting!

Hydrogen sulfide in a well: what the threat is and what to do Read more

The size of the cells and their shape in mesh filters vary. They need to be selected depending on the size of solid particles found in the water after the analysis.

An additional filter layer of gravel is placed near the well pipe. Coarse sand and small smooth pebbles are also suitable for these purposes. They are a natural high-quality filter capable of self-cleaning.

When constructing a filter for a well, a formula with the exact parameters of the aquifer is used. Although builders usually focus on professional experience.

- With a casing pipe diameter of 10–15 cm, a one-meter high filter is required for sandy water horizons. The optimal size of the cleaning part is two meters.

- If there is too fine sand in the water, you need to make a filter for the well twice as high as usual. If sediment in the form of dust is present, six-meter equipment can be used if the aquifer depth is sufficient. Use a filter diameter that allows you to freely install the pump in the well.

When the source is already in operation, it will not be possible to change parts. Therefore, they immediately choose high-quality materials and elements that can last up to 30 years or more and do not require repairs.

Main types of iron removers

Filters for water from a well to a private home allow you to get rid of not only iron, but also various chemical impurities: fluorides, nitrates, nitrites, lead, radium and arsenic. The presence of such substances is unacceptable. An increased concentration of iron can harm human health. To reduce its concentration the following are used:

- Non-pressure installations.

Water coming from the well flows through nozzles into a large reservoir. Its capacity starts from 600 liters.

The water level is controlled using special sensors that determine the upper and lower levels. To prevent the tank from overflowing, a special pipe is provided through which, if necessary, excess water is discharged. As soon as the container is completely filled, the compressor turns on and air begins to flow inside and is distributed using a divider.

In the process of spraying water, dissolved iron combines with oxygen, forming a trivalent compound. Mesh models are used to remove the resulting sediment.

Gravity water treatment system Source wixstatic.com

Pressure aeration systems

According to their design, aerators can be divided into non-pressure and pressure-operated. A pressure aerator consists of an aeration column and a compressor that pumps air. There is an automatic release valve at the top of the column that removes excess air. Water can get into it, so it is connected to the sewer system.

Method of purifying water from iron using pressure aeration

Water is taken from the lower third of the aeration column, but not too low, since insoluble sediment accumulates at the bottom - the result of purification. The system turns on only when there is water flow. For this purpose, there is a flow sensor at the output. As soon as the tap is opened, the compressor turns on; when it is closed, it turns off.

A pressure aeration system is also not the cheapest pleasure. But it is necessary if the content of iron or other dissolved substances is exceeded 30 times or more. Otherwise, you won’t be able to get rid of so many contaminants: the filters will become clogged very quickly.

Reverse osmosis plants

The devices help to completely disinfect water. They allow you to get rid of unwanted bacteria and achieve high-quality cleaning. A multi-stage well water purification system allows you to get rid of various types of impurities. The operation of such equipment is based on the principle of liquid passing through a membrane under high pressure. A special pump is used to supply water.

The design of the membrane is such that only water molecules pass through it. The impurity remains outside. After cleaning, the accumulated dirt is simply washed off the surface of the membrane and sent down the drain. The presence of a self-cleaning function significantly increases the efficiency and service life of such equipment.

Having passed through the membrane, the water enters the flasks with a carbon backfill or a mineralizing layer. This is necessary to enrich it with microelements necessary for humans, since after passing through the membrane, the water’s parameters are close to distilled.

Criteria for choosing the best filter for well water

If you need to install a filter in the kitchen to purify water from a well or well, study the issue of choosing and purchasing it. Consider not only your desires, but also the financial capabilities of purchasing a specific product.

- If your water is heavily polluted and you can afford to buy an expensive, effective filter for well water from, for example, lime, choose a device with reverse osmosis. Such equipment is quite expensive, but the water it produces is clean and of the best quality. The investment in purchasing this filter will be worth it. You do not need to purchase bottled water for cooking and drinking.

- If you can’t afford a complex cleaning system, purchase a filter for your sink. It will significantly improve the quality of the supplied water.

- When you have a well or well and the water from it is of normal quality, but you just need to soften it, buy a system with osmosis for this purpose. Do not purchase filter attachments, because such devices do not perform high-quality cleaning. Even jug filters do a better job.

- Take care of your health and that of your loved ones, install a well water purification system. Filters for purifying water from a well vary in price. Among the variety of devices presented in stores, choose the option that is suitable for your water.

Before choosing a particular type of filter device, study their main types. Each has its own characteristics, pros and cons. Consider the quality of the source water and your financial capabilities.

;

Well

Did you find this article helpful? Share it with your friends:

Video description

Reverse osmosis fights not only impurities, but also odors, as evidenced by the following video:

Systems are usually installed directly under the sink. A separate tap is used to supply drinking water. Replacement of the membrane and backfill must be carried out at specified intervals.

Purified water is close to distilled Source thewalls.ru

Disinfection

An important step to ensure that water meets regulatory requirements. To remove bacteria and unwanted microorganisms, the following are used:

- Blocks filled with sorbents of various types . Products containing coal have become widespread in everyday life. Thanks to its use, the filter improves the organoleptic properties of water.

- Ultraviolet . The device consists of a steel case with a quartz case and an ultraviolet lamp located inside. Passing through the device, water is irradiated by an ultraviolet stream and is thereby disinfected. The radiation dose depends on the level of contamination of water by microbiological organisms. The device allows vertical and horizontal placement.

- Chlorination, fluoridation . The method can be called traditional. The resulting suspension is subsequently removed. It is practically not used in private home water supply systems.

Types of filters and their features

Well filters can be divided into two large groups:

- simple - with various types of holes in the bottom casing pipes;

- complex - they are a separate structure placed at the location of the bottom pipe or with filter elements mounted on the casing pipe.

In simple devices, round or slot-like holes are cut in the pipe surface; in more complex designs, wire is wound in dense rows or a fine mesh is fixed.

Briefly about the main thing

The filter is an important element in the water supply system of a private home, using a well as a source. With the correct selection of the model, it allows the produced water to comply with regulatory requirements. This makes it possible to use it not only for technical needs, but also for drinking.

Before you begin selecting filtration equipment, you should do a chemical analysis of the water. It will allow you to understand what impurities need to be gotten rid of and in what quantities.

To achieve the best effect, you should take care of multi-stage cleaning. Consistently passing through filters of different types, water can get rid of mechanical impurities, harmful substances and bacteria. Subsequent enrichment with useful elements will ensure compliance with regulatory requirements.

Types of filter elements

The filter design consists of 3 parts:

- filter unit - performs primary mechanical cleaning;

- above-filter section - necessary for fastening to the pipe;

- settling tank for settling particles.

Several types of products are used for primary cleaning:

- Perforated - a simple option with low cost.

- Slotted is one of the types of pipe perforation that provides high throughput. This characteristic is explained by the larger area of the holes compared to a perforated element.

- Gravel - there are two types of device: a 30 mm thick gravel contour collected on the surface and a backfill between the casing and the walls of the shaft, made of homogeneous gravel.

- Wire filters are a durable and efficient design made from spiral wound wire. The distance between the turns is 2 mm; for strength they are welded together.

Types of filters

Not only the type of filter for a sand well is of significant importance, but also the material from which it is made. Plastic pipes do not undergo oxidation and are inexpensive; their disadvantage is low resistance to compression. Stainless steel pipes do not react with water and are resistant to any load. High quality determines the corresponding cost of products.

Filter requirements:

- Provide high throughput with small dimensions.

- Comply with sanitary environmental safety standards.

- Have increased resistance to corrosion.

- Affordable price, but not at the expense of quality.

Attention. The strongest and most durable are stainless steel elements, but it is better to avoid galvanized metal. It becomes a source of zinc contamination of water.