Any person who has basic skills in handling household tools can assemble a timber frame on their site. Based on this, frame construction is becoming increasingly popular among private developers and construction companies specializing in the construction of houses, cottages and commercial facilities. Initially, frame housing was considered a temporary building. But time has shown that such structures are not only inexpensive, but also quite practical.

Board dimensions

So, we go to the nearest large construction market, having previously purchased a tape measure and calipers. We ask how much an edged board with a section of 150-200 x 40-50 mm costs. 5000-6000 rubles per cubic meter is the average price. Great, we need 20 cubic meters of timber for the frame, and we will spend about 100,000 rubles on the frame skeleton of a 2-story house, with some left over for the roof. That's why everyone thinks that a frame house is inexpensive.

Let's now take a closer look at these boards; to do this, we measure 6-meter boards with a tape measure, the length of which turns out to be in the range from 5.80 m to 6.10 m. The edges are cut poorly, so when trimming we will lose another 5-10 cm. If you have 3 -x meter ceilings, then a quarter of the racks (2.70-2.90 m) will be used as trimmings.

We check the thickness and width with a caliper. For example, for a board thickness of 50 mm declared by a dealer, you will find boards in one stack whose length range is 37...52 mm. For a board thickness of 150 mm, the range will range from 130 mm to 153 mm.

An experienced builder with 30 years of experience will say: “So what? At a construction site they measure cm, not mm. This is within the tolerances.” Yes, but such tolerances in a frame house will lead to this: you lay the bottom frame of such boards on a level foundation and you get an uneven floor and base for the walls. And errors will accumulate with each floor.

That is why in America and Northern Europe no one would think of building a frame house from ordinary edged boards.

Stages of frame construction

Before construction begins, the work site must be prepared. All stumps, bushes and large stones should be removed from the ground.

Frame installation consists of the following steps:

- Construction of the foundation. Since the frame is light in weight, the base for it can be made light. The foundation can be strip, pile or column type.

- Foundation waterproofing. Ruberoid is used for this.

- Laying the bottom trim. The timber is attached to the concrete with anchor bolts no less than 200 mm long.

- Installation of corner posts. Fixation is carried out using dowels or steel corners. The racks are secured with jibs.

- The remaining racks are installed. They are corrected according to the corner elements.

- The top trim is installed.

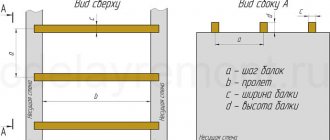

- Ceiling beams are laid and secured. Their fastening is carried out using cutting, brackets or corners.

- Floor joists are installed.

- The rafter system is being installed.

The frame is ready. All that remains is to insulate it and cover it with finishing material.

Actual cost

The second obvious disadvantage of buying edged boards on the market is the conditions into which the buyer is forced. Regular edged boards are sold individually on the basis that:

1) edged board with dimensions 50 mm x 100 mm x 6,000 mm: 33 boards per 1 m3;

2) edged board with dimensions 50 mm x 150 mm x 6,000 mm: 22 boards per 1 m3;

3) edged board with dimensions 50 mm x 200 mm x 6,000 mm: 16 boards per 1 m3;

4) edged board with dimensions 50 mm x 250 mm x 6,000 mm: 13 boards per 1 m3;

5) edged board with dimensions 50 mm x 300 mm x 6,000 mm: 11 boards per 1 m3;

5) edged board with dimensions 25 mm x 100 mm x 6,000 mm: 66 boards per 1 m3;

6) edged board with dimensions 25 mm x 150 mm x 6,000 mm: 44 boards per 1 m3;

7) edged board (bar) with dimensions 50 mm x 50 mm x 3,000 mm: 133 pieces per 1 m3;

edged board (bar) with dimensions 40 mm x 50 mm x 3,000 mm: 166 pieces per 1 m3;

edged board (bar) with dimensions 40 mm x 50 mm x 3,000 mm: 166 pieces per 1 m3;

9) edged board (bar) with dimensions 40 mm x 40 mm x 3,000 mm: 208 pieces per 1 m3.

All fractional parts are rounded to a natural number, not in your favor.

In fact, you buy a board with a cross-section of 46 mm x 142 mm x 5,850 mm - 26 boards 1 m3, but you get 22 boards, which is 18% less. In this case, your project was created for a board with a cross-section of 50 mm x 150 mm; it will have to be changed according to the actual dimensions directly at the construction site.

When you buy a planed board, you pay for the actual dimensions, for example, 38 mm x 140 mm x 6,000 mm (31.32 boards per 1 m3); when you buy an edged board at a nearby market, you pay the extra money into the pocket of a cunning seller.

Greenhouse project

The first stage is project development. This includes determining the shape and dimensions, making a general drawing (sketch), detailing the elements and components of the structure.

The shape and dimensions of the greenhouse depend on the size of the site on which it can be located. And recommendations for choosing a location, in turn, depend on the design features. Although there are general provisions that guide the development of a project and linking it to the territory:

- The place should be open and well lit by the sun.

- Rectangular structures are oriented with their length from south to north.

- The location should be such that the greenhouse is protected from the wind as much as possible.

- Greenhouses made of timber are made with a gable or pitched roof. In the latter case, with a slope to the south.

- Optimal frame dimensions: height at the top point of the slope—2.5 m, height at the bottom point of the slope—1.7 m, width—3.5 m, length—up to 6 m.

In addition, take into account the following recommendations:

- convenient access;

- Possibility of access with a garden cart;

- proximity to the connection point to the water supply, if automatic and automated drip irrigation is provided.

Humidity of boards

Pay attention to the edged board in the photo above: this is a regular edged board of natural moisture with a cross-section of 50 x 100 mm. At the time of purchase it was an ordinary flat board. During natural drying in a stack, it lay in the top rows, and as a result it was deformed in two planes at once. Such boards may look decent at the time of purchase; you will even have time to build a frame house from it, but then, while drying, it will begin to “twist”. The board must reach a humidity of 12-16% before construction begins. Otherwise, you will get a typical frame-and-slot house with all the delights in the form of blown walls and cracked drywall. The board used to build a frame house must be dried without deformation in the chamber. The drying process takes several days. For this purpose, heating, blowing, vacuum, etc. are used. The main task is to “take away” excess moisture from the wood and minimize the deformation of the boards during drying.

Caring for a wooden frame garage during operation

Proper operation of a frame garage is the key to its durability. Since the structure is wooden, high air humidity is detrimental to it . From the outside, the building is sheathed with cladding materials that protect the walls and roof from precipitation. Indoors, high-quality ventilation is required, natural or supply and exhaust.

Maintenance of a building consists of several regularly repeated actions:

- inspection of the foundation and its timely repair;

- inspection of finishing coatings of walls and roofs, elimination of detected deficiencies;

- maintaining cleanliness and dryness indoors;

- installation of drainage that removes ground and surface water from the foundation.

In order to build a frame garage made of wood, you need to choose the right materials and type of foundation, and study the instructions for performing each stage of installation work. A building built by oneself is the pride of the owner. Compliance with technology requirements guarantees the reliability and durability of the garage.

Board defects

Wood is a natural material. It is impossible to ensure that the boards are ideal along the axes and with dimensional accuracy of tenths of a mm. But on the other hand, the construction of a frame house is not a furniture factory, and a carpenter is not a joiner. Boards, even kiln-dried and planed, may have slight defects. For example, have the shape of a “bowl” or “saber”. The main question is how pronounced these defects are. You can use “small sabers” for small-sized frame racks under windows, and the spacers and “bowls” will be used as jibs. When choosing and purchasing boards for a frame house, pay attention to the number of defective boards. To do this, it is necessary to take an active part in loading or unloading goods. The cunning of market traders usually manifests itself in two ways: You are offered to load the boards by local Tajiks, who are instructed to work quickly and load everything. In this case, it is very difficult to control the quality of the boards. The second method is the absence of choice, that is, the trader keeps a couple of cubes on the site, thereby the selection of boards is only indicated, since there is nothing to choose from. You are forced to accept a decent amount of boards with defects, because otherwise you will have to swear and unload the machine back. And it is not at all obvious that the neighboring merchant will want to sell you only the best boards and keep the crooked ones with wane.

Americans are quite relaxed about “light sabers” and actively use them for rafter systems, frame house posts, and interfloor joists. For rafters and joists, it is recommended to place the boards with the saber facing up so that the load from above can straighten them along their axis. For frame racks of external and internal walls, it is necessary to place the sabers in one direction. In this case, you can trim off the excess, or use plywood overlays to level the base for the drywall.

Is it worth it or not to build it yourself? Expert opinion

The question to build or not to build, although it is reminiscent of Hamlet’s “To be or not to be?” in many respects can be decided after studying the opinions of experts, where you can conditionally attract both truly professionals and those who can boast of a self-built change house.

Professional builders will always be against building such a facility on their own; this is explained by certain difficulties of the work, its labor intensity, and the need to carry out several operations when using non-standard material.

For those who already have experience in assembling such buildings and can share their own experience, both positive and, alas, not entirely, I will assure you that this is quite possible and even needs to be done, well, at least in order to believe in your abilities.

The truth lies somewhere in the middle. For a person who has a clear work plan, knows how to handle basic tools, or at least hold a hammer in his hands, this is quite possible. For those who think that this is irrational, it will be quite normal to buy a ready-made project.

What are the consequences of self-construction? Builder mistakes

When constructing a summer cottage yourself, you must take into account:

- documentation of construction, this is relevant for all types of buildings, both on the land of gardening partnerships and other lands, because the structure does not hang in the air;

- the presence of a project, even the simplest one, but with minimal calculations of materials, it can be corrected at any time, but without calculations the material will have to be constantly purchased;

- the project must take into account the power of the electrical wiring, the placement of heating devices, and support systems, and this should be done primarily by professionals, since incorrect calculation of the cable cross-section can lead to a short circuit in the wiring and a fire.

But professional builders, as a rule, make the following mistakes:

- incorrect placement of the building;

- violation of construction technology;

- poor quality of various operations and works;

Time to buy

It is believed that the best quality is winter wood, that is, boards sawn from wood harvested in winter. At this moment, the movement of juices (moisture) through the wood is minimal, so boards from winter wood are stronger and less deformed. Many builders prefer to buy timber in winter and arrange stacks for atmospheric drying. The idea is good, however, 2 questions immediately arise: how to protect yourself from the fact that the boards can be stolen; how to protect the boards of the upper rows, which are not fixed by the load of the overlying boards, from deformation. If you ask market traders at any time of the year what kind of wood the boards are cut from, you will get a clear answer: “From winter wood.” Even in September they told me that in the winter we bring in logs and cut them as needed. On the left in the photo is a damp log cut down in the summer.

The demand on the building materials market in our country is so high that during the high construction season, boards from winter wood are finished by June. Timber industry enterprises and black loggers continue to fell trees all year round. Having bought a board from a winter forest at a nearby market, you are surprised to notice that it weighs twice as much as usual, a circular saw gets stuck in it, after 3 days of storage it was twisted into a spiral and black spots of mold appeared. These are signs of damp, freshly cut wood. The Americans call them green lumber, and according to their construction requirements, you can use such boards to light a fire in a barbecue. The main problem of a summer forest is the increased moisture content with all that it implies and insufficient strength for the construction of a frame house. A reasonable question: can such boards be used to build a frame house?

It is possible if you meet 2 conditions: the board must be dried in a chamber and the board must be made from mature (old) forest, and not young pine or spruce. In order to distinguish a mature forest from a young one, pay attention to the width of the rings on the cut. Young wood has wider annual rings. The best thing to do is come to the sawmill and look at these logs. An order of 20-25 m3 of timber is a decent amount for any seller, so he will be ready to invite you to production and answer any questions you may have.

Board storage

It may take several months from the moment you purchase the boards until they are used. They must be stored in a stack, protected from rain and snow from above, dirt and water from below, and blown by all winds from the side. Rows of boards are laid through spacers, which provides access to fresh air from all sides and minimizes the risk of fungus developing on the surface of the boards. If the boards upon purchase have an unhealthy gray appearance, black spots are visible on the surface, it is better to refuse such a purchase, since the wood was stored incorrectly. The fungus can theoretically be bleached with bleach, scraped off and trimmed off, but why do you need these problems?

A good seller stores timber in normal, ventilated stacks. Although very often you can see stacks of edged boards on construction markets without gaskets or protection from rain. The process of rotting of the boards has already begun and they will finally acquire a black-gray color at your construction site after purchase. You can store boards in stacks without spacers only if the boards have been processed in a drying chamber. You can store the board in this way for a short time, since rainwater getting into the stack will lead to the appearance of black mold on the boards.

Do-it-yourself change house - how to do it right

The construction of such a small structure is practically no different from the construction of permanent buildings and involves several stages:

- project selection;

- preparation of necessary materials;

- foundation device;

- assembly of wall frames and internal partitions;

- installation of doors and windows;

- roofing;

- insulation device;

- covering the external and internal surfaces of walls.

Materials

For such a small house, the main material will be 50x50 mm timber.

It will be used to construct the building frame, the frame of internal partitions and the rafter system. For cladding the outer surface, it is recommended to use a block house or wooden lining of appropriate length.

It is recommended to cover the internal surfaces with panel materials, on top of which you can install cladding from various types of lining or block house to imitate a log house.

It is recommended to use metal tiles, sheet metal or corrugated sheets as roofing materials. Roll roofing materials, although they have excellent properties, but with a small roof slope such materials will last much less. In addition, the use of metal materials will make it possible to extend the roof by 10-15 cm, thereby ensuring the drainage of rainwater from hitting the walls.

For fastening work, it is better to choose standard fasteners that provide sufficiently strong fastening of parts and the ability to use the same type of elements in different places in the structure. There is no great need to use home-made elements in this case - it is irrational both from the point of view of the time spent on their production and the gain, from an economic point of view.

Fungus and mold.

Wood is affected by fungus if you have created “favorable” conditions for this: high humidity + poor ventilation. Black mold spores can be found even on healthy, freshly cut wood, but its growth occurs only in suitable conditions. Within a few days, the boards become covered with black spots that can still be scraped off. But if the process of fungal development goes further, then the mold affects the entire depth of the board.

You can bleach surface damage with a chlorine solution and trim it off. You cannot remove deep mold. What is the danger of boards covered with black mold? Fungal spores can cause allergic reactions in people living in contact with such wood. Boards affected by mold lose strength and are capable of infecting neighboring healthy boards if “favorable” conditions are created for this (humidity and lack of ventilation). You can use boards slightly touched by black mold to build a frame house if you treat them with bleach, plan them and cover them with an antiseptic. If the depth of fungus damage to the boards is considerable, then such boards cannot be purchased, much less used for the construction of a frame house.

The presence of white mold is a sign of rotten wood. Such a board is unsuitable for building a frame house.

Presence of natural wood defects

Knots, bark residues (wane), and resin pockets reduce the quality of the boards, and hence the price. All these defects directly affect the strength of such boards, so even by removing the bark, peeling out the knots and emptying the resin pockets, you can use such boards in those parts of the frame house that do not bear a significant structural load. For example, frame racks of non-load-bearing walls. To assess the quality of wood in Russia, the GOST system is in force. However, when buying a board on the market, you will not be able to receive a quality certificate unless it is a board manufactured for export.

States have their own quality assessment system, according to which boards are assigned grades 1-4. For the construction of frame houses, boards of the 1st and 2nd classes are usually used, that is, the number of natural wood defects is minimal.

Tree age

The age of the tree from which the board is made is determined by the number of annual rings. Small, frequent rings are signs of a mature tree, wide and light - signs of young green wood. Pay attention to the photo below. The top board is made of 8-year-old pine. The age of the wood on the bottom board is 57 years.

Age affects the strength of wood. Therefore, when you choose edged boards for building a frame house, pay attention to the end parts of the boards in the stack. Boards made from mature wood are best used for load-bearing structures and floor joists. Such boards should not be cut into small pieces for window mullions or fire bracing. For this purpose, you can use boards from young “green” wood.

Cutting method

Boards made from the same log may have different technical characteristics, which directly depend on what part of the tree the board is made from and in what direction the cut was made. The strongest part of the tree is located closer to the center. The outer layers in a living tree are responsible for delivering nutrients to the branches, so they are inferior in terms of strength and moisture content to the core. That is why the most durable boards and joists should be chosen from wood close to the center.

The strength parameters are also affected by the direction of the cut: radial or tangential. The radial-sized board contains parts of the core and the softer outer part. Usually only weak wood from the outer part is cut into a tangential cut, since the core is used to make high-quality timber. An intermediate option No. 3 in the figure below is also possible, which is something between radial No. 1 and dance No. 2 cuts.

Radial cut boards are preferable to those sawn from the outer layers, as they are less deformed during drying.

I hope that a small educational program will help you, at least, not to approach the choice of boards for building a frame house at random and with childish gullibility towards hardened sellers on the construction market. In addition to the above parameters, there are a dozen more requirements that experts place on edged boards, but many of them are of little use to a private buyer. For example, almost 100% of edged boards on Russian markets are pine or spruce. In America, each type of pine is described in detail according to dozens of parameters, which are included in the form of large tables in the thousand-page Building Codes (Codes). In Russia, at best, you can find out in which region the tree from which these edged boards were made was cut down. However, using simple rules and your powers of observation, you can choose a decent board from which to build your frame house.