Purpose and principle of operation

Plugs shut off the water supply to a certain section of the water supply.

A plug is a special fitting that can be used to shut off the water supply to the system at a certain section of it. The element has the shape of a circle or square. The latter are rarely used for plumbing work.

The plug is used for the following purposes and in the following situations:

- Protection of the inside of the pipe from moisture and dirt, penetration of rodents and insects. This option is observed when installing fence posts made from round/square tubes.

- Suppression of a plastic water pipe or metal/polymer sewer pipe at the time of plumbing repair work in the system (installation/dismantling of its individual elements).

- Protection of tubes from the ends during their transportation.

To plug the gas pipeline, special flange plugs are used. They are subject to repeated installation/dismantling.

Any plug works on the principle of completely sealing the pipe opening. It is a kind of traffic jam. If it is necessary to extend the system (sewage, gas or water supply), the plug is simply removed from its place.

When is it illegal?

- The supplier does not have the right to turn off the gas to the entire apartment building if only individual apartments have debt. In such a situation, affected consumers can complain to Rospotrebnadzor, the prosecutor's office, or the court. Suppliers must find a way to cut off gas supplies only to direct debtors.

- Gas may not be connected for a long time after completion of repair work.

Info

Connecting gas to a private home is accompanied by obtaining permits from the service provider, as well as conducting an additional survey to determine the fire hazard of the property and the correct location of gas fittings. Thanks to changes in legislation, it has become easier to connect gas. The duration of work has been reduced, approximate prices have been indicated, and a uniform procedure has been fixed.

Types of stubs

All fittings used to plug pipes are classified according to the material of manufacture, installation method and type of construction. Products are made from the following materials:

- Metal (brass, steel, cast iron elements). The fittings have a high tensile strength, therefore they are widely used in public highways (gas and water supply, sewerage). However, metal plugs are susceptible to corrosion. The exception is chrome steel fittings. This material does not rust. Metal fittings also include a special plug for sealing. It has a special technical hole for installing a seal. As a result, it will be impossible for third parties to interfere with the system.

- Polymers. Plastic plugs are widely used in private construction. The material does not rust or wear out. Polymer fittings are deformed under the influence of high temperatures (sun, hot water from +85 degrees). Polyethylene fittings are used for the internal pipe plug.

- Rubber. The simplest type of element, used either for decorative purposes or exclusively in private water supply.

According to their design, silencing fittings are divided into the following types:

- Threaded. The simplest of all plugs. They simply screw into or onto the pipe.

- Flanged. It is assumed that there are technical holes along the edge into which mounting bolts are driven. The flange plug is often attached to the casing or gas pipe using reinforced hardware (nuts/bolts). If necessary, the fitting can be removed at the right time. As a rule, the flange element is made of metal.

- Pneumatic. Made of rubber. You can install such an element using a pump by forcing air into it. The fitting has a special fitting with a hose. Air is pumped and pumped through it into the plug and back. Such an element can operate at temperatures from -40 to + 70 degrees. The peculiarity of a pneumatic fitting is that it will hermetically close the lumen of the pipe, regardless of the evenness of its inner walls.

- Elliptical. Installation is performed using welding.

Threaded internal Flanged plastic Pneumatic Elliptical Flanged brass Threaded external

Based on the type of installation, all plumbing elements for silencing are divided into two types:

- Internal. Mounted using special ribbed notches. The upper part of the fitting is covered with a lid.

- External. They work simultaneously as a decorative element and as a dampening element.

There are types of plugs according to their purpose - end and transportation. The first ones jam a section of the system. The latter are used to protect the ends of pipes during transportation. Their strength characteristics are seriously inferior to those of end caps.

Violation of the gas seal

- If the inspector has recently visited and the seal has not been damaged intentionally, there is a chance to get away with a minimal fine. Its size can vary from 100 to 1,000 rubles or amount to the cost of re-sealing. Usually, the gas service is loyal to conscientious payers who maintain gas appliances in good condition and comply with all the rules for their operation. However, the meter will be taken away for examination at the client’s expense and if there is no damage to the meter.

- If the anti-magnetic seal is broken. This is considered a serious violation, since the use of special magnets is prohibited by law. Sometimes such punishments are imposed by the court, but most often the gas service imposes a fine of 3,000 rubles plus payment of losses incurred by the enterprise. Damage is calculated depending on the type and power of gas appliances and other factors affecting consumption. Sometimes these amounts turn out to be colossal.

- Representatives of the gas service recorded not only a violation of the gas meter seal, but also an unauthorized connection or connection of an unregistered device. Since such consumer behavior entails a danger to the life and health of others, the violator risks ending up in prison. As a rule, gas workers in such situations prefer to refer cases to the courts.

Vapor barrier for the roof: design features and installation details

We recommend reading: What length of experience does vocational school include?

However, some unscrupulous consumers are trying to resort to various tricks to reduce readings and pay less for gas. Unfortunately, in an effort to save money, not everyone understands what their manipulations will ultimately lead to. All sorts of tricks and tricks can damage the device, and this will lead to a gas leak or more serious consequences.

Fitting selection criteria

The plug is selected according to several parameters:

- Material of manufacture. As a rule, PVC fittings are used for metal-plastic pipes, polyethylene for PET, and steel or brass for metal. Rubber ones are used as temporary ones.

- Diameter, size and shape. The cross-section of the plugs must exactly match the parameters of the communication pipes. In addition, round fittings are used for round elements, and square fittings are used for profile elements.

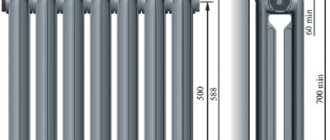

- Purpose. For long-term sealing of the pipe, it is better to buy a threaded or elliptical fitting. If the plug is installed for a short time, it is better to use a flange one. Moreover, it is not recommended to buy rubber and polymer plugs for the hot water system or heating pipes. They change their shape when exposed to high temperatures. As a result, system depressurization may occur. Pneumatic and threaded plugs are not installed on gas pipelines. It is better to use flanged ones here.

Decorative plugs are made from PET in various shades. The color is added to the polymer at the casting stage. The fitting is painted uniformly throughout the entire thickness of the plastic.

Materials

Modern industry offers the buyer a huge selection of shapes and materials. This applies to both pipes and the plugs connecting them. As for fittings for the communication system, among them are the options described below.

Metal and chrome plugs

Pipeline fittings made of this material are currently used very widely. They are used to lay water and gas systems made of cast iron and steel. They are ideal for industry. A significant disadvantage of muffling elements of metal systems is their sensitivity to corrosion and rusting.

Metal plugs with chrome coating cope well with external influences. It not only protects the main structure from external influences, but also performs a decorative function. Such pipeline elements add gloss and genuine beauty to all structures. Sometimes such constructive parts of communications become the center of the entire interior. The only disadvantage of the described option is the rather high cost.

Variations made of brass save pipelines from rust. A significant disadvantage of this option is the very high cost and complexity of the production procedure. They are being replaced by modern analogues.

Plastic and polyethylene plugs

Inexpensive “plugs” made of plastic materials are characterized by high resistance to rust and corrosion. However, they are afraid of sunlight and high temperatures. For this reason, plastic systems are used exclusively for interior work. And they are also well suited for the role of “covers” for the fence. But they are not suitable for sewerage.

Rubber plugs

There is a rubber version of “jammers.” They are unable to securely secure any structure. The reason for this is the plasticity of the material. However, rubber products do a good job of protecting pipelines from debris and dirt.

Principles and features of installation of various types of plugs

When screwing in the plug, it is important not to strip the thread.

The device for plugging the pipe can be installed in different ways, depending on its design features. The following actions are performed:

- Screwing in. This method is used to install a threaded fitting. Before installing it, you must use fum tape and sealant. They will additionally protect the system from leakage. The tape is wound in a small layer on the outer part of the fitting and screwed on. The threaded plug is screwed in by hand until it stops, but without excessive tension.

- Welding. Suitable if an elliptical element is being installed. It is possible to achieve complete tightness of communication. In this case, the work should only be carried out by a specialist. The welded plug is installed for a long period and is not suitable if any repair work is expected to be carried out on the communication section in the near future.

- Use of bolts and nuts. This method is used to install a flange muffler. Before installation, you need to place a seal between the fitting and the pipe. It, in turn, is selected in accordance with the permissible temperature values for a particular system and the pressure requirements in it.

- Air injection. The water supply plug can be installed in several stages. Water is removed from the pipe, a hole is made in the desired section of the system, a fitting is inserted and air is pumped into it. Expanding, the walls of the plug fit tightly to the inside of the pipe. Remove the pneumatic fitting upon completion of the repair work. To do this, you just need to pump out the air from the rubber stopper and remove it.

Thanks to a huge assortment of shut-off fittings, it is possible to solve the issue of sealing the pipeline and the decorative appearance of profile tubes used as fence posts. It is only important to make the right choice.

How to plug a water pipe

The procedure itself is simple, and if you have basic knowledge and skills in the repair and construction field.

Those who have not encountered plumbing work should adhere to the following recommendations:

- Threaded connections are sealed using FUM tape. This is necessary for sealing.

- Before plugging the water pipe, you need to turn off the ball valve and cut it off from the supply system.

- The welding machine must be used in accordance with safety requirements.

- If a flange plug is installed, the bolts must be the same size as the holes made.

A decorative plug works on the same principle as a regular one, and therefore, during installation, all requirements must be met. The technology for installing fittings differs depending on the pipeline materials.

Metal pipe

Metal is different in that such a pipe can be threaded, welded (except for cast iron), flanges can be installed, which means any methods can be used. You need to choose one that has all the necessary tools at hand. Plugs are made from different materials, and the choice depends on what kind of subpipe it is.

Cast iron pipe can be terminated with flanged fittings. The welding machine is useless; cutting threads will not work. In this case, sealing is performed with cotton fiber. Steel is a more malleable metal, and all those methods that are not available in the case of cast iron can now be applied.

To plug such a pipe, you can use:

- Metal spherical plugs. Used for water pipelines, gas pipelines, oil pipelines.

- Flange devices. Cold water pipes are sealed with a rubber gasket, hot water pipes are sealed with paronite.

- Pneumatic plugs. They are used to eliminate emergency situations in production and in household support systems.

- Decorative fittings. This is the case if the main task is not to maintain pressure in the pipeline, but the appearance of the structure.

The last category includes products made of plastic, rubber, and metal. Regarding copper pipes, it must be added that welding is possible, but the technology requires the use of special devices and materials. Copper is a soft metal. You can cut the thread, but you need to tighten it very carefully.

Plastic pipe

Technologically, measures for end sealing of plastic pipes are divided into two categories. The first includes methods that involve soldering or gluing a plug and a pipe. Installing the plug in this way means that it can only be cut off later. The second method is temporary and involves the possibility of dismantling.

Gas fine

The fine for unauthorized gas connection and other actions related to gas equipment that are a violation of the law is imposed in a fairly significant amount. In this case, the owner of the structure will additionally be required to remove all installed items. After this, you will still have to contact specialists to install the necessary equipment.

How to connect correctly?

- connection to the gas main without first signing an agreement with the gas supply company;

- implementation of installation independently or with the involvement of third-party companies or persons who do not have the necessary authority, and often the knowledge, to complete this work correctly and in the required time frame;

- connecting a neighbor to the highway without notifying him of this fact, as well as hiding information from the company that provides the resource.

Gas services systematically carry out work to suppress and punish subscribers who use natural gas on their site in an unregistered manner. This fact is identified by checking the gas pipes supplying fuel to houses, checking for the insertion of other pipes into it, etc. Checks are also carried out based on complaints from citizens who insist that gas is used illegally by a particular citizen.

We recommend reading: Bryansk region benefits for military veterans for the removal of muni

Types of structures

The manufacturer makes various designs. These include:

- Threaded. Most often it is done for the pipe itself. This is a metal element, it is difficult to find this on plastic. To fix it on the pipe, you do not need to have any specific skills, and the fixation will be maximum and practical. There is only one rule - this is the accompanying thread on the pipe itself.

- Pneumatic system. For installation you will need an air pump. When there is flow, the shape of the plug becomes larger. It is put on the pipe, and then tightly fixed on it. This reliability condition is required for gases or liquids. Sometimes it is placed on a water supply to temporarily stop the flow.

- Elliptical option. This requires an auxiliary component - a welding machine. Sometimes fixed as a permanent part on a faulty pipeline.

- Flange. This option is most suitable for metal parts. Fixation occurs due to the fastening element - bolt, rivet. Special entrances have been made for them. The flange is convenient to use because it is easy to install and remove.

Thanks to this distribution, it is easier to make your choice. Because everyone is trying to create a reliable design and put liquid and gas through the pipe without loss.

Characteristics

The most popular spherical plugs have the following diameters:

- 40 mm;

- 250 mm;

- 1600 mm.

The pipeline element is made from durable steel of various grades, usually high-strength, not afraid of the negative influence of the external environment. Actually, the very shape of the plug is the guarantor of its strength and reliability. Additionally, when installing plugs, seals are used, which increase the reliability of the pipeline structure.

In general, spherical plugs have gained great popularity due to their strength to weight ratio. They are lightweight but very durable.