A well in a country house, garden plot or in a vegetable garden allows you to successfully solve the problem of providing technical and drinking water in the absence of a centralized water supply or a well. However, many owners are forced to struggle with the problem of how to clean iron from water from a well with their own hands.

If a yellow-brown or orange liquid flows from the tap, everything is clear without analysis: the water needs iron removal

Ferrous waters are a fairly common occurrence. Iron impurities can be removed from water using special reagents, filters, etc. Most often, such purification requires substantial financial investments. However, there are effective and yet inexpensive ways to purify water. Let's take a closer look at the dangers of exceeding the norm for iron content in water and how it can be reduced at the lowest cost.

The main difficulty of cleaning

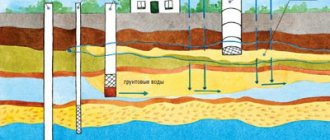

If rusty water appears in the source, samples must be taken to a laboratory for research. Based on the results, it will be known whether such a liquid is suitable for consumption and which cleaning systems are more appropriate to use in a particular case. The main difficulty in purification is that iron in water can be contained in different chemical forms.

Read also: Crisis of 3 years. Tips for parents

- Bivalent is a soluble form, so getting rid of it is much more difficult. This is due to the fact that the medium must first be oxidized in order for the iron to transform into trivalent iron.

- Ferric iron is an insoluble form of the chemical element, which is small particles. Dealing with the problem is usually quite simple - you need to install cartridge filters.

Rust can appear as a result of the active life of certain organisms. This is a more significant problem, since modern filters are not able to retain such elements.

Why is high iron levels dangerous?

Rust in water can cause the following diseases:

- allergic reactions in the form of skin itching and rash;

- dysfunction of the gastrointestinal tract.

In addition to the impact on human health, corrosion and clogging of water pipes negatively affect the operation of washing machines, dishwashers, faucets and other plumbing fixtures. Therefore, it is important to use methods of protection against corrosion, and if the color of the water changes, test for iron content.

How to purify water from a well

There are expensive and budget options that allow you to purify water and make it suitable for consumption. Cleansing methods:

- operation of ion columns;

- settling;

- mechanical clarification;

- aeration.

To achieve maximum results, it is recommended to use a comprehensive water purification system, since each method is designed to solve one specific problem.

Read also: Eyebrow and eyelash dye “Estelle”

Advocacy

This method can be called the most primitive due to its ease of implementation with minimal financial costs. Operating principle:

- The liquid is collected in a clean reservoir and remains at rest for several hours.

- Sediment accumulates at the bottom, and clean water remains on the surface.

Disadvantages include incomplete purification of the liquid, as well as the inability to implement the method in places where pumping equipment is used.

Mechanical cleaning method

The higher the rust concentration, the more often the filters need to be changed.

To implement the method, it is necessary to install various types of cleaning filters. Typically, one of the following varieties is used:

- Sorptive. Their work is based on an active substance that reacts actively with water. Typically, this is activated carbon, potassium permanganate or salt.

- The deep one is designed for rough cleaning of tap or well fluid, mounted in the casing.

- Cartridge filters visually represent a system of flasks with replaceable filter segments.

- Rough cleaning - mounted at the outlet of the casing in front of the water supply system.

The disadvantage of the mechanical purification method is that it does not remove soluble impurities. It does not affect the chemical composition of the liquid.

Ionic filters

This purification method is used if it is necessary to change the chemical composition of the liquid. The columns contain a large amount of a special reagent; its composition is selected depending on the initial composition.

The principle of operation is quite simple - by reacting with substances contained in water, the active components replace iron ions with sodium.

Aeration

The main advantage of this method is that the purification is carried out in several stages - first the medium is oxidized, then ferric iron settles on the walls of the filter.

Expert advice

To ensure that the parameters of the dynamic and statistical level do not change critically for the worse over time, it is necessary to periodically carry out maintenance. To do this, water must be regularly collected for laboratory analysis. This is especially necessary if there is an unpleasant odor or color change.

Also, experts do not advise developing a well on your own. It is better if it is dug by professional workers. In this case, a passport will be issued containing all the necessary data about her condition. Each company issues a passport according to its own model, but the main columns of all executors are the same.

When operating a well, it is necessary to use proper equipment. In this case, its uninterrupted operation for a long time is possible.

It is important to remember that repairing wells comes with costs and some risks. The ultimate goal of all manipulations related to level measurements is to provide the area with clean and fresh water of good quality

Water purification

The main task of measures aimed at purifying water from a well is to make it safe and suitable for drinking. How to clean rusty water from a well and prevent rust from reappearing? Pollution can be combated using filtration systems.

Cleaning solves several problems:

- removal of insoluble impurities;

- neutralization of organic and bacterial components.

The presence of undesirable impurities requires the installation of purification equipment, but before buying filters or a compressor, you need to check which elements reduce the quality of the liquid. To do this, a well inspection and laboratory water analysis are carried out.

Iron removal filters

Filtration systems for water with a high iron content are called iron removal filters. The operating principle of such systems is based on the catalytic oxidation of metal impurities.

During the purification process, divalent iron dissolved in water reacts with the oxidizing agent and is converted into the insoluble Fe+3 fraction. Insoluble rust flakes settle in the filter, so the resulting water becomes potable.

There are two types of iron removal filters:

- reagent-free, where water is treated by aeration with oxygen;

- reagents, where auxiliary substances are used (potassium permanganate, sodium hypochlorite), which act as catalysts for the oxidation reaction.

Iron removal filters show high efficiency and are compatible with other water treatment systems. The average service life of such filtration elements is 5 years .

Reverse osmosis systems

One method of purifying well water is reverse osmosis . The rusty water filter, operating on the principle of osmotic pressure, is equipped with a special membrane. Its surface is permeable only to water and does not allow any impurities to pass through.

All iron compounds (including dissolved ferrous iron), soil particles and other contaminants are retained on the membrane and washed into the sewer. Clean water flows into a storage tank, which can be conveniently placed under the sink.

The membrane in the osmotic filter filters out foreign fractions up to 0.001 microns in size.

Reverse osmosis filtration systems are among the most reliable, but require the organization of sewage drains . Since impurities are removed by flushing the membrane, an area with local sewerage may require frequent pumping of wastewater.

If the supply pressure is insufficient, part of the treated water is also discharged into waste.

Ionic purifiers

Ionic filters help remove traces of iron from water . Softeners contain ionic resins that interact with hardness salts.

Removing impurities using ion exchange does not require starting the oxidation process and subsequent mechanical purification - water is filtered by replacing iron ions with sodium or chlorine ions.

Is water filtered this way harmful? Ion exchange resins are made from polymer materials with a porous structure, which ensures the gradual release of replacement ions. This cleaning method does not affect health, since the permissible concentration of Na or Cl ions is not exceeded.

Signs of the presence of iron compounds

To find out whether drinking meets the standards, you should contact a specialized organization. Professionals will take samples and send them to a laboratory equipped with diagnostic equipment to decide how to best remove ferric iron from your water. You can detect visual signs yourself, but this method is not accurate. It is not always possible to determine anomalies on your own, but there are signs that may indicate excess content:

- metallic taste;

- orange or brown sediment;

- unpleasant odor and dark yellow color;

- organic compounds are visible through an oily film on the surface.

Thus, impurities can be seen by the brownish tint of the settled particles or the iridescent film.

1.5 m3/h For process water

1.5 m3/h For process water

MBFT-75 Membrane for 75GPD

Cleaning methods

There are several methods for purifying water from iron:

- settling;

- mechanical cleaning;

- aeration;

- use of ion columns.

In fact, each of these methods solves a specific problem. Therefore, the ideal option when the liquid is rusty in color is to use complex systems. They include several different systems and guarantee clean water output.

Advocacy

This is the most primitive method, which is suitable for removing large fractions of iron. The operating principle is very simple:

- the liquid is fed into a large container;

- After some time, sediment accumulates at the bottom, and clean water remains at the top.

However, this method is clearly not suitable for a stationary water supply system that uses pumping equipment.

Mechanical cleaning

Based on the use of various types of filters. The following types are commonly used:

- deep – installed in the casing;

- rough cleaning - placed at the exit of the casing in front of the water supply system;

- cartridge - are systems of flasks with replaceable filter elements;

- sorption - they act due to the active substance that reacts with water. Usually this is salt or activated carbon.

You can read more about existing types of filters in the article “Filters for well cleaning.” However, this method allows you to get rid of insoluble impurities; mechanical filters do not affect the chemical composition.

Aeration

The main advantage of this method is that aeration oxidizes divalent iron and converts it into ferric iron.

There are two types of installations:

Operating principle of the pressure system:

- water supply is connected in the aeration tank;

- air is supplied into the column under high pressure, which oxidizes the iron;

- at the outlet, the sediment is retained by filters.

Operating principle of a non-pressure system:

- water from the well is also supplied to the tank;

- inside it, it is sprayed through nozzles, due to which oxidation occurs;

- a sediment drainage system is provided at the bottom;

- because the pressure in the water supply is lost, an additional pump is connected to the tank, which supplies water to consumers.

The big advantage of aeration is that in addition to removing iron, it removes manganese and hydrogen sulfide. It also saturates the water with oxygen.

Aeration cleaning system

Ionic filters

Used to change the chemical composition of a liquid. The columns contain a special reagent, the composition of which is selected depending on the composition of the liquid.

The principle of action itself is quite simple - when it reacts, the active substance changes iron ions to sodium. Due to this, it can further linger on coarse filters.

Types of iron impurities

Like any element, Fe can exist in the form of various compounds with other components, and the number of bonds formed with atoms varies. The following types are distinguished:

- Divalent oxide. When it enters a water mass it becomes trivalent, and it acquires the color of rust.

- Bivalent iron, the removal of which from water is necessary if the molecule consists of two atoms. The presence of this component is difficult to see without equipment, since it is soluble and does not change the color of the solution.

- Ferric iron, which usually produces a precipitate.

- Organic suspensions.

Most often, iron-containing fractions of different types are contained, so when choosing a filter, you need to take care to remove all varieties.

Best answers

Esmeralda:

nothing, pull out the pipes and wash

Vladimir Z:

if the well is shallow - 15 meters (on a sand layer) - hammer it and forget it. it cannot be restored. they work for 7-8 years, no more. drill one more time. if it’s deep - 60 meters - on limestone, call a serious company. they will blow the well with a special one. solution under pressure from the tank machine and operation will be restored.

Dmitry Vasiliev:

I'll probably have to cut a new one

Elena:

...have you seen a machine that breaks through a sewer with water under very high pressure?... it will help... you won’t find a new one, just drill... there is no point in pulling out pipes - it will cost 2 times more..

Barabas:

We usually “shoot” a well, that’s what the method is called. Take a glass vial (from naphthyzine, for example, gun casings used to be used, but they often pierce the filter mesh), gunpowder is poured into it (the dose is selected experimentally) and wires (thin stranded 2 * 0.75 or even thinner, so that the ends touch each other so that there is a spark), then we close the bottle tightly and into the hole so that it doesn’t touch the bottom half a meter and we close the wires with a battery. Alternatively, you can do the same thing without a bubble, like making an explosion out of a thick paper bag, be sure to tightly wrap it with electrical tape and wrap it in a balloon.

Collecting fluid for bacteriological examination

Analyzes for organoleptics and radiological impurities do not require such a thorough and careful approach to collecting material

- For this analysis, you need to purchase exclusively sterile containers (as sanitary standards say).

- If your well is not new, it should be treated with sodium hypochloride. The same applies to a new source.

- The tap from which water will be drawn must be burned or treated with medical alcohol.

- When taking liquid, you should not touch the neck of the bottle with your hands (it is better to wear sterile gloves), and the neck of the tank should not touch the tap.

- After collecting drinking water, we tightly screw the lid on and quickly send the water to the laboratory to determine its tank composition.

Methods for cleaning rust

To remove foreign impurities, the method of settling, physical purification, oxidation is used, or ionic filters are installed. The use of each method is aimed at solving one of the problems. Therefore, if the water in the well rusts, you need to use several methods to ensure high quality cleaning.

Water purification by water settling method.

Advocacy

The method is based on the ability of heavy particles to settle. Settling helps remove large iron fractions. The liquid is fed into a reservoir, where it remains for several days. During this time, contaminants precipitate, clean water remains at the top.

The method is not suitable for a stationary water supply system equipped with a circulation pump.

Mechanical cleaning

For mechanical cleaning, different types of filters are used:

- Deep. Installed at the stage of laying the casing.

- Rough cleaning. Installed in the upper part of the shaft in front of the water supply system.

- Cartridge. It looks like a container with removable filter parts.

- Sorptive. Contains chemicals that react with contaminated liquid. Most often, activated carbon or salt are used as a sorbent.

The mechanical cleaning method is used only to remove insoluble particles. The chemical composition of the liquid does not change when using filters.

Aeration

Water purification by aeration.

The method is based on the oxygen oxidation of divalent iron to trivalent iron.

There are 2 types of aeration units:

- Pressure. A water supply is connected to a special tank. Air is supplied under pressure into the system and reacts with contaminants. The resulting sediment is captured by filters.

- Non-pressure. The liquid coming from the well enters the tank, where it is divided into small droplets by nozzles. This feed ensures the oxidation of impurities. The bottom of the tank is equipped with a drainage system for sediment. The process is accompanied by a loss of pressure in the water supply system, so the system includes a pump that distributes the liquid to consumers.

The advantages of this purification method are the ability to eliminate hydrogen sulfide, manganese and other oxidizable impurities, as well as saturate the water with oxygen.

Ionic filters

Installations are used to change the composition of the liquid. The columns contain a special filter material. Its composition depends on the type of foreign impurities contained in the liquid. The filters have a simple principle of operation - the active substance reacts, replacing iron ions with sodium. The resulting insoluble compounds are captured by coarse filters.

Drawing conclusions

The effect of filtration depends on the degree of presence of harmful impurities. If it contains ferrous substances of organic origin, the hardness is increased, multi-stage purification is needed. This will include a coarse filtration filter, then aeration, adding reagents so that the ferrum settles. In addition, you will need a reverse osmosis membrane. When the composition of the liquid is close to the standards, a small set of equipment is sufficient. If you plan to purchase a deferrizer, please contact. Call to get advice and purchase equipment at a competitive price.

What to do if rusty water comes from a well or well?

The presence of such impurities significantly worsens visual and organoleptic parameters, so anyone faced with a similar problem will be glad to solve it. Let us consider further examples of the correct sequence of actions using typical situations.

How does rusty water appear in a well?

First, let's establish precise definitions of the concepts that will be used for the work. The name "rusty water" is not a completely accurate description of all problems.

A rich brown liquid can be contaminated with tiny particles of oxidized iron, insoluble chemical compounds that settle and appear on the walls of the pipeline in the form of rust. Such impurities, with relatively large individual fractions, are easily removed. To do this, you need to select a filter with suitable pore parameters (mesh cell sizes).

It will be much more difficult to select a set of equipment for removing Fe+2 (ferrous iron) and rusty water in a well or well. It is found in water in dissolved form. It is these impurities that are found at great depths. They are washed out from different types of rocks and will not oxidize for a long time due to the lack of free access to oxygen.

Some types of microorganisms in water from wells and wells, in the process of their own life activity, consume iron, convert it into other forms, and form special shells around themselves from such jelly-like compounds. There are other types of iron, organic and inorganic, of natural and artificial origin.

Why are they difficult to remove?

The variety of techniques used is explained by the large number of different forms of iron. If rusty water comes from a well or well , then it is necessary to have it analyzed in a specialized laboratory that has passed the appropriate certification. This will allow you to localize the problem and help you more accurately select the means to eliminate it.

The form of organic iron mentioned above is not the only one. For example, lignins and some other compounds are insoluble. It would seem that it is not difficult to remove them. In reality, there will be difficulties. The sizes of such particles are so small that it will be impossible to retain them even when using large column-type plants with granular backfill. If you try to let such a solution sit, then even in this case the desired result will not be obtained. Such particles are too light in weight. On their surfaces, charges of the same sign are formed, which repel each other, preventing them from combining into large fractions.

It is able to bind magnesium and iron and form a complex organic complex. This is just one example of chelates. In nature there are many such compounds that are highly soluble in water and are able to penetrate the soil to great depths.

Now let's try to purify rusty water using a high-quality ion exchange resin. If all installation parameters are selected accurately, the corresponding connections will be delayed, and subsequent high-pressure flushing will remove accumulated contaminants into the drain. Next, you can restore the initial parameters of the backfill using a saturated solution of ordinary and inexpensive table salt.

But such an algorithm of actions will be effective only if one of the forms of iron is available. In real life, this almost never happens. Outside the city, where wells and artesian wells are used, a variety of organic impurities, including the corresponding iron compounds and bacteria, disappear into the groundwater. They create a shell around each resin granule that will be difficult to remove by washing. Such layers prevent ion exchange. They will reduce or completely eliminate all the beneficial properties of high-quality backfill.

Why do you have to drill deep wells, and what problems arise?

Let's study some technologies in more detail using one practical example. Outside the city, one of the neighbors uses a shallow well (3-4 meters). The water in it is clean, without visible impurities, rust and others. Another owner has an artesian well 25 meters deep. Only a few minutes after water is extracted from it, the liquid remains transparent. Later, flakes with a characteristic rust color appear in it. Geological data states that there are no aquifers to a depth of 80 meters. There are no iron impurities below. But at the same time, water hardness increases to 10 mEq/liter.

Solving the problem will not be easy. The clarity of water in a shallow well is not a guarantee of its actual purity. At such a depth, a variety of organic impurities, microbes, bacteria, petrochemical products, industrial and agricultural waste will almost certainly be present. According to environmentalists, in almost the entire territory of the Moscow region, the water in wells is unsuitable for drinking and cooking. It may not contain iron, but other impurities may be too dangerous.

Clear water turns brown when kept in the open air for a short time. This is a typical sign of the presence of divalent iron in divalent form. As described in the previous section of the article, it is possible that there are other forms of this substance, so chemical and bacteriological laboratory tests will be needed.

In this area, excellent water purified from microorganisms is only available in deep wells. But, as it turned out, it contains hardness salts in quite high concentrations. Not every ion exchange unit is suitable for working with such liquids. In this case, it is better to use filters to purify water from a well of a certain model. It will not retain impurities, but will completely eliminate the possibility of scale formation. Calcium and magnesium salts will combine as insoluble particles. They are then removed into the sewage system or separated from the water using filter elements.

Algorithm for the correct actions in the fight against rust in a well

Here is a sequence of operations that will be useful if you are solving the problem of rusty water coming from a well or a well:

- Analysis of chemical and bacteriological composition in a specialized laboratory. It is recommended to perform this procedure several times a year, at least twice. It is necessary to take into account significant changes in the composition of groundwater during snow melting and during floods;

- Study of geological data on the land plot. In their absence, consultations with relevant specialists will be required;

- Determining the composition of the equipment that will be used to completely clean the well from rust. It makes sense to remove all harmful and dangerous impurities, and not just iron compounds. The system can include mechanical filters and ion exchange units, electromagnetic converters and reverse osmosis systems. It will be necessary to accurately take into account the existing needs and the required quality of hard water obtained after softening in the well. A good specialist will select all the components of the equipment in such a way that they complement each other.

Checking alternatives. It is likely that cleaning from too much rust in a well and well will be too difficult, require large initial costs, and large expenses during the operation period. In this case, it is necessary to check the economic feasibility of creating a deep well, which is equipped with additional necessary equipment to reduce the level of hardness, or eliminate the processes of removing scale and rust.

For modest needs: pitcher filter

- What's good: does not require installation

- What's bad: low performance

If your water is not of terrible quality and you need a small volume for cooking and drinking, you can try using a simple jug-type filter . Such models can have both simple activated carbon cartridges and complex ones for complete cleaning. The capacity is small, so for a large family it is better to choose an option with a larger volume: so that there is always water.

For example, this jug from Aquaphor holds 4.2 liters:

For dacha conditions, it is usually important to remove iron (it is what gives the water a “rusty” tint. Pay attention to filters with several stages of purification, including softening and especially iron removal. For example, this Geyser with a 4-liter jug:

Installation features

You can install a filter for hot water supply directly at the entrance to the home mains, provided that it is a coarse cleaning device. To improve the quality of the final product, fine cleaning devices are used.

Before installation work, you need to make sure that the cross-section of the hot water pipes corresponds to the parameters of the outlet and inlet on the filter or is 1 cm less.

In this case, the installation will be completed without any particular difficulties.

The filter must be installed at the entrance to the home mains.

Installation of the main filter is carried out according to the following instructions:

- Apply sealant to the threads using appropriately sized fittings.

- Tighten the connecting parts until they stop on both sides and leave for 15 minutes until the silicone is completely fixed.

- Apply fasteners to the filter, following the direction of the arrows.

- Try on the unit and place it with the fastening side against the wall.

- Use a pencil to mark the wall through the mounting holes.

- Putting the device aside, drill holes in the wall and install dowels.

- After returning the filter to its original position, attach the fasteners with self-tapping screws and tighten securely.

- Using plumber's scissors, cut off part of the structure before entering and exiting the filter device.

- Remove the part called “American” from the filter and put it on the product.

- Install the filter and crimp the edge of the pipe with a ring.

- Place the cartridge in the device flask if it has not been installed before.