For individual water supply to country private houses and cottages that do not have access to the central water supply main, the main source of water is underground pools, which are easier and cheaper to access using a well. Typically, specialized companies are engaged in drilling deep-water wells with high flow rates (fillability), but you can significantly reduce financial costs by further equipping the water well yourself.

The task is not so simple due to the many factors influencing decision-making on the well construction method; you will mainly have to take into account your financial capabilities, the casing material, the characteristics of the well source and pumping equipment, and the climate in the region where you live. When installing (piping) a well yourself, you should select in advance the type of electric water pump (surface or submersible), draw up a plan for connecting it to auxiliary devices and determine its location.

Station in a caisson

Connection sequence

Connection to a well and borehole

First, let's look at how to properly connect a pumping station to a well or well.

In this case, we will pay attention specifically to the two-pipe connection diagram, since it is more complex. We work in this order:

- First, we assemble the ejector with our own hands. As a rule, this is a monolithic unit made of cast iron, which has three outlets.

- We install a coarse filter made of propylene mesh at the lower outlet of the ejector.

- There is a plastic socket at the top of the cast iron structure. You need to put a squeegee of the required length with a diameter of 32 mm on it.

- Next, you need to assemble a squeegee to fit the diameter of the pipeline. Usually two parts with adapters are enough for this.

- A bronze coupling is installed at the outlet of this outlet. With its help, the transition to the polyethylene pipe will be made.

- Next, trenches are dug from the hydraulic structure to the house below the freezing point of the soil.

- Water pipes are laid in the trenches.

- A cap is installed at the exit of the well casing. If you can't find it, you can use a knee with a smooth angle.

- To connect the ejector to the water supply pipeline, couplings are used.

- Before lowering the second end of the pipe, it must be passed through the elbow at a right angle.

- Polyurethane foam is used to seal the space. After this, the pipe can be connected to an adapter (angular), and it, in turn, must be connected to the outer part of the water supply.

- Now you can lower the ejector into the well. In this case, the immersion depth must be determined in advance, taking into account the elevation of the top of the casing pipe.

- The head is fixed to the casing using reinforced sanitary tape.

Features of connecting to the water supply

If there are centralized water supply networks near your home, then the pumping station can be connected to them. Typically, the need for such a connection arises when the pressure in the system is too low, which does not allow the heating equipment to function efficiently and correctly. This situation can arise for several reasons:

- the hydrogeological conditions of the area have changed;

- outdated equipment is used;

- As the number of residents has increased, water consumption needs have become greater.

To connect to the central water supply you need to perform the following sequence of actions:

- The place where the pipeline will be disconnected is selected in advance. After stopping the water supply, the water supply is divided into two parts.

- So the part that comes from the city highway is connected to the storage tank.

- The liquid from this tank must flow through pipes to the pumping unit. A pipeline leading to a residential building is connected to the outlet from the pump.

- Next, the electrical wiring is laid and connected.

- After this, you can perform a test run, configure and adjust the equipment.

The main thing in setting up a pumping unit is to select the correct pressure in the system. To adjust the equipment, a small amount of water (about 2 liters) is poured into a special hole on the pump unit. Now you need to open the tap and measure the pressure in the system at which the pump turns off and on.

If the pressure at which the unit operates does not fall within the specified limits, it is necessary to adjust the device. It's very easy to do this:

- The cover on the pressure switch opens.

- To adjust the device shut-off pressure, use a screw marked “DR”. It needs to be twisted towards decreasing or increasing depending on the results.

- To adjust the switching pressure, you need to turn the screw marked “P”.

- After adjustment, the cover on the relay is put in place.

Also, do not forget that the long-term and proper operation of pumping equipment is affected by the composition of the water, namely various admixtures of sand and clay. To protect the equipment from impurities, a filter is installed at the suction inlet of the station.

Caisson installation

The caisson pit is one of the strapping methods. It is assumed that the equipment and head will be hidden. A pit is dug in the ground where the upper part of the casing pipe is placed.

The scheme is implemented in several ways:

- Metal caisson. Steel is now a fairly expensive material, but it allows for good sealing. It is necessary to apply anti-corrosion compound on the outside. Assembly can be done independently without the use of special equipment. All you need is a welding machine.

- Reinforced concrete rings. Installation is quite fast. But such arrangement does not allow achieving good waterproofing. You only need one or two rings, which are then covered with a concrete lid with a hatch. A frame of reinforcement is laid at the bottom and filled with concrete.

- Plastic caisson. This is a lightweight and durable material that can only be destroyed by mechanical stress. The structure is completely sealed.

For proper operation of the system, the correct configuration is required. For this purpose, calculations are performed to select equipment.

Connecting the pumping station

Selecting equipment and installation location is only half the battle. You also need to correctly connect everything into the system - the water source, the station and the consumers. The exact connection diagram of the pumping station depends on the selected location. But in any case there is:

- A suction pipeline that is lowered into a well or well. He goes to the pumping station.

- The station itself.

- Pipeline going to consumers.

All this is true, only the strapping patterns will change depending on the circumstances. Let's look at the most common cases.

Water supply from a well for permanent residence

If the station is installed in a house or in a caisson somewhere on the way to the house, the connection diagram is the same. A filter (most often a regular mesh filter) is installed on the supply pipeline lowered into a well or borehole, a check valve is installed after it, and then the pipe goes. Why a filter is understandable - for protection against mechanical impurities. A check valve is needed so that when the pump is turned off, water does not flow back under its own weight. Then the pump will turn on less often (it will last longer).

Installation diagram of a pumping station in a house

The pipe is led out through the wall of the well at a depth just below the freezing level of the soil. Then it goes into a trench at the same depth. When laying a trench, it must be made straight - the fewer turns, the lower the pressure drop, which means that water can be pumped from a greater depth.

To be sure, you can insulate the pipeline (lay polystyrene foam sheets on top, and then cover it with sand, and then with soil).

Option of passage not through the foundation - heating and serious insulation are required

At the entrance to the house, the supply pipe passes through the foundation (the passage place is also insulated); in the house it can already rise to the installation site of the pumping station.

This method of installing a pumping station is good because if everything is done correctly, the system works without problems. The inconvenience is that it is necessary to dig trenches, as well as to remove/introduce the pipeline through the walls, and also that when a leak occurs, it is difficult to localize the damage. To minimize the chances of a leak, take proven quality pipes and lay a whole piece without joints. If there is a connection, it is advisable to make an inspection well.

Detailed diagram of the piping of the pumping station when connected to a well or borehole

There is also a way to reduce the volume of excavation work: lay the pipeline higher, but insulate it well and additionally use a heating cable. This may be the only way out if the groundwater level is high on the site.

There is another important point - the well cover must be insulated, as well as the outside rings to the freezing depth. It’s just that the section of the pipeline from the water surface to the outlet into the wall should not freeze. This is why insulation measures are required.

Connecting the pumping station to the water supply

Often a pumping station is installed to increase the pressure in the water supply system during a centralized water supply. In this case, a water pipe is connected to the station input (also through a filter and check valve), and the output goes to consumers.

Connection diagram of the pumping station to the water supply system

It is advisable to install a shut-off valve (ball valve) at the entrance so that, if necessary, you can turn off your system (for repairs, for example). The second shut-off valve - in front of the pumping station - is needed to repair the pipeline or the equipment itself. Then it also makes sense to install a ball valve at the outlet - so that, if necessary, cut off consumers and not drain water from the pipes.

Well connection

If the suction depth of the pumping station for the well is sufficient, the connection is no different. Is it just that the pipeline comes out at the place where the casing ends. A caisson pit is usually installed here, and a pumping station can also be installed here.

Installation of a pumping station: connection diagram to a well

As in all previous schemes, a filter and check valve are installed at the end of the pipe. At the inlet you can install a filler tap through a tee. You will need it the first time you start.

The main difference between this installation method is that the pipeline to the house actually runs along the surface or is buried to a shallow depth (not everyone has a pit below the freezing depth). If the pumping station is installed at the dacha, it’s okay; the equipment is usually removed for the winter. But if the water supply is planned to be used in winter, it must be heated (with a heating cable) and insulated. Otherwise it won't work.

https://youtube.com/watch?v=_d3RXbFArls

What is needed to supply water from a well?

When drilling individual wells using drilling equipment, a column of casing pipes is lowered into the mine, the material of which is polymers (unplasticized polyvinyl chloride UPVC, HDPE) or steel, sometimes plastic pipes are inserted inside metal ones at great depths. At this stage, the well arrangement diagram should be known, for example, if water is supplied to the water supply through an adapter, it is not recommended to attach it to the fragile plastic wall of the pipe; the column or its top should be made of metal.

To understand how to install a water well after drilling, you should consider all the equipment and engineering structures that are needed to deliver water to the internal water supply of the house. To provide housing with well water you need:

Casing string . After passing the borehole channel, a column of pipes 6 m long is immersed into it, which are connected to each other by means of threads. It must have smooth, strong walls that can withstand external soil pressure, and a diameter suitable for immersion of the selected electric pump model.

Recently, individual drilling of Abyssinian wells by private individuals has become popular in cases where the water surface on the site is closer than 9 m from ground level. To do this, use a hydraulic drill to make a narrow hole in the ground and immerse a low-density polyethylene (HDPE) pipe with a homemade filter at the end inside, which is connected to a surface electric pump. The depth of homemade Abyssinians reaches 30 m; the casing and supply pipeline are simultaneously a HDPE pipe section lowered into the channel.

Devices for immersing the pump and suction hose into the source . When lowering a deep-well pump, always use a head or cover with an adapter connection, to which the unit is tied and the supply pipe is attached. When attaching the adapter, the water supply pipeline is passed through its side fitting, fixed to the wall of the column.

Piping diagram for a well with a deep-well pump

Electric pump . There are two groups of electric pumps for supplying water: submersible and surface, the first are lowered into the well to a great depth, so that they plunge without interference, a casing of a suitable diameter from factory well pipes is required. Surface electric pumps for water intake from depths of up to 9 m use a narrow hose or a water pipe of small cross-section, so a wide column is not required for their operation - this is the determining factor when using them to suck water from Abyssinians.

Automation. To turn off the pump after filling the water supply system, a pressure switch is used, a pressure gauge is installed to configure and control it, an expansion tank is used to store water reserves and maintain pressure in the line. The listed devices are the main components of a household water supply main with an electric pump; when using surface types, all of the listed elements and the pump are often assembled into a single unit - a pumping station.

Optional equipment

The direct scheme for connecting the unit to the network without the use of auxiliary equipment looks quite simple and is carried out by connecting pumping equipment to the contact group. However, this connection diagram may not be used in all cases. Moreover, most often the connection of a submersible well pump is done using automation. This makes it easier to maintain the water supply system and improves its performance characteristics. As a rule, the list of used automation includes the following elements:

- electric starters;

- intermediate relay (switches);

- pressure and liquid level control sensor;

- hydraulic tank

Purpose of automation

Thanks to the use of automation when installing well-type pumping equipment, it is possible to achieve automatic operation of the water supply system. The fundamental element of this system is a contactor with an open contact group. Power conductors are supplied to the contactor input, and a well pump is connected to the output.

In such a connection scheme, a hydraulic accumulator must be used, which is supplemented with a check valve. A pressure switch is installed next to the hydraulic tank, without which it is impossible to imagine the automation of pumping equipment. The relay controls the contact group and ensures the start and stop of pumping equipment when the pressure increases or decreases to a predetermined level in the water supply system.

Automation for a well pump works according to the following principle:

- When the pressure in the system drops to the set minimum, the relay sends a signal to turn on the pumping equipment. At this moment, the contacts of the working group are closed, and the power supply to the pump is turned on.

- As the system is filled with water, the pressure in the hydraulic tank gradually increases.

- When the pressure reaches the set maximum, the relay sends a signal to the contactor. As a result, the contacts open the circuit and the pumping equipment is automatically disconnected from power.

For water supply systems that work with significant volumes of liquid, it is not electric automation that is more suitable, but float sensors that automatically control the water level in the storage tank - the hydraulic tank. In principle, this connection diagram for pumping equipment does not differ from systems using automation. The only difference is that instead of a pressure switch, a level sensor is installed here.

Purpose of the hydraulic accumulator

The operating principle of the submersible unit involves starting it when the pressure in the water supply system decreases. However, frequent opening and closing of taps in the house will lead to frequent starts and stops of pumping equipment. Since even when the tap is open, the pump creates a fairly strong pressure, the unit can automatically turn off. As a result of this mode of operation, pumping equipment will quickly wear out and fail. To protect the engine from frequent starting due to pressure changes, the pump unit is connected through a hydraulic tank.

A hydraulic accumulator is a sealed steel container with a rubber bulb inside. The wall of the bulb, like a membrane, divides the tank cavity into two chambers: inside the first chamber (bulb) there is water, and in the second chamber (in the space between the walls of the bulb and the body) air is pumped. The pump pumps water into the bulb until the air pressure balances the water pressure. If you open any tap in the system, air will push water into the pipes.

Some hydraulic accumulators are made in the form of a container divided into two parts by a rubber membrane, and not with a bulb in the middle. In one part of the tank there is air, in the other - water is pumped. Their operating principle is the same. The volume of the hydraulic tank depends on the number of residents in the house and water consumption. For an average country house, a tank with a volume of 100 liters is sufficient.

The main purpose of the hydraulic tank:

- it maintains the pressure in the system at the required level;

- a certain amount of water is stored in the tank;

- The hydraulic accumulator reliably protects the water supply system from water hammer.

Options for water distribution in a private house

There are two main ways to connect consumers to the water supply; when choosing an option, the volume of water consumed and the required pressure in the system are taken into account.

Serial (Tee) connection. The scheme consists of a common hot and cold water supply pipe, from which water is supplied to the consumer using tees; it is economical and easy to install. Its disadvantage is a sharp drop in temperature when several consumers are connected to the line, and the water pressure in the system of the last of them will be much lower than normal.

Parallel (collector) connection. With this method, pipes are routed separately from the common collector to each point of consumption. The system is characterized by uniform water pressure and temperature throughout, but requires a large number of pipes, which complicates installation and is more expensive than the previous option.

Rice. 3 Series and parallel water distribution

Pump selection

Before considering the pumping equipment connection diagram, it is necessary to select the correct unit. All pumps can be divided into two types:

- Submersible units. These pumps work below the surface of the water and push water from the well or well in the country up through a piping system or hose.

- Surface-type devices are installed on the surface and pump out water from a hydraulic structure.

Submersible pumping equipment has a number of advantages over surface products:

- Since the unit operates underwater in the depths of the well, the noise from its operation is practically inaudible on the surface.

- For the same reason, the product saves space on the site. In addition, to install the unit you do not need to allocate a separate room or install a caisson.

- During operation of a well pump, less electricity is consumed than when operating a surface product.

In turn, submersible pumps can be divided into several groups:

- deep well units, which are divided into two subtypes: vibration and centrifugal;

- drainage pumps;

- circulation pumping equipment;

- fountain units.

As you can guess from the name, setting up a water supply system requires the installation of a deep well pumping product. We will look at the connection diagram for such a pump in our article.

Before moving on to the connection diagram, it’s worth figuring out whether we need a vibration or centrifugal type of product. Thus, vibration pumping equipment is suitable for shallow wells. This is inexpensive equipment that can pump even very contaminated water. But its disadvantage is that vibrations during pump operation can destroy the hydraulic structure. Centrifugal units are more productive, safe and durable, which is why they are most often used to connect to the water supply system of a country house.

Construction of a water well from A to Z: video

Below are examples of videos that clearly display many stages of well piping:

- Borehole drilling, independent arrangement of a well caisson under water, installation of a deep-well pump in a well, installation and connection of a hydraulic accumulator, automation in the caisson:

- Drilling, constructing a caisson well with your own hands, assembling a pumping station for a submersible electric pump:

- Installation of a steel coffer chamber, installation of a hydraulic accumulator and automation for a submersible electric pump:

- Installation and connection of the pumping station to the well in a caisson chamber made of concrete rings:

When piping a well, they focus on the physical parameters of the source: depth, flow rate, static level, water quality. Based on the listed factors, choose the type of pump (surface or submersible), and then the placement option (caisson, house) and connection (via a head or adapter). The complexity of the filtration system depends on the quality of the water; usually artesian sources require the use of expensive purification systems for removing metal oxides and hydrogen sulfide.

Connecting the pumping station

Selecting equipment and installation location is only half the battle. You also need to correctly connect everything into the system - the water source, the station and the consumers. The exact connection diagram of the pumping station depends on the selected location. But in any case there is:

- A suction pipeline that is lowered into a well or well. He goes to the pumping station.

- The station itself.

- Pipeline going to consumers.

All this is true, only the strapping patterns will change depending on the circumstances. Let's look at the most common cases.

Water supply from a well for permanent residence

If the station is installed in a house or in a caisson somewhere on the way to the house, the connection diagram is the same. A filter (most often a regular mesh filter) is installed on the supply pipeline lowered into a well or borehole, a check valve is installed after it, and then the pipe goes. Why a filter is understandable - for protection against mechanical impurities. A check valve is needed so that when the pump is turned off, water does not flow back under its own weight. Then the pump will turn on less often (it will last longer).

Installation diagram of a pumping station in a house

The pipe is led out through the wall of the well at a depth just below the freezing level of the soil. Then it goes into a trench at the same depth. When laying a trench, it must be made straight - the fewer turns, the lower the pressure drop, which means that water can be pumped from a greater depth.

To be sure, you can insulate the pipeline (lay polystyrene foam sheets on top, and then cover it with sand, and then with soil).

Option of passage not through the foundation - heating and serious insulation are required

At the entrance to the house, the supply pipe passes through the foundation (the passage place is also insulated); in the house it can already rise to the installation site of the pumping station.

This method of installing a pumping station is good because if everything is done correctly, the system works without problems. The inconvenience is that it is necessary to dig trenches, as well as to remove/introduce the pipeline through the walls, and also that when a leak occurs, it is difficult to localize the damage. To minimize the chances of a leak, take proven quality pipes and lay a whole piece without joints. If there is a connection, it is advisable to make an inspection well.

Detailed diagram of the piping of the pumping station when connected to a well or borehole

There is also a way to reduce the volume of excavation work: lay the pipeline higher, but insulate it well and additionally use a heating cable. This may be the only way out if the groundwater level is high on the site.

There is another important point - the well cover must be insulated, as well as the outside rings to the freezing depth. It’s just that the section of the pipeline from the water surface to the outlet into the wall should not freeze. This is why insulation measures are required.

Connecting the pumping station to the water supply

Often a pumping station is installed to increase the pressure in the water supply system during a centralized water supply. In this case, a water pipe is connected to the station input (also through a filter and check valve), and the output goes to consumers.

Connection diagram of the pumping station to the water supply system

It is advisable to install a shut-off valve (ball valve) at the entrance so that, if necessary, you can turn off your system (for repairs, for example). The second shut-off valve - in front of the pumping station - is needed to repair the pipeline or the equipment itself. Then it also makes sense to install a ball valve at the outlet - so that, if necessary, cut off consumers and not drain water from the pipes.

Well connection

If the suction depth of the pumping station for the well is sufficient, the connection is no different. Is it just that the pipeline comes out at the place where the casing ends. A caisson pit is usually installed here, and a pumping station can also be installed here.

Installation of a pumping station: connection diagram to a well

As in all previous schemes, a filter and check valve are installed at the end of the pipe. At the inlet you can install a filler tap through a tee. You will need it the first time you start.

The main difference between this installation method is that the pipeline to the house actually runs along the surface or is buried to a shallow depth (not everyone has a pit below the freezing depth). If the pumping station is installed at the dacha, it’s okay; the equipment is usually removed for the winter. But if the water supply is planned to be used in winter, it must be heated (with a heating cable) and insulated. Otherwise it won't work.

https://youtube.com/watch?v=_d3RXbFArls

Caisson or adapter - in what type of wells is it installed?

To provide water to individual houses, wells are drilled, which are divided into three categories:

Abyssinian . This type of well is installed when aquifers are located at a shallow depth from the surface; hydraulic drilling is carried out by individuals and organizations. The Abyssinian well is drilled within 24 hours; instead of casing pipes, a piece of HDPE pipe with a filter at the end is taken. The depth of the Abyssinian depends on the location of the aquifer and lies in the range of 5 - 30 m. The water surface in the Abyssinian should not fall below 9 m; external centrifugal electric pumps or stations, which are located in close proximity to the source, are used to draw in water.

To protect the external pump from precipitation and frost in winter, an insulated coffered well is installed in the Abyssinian area.

Wells in the sand . This is the main type when the water table from the ground level is below 9 m, the depth of the wells ranges from 20 to 60 m, a submersible pump is used for intake. When installing a deep-well electric pump, it is easier and more cost-effective to connect it through an adapter screwed into the side of the casing wall; the caisson is not mounted.

Artesian . To access water artesian basins, a well with an average depth of 100 m is drilled; in domestic water supply sources it can be larger, but at depths of more than 200 m, already significant costs increase sharply due to the use of industrial technology for drilling such distances.

Due to the pressure of earth layers on a deep water basin, water from artesian wells often rises to a great height and even comes to the surface; a surface electric pump is used for supply and a caisson well is installed accordingly. No one forbids extracting water from an artesian source with a deep-well pump, which has higher efficiency and characteristics; when installing it, it is more economical to use a well adapter to drain water into a house.

Although the use of an adapter is more rational when operating deep-well pumps for water intake, a caisson well has the advantages of convenience when it is necessary to remove and maintain a submersible electric pump, and it also protects the well channel from freezing in winter. Therefore, a caisson is often installed when lifting water with a submersible pump, placing automation in it: a pressure and dry-running switch, a pressure gauge, a hydraulic accumulator.

Surface pumps and pumping stations

Scheme for a surface well pump

Conditions allow the pump to be installed upstairs. Then a scheme is used for a surface well pump, which is recommended to be placed next to the source. The advantage of an outdoor location is that the device is easily accessible if repairs need to be made.

Operation of a surface hydraulic unit is not complicated. Install a pump to the water well, lower the hose into the tank, turn on the start-up protection unit, and press the “Start” button. Recommended location for efficient work and safety:

- a few meters, closer to the water intake;

- as far as possible from the populated area;

- indoors, with exhaust ventilation;

- on a solid foundation.

When connecting a surface water unit, use:

- fitting for connections;

- hose, water intake hose;

- pipe entering the storage tank;

- a set of irrigation hoses;

- fittings, fasteners, clamps.

Required materials and tools

In order to quickly install a submersible or surface apparatus in a well, install a water pipeline into the house and install automation for starting and monitoring the water supply, it is necessary to carry out preparatory work.

Purchase materials and equipment that will be needed to install the system:

- submersible or surface pump;

- set of automation equipment with hydraulic accumulator;

- pressure hose;

- distribution tee for submersible version;

- check valve;

- coarse filter for surface version;

- fitting;

- insulation;

- geotextiles;

- stainless steel cable;

- cable for supplying electricity to the pump;

- auxiliary materials for fastening and waterproofing.

To carry out installation work you will need the following tools and equipment:

- Shovels, crowbar.

- Bulgarian.

- welder.

- Electric drill.

- Screwdriver.

- Roulette.

- Set of open end and socket wrenches.

How to choose a pumping station for a well

It is necessary to select a pumping station for a well on a site taking into account the parameters of the pump and factors characterizing the water source. In particular we are talking about the following:

Distance of the water source from the main building. Lowest point of water intake. Conclusions should be drawn based on the dynamic water level, analyzing the indicators for about two days with constant use of the liquid. In this case, it is not recommended to take into account the static level, since the calculations may be erroneous. Nominal pump head

Here it is important to determine how high the water column can be created by the connected equipment. The calculation formula involves summing up the suction value, the length of horizontal sections of the water supply system, vertical lift and losses for transportation through pipes. Unit performance

Calculations can be taken based on the average water flow at all connected points. The resulting total value should not exceed the flow rate of the water supply source (read: “How to choose a pumping station for a private house - rules for choosing a water pumping station”). Mains voltage. Most pumping stations for domestic use operate on a 220 V network. As for powerful units, they are equipped with three-phase motors that operate on a 380 V network. Station power. Pumping stations of various types consume quite a large amount of electricity, from 500 W to 2 kW. Depending on the power of the pumping station, the type of circuit breaker should be selected. Storage capacity volume. This parameter depends entirely on the number of people living in the house. For example, a 24-liter capacity is sufficient for a family of 2 people; for a family of more than 5 people, a 100-liter tank should be installed.

The depth of the well also affects the type of pump. For example, for a well up to 15 meters deep, a pump with a built-in ejector is required; if the depth of the source exceeds 20 meters, then you need to use a pump with an external ejector. Loop suction increases water pressure, but at the same time reduces productivity and increases electricity consumption.

Length of water pipeline and number of nodes

Although water will move horizontally through the system, losses in nodes and pipes cannot be avoided. It is recommended to purchase purchased equipment with a power reserve of up to 20%.

These devices are also divided into two categories:

- centrifugal , which have a higher price and better performance;

- vibration ones , which cost less and work worse.

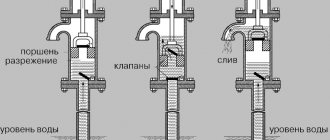

Vibration pumps have a suction valve, which can be located:

- at the top of the device;

- at the bottom of the device.

The ability to avoid the ingress of bottom dirt, in the first option, can be compensated by the problem of working with a low water level in the well.

The second option has downsides - such a pump sucks up clay near the bottom, while the low water level will become much less of an obstacle.

The installation of vibration devices is not recommended in sand wells, which are generally considered to be all channels drilled to the depth of interstratal or groundwater.

Basic installation and connection diagrams

The most common schemes are:

- Diagram of direct connection of the device to the supply pipeline.

- Scheme with a storage tank.

Direct connection involves placing the station between the water intake and the in-house pipeline. Water is directly sucked from the well and supplied to the consumer. With this installation scheme, the equipment is located in a heated room - in the basement or basement. This is due to the fear of low temperatures. Freezing of water inside the device can cause its failure.

However, in regions with relatively mild winters, it is possible to place a water pumping station directly at the top of the well. To do this, a well buried in the ground is built above it, which is insulated to prevent the water inside the pipeline from freezing. If necessary, it is possible to use an electric heating wire. We will discuss all aspects of choosing an installation location in more detail below.

The connection diagram for a station with a storage tank looks slightly different. Water from the source is not supplied directly to the in-house system, but to a special volumetric storage tank. The pumping station itself is located between the storage tank and the internal pipeline. Water is pumped to the water collection points by the station pump from the storage tank.

Thus, in this scheme two pumps are used:

- A deep-well pump pumping water into the storage tank.

- A pumping station that supplies water from a storage tank to the water supply system.

The advantage of the scheme with a storage tank is the presence of a sufficiently large amount of water in it. The volume of the tank can be several hundred liters, and even cubic meters, and the average volume of the station’s damper tank is 20-50 liters. Also, a similar version of the water supply system is suitable for artesian wells, when one way or another it is necessary to use a deep pump.

Conclusion and video on the topic

All work can be done with your own hands. A closed caisson is better than an open caisson, as it can be used all year round. The structure must be as tight as possible so that flood and groundwater do not flood the cavity with the equipment inside.

A pump, hydraulic accumulator, pressure gauge, and filtration system are installed and connected in the pit. The power cable is connected last. The pipes enter the caisson through special holes that will need to be sealed.

The material for the walls of the pit is reinforced concrete, brick, plastic or metal. Everything is determined by the wishes and capabilities of the homeowner.

Source of the article: https://vodatyt.ru/skvazhina/obvyazka.html

Procedure for installing a water pressure system

The location of the devices must provide access for maintenance and control of the operating mode. It is imperative to provide for the ease of replacement of non-working parts. Take care in advance about protection from precipitation and freezing. To connect the submersible pump to the electrical network, you must use a special cable marked VPP or KVV. The insulation of these wires is designed to last for a long time in water, without loss of flexibility and insulating properties. The imported analogue is labeled AQUA RN8.

We recommend connecting the well pump to electricity through an RCD, which is necessary to monitor the insulation of the included devices and cable. After all, a problem identified and resolved in time means a saved budget and nerves for the head of the family.

To install the pump and run water through the pipes we will need:

- the water-lifting unit itself;

- special tank - hydraulic accumulator;

- pressure switch, selected for the capacity of the hydraulic accumulator tank;

- American coupling for connecting the pressure switch to the hydraulic accumulator;

- collet coupling, for changing from size to size;

- brass adapters;

- fittings, plastic pipes, FUM tape.

As a rule, the installation and connection of a submersible pump begins with tying up the hydraulic accumulator and installing equipment on it. All stages of assembly are presented in order in the photo:

The first stage is the preparation process. In the second photo, we use FUM tape to wind the threaded connection. Next, we install the “American” connection, which allows for simple assembly and disassembly in the future. The fourth and fifth pictures show the installation of a pressure switch and pressure gauge for visual monitoring of the process in the system. After this stage, the process of installing an outgoing bend from a PVC pipe to a tee with sensors is demonstrated. The eighth and ninth photos show the installation of the collet clamp and the water supply pressure pipe. The tenth picture shows the installed group connected to the water supply. Well, the last steps are opening and connecting to the relay block.

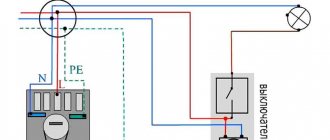

If your system consists of one automation unit, a pressure sensor, then the terminals of this device will indicate the input “LINE” and the output “MOTOR”. That is, the input from the “LINE” socket and the connection of the “MOTOR” submersible pump. More advanced automation consists of an electronic unit.

The pump start control unit ensures an uninterrupted supply of water to the system, protecting the engine from running dry, reacting to the presence and level of water around the pump. The unit produces a smooth start and smooth stop, extending the engine's service life, and monitors its operating mode.

Control unit diagram:

Dry running is the operation of the engine without a sufficient amount of water or without it, which causes overheating of the working windings of the engine, destruction of the insulation, and failure of the motor. This is because water in deep-well pumps plays the role of a coolant, because... passes through it and cools the case.

Finally, we recommend watching videos that clearly demonstrate the technology for assembling a water pressure increasing system, as well as the process of installing a submersible pump in a well:

So we have provided step-by-step instructions for connecting a submersible pump to the network and water supply system. As you can see, it’s not too difficult to do everything yourself, the main thing is to have a suitable installation diagram at hand, and also to know some of the nuances that we talked about in this article!

It will be interesting to read:

- Heating of water pipes with cable

- Economical heating system for a private home

- Connection diagram for a pump with a float

Head installation

A typical head has a simple structure; its body consists of two parts, which are connected to each other through studs with nuts, and between them there is a donut-shaped rubber ring. The top cover has holes for entering the power cable and pressure pipe (the latter is located in the center), a carabiner is welded at the bottom to secure the electric pump cable, and two eye bolts are screwed on top to facilitate landing on the well.

Installation of the head is carried out in the following order:

- Place the bottom cover and rubber donut over the column, pass the power cable through the head through the rubber seal and the HDPE pipe, and thread the loop of the cable tied to the pump into the carabiner.

- A pump with a head is lowered into the well channel using a cable tied to its eye bolts, after the top cover rests on the top of the column, 4 threaded rods are inserted into its holes.

- The nuts are tightened with a wrench, connecting the upper and lower halves of the head, while the ring in the middle is compressed, tightly fixing the structure to the surface of the pipe.

- Cut the HDPE pressure pipe, put a feed-through and compression fitting on it, and clamp the pipeline in the head.

Head installation

Connection diagram of a pumping station to a well at the dacha

The pumping station can be placed inside the well, if there is space for this; in addition, utility rooms are often allocated for it in the house itself or in the room

Pay attention to the depth at which the pipeline will be located. The pipe must not only be insulated, but also placed below the freezing depth of the soil so that the water in it does not freeze during the cold season

In order for the system to work correctly, you need to choose not only the type of pump, but also the depth at which it will operate. The deeper the water source and the farther it is from the building, the more powerful the pump itself should be. There should be a filter at the end of the pipe; it is located between the pipe and the pump, protecting the latter from debris getting into the mechanism.

It is usually written on the devices what depth they are designed for, but it is worth taking a more powerful one, since the calculation is carried out only from the bottom of the well to its surface, without taking into account the distance to the building. It is easy to calculate: 1 meter of vertical pipe location is 10 meters of its horizontal location, since it is easier to supply water in this plane.

Depending on the type and power of the pump, the pressure may be stronger or weaker. It can also be calculated. On average, the pump provides 1.5 atmospheres, but this is not enough pressure for the normal operation of the same washing machine or hydromassage; the water heater may require a higher temperature.

In order to control pressure, the equipment is equipped with a barometer. Depending on the pressure parameter, the size of the storage tank is calculated. The productivity of the station also plays an important role. This parameter indicates how many cubic meters per minute the pump is capable of delivering. You need to calculate based on peak water consumption, that is, when all the taps in the house are open or several consumer electrical appliances are running. In order to calculate which pumping station for a well is suitable, you need to know the productivity. To do this, you need to add up the number of water supply points.

From the point of view of power supply, it is more convenient to use those systems that are powered from a 22 Volt network. Some stations operate on 380 V phases, but such motors are not always convenient, because a three-phase connection is not available in every home. The power of a household station may vary, on average it is 500-2000 W. Based on this parameter, RCDs and other devices that will work together with the station are selected. To prevent the structure from overheating, many manufacturers install automation that will turn off the pumps in the event of an emergency load. The protection also works if there is no water in the source when power surges occur.

How to calculate the volume of a hydraulic accumulator?

The size of the tank determines how often the pump motor will turn on. The larger it is, the less frequently the installation operates, which allows you to save on electricity and increase the service life of the system. A hydraulic accumulator that is too large takes up a lot of space, so a medium-sized one is usually used. It holds 24 liters. This is enough for a small house inhabited by a family of three.

Trailer operation of hydraulic accumulator expansion tank

If up to 5 people live in a house, then it is better to install the tank at 50 liters; accordingly, if there are more than 6 people, it should be at least 100 liters. It is worth noting that the standard tanks of many stations hold 2 liters; such a hydraulic tank can only cope with water hammer and maintaining the required pressure; it is better not to save money and immediately replace it with a larger one. It is the number of water users in the house that will determine which pumping station to choose for the dacha.

Water purification

Do not forget that water from a well, even if it is suitable for drinking, may have impurities, for example, sand, small stones, and various debris may get into it, which can be gotten rid of by using a special water purification system. The most commonly used filters are filters. They are placed outside to make them easy to change. They can have different fractions and purify water to varying degrees. At the output, deep fine filters are used.

Models

- Gilex.

- Vortex.

- Ergus.

- Bison

- Gardena.

- Wilo SE.

- Karcher.

- Pedrollo.

- Grundfos.

- Wilo.

- Poplar.

- Unipump.

- Aquario.

- Aquarius.

- Biral.

- SFA.

- Vortex.

- Waterstry.

- Zota.

- Belamos.

- Pedrollo.

Before choosing a pumping station for a summer house with a well, it would not be superfluous to find out how things are with servicing the products of the selected manufacturer, and whether there are nearby dealers who can provide spare parts.

Characteristics of systems that create water pressure

If we do not consider the device, then the main indicators describing the operation will be:

- Power (in terms of volume of moisture pumped and energy consumed).

- Maximum pressure.

- Optimal lifting height.

The first parameter shows how many liters the device is capable of delivering per unit of time with a given excess. A secondary characteristic is the amount of electricity consumed.

The second one indicates the highest guaranteed outlet pressure value.

The third one specifies the normal height at which the first function is performed.

Why is it necessary to connect a submersible pump?

The use of such pumping units when providing a private water supply complex is a necessary measure. This is the only solution to the problem of drinking water, since connection to a centralized water supply system is impossible in most cases.

As mentioned above, the aquifer is not always located almost on the surface. This is due to the structural features of the soil. Therefore, connecting a submersible pump will help pump water even from the deepest well or well.

Important: It is worth noting that the electric pump itself cannot operate continuously, otherwise it will burn out. Therefore, to supply water to the transport main and to automate the work, reducing the load on the water supply line, automation elements are additionally connected to the pump

Due to them, you practically do not have to spend time on system maintenance.

The correct submersible pump design will ensure long-term and uninterrupted operation of the entire water supply system.

Main functions of automation units for pumps

A large number of suburban areas are equipped with wells and boreholes. The owners strive to have an autonomous source of water. More often this is a technical resource that is used for irrigation. But such water is also used quite actively as drinking water. In terms of chemical composition, it can significantly exceed tap water, especially if the intake is carried out from a great depth.

The automation operation scheme for water supply pumps and wells is not inferior in efficiency to central systems.

In order for the process to be technically optimal and meet the requirements, many people prefer to buy automation for a well pump.

Based on functionality, mechanisms can be divided into two types:

- automatic control of water supply;

- protective system.

Regulating mechanisms allow you to adjust the required flow. When watering - more intense, for domestic needs, including for supply to heating and household appliances - less force.

A protective mechanism prevents damage to the unit in the event of a significant voltage drop. In situations where the water level has changed, pumping is impossible; when turned on, dry running occurs.

A well-established scheme for the operation of a well and automation for water supply pumps is not inferior to central systems in terms of operating efficiency and even in some respects surpasses them. When using an individual source, interruptions and shutdowns are eliminated; electricity costs are less than paying for the amount of water consumed from the central water supply system. In cases where it is possible to use it as drinking water, the advantage becomes even more significant.

Based on functionality, automation is divided into regulating water supply and protective.

Turning on the pump and checking the water supply system

- The hose from the pump should be free and not yet connected to anything;

- Plug in the pump. The socket must be grounded;

- Pump the water until it becomes clear;

- We disconnect the pump from the outlet and switch it to the hydraulic accumulator, to the “Motor” terminals;

- We pump air into the expansion tank of the hydraulic accumulator (using a machine pump) to 1.5 atmospheres;

- We supply water from the pump to the inlet of the hydraulic accumulator fitting;

- We connect the house water supply to the outlet after the filter;

- Close all valves and faucets in the house;

- Turn on the accumulator automatic switch;

- We check for leaks in the entire system;

- On the battery pressure gauge we expect a pressure of 2.8 atm;

- We begin to open the taps in the house one by one and check the system;

- You can reduce the pressure to 2.3 atm. (for the period of testing the system 1-2 days).

All! Installation of the well pump, connection and launch of the entire water supply system are completed.

Elesant.ru

Tags: , automatic, beat, sconce, view, water heater, choice, switch, engine, house, , capacity, clamp, grounding, cable, how, design, contactor, , installation, smooth, connection, rule, principle, check, wire, manufacturer, laying, start-up, work, size, calculation, relay, repair, row, garden, system, connection, means, term, diagram, ten, type, current, installation, filter, photo, shield, effect

How to make a water pump with your own hands at home

Summer residents are not lazy and savvy people. Therefore, the question of how to make a water pump with your own hands without electricity is asked quite often. In fact, there are many options, all of them are quite feasible. One of the most effective and most affordable is a pump based on a pump mechanism. This is the type that is most often used in conditions where there is no electricity.

We recommend: Do-it-yourself false fireplace - instructions with photos and drawings

To create a pump you will need the following elements and parts:

- PVC pipe with a diameter of 5 cm;

- PPR pipe with a diameter of 2.4 cm;

- two 0.5 inch check valves;

- pipe plugs and bends;

- 8 mm bolts with nuts, rubber gaskets.

The pump is assembled from the above parts. The main thing is to ensure the tightness of the structure, otherwise the mechanism will not work. The piston creates pressure in the working chamber. Under its influence, water, passing through the valves, is supplied to the outlet. It is very important that the gaskets fit tightly.

It is difficult to perceive when described, but in fact it does not cause problems to create a pump powered by solar energy with your own hands. The operating principle is somewhat reminiscent of how a submersible pump is connected to a hydraulic accumulator: gas takes part in pushing out water.

A pump based on a pump mechanism is the most affordable to make yourself.

Required components:

- metal grate;

- rubber bulb;

- cylinder with propane-butane mixture.

The grate is filled with gas and connected to the bulb. The pear is placed in a tank pre-equipped with valves for inlet and outlet. Solar energy expands the gas, the latter pushes out air, providing a pressure difference in the water tank.

Note! All tank seams must be sealed tightly. Such a pump must be located in a well-lit place.

Installation of plumbing system components

Second step

Install the pump. Deep-type equipment is lowered into a water supply source. Surface pumps are mounted next to a well or well. The pump is installed in a heated room or in a caisson.

Pumping station

Third step

Connect the water pipe to the installed pump. Attach the free end of the connected pipe to a fitting with five terminals.

Fourth step

Installation of a water supply system

Connect a storage tank, a pressure gauge, and a pressure switch to the free outlets of the fitting. The volume of the storage tank can reach 400-500 liters or even more. Thanks to this device, optimal pressure in the water supply system will be ensured. In addition, you can store water in the storage tank in case of unforeseen situations.

Fifth step

Connect a pipe to the remaining free fitting outlet, and then run the line along the pre-leveled bottom of the dug trench straight into the house. You also need to lay a protected cable along the bottom of the pit to connect the pump and accumulator.

It is important that the outlet intended to power the above-mentioned units is properly grounded

Sixth step

Installation of water supply at the dacha

Install a shut-off valve before the pipe enters the building. It will allow you to shut off the water supply if the need arises.

Seventh step

After making sure that the external pipeline is working correctly, fill the hole and begin installing the internal wiring.

Regardless of the chosen source of water supply, it is strongly recommended that the water supply system be equipped with cleaning devices

Perform internal wiring in accordance with the previously prepared diagram. At this point, be guided by your preferences. Do everything so that in the future it will be convenient for you to use the connected water supply.

Installation of internal water supply at the dacha

Finally, all you have to do is arrange water intake points by connecting faucets, appliances, etc.