Drilling water wells » How to sprinkle the well pipe after drilling?

Drilling a source of personal water supply is a necessary operation in areas significantly removed from main water supply lines, connection to which becomes impossible or very expensive.

Then the supply of water (technical or drinking) to a private house can be ensured by its supply from the bowels of the earth.

For its long-term uninterrupted operation, the issue of correct installation of the system is important, as well as exact knowledge of how to fill the pipe, and what to sprinkle the well around the pipe with.

Article outline:

- Basic provisions

- Why do you need to line a well?

- Materials for backfilling Sand and gravel mixture

- Granite crushed stone

- Limestone crushed stone

Answer

First of all, you need to figure out what you are planning to fill - the well (the aquiferous section of the shaft) or the so-called annulus (the rest of the pit). In the first case, backfill with fine crushed stone (approximately 5X20 fraction or even less) is used. It will create a frame for smaller sand inclusions and will not allow clay to float onto the filter. In silty sands, it is better to add coarse river sand to the crushed stone in a ratio of 3:1. This will increase the throughput of the filter zone. The filling is kept low - otherwise, overflow from the upper aquifer is possible. As a rule, in order to create a high-quality natural filter, 12-14 buckets of the mixture will be enough.

As for the annulus, it is best to fill it with clay - it will create a reliable waterproof castle. At a distance of 1.5-2 m from the surface, the clay can be replaced with sand. A similar trick is needed to obtain a drainage channel through which water from the pit will flow into the upper layers of the soil. Finally, I would like to remind you that when backfilling the casing, you must strictly monitor its vertical position. Otherwise, there is a possibility of the walls being rubbed by the holding cable or the filter being damaged by the pump housing.

Source

Basic provisions

During drilling, casing is also installed. It is necessary to install it: it performs important functions that ensure long-term operation of the home water supply:

- preserves the integrity of the water intake pit;

- protects the source from shifts in soil layers and rock falls;

- prevents dirty groundwater from seeping inside.

- ensures water intake from clean aquifers.

If the pipe is properly reinforced, it will restrain the natural pressure of the soil, which can “seal” the structure.

Casing pipes come in different materials: metal, asbestos, plastic. However, many homeowners choose not to install asbestos pipe.

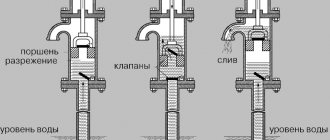

What does filter sprinkling cheat look like?

The contractor promised to fill the filter with gravel. After completion of the drilling work, the contractor’s specialists approach the well and pour 1–2 buckets of gravel into the annulus. This is a lie!

In fact, there are no guarantees that this gravel will fly more than 2 - 3 meters through the annulus. And the fact that it will not get into the filter area can be 100% guaranteed. The fact is that when creating filter wells for sand, the section of the casing that falls into the aquifer is immediately covered with a moving aquifer.

Do you have questions about drilling wells for sand? Our experts can answer them in groups on social networks!

Preventive methods to combat siltation

In order for the well to work correctly, it must be pumped periodically. It is especially important to turn on the pump for prevention in winter. At this time of year, water intake is reduced and re-siltation is possible. In summer, the purification process occurs naturally, since a lot of water is spent on irrigating the garden plot or filling tanks. If you follow preventive measures, you won’t have to wonder every month how to pump a well.

If the well has not been used for a long time, more serious measures are required. A thick layer of silt and sand deposits forms at the bottom; resuscitation is carried out using high pressure to purify the water. We must try to use this procedure as rarely as possible, since after it the mesh filter may break.

To revive a well, pipes connected from several parts are lowered into it, through which water is supplied using a fire hose or a high-pressure hose. It washes away the silt layer and cleanses the aquifer. If necessary, the length of the pipe can be increased. The process is considered complete when gravel particles from the bottom filter appear on the surface.

Well owners are often interested in the question of how long it takes to pump a well after drilling. In each specific case, the duration of the process depends on indicators such as the degree of water contamination and pump power.

How do you solve the problem of filter dusting correctly?

Option 1.

During the drilling process, an auxiliary column is installed. Its diameter should be larger than the diameter of the working column by the amount of sprinkling. After this, the work column is installed. The next step is loading the gravel backfill. In this case, the backfill should be as fine as possible. After backfilling, the auxiliary column is removed.

To implement this algorithm, you not only need a special (powerful) technique for the final removal of the auxiliary column. Theoretical knowledge and experience in carrying out similar procedures are also important.

Are you planning to drill a well in the spring? Subscribe to the channel. You will learn how to avoid falling into the clutches of hack drillers.

Option 2.

Currently, it is possible to purchase a filter section with pre-installed coating. In this case, the installation of a column with a similar filter is also carried out using an auxiliary column, or by drilling the original wellbore with a large-diameter tool.

A filter with backfill is quite expensive. In practice, only very high-level professionals solve problems using such products.

Types of materials

There is a fail-safe way to insulate and improve a well in a country house without the use of additional heating equipment - this is to cover all its components and protective structures with thermal insulation material. For professional installation, the following 4 types are used:

- Expanded polystyrene and penoplex.

- It is characterized by low thermal conductivity, strength and moisture resistance. Suitable for lining both inside and outside caissons, as well as external and underground pipes.

- Foamed polyethylene.

- It is characterized by good thermal insulation and low load resistance. Therefore, it is used for lining internal walls of rooms and external pipelines.

External insulation of a well with foamed heat insulatorSource pechiexpert.ru

- Mineral or glass wool: the main feature is its high moisture absorption capacity. In view of this, it is used only during the inactive stage of water intake - for the period of winter conservation.

- Penoizol or polyurethane foam: applied in liquid form through a special sprayer. The main disadvantages are the need to use equipment, low density and unevenness of the surface formed.

- Expanded clay: a fairly free-flowing, moisture-resistant material. Used for backfilling water supply trenches and caissons at a level below the ground surface.

Why is filter sprinkling necessary?

Fine gravel increases the degree of water filtration on the filter column. This solution is especially relevant in situations where the aquifer sand layer contains a significant portion of fine fractions. The sprinkling is most effective when used in conjunction with filters made of stainless galloon mesh or with slot filters.

Previously

we wrote about deception when drilling for water:

Forgot to get a passport from the drillers? Find out what this means.

An overview of the options for deception when drilling for water is here.

Source

How to fill the bottom end of the well. 3 materials. Where can I get them?

Backfilling the lower end of the well serves to protect the casing from the ingress of small fractions from the aquifer. This is a classic solution. Over many decades it has shown its effectiveness. But a high-quality result is possible only with proper execution and the right choice of material for filling. We will discuss what materials to use in the article.

We have already touched upon malfunctions associated with poor-quality filling of the lower end of the casing:

In addition, the channel has popular material on the topic:

There are a number of requirements for the material for filling the lower end:

- Small size;

- Insolubility;

- No other effect on the liquid.

The use of fine material for filling is due to the fact that with a decrease in the fraction, the density increases and the likelihood of the formation of channels in the thickness of the filling for the entry of foreign particles from the aquifer decreases.

Insolubility is necessary to ensure long-term operation of the end fill in water conditions.

A different effect on a liquid can mean a lot of things. For example, granite of small fractions can be considered an excellent option for backfilling. But, as you know, it has an increased radioactive background. In addition, some other materials may contain soluble fractions that are hazardous to human health.

Now we will discuss three materials that are best used for filling in a well.

Source

Pump installation

Before installing the unit, prepare:

- pressure gauge;

- steel fixation unit;

- fittings - optionally - clamps;

- back pressure valve;

- valve for shutting off the water.

Selecting a suitable pump. Fastening at the right depth

Which pump to choose depends on the specific situation. Experts recommend centrifugal-type submersible models. They explain this preference by the natural vibrations that vibrating structures cause. This leads to soil destruction and equipment failure. Avoid vibration pumps when the well is installed on a sand base.

The power of the equipment depends on what kind of performance you expect. Remember, the greater the depth, the more powerful the pump will be required.

A separate selection criterion that also needs to be taken into account is the quality of drilling. There are special models of pumps that are used in wells dug without the help of professionals.

It is important to correctly calculate the depth of immersion. The device must be kept in water at all times. In this case, the device is mounted remotely from the bottom of the water intake. Otherwise there is a risk of clogging.

Standard pumps are fixed at a depth of 8-10 meters, injection pumps - 18-20 m, special ones - 35-40.

Surface pump

The main disadvantage of the models is their limited application. The device is only suitable for shallow wells. The advantage is ease of installation.

Work according to the scheme:

- mount the device in a stationary room or an individual caisson;

- connect a hose of the required size to the suction pipe;

- Secure the check valve on the other side of the hose. It will perform a protective function and prevent water from draining after the equipment is turned off;

- Place a protection filter on the valve - it will not allow debris fragments to penetrate inside;

- lower the hose into the well.

Submersible pump

Such structures are installed directly in wells. They do not require a caisson or permanent premises. The device is assembled, a water pipe and an electrical cord are connected to it, and the equipment is lowered into the well.

Note! In most models, water is supplied through plastic pipes. But there are also those that use a rubber hose.

The optimal immersion depth is 1.5-2 meters.

Submersible pump installation diagram:

- preparation of materials and equipment;

- immersing the device into the well;

- calculation of the operating point of the unit.

Arrangement of eyeliner

The power supply is provided by a separate line. It is equipped with an automatic power cut-off device. Don't forget about grounding. Before starting the equipment, the pump is filled with liquid. Observe the required pressure parameters.

After connecting the power, bleed the air by opening the valve. After a couple of minutes, the water supply starts. If this does not happen, turn off the device and add more water.

Turn on the device again. Set up the relay. By turning special screws, the required indicators are set.

Wells: theory and practice. (Continued)

Hello dear readers of “San Samych”.

In the previous part of the article, we looked at what wells can be and what mandatory elements any groundwater source should have. I also told a story about a friend of mine who, having trusted the skill of the drillers, ended up with a well that was essentially an Abyssinian well, to put it mildly, very inconvenient to use. In continuation of the article, we will analyze other typical mistakes when constructing a well and their consequences.

Mistake #2. Let's pick it up.

A friend called with a complaint that very often we have to change fine filter cartridges. She has a well 27 meters deep and a pumping station based on a submersible pump.

The first question I asked her upon arrival was: was there a filter installed on the well? The answer did not surprise me: “I don’t remember. Should he stand? Let’s pick it up and clean it.”

Actually, a well filter, made according to all the rules, is still a structure. In my opinion, it is impossible not to remember him. This is a perforated (with holes) pipe, wrapped with wire or mesh with a fine mesh, sometimes more than two meters long. In addition, before planting the casing or while lowering it, drillers must pour several buckets of crushed stone to the bottom of the well.

Filters, as a rule, are installed for the entire life of the well, and cleaning it is no less difficult than drilling a new well. They are trying to clean it, however, by filling the well with water under pressure, pumping it with a compressor and even exploding small charges inside. It might be enough for a while.

Mistakes that are made when pumping

Mistakes are rare, but they exist if a citizen decides to act independently without consulting with specialists:

- Wrong pump selected.

- The pump is installed extremely high or low from the aquifer with incorrect alignment (when the device touches the walls of the casing).

- Uncontrolled and prolonged operation leads to silting of the hole or depletion of the resource.

- The operation was completed prematurely, meaning there was no clean flow from the pump. This threatens the settling of sand, abrasive and clay masses to the bottom.

- Construction of a sump in close proximity to the mouth of the source. In this case, the pumped-out substance may overflow in the opposite direction.

Be attentive to these nuances and your work will be rewarded with clean water suitable for drinking and cooking!

How to sprinkle a well after drilling

In areas where there is no centralized water supply, owners have to use alternative water sources. Many owners, when choosing between a well and a well, prefer the latter design. The reason is simple and clear: this is the purity of the liquid that does not come into contact with the external environment. However, even wells have disadvantages, one of them is sudden contamination of the source after some time. The most common problem is sand in the well. To understand what to do in this case, you first need to find the causes of this phenomenon. And then try to eliminate them as quickly as possible.

Why is this event required?

The structure definitely needs cleaning, since the brown-colored liquid released to the surface is absolutely unsuitable for domestic and agricultural needs. Imagine how moisture, over centuries, formed its path deep underground, making its way between various layers of rocks, thereby being purified naturally and enriched with various minerals (this depends on the geographical latitude of our country). And here, overnight, the movement of the riverbed changed; accordingly, the liquid rushes to the surface and at the same time swirls the soluble and insoluble inclusions and organic matter found in its whirlpool. In addition, silt deposits and large volumes of sand can accumulate at the bottom of the column in the source. The only way out of this situation is to pump out the dirty substance.

Why does sand appear in a well?

Most often, such force majeure occurs among owners of sand wells. The problem is caused by the peculiarity of this aquifer. However, owners of other sources may also encounter trouble. The main, typical reasons for the appearance of sand in water from wells are known.

Filter problems

The filter mesh in most cases becomes the first suspect, and for good reason. When installing the casing pipe, its lower part is perforated, then covered with a mesh with small cells. Such a simple filter can fail quite quickly and easily. There are several “classic” situations.

- Even during installation of the lower part of the casing, a mesh rupture may occur. In this case, the owners will find out about the problem immediately: sand appears in the well almost after pumping. The volume of impurities will only increase over time. Symptoms of trouble are multi-fraction (large, medium, small) particles of material.

- Incorrect cell size. If the mesh is too large, small grains of sand can easily fall into the casing, where nothing will prevent them from mixing with the water and rising. Grid selection requires fractional sand analysis, but this is rarely done. A sign of “wrong” cells is particles of the same fraction, often the middle one.

Both troubles suggest two development options. If small particles fall through a coarse-mesh filter and then gradually but regularly settle to the bottom, then soon a layer will form at the bottom of the well, which after some time will cause less water supply. The worst-case scenario is that the structure stops operating.

When the aquifer is high enough, there will be no shortage of water, but a large percentage of impurities will be present in the liquid. Possible consequences of both options: failure of the working components of the pump, damage to the pipeline, failure of the automation. For these reasons, after an emergency occurs, it is necessary to immediately begin to eliminate the problem.

Casing leakage

Depressurization occurs for various reasons.

- After incorrect installation. If sections of pipe sections were not tightened to the limit, then after some time rust will appear in the areas of “inadequacy”, and then a fistula. In this case, sand can enter through any of the areas. When the installation is carried out according to all the rules, the sections are screwed to the end, there is no need to worry about such problems: such a column is usually designed to serve for 50 years.

- Poor quality welding of joints is to blame. In this case, after some time, holes appear in the seams, through which impurities easily enter the casing. Sand in the well will not be the only problem. Along with it, soil particles and contaminated water, which is no longer suitable for drinking, will penetrate. The service life of welded structures is much more modest: it is 20 years.

- Sand in a well is a situation that can occur even in an artesian source. If during its installation the technology was violated, and the installation was not carried out entirely correctly, then there is a risk of the casing being displaced relative to the limestone layer. However, this is rather a hypothetical possibility, since land owners do not create an “artesian” on their own, and professionals are unlikely to make a serious mistake.

DIY thermal insulation stages

The future fate of the entire water supply system will depend on how well the thermal insulation is carried out. Therefore, it is better to entrust it to professional companies with extensive experience. However, every private homeowner has the right to know how to insulate a well and water supply system for the winter on the surface - a turnkey well for their own home for the entire cold period with their own hands.

For a clear overview of well insulation, watch this video:

In the standard case, the procedure consists of sequential thermal insulation of the following main elements:

Caisson

Stages of work:

- The required amount of polystyrene foam or other heat insulator is prepared.

- Next, the material is cut into the necessary fragments, based on the shape and size of the caisson.

- The outer part of the caisson is waterproofed with bitumen, unless it is made of plastic or iron.

- The prepared fragments are applied to the outer walls and secured with wire, stops, mesh or tape.

- The joints between the sheets are filled with polyurethane foam for sealing.

- Upon completion of fastening, the structure is covered with a layer of expanded clay.

Casing and cap

Subsequence:

- A box is made from pieces of chipboard, boards, plywood, sheets of metal or rigid insulation for the external closure of the casing and head.

- The box is installed on top of the casing and cap.

- Its internal space is filled with parts of mineral wool, glass wool or natural components (hay, straw, paper).

As an option, instead of a box, a cylinder is formed from a chain-link mesh with a diameter exceeding the head by 0.3 m.

Do-it-yourself well insulationSource kimberia.ru

Street water supply

Sequence of work:

- At the outlet of the pressure pipe of the well, at the point of connection to the home water supply, a piece of heating cable is wound or a special tee with a gland is installed.

- Next, the water pipe is placed in an EPS shell or in a sewer pipe of larger diameter, which creates an air gap.

- The structure is laid in a pre-dug trench and then filled with expanded clay, then a layer of sand and previously removed soil.

Connection to the house

Due to the fact that the wellhead is already heated by a heating cable, and the supply water supply is insulated with a shell, there is no need to do special heating of the liner. As a standard, it is thermally insulated together with the supply pipe.

Watch in this video how to install a heating wire inside a pipe

Why do you need to dig a well?

Such a pit is necessary in order to provide the possibility of convenient repairs. The slope directed away from the well ensures the removal of dirty and melt water. A moisture-proof junction box is installed inside the pit, through which the cable is routed to the pump.

Read also Cinquefoil goose seeds buy

If the casing pipe is made of plastic, it is necessary to purchase a steel cap 60 cm high. To protect the well, it is necessary to cover it with a concrete cover.

If you use a metal hatch, condensation will form. It pollutes the water in the well.

Ensuring the tightness of the casing pipe

To keep the water clean, it is necessary to protect the casing. Tightness is achieved using a well cap - a steel cap. The device has communication holes. Additionally, there is a hook on the hatch - the pumping unit is hung on it.

The size of the cover is selected based on the size of the pipe. A rubber cuff is included. It is the main sealant. In addition, the lid has sealing gaskets for inserting the electrical cord and water pipes.

Important! The casing pipe is cut at a distance of at least 30 cm from the bottom of the caisson.

What are the dangers of sand in a well?

Water pollution is an emergency, since such water cannot be drunk, it is quite problematic to filter it well, and it is not suitable for any other needs. However, the list of undesirable consequences does not end with inconvenience.

- Really significant reduction in well productivity. Filling the casing with sand is inevitable. In this case, due to a clogged sump, water access is severely limited.

- Sand particles are an abrasive, therefore, passing through the pump, they will cause harm - they will wear out the impeller material. The inevitable consequences are the rapid failure of expensive equipment.

- Sand in the well contributes to the rapid occurrence of blockages in fine water purification systems. Filters clog in them much faster. The result is their frequent replacement, which means additional expenses.

- Pipeline clogged. Sufficiently heavy particles of sand will be regularly added to the already existing “deposits”, so sooner or later problems will arise with the throughput of the pipes. Another unpleasant moment is the increasing weight of the most critical components and sections of the pipeline.

- Inevitable contamination of faucets and siphons of plumbing equipment. It faces not only problems during operation, but also failure. This also includes clogging of elements of household appliances, expansion tanks and automation. The consequences of serious sanding of a well are similar for them.

The most serious result of sand blasting is a reduction in the life of the well. If the installation of the casing pipe was carried out according to all the rules, and the filters were selected correctly, then the first clogging can be expected only after 3-5 years. Some equipment can operate for a record period of up to 40 years without washing or problems.

Connecting a hydraulic accumulator, automation

Connection diagram for a pump with a hydraulic accumulator:

- make a connection to the battery, power all the nodes in series. Use fum tape;

- place the “American” on the thread. Attach an adapter with wiring to it;

- connect a relay and a pressure gauge to the branches;

- connect the pipe and the end of the adapter;

- secure one end of the pipe to the pump with a fitting;

- lay the pump and supply pipe on a flat area;

- there is a hook on the body of the device; attach a safety belt with a length of at least 3.5 m to it;

- Attach the cable and cable to the pipe at a distance of 1.5 m. Secure the second part of the insurance to the casing;

- carefully lower the equipment into the well;

- pull the safety rope;

- cover the pipe head - this will protect the device from debris getting inside;

- power the electrical cable;

- connect the device, release the remaining air - open the tap. If everything is done correctly, the accumulator will begin to pump water;

- close the valve. Check the pressure gauge readings. The pressure standard is 2.8x1.5 atmospheres.

A surface pump with automation is mounted according to a similar scheme. The difference is as follows:

- a pipe with a diameter of 2.5-3.5 cm is connected to the pump;

- a check valve is fixed to the opposite end using a fitting. Lower the unit into the well so that the pipe is 1 meter below the water surface level;

- before starting, the engine is filled with water;

- The equipment is switched on simultaneously with the automatic pumping of water.

Sand in a well: what to do?

Even a small “accident” at home always causes discomfort. But dirty water is not one of those little things. To successfully avoid all unpleasant consequences, appropriate measures must be taken immediately after the appearance of “sandy symptoms.” There are several options for “treating” a well.

The bailer is a simple salvation

This method will help if the well depth is limited to 10-15 meters. With more serious sources, a simple tool will be powerless. A bailer is a piece of steel pipe, about a meter long. In the lower part it is made of teeth, there is also a ball valve or flaps, between which there is a spring.

Since the cylinder with mud weighs a lot, to lift it they build a simple “helper” - a tripod made of timber or pipes. The operating principle of this small structure is elementary. When falling into the well, the bailer cuts into the thickness of the sediment, and through the opened valve (flaps), sand or silt gets inside the pipe. When lifted, the “trap” closes, so the dirt is trapped inside.

The sand collection operation is continued until the lifted portions become minimal. After this, a stream of water under high pressure is applied to the bottom. They should finally rinse the filters and bottom. The dirty liquid is pumped out until clean water appears. The simplest tool has a drawback. There is a real risk of damaging the strainer, so the bailer must be handled carefully.

Mechanical flushing

This operation is done using pumps. There are two options. The use of one vibration pump is suitable for shallow wells (up to 10 m). Two hydraulic machines will be needed for deep sources.

Lonely pump

For work, purchase an inexpensive vibration household pump (for example, Spring, Brook or Malysh). First, the unit is lowered to the bottom several times and raised back up. This step is necessary to agitate the sediment. You can “muddy” the water with another tool - a metal pin to which a massive nut is welded. He is tied to a long rope, thrown, pulled out and thrown again.

Then the pump is fixed at a distance of 20-30 mm from the bottom, and only then is it turned on. After half an hour of work, it is turned off and pulled out of the well. Dirt is easy to get rid of. The pump is placed in a container with clean water and turned on. This method is as simple as possible, which is why it is popular, but it is not suitable for deeper sources (more than 10 m).

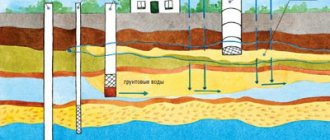

What are the sources underground?

Geological sections of land plots are not the same, but patterns in aquifers exist. As underground water moves deeper from the surface into the depths, it becomes cleaner. Water intake from the upper levels is cheaper and is used by private homeowners.

Verkhovodka

The water resource located in the ground close to the surface above the impermeable layer of rocks is called perch. Waterproof soils are not available in all areas, and it is not always possible to find a suitable site for organizing shallow water intake. There is no filtration layer above such lenses; harmful substances, organic and mechanical impurities with rain and snow penetrate into the soil and mix with the underground reservoir.

Verkhovodka is characterized by the following indicators:

- Depth. On average 3-9 m depending on the region. For the middle zone - up to 25 m.

- The area of the formations is limited. Manifestations do not occur in every area.

- The reserves are replenished by precipitation. There is no water inflow from the underlying horizons. During dry periods, the water level in wells and boreholes drops.

- Use - for technical needs. If the composition does not contain harmful chemical contaminants, the filtration system improves the water to drinking water.

Verkhodka is well suited for watering the garden. When drilling shallow wells, you can save money: drilling can be done independently. An option is to construct a well with reinforcement of its walls with concrete rings. It is not recommended to draw water from upper deposits if fertilizers are used near the land plot or if there is an industrial zone.

Primer

Verkhovodka is a disappearing resource, in contrast to the primer, which is the first permanent underground reservoir. Extraction of perched water from the subsoil is carried out mainly through wells; wells are drilled to collect the primer. These types of groundwater have similar characteristics in terms of depth -

Features of the soil variety include:

- Filter layer of rocks. Its thickness is 7-20 m, it extends directly to the formation located on a waterproof platform of rocky soil.

- Use as drinking water. Unlike perched water, for which a multi-stage cleaning system is used, mechanical impurities are removed from the primer using a well filter.

Groundwater recharge is stable in forested and temperate regions. In dry areas, moisture may disappear in summer.

Sources between layers

Groundwater diagram.

The name of the second permanent source of water is the interstratal aquifer. Sand wells are drilled to this level.

Signs of lenses interspersed with rocks:

- water is pressurized because it takes on the pressure of surrounding rocks;

- There are several productive water carriers; they are distributed in depth in loose soils from the upper waterproof layer to the lower underlying cushion;

- Supplies of individual lenses are limited.

The quality of water in such deposits is better than at the upper levels. The depth of distribution is from 25 to 80 m. Springs make their way to the earth’s surface from some layers. Underground water discovered at great depths, due to the stressed state of the liquid, rises along the wellbore to its usual proximity to the surface. This allows water intake to be carried out by a centrifugal pump installed at the mouth of the mine.

The interstratal variety of groundwater is popular when constructing water intakes for country houses. Sand well flow rate is 0.8-1.2 m³/hour.

Artesian

Other features of artesian horizons are:

- High water yield - 3-10 m³/hour. This amount is enough to supply several country houses.

- Purity of water: penetrating into the depths through multi-meter layers of soil, it is completely freed from mechanical and harmful organic impurities. The host rocks gave rise to the second name for water intake workings—limestone wells. The statement applies to porous varieties of stone.

On an industrial scale, artesian moisture is extracted for commercial purposes - for the sale of drinking water. In areas located in lowlands, there is a possibility of finding a pressure reservoir at a depth of 20 m.

Well insulation

To prevent the water in the well from freezing, the concrete walls of the tank are insulated with polystyrene foam. Foam plastic is also used to insulate the well. After insulating the concrete walls, you will be able to receive water from the well all year round.

Proper arrangement of a well - video

Immediately after the well drilling installation , several more actions are performed, which in no case should be postponed for several days.

casing pipes for the well must be installed immediately . And the second work that cannot tolerate any delays is filling the well with gravel.

All this is done to strengthen the walls and fix the casing pipes, as well as for the normal functioning of the well. One filter located on the last section of pipes does not guarantee the supply of clean water. Filling the space between the walls of the well and the outer surface of the filter with a sand-gravel mixture enhances its effect.

An additional filter layer traps large soil particles that flow along with water to the holes in the filter.

It is necessary to take into account that the casing pipes for the well are located in a dense water-resistant layer, and the filter itself is directly in the sandy aquifer. Therefore, backfilling of the lower part of the well should be done with a sand-gravel mixture of a coarse fraction, no less than 4 times higher than the fraction of the natural layer.

It is possible to use crushed stone of 2-4 mm fraction, but this material is much more expensive than sand mixture. It is necessary to ensure that there are no particularly large particles in the sprinkling, which could cause voids to form in the space being filled.

Sprinkling is carried out to the entire height of the filter and about a meter higher to increase the filter layer. After this, a clay castle is installed, also no less than a meter thick.

Read also Natural tile roof photos

After this, the wellhead can be filled with ASG of a finer fraction. At this point, the urgent work ends and the piping (or arrangement) of the well can be done in a few days.

Hello! We drilled a well, and the question arose of what to fill it with, since there were gaps of 4-5 cm on each side between the casing pipe and the soil (the diameter of the trunk is 200 mm, and the pipe is 125 mm).

Insulation materials

To insulate a DIY water supply system in a dacha, several options for special materials are used. The first variety, called “pipe shell,” is a pipe-shaped shell.

The second type is a variety of insulating materials, manufactured in rolls of various widths and lengths.

“Pipe shells” are made from polystyrene foam, extruded polystyrene foam and polyurethane foam. It is a product in the form of a semi-rigid cylinder, which consists of two halves. It is put on the pipe and fastened with overlaps, special glue, clamps and foil tape.

Typically the length of such a “shell” is one meter, but can reach two meters. Such products can be produced with additional coatings made of foil, fiberglass or galvanization. This type of insulating material is quickly and easily installed, as well as removed and replaced during repairs. The “shell” covered with fiberglass can be used for all types of water pipes or pipelines that are located in the ground, outdoors and indoors.

It will be useful to read:

Methods for drilling a well for water Water has always been and is one of the necessary elements of life. And even the very first settlements tried to be created on...

Foam plastic is called foamed plastic in the form of small white balls (known to absolutely everyone), which, when making a “shell,” are pressed into the shape of a pipe and then treated with steam. Interestingly, this material is almost 97-98 percent air. The advantages of polystyrene foam are lightness, practicality and low cost. Disadvantages include fragility and fragility.

Styrofoam

Extruded polystyrene foam is a type of foam plastic, the production of which uses pressure and high temperature. The result is a material that is stronger than polystyrene foam. I like this material for its resistance to environmental influences (does not rot). It does not absorb moisture, has a long service life, is lightweight and easy to install.

Polyurethane foam is a foamy plastic material consisting of numerous cells filled with gas

It attracts attention with the best noise insulation characteristics, good mechanical strength, ease of use and low weight.

Polyurethane foam

Among the insulating materials that are produced in the form of rolls, it is worth mentioning stone wool, foamed polyethylene and glass wool.

Glass wool is an insulation material consisting of glass fibers

It attracts attention with its noise and heat insulation characteristics, durability and price. The disadvantages include the fact that when working with glass wool it is necessary to follow safety precautions, since this material is prickly

During isolation work, the respiratory organs and skin are protected with protective equipment (special work suits, gloves and masks).

Glass wool

Stone or basalt wool

Stone or basalt wool fibers are made from molten rocks of volcanic origin, slag and silicate materials

This insulating material attracts attention due to its high resistance to various loads and impacts, its non-flammability, and the fact that products of various shapes and densities are made from it.

Foamed polyethylene is obtained by processing ordinary high-density polyethylene using propane and butane. It is an elastic porous material consisting of a large number of cells. Foamed polyethylene stands out among other insulating materials for its highest resistance to water, and it is also unaffected by fungi and bacteria. It tolerates the effects of petroleum products, alkalis and acids well.