From the times of Ancient Rus' to the present day, the tradition has been widely in demand - a log bathhouse is quickly built and is environmentally friendly.

The performance properties of wood, especially natural logs, are very high. Let's look at them in more detail below.

Is the material suitable for a log steam room?

It is not only possible, but also necessary to build log baths , as they guarantee:

- maximum functionality;

- practicality;

- durability;

- provide an opportunity to gather with loved ones and friends in a warm, sincere atmosphere.

Coniferous trees are considered the best building material, as they emit unique resins and create a unique microclimate with a healing aroma. This wood practically does not crack due to temperature changes.

Deciduous trees such as birch, oak, aspen or linden are excellent for work. They also release elements and aromas that are beneficial to the human body.

The following types of logs are suitable for construction. Let's consider each type separately.

Chopped and planed

These are log houses of a standard shape, which are processed manually .

The top layer (sapwood) is carefully removed, and logs of different sizes in diameter are obtained, in their original form. The properties of reacting to external influences from outside and inside the building are preserved.

Minor roughness and knotiness are acceptable, the cost is inexpensive. It is difficult to assemble this material, since the logs have different diameters, which complicates the work of thermal insulation.

A detailed article about a bathhouse made from chopped logs is here, and from planed logs here.

Rounded

The logs differ from the previous ones in their beautiful, even appearance and size. They are processed on special machines, which additionally give the material a flat, smooth surface. The material becomes less resistant to negative influences, but this can be eliminated by using protective impregnations. This option is more expensive.

Full information about the bathhouse made of rounded logs is at the link.

Carriage

The log has a flattened appearance, is processed on both sides, gives minimal shrinkage and a slight appearance of cracks.

Logs with a diameter of 30 cm or more are suitable for construction; the buildings will be of high quality, warm, and durable. But options of 20-25 cm are possible; a smaller diameter will retain heat worse.

Large, thick logs with a large diameter crack faster and more often than others, but they look very impressive and rich, especially cedar ones. This wood has antibactericidal and medicinal properties and does not harbor insects. Young trees with an average diameter are most suitable for mass use.

Stage 5. Preparing tools

To work you will need the following equipment:

- chisel;

Chisel - carpenter's axe;

Carpenter's Ax - medium power chainsaw;

- plumb line;

Plumb - level;

Laser level - electric drill;

Cordless drill/driver - mallet;

Wooden mallet - "trait".

Trait (tool)

We will pay special attention to the last tool - the “line”. For manufacturing you will need steel wire with sharpened ends. Bend the wire in half so that it takes the shape of a compass; you can additionally secure the handle. This tool will be needed when marking logs.

Rules for building a steam room

In the 21st century, the requirements for the construction of a bathhouse have changed dramatically. Now a dressing room and a steam room are not always enough; relaxation rooms, billiard rooms, showers and toilet rooms are very important. The total footage and amount of materials will depend on how many floors and rooms there are in the bathhouse, what kind of design and layout it is.

The best wood is considered to be that harvested in the northern regions of Russia, and in winter, since during the winter season it has the lowest level of humidity.

When building a log bathhouse, some features should be taken into account :

it is better to use logs with special protective impregnation against rotting, fungus and parasites;- raw wood will require a longer period of shrinkage - only after this are doors, windows installed and finishing done;

- the cracks must be sealed hermetically to retain heat in the room as much as possible;

- the creation of ventilation and installation of the stove should be entrusted to a professional - this guarantees safety in operation for decades.

To build a bathhouse, you need to choose the right location on the site ; it depends on the building codes of SNiP, which take into account:

- communications (underground);

- the distance from buildings and neighbors’ plots is no closer than 8 m from other buildings, since the bathhouse is a fire hazard;

- distance from the roadway and water bodies - at least 5 m.

Many people plan in advance to landscape the area where the log house will be located, creating the most cozy and comfortable corner.

The most popular, inexpensive wood options are spruce and pine. Experts recommend giving preference to northern tree species; they absorb less moisture, unlike southern varieties.

It is necessary to start construction after the purchased “timber” has rested and “inhaled” for 25-30 days . The log house is assembled using the technology of cutting logs “into a paw” or “into a bowl”. The first option is cheaper, easier to assemble, provides a larger area, but requires additional insulation and external finishing. The second is durable, saves heat as much as possible, is more labor-intensive, expensive, but does not require external finishing.

Roofing device

What shape the roof of the bathhouse will be is, of course, an important question, but first of all you should take care of the correct design of the roofing pie, which should also serve as protection against heat loss, and not as a source for heating the air in the area. To do this, you need to choose the insulation wisely, giving preference to moisture-resistant materials with a low thermal conductivity coefficient and low weight.

There must also be a vapor barrier layer ; waterproof membranes are often used for this, which at the same time serve as moisture protection for rafters, sheathing and, especially, insulation - if mineral wool is used as such, the thermal insulation characteristics of which are noticeably reduced when wet.

And the roof itself can be pitched or gable , or less often flat. The first option is suitable for both extensions to the house and free-standing baths. Regarding the choice of the upper roofing element, the most compatible option is natural tiles, instead of which, due to the high price, ondulin can also be used.

But most often the choice was made at the stage of installing the roof of other buildings on the site - therefore, in order not to disturb the architectural idyll, you should take this fact into account and choose a similar material, but you should still think about its thermal conductivity, which, for example, is very high.

Tips for building a bathhouse:

Calculation of the amount of wooden material

To make a correct calculation, you need to know the length, height and width of the load-bearing walls, and all internal walls and partitions - this is the first thing. The second is the parameters, dimensions of the logs (thickness, width).

For example , for a log house 3x6 m3 (five walls) - two walls of 6 m each (12 m.) and three walls of 3 m each (9 m.). The standard height is 3 m, and the diameter of the log is 30 cm.

Calculation:

- The length of one crown is considered to be 12 m + 9 m = 2 1 m.

- Calculate the number of crowns in the log house. 3 cm is subtracted from the diameter of the log (to make a groove). The height of 300 cm is divided by the resulting figure of 27 cm, resulting in 11 rows up.

- The number of logs for a log house - the number of crowns and the length of one crown are multiplied. 11 x 21 = 231 m. This total length is divided by the standard log length of 6 m, rounded up. 231:6=39 logs in total will be needed to build a bathhouse 3x6 m3.

To find out how much this amount of timber will be in cubes, you should refer to a special table - the round timber cubes. In this example it will be 20.3 m3.

Stage 7. Doors and window openings

We specifically started talking about openings after construction was completed, since there are two options for their arrangement.

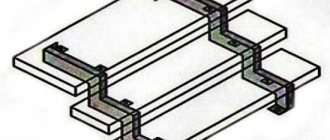

Installation of a casing for installing windows and doors in a log house

- In the first case, holes are created after the completion of construction work. At the same time, in the crowns located in the places of future openings, first leave small gaps (the dimensions of the latter depend on the size of the mounted products). Once you've finished laying the logs, simply cut the openings with a chainsaw.

- In the second case, leave openings during the construction process. This is very labor-intensive and expensive, since you will use bars with notches at the ends and special grooves.

How to install a window in a log house

Window installation

Bath windows

Doors for a bathhouse made of logs

Therefore, we advise you to give preference to the first option.

How to build a sauna with your own hands?

Construction work should be carried out in stages, following the instructions.

Project

The layout, number of floors and dimensions of the bathhouse structure are determined - individual solutions or a choice of ready-made turnkey projects are possible. Based on the selected drawing and calculations, materials are prepared.

Laying the foundation

For log structures, a reliable, durable concrete strip foundation is created. A pile option is possible depending on the composition of the soil. Ventilation vents are provided around the perimeter.

Installation of the first crown and walls

The foundation is covered with waterproofing, for example, roofing felt, and the wood is pre-treated with antiseptics. The logs are carefully laid crown by crown to the desired height and allowed to dry. The inter-crown insulation can be anything - from modern materials, or natural moss.

The logs should be laid with the north side outward, and the south side inside the log house. You can see from the annual rings on the cut that they are thinner on the north side, and the tree on this side is more resistant to the negative influences of nature. This extends the service life of the building significantly.

Roof

Often, for a small bathhouse, a pitched roof is chosen. This budget option is easy to install.

A gable roof of a more complex design is used in the construction of spacious, large options.

For work you will need:

- wooden beams;

- lathing boards;

- the covering can be anything - tiles, slate.

Bake

The best type is a brick oven; it guarantees maximum thermal properties. The walls of the stove should not come into contact with the walls of the bathhouse . You can choose ready-made models (made of metal), wood-burning or electric models.

Insulation

The cracks between the logs are carefully insulated with tow, moss or flax with sealant. In a completely finished log house (according to the drawing), openings are cut and window and door frames are installed.

To preserve heat, it is advisable to make the doorway at a height of 30 cm from the floor, and the window no higher than 100 cm. The floor is laid in a continuous manner, or a strip covering with slots is created for water drainage. Concrete screed guarantees up to 50 years of service compared to wood (up to 10 years); tiles are also durable.

Finishing of external walls and partitions

External finishing for rounded wood is not necessary, but chopped round timber requires decoration, but only after complete shrinkage. Each crown is aligned relative to the previous one. In finishing they use:

- stains;

- antiseptics;

- varnish coatings.

If desired, use siding or brick decoration with insulation. For interior decoration, lining, edged boards, and varnishes are used.

After removing the top layer during rounding, the number of cracks on the logs decreases - this increases the thermal insulation of the material.

Stage 4. Waterproofing the base

Waterproofing strip foundation

Waterproofing a strip foundation with roofing felt

Treat the surface of the foundation with molten bitumen and lay a layer of roofing felt on top. After the bitumen has completely dried, repeat the procedure. As a result, you will have reliable two-layer waterproofing.

Waterproofing with mastic

Additional insulation with roofing felt

Advantages and disadvantages

Natural wood has an undeniable, beautiful appearance, guarantees safety and durability. A log bathhouse has the following undeniable advantages :

minimal thermal conductivity - retains heat in the room for a long time, warms up many times faster in winter compared to a brick building;- excellent air circulation - condensation does not accumulate, steam “flows” freely;

- sound insulation – absorbs extraneous noise as much as possible, including from the street;

- wood is easy and quick to process - a log house is created in a short time, exclusive options are possible (to order), both in project development and in finishing, carving;

- environmental friendliness, being in a log bathhouse is not only safe, but also useful - pine, cedar and other wood release beneficial essential substances and resins into the air (the steam becomes medicinal);

- affordable price compared to brick construction;

- wear resistance - the structure, if all technological processes during installation are followed, will last for many decades, up to 50 years or more.

a log bathhouse ; additional ventilation is a big savings. Facade cladding and interior finishing are also not required; the log house looks impressive, status-bearing and noble. The variety of different ready-made turnkey projects significantly reduces the construction time of the structure.

But you should not forget about some disadvantages

- a fresh log house needs time to shrink - this period can be shortened by rounded, dried logs;

- wood that is too dry may crack;

- in humid climates, poorly processed logs are susceptible to mold and mildew;

- fire hazard.

If you carry out construction work, following the instructions, taking into account all the features, and choosing the right type of high-quality wood that matches the climate zone, then the log house will last for many decades.

Finishing work in a bathhouse made of rounded logs

You can begin interior decoration after caulking the walls and laying communications. It is necessary to start installing floors , which are most often installed on logs, although in a washing room it would be more convenient to use a concrete screed with the possibility of laying ceramic tiles or other material with similar characteristics.

The walls of the bathhouse do not require special finishing, since the wooden frame itself has a very aesthetic appearance. But to protect wood, you can use varnish or colorless impregnations, but this is true for all rooms except the washing room and especially the steam room.

In the washing compartment, you can protect the walls and ceiling with moisture-resistant decorative materials, but be sure to take care of the problem of vapor barrier and moisture removal. To do this, it is necessary to install special ventilation gaps between the rounded log and the finishing coating.

Things are different in the steam room - since coniferous wood is often used to build walls, which actively releases resins that can slightly spoil the appearance of the walls. Therefore, it is better to sheathe the steam room with clapboard made of hardwood , for example, linden, alder, oak, etc.

In the event that the diameter of the rounded log for the construction of the bathhouse was selected correctly, then there is no point in dealing with the external decoration of the walls - such a structure has its own charm, and bathhouses look especially impressive if the ligation of the crowns is done “without remainder”, although in this case , more expenses will be required for the purchase of material, but the corners will be warmer , since cold bridges will not form at the joints.

How much does it cost: prices in the Russian Federation

In our country, it is possible to build an excellent, high-quality bathhouse in a short time in any region. Average prices , taking into account the diameter of the log, size, number of floors, layout and cutting are as follows:

- budget option 3x3m - from 80 thousand rubles. (chopping by hand), from 95 thousand rubles. (chopping into a bowl);

- sizes 3x4m or 3x5m are slightly more expensive by 7-15 thousand rubles;

- 3x6m – from 105 thousand rubles. up to 120 thousand rubles;

- 4x6m – from 114 thousand rubles. up to 132 thousand rubles;

- 5x6m, 6x6m differ little in price - from 120-135 thousand rubles. up to 140-150 thousand rubles.

Cedar logs have the best resistance to moisture, the highest thermal protection, and healing properties, so they are expensive; larch is also considered expensive for its super strength. And pine, spruce, aspen or linden are cheaper.

Log houses made of rounded logs will cost more:

- 2x4m – from 255 thousand rubles;

- 4.6x5.5m – from 550 thousand rubles;

- 5.5x7m, 2 floors. – from 770 thousand rubles.

The choice of materials for finishing and its delivery to the installation site also affect the total cost.

Stage 8. Caulking logs

Types of tools and caulking methods

After shrinkage is completed, the log house is caulked. To do this, prepare the following equipment:

- hammer;

- caulk (made of wood or metal).

Attention! If you sealed the inter-crown space with tow or moss, you can skip this step, since you most likely will not need caulking. But if you find even the slightest cracks, then it is still better to carry out the procedure.

Proceed to work only after the insulation has completely dried. First, twist the material (tow or moss) into a rope, then hammer it between the crowns with a hammer and caulk.

Caulk

You can use tape jute - in this case, the material is simply fixed with nails or a mounting stapler.

Primary and secondary caulking of a log house

Video – Caulk of a log house

Photo

What kind of baths can be built from logs? Photo below:

Common Projects

- standard type, which is attached to one wall;

- a terrace connecting the house with the bathhouse;

- multi-level terrace (with attic or second floor);

- outdoor terrace with swimming pool;

- two-story bathhouse with a terrace on the second floor;

- closed type (veranda).

The MariSrub company presents a wide selection of buildings of various layouts, sizes and designs. Choose any one, and the company’s architect will add or change the project taking into account the client’s wishes, parameters of the land plot and soil.

Do you want an original bathhouse? Let's create a custom sketch! When you order construction, we carry out the project for free!

Where is the best place to place the sink?

In a one-story 3 by 3 bathhouse with an area of 9 square meters, everything must be placed as conveniently and compactly as possible so that everyone is comfortable and the premises function according to all the rules. It is better to combine a room with a sink with a steam compartment. To make washing more convenient, it is better to attach an additional insulated dressing room to the bathhouse.

The bathhouse can be equipped to the highest standard without going beyond the planned budget.

Log processing

The first thing you need to know is that a log house made of logs or timber (except laminated veneer lumber) must remain under the roof for at least 8 of the driest months. Most often, a bathhouse is installed in December, finishing work begins in August. But only if these are really dry months and they are in a hurry to start the sauna. If there is no rush, it is better to wait one and a half to two years.

The ends of the logs must be coated with a special compound

There will be enough work for the drying time. After installation, the logs must be treated with solvent-based antiseptics. For example, Tikkuril has Valti Pohjusta impregnation, and Woodex Base. They will protect the wood from fungi and blueing. To prevent them from being torn during drying, the ends of the logs are coated with another composition “Teknol JRM” from the same “Teknos” or its equivalent.

The log house itself also needs processing

After the wood dries, the log is sanded, removing the bacterial treatment. This operation opens the pores of the wood, allowing it to be painted with high quality. Oil-wax is most often used to paint a log house. These products also contain a coloring pigment that gives the wood a tint. Therefore, in addition to protective properties, they also perform a decorative function.

After shrinkage, the frame is sanded and then painted

Flaws

- Fire hazard. To reduce the influence of this property, all wooden structural elements should be treated with special means that help increase their resistance to fire.

- Shrinkage. Finishing work can only be done after six months.

- Care. In order for wood to preserve its original appearance and properties, it requires special care. Alternatively, you can cover the logs with veneer material to protect them from the environment.

Bathhouse 6x4 with veranda under construction