Today, slate means a building material in the form of slabs, which is used not only to cover roofs, but also as cladding, partitions, fences - wherever its technical characteristics can be used. Knowing what slate is made from, you can determine where which type of slab is best used. When choosing a material, tips will be useful: what are the common types of slate, what shapes it comes in, other characteristics: color, weight, degree of toxicity and price. This article will help you figure out how to profitably use knowledge about a popular, in-demand building material.

Wide selection of slate shapes, materials, colors. Source promstan.com.ua

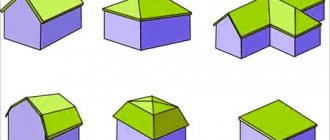

What shape does slate come in?

The construction products market offers to choose a material based on its functional purpose. The cross-section of the crossbar for the roof, for partitions, for a summer gazebo or fence can be:

- trapezoidal;

- wavy;

- flat.

The roofing material chosen is not only durable, but also beautiful. Almost all products have this property. For buildings with simple architectural ideas, soft slate made of mineral fiber with bitumen impregnation is suitable. Sold not only in sheets, but also in rolls.

Flat sheets of different usable areas made from asbestos cement are used for outbuildings, small fences, and temporary partitions. This is how they try to reduce the harmful effects of asbestos on humans.

Modern luxury houses are covered with slate tiles, the shape of which depends on the wishes of the customer. The slates are processed by hand, the process is labor-intensive, but the result is worth it: the building looks important and presentable.

When planning to install a gazebo on a summer cottage, they turn to plastic types of slate - modern manufacturing technology provides flat sheets of square and rectangular shapes. They bend, which allows you to make roofs and walls of complex configurations.

On a note! Surfaces with a wavy or trapezoidal profile are more durable. Withstands strong shock loads.

Country courtyard with a fence made of asbestos wave slate and a gazebo made of flat polycarbonate Source dom-i-remont.info

So the shape of the product matters. Therefore, it is important to know what the slate is made of in order to choose the one that will best perform the assigned tasks.

Number of waves

The number of waves is already determined by the name - 7-wave and 8-wave.

In individual construction, a 7-wave sheet is most often used, since it is lighter and easier to lift to the installation site manually.

At the same time, its useful area is smaller than that of an 8-wave one , since the amount of overlap for both brands is the same and the difference of one wave is not compensated for by anything.

However, a study of demand shows the predominant use of the 7-wave option.

The composition of slate and the effect on health: which one to choose

Among the points in the characteristics of slate, its environmental friendliness is not the least important. If the choice fell on beautiful corrugated slabs, then those who adhere to a healthy lifestyle will choose a material that will not harm their health. Other owners, knowing what wave slate is made of, will still buy something that suits the functionality. Let's try to figure out which slate mix with a beautiful “wave” will not harm your health:

- Plastic slate consists of 70% polyvinyl chloride (homogeneous), with the addition of fiberglass for strength. Does not emit environmentally toxic substances.

- Bituminous slate is made from synthetic and bitumen resins, cellulose fibers, and mineral fillers. Natural materials based on it make ondulin environmentally friendly.

- Fiber cement corrugated sheet is made of cement, PVA fibers, cellulose fibers, limestone. The absence of asbestos is an advantage of the material, which often influences the client’s choice.

- The metal one is made of steel coated with zinc on both sides; varnish is applied to the inner surface. Sheets are considered an environmentally friendly material.

- Rubber slate , a relatively new material on the market, is made from rubber-fabric waste, fiber optic twisted dense thread, and is non-toxic.

- Domestic composition of asbestos-cement : 85-90% Portland cement M300 - M500, 10-20% asbestos fiber with the addition of chrysolite, water.

A dangerous element is asbestos fibers, which has been discussed since the beginning of slate production. In the European Union, such coverage is prohibited. The choice of material is up to the buyer, and since asbestos fiber coating continues to be in demand, its production has not stopped. Craftsmen working with such slate adhere to safety rules during production and cutting.

This is what asbestos looks like in nature - menacing beauty Source gorod55.ru

Effective area

The sheets are installed with an overlap, 1 or less often 2 waves are overlapped. In this case, the useful area of the sheet is reduced by the amount of overlap.

- For a 7-wave sheet, the usable area is 1.336 square meters. m .;

- wave slate is 1.57 sq.m.

The dimensions are indicated with an overlap of 1 wave, which is most often used in construction. Sometimes in some places it may be tempting to lay the sheet end-to-end to save material.

CAREFULLY!

It is impossible to lay sheets end-to-end, as leaks will occur at all joints.

Saving one or two sheets will result in water entering the room.

Overlap width

Technology for making slate from asbestos concrete

It is not very important for the average consumer to know how slate is made. It’s another matter if a person plans to open a small production facility for the production of material. The demand for products is constantly growing, the aspiring entrepreneur hopes not only to invest money, but also to make a profit. Then he will definitely need knowledge about how slate is made, what slate is made from, and how the technological process itself occurs.

The formation of a slate unit begins and ends in the laboratory. Here technological calculations are made, as well as control of the characteristics of the finished product. The process itself looks like this:

- Stage 1. Loading material onto sorting belts. Depending on the type of slate, materials are loaded according to the “recipe”. Grinding of material, fluffing. Mixing components.

- Stage 2. The base for the future slate is formed in the sheet-forming machine. Primary sheet forming.

- Stage 3. Sheets with a moisture content of 25% are cut.

- Stage 4. The wavy box takes the sheet, sucks it in with a vacuum - the result is a product with a familiar wavy shape. The sheets are interlaced with metal spacers. This will give a smooth surface and hold its shape.

Slate manufacturing process Source krysha-expert.ru

- Stage 5. Marking. Plain gray slate is marked on the front side, painted - on the back.

- Stage 6. Curing chamber.

- Stage 7. Product disassembly line. The gaskets are removed and sent to cleaning and lubrication machines.

- Stage 8. “Young” slate lies in a warm warehouse for 7 days.

- Stage 9. Strength test.

- Stage 10. Dispatch if the consumer ordered gray slate.

Customers have the opportunity to purchase a color version or a lightweight sheet.

Designation and marking of sheets

Flat slate sheets have their own symbol, characterizing their type and size. It contains the letter abbreviation of the product type (LPN or LPP - unpressed and pressed sheets, respectively), dimensions (length, width, thickness - in millimeters), and the designation of the current standard.

For example, pressed sheets with a length of 3000 mm, a width of 1570 mm, and a thickness of 10 mm, manufactured according to GOST 18124-2012, are designated as LPP 3000 x 1570 x 10 GOST 18124-2012. And unpressed products with a length of 1200 mm, a width of 1120 mm, a thickness of 6 mm - like LNP 1200 x 1120 x 6 GOST 18124-2012.

The symbol of the sheets is indicated in the accompanying documents for the products, in construction drawings, etc. Directly on the sheets you can see another mark for identification - marking.

It is usually applied to slate using printing. But it is also allowed to use printed labels that are glued to sheets. A minimum of 1% of sheets in a lot must be marked.

The marking contains:

- manufacturer's name or trademark;

- batch number;

- a sign indicating the type of sheet and its thickness (a square with a number in the center - an unpressed sheet, the same square, but symbolically “compressed” by two arrows - a pressed sheet).

Table of comparative characteristics of slate materials

To help those who are still wondering which slate to buy, here is a table of comparative characteristics of various building materials:

| Slate | Natural slate | Asbestos cement | Asbestos free | Bituminous | Made of metal | Rubber | Made of plastic |

| Form | Rectangular tiles, scales, others. | Wave, flat | Wave, flat | Wave, tile, roll | Wave, flat, corrugated | Flat, roll | Wave, flat |

| Flexibility | No | Yes | Yes | Yes | Yes | Yes | Yes |

| Strength | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Toxicity | No | Yes | No | No | No | Yes | Yes |

| Fire resistance | Yes | Yes | Yes | Yes | Yes | No | Yes |

| Light resistance | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Corrosion | No | No | No | No | Yes | No | Yes |

| Weight 1 m², kg | 27 | 9-18 | 10-14 | 3-6 | 2,5-32 | 6,5 | 1,2-3,2 |

| Price 1 m², $ | $60-100 | $2-3 | $5 | $5-6 | $4-5 | $4 | $1.5-15 |

| Life time | 100-500 years | More than 30 years | More than 50 years | 15-20 years | 50 | 30-50 | 40 |

Safety of use in construction

The main concerns about environmental friendliness and possible harm are caused by asbestos grades of slate . Asbestos, Portland cement and standard cement with the addition of water are used as raw materials for sheets. Fine-fiber silicate minerals perform the function of bonding. The strength of the structure to wind and other types of loads depends on this component. Asbestos evenly distributed over the entire surface of the sheet occupies no more than 18% of its composition.

Because of this, opinions about the safety of slate differ . Some consumers claim that the material is harmful to health and can cause serious illness. Other buyers suggest that premium roofing manufacturers created this myth.

The presence of asbestos in slate can indeed provoke a negative reaction if it enters the body. However, the fibers used in production are divided into two categories - arizotile and amphibole . The amphibole type of slate has a harmful effect on human health. However, it is used in the mixture only in Europe due to the lack of the first substance in the public domain. Thus, Russian-made roofing material is safe.

How to care for slate so it lasts longer

Despite the positive characteristics of each type, manufacturers do not hide that the material has some disadvantages:

- fragility, inconvenience of transportation, toxicity (asbestos cement);

- sunburn, fire hazard (ondulin);

- high cost (shale);

- sound conductivity, high electrical conductivity (metal);

- flammability (ondulin, rubber).

Having paid for the material and installation, everyone hopes for the declared service life of the product. But a real owner will take practical steps that will extend the life of slate sheets:

- Step 1. Initially, when purchasing, choose those that have a protective coating of water-dispersed paints and varnishes. The slate will look good for 10-12 years, but every year the color will fade.

- Step 2. Start painting. First, he will clean the slate from dust, dirt, and moss, then paint it with suitable paint. For asbestos, this is a special weather-resistant paint with an acrylic base. Rubber paint is also popular; the coating will not only be renewed, but will also become frost-resistant and wear-resistant.

Features of the sales market

It cannot be said that there is high competition in this market segment. Of course, there are manufacturers, but if the process is properly organized, the sale of slate can proceed quite quickly even for a novice entrepreneur.

Who is interested in buying slate?

- construction companies,

- private builders,

- industrial entrepreneurs,

- farms.

Having found your own niche in the market, you can firmly take your place here, offering customers quality products. But the main goal for a beginner should be to establish wholesale connections. Thus, you can immediately sell the released goods in large quantities.

As for advertising, in the case of wholesale sales, large-scale marketing campaigns, of course, are not needed. But if you open your own warehouse store, the production of wave slate will still have to be advertised among a potential audience.

You might be interested in:

How to draw up a business plan for the production of drywall?

How to open a mini-factory for the production of paving stones in Russia?

Business idea: home production of aerated concrete blocks.

Video description

In this video, watch the process of cleaning and painting the roof:

Caring for plastic sheets involves periodically getting rid of dust.

Metal sheets (corrugated sheets) also lose color. Paint with alkyd enamel on metal.

- Step 3. All repair, restoration, and decorative work will be entrusted to specialists with permission, the necessary tools and a wealth of knowledge, experience and skill. When receiving an application, the first thing they will do is ask what the slate is made of in order to determine the scope of work.

Workshop technical equipment

Extrusion line

And then the entrepreneur will need to buy equipment for slate production. There is plenty of choice here, which means everyone can find an option that is worthy of both price and quality.

With the help of modern equipment, you can obtain a high-quality product with virtually no manual labor involved. But we are talking about automated lines. And in machines, which are cheaper, some processes are mechanized, which sometimes really “slows down” the process.

A slate production line can cost differently, as its capacity and equipment vary. The cost of low-power mechanical machines (≈50 sheets/hour) does not exceed 700,000 rubles. But a full-fledged automated line can be bought for 1,200,000-2,000,000 rubles.

In addition to the main line, you will also need to purchase additional equipment - a beam crane and a loader. And this is at least 300,000 rubles.