Transparent slate is a relatively new material that has quickly won its place in the construction market. This roofing material is quite distantly related to the more familiar slate made of gypsum and cement, and the similarity is only in the wavy profile and shape of the sheets. But so many advantages! Popularly, “transparent slate” refers to all wavy and corrugated transparent sheets of sufficient strength to be mounted on a roof. This includes corresponding products made of plexiglass, PVC and monolithic polycarbonate. And they cover everything possible with this material: canopies, gazebos, winter gardens, outbuildings and even part of the roof of a residential building. But what is the advantage of transparent slate over more traditional and proven materials, and how to work with this new product? Let's find out!

Transparent slate: types and manufacturers

Transparent slate is mainly divided into types based on the material from which it is made:

- Transparent PVC slate. It is produced completely transparent or can be tinted. Varies in thickness and height. Positive qualities include a high level of fire safety and low weight. The only drawback is that it is rarely available for sale.

- Polycarbonate. It is made from monolithic polycarbonate, unlike material for greenhouses, it uses polycarbonate “honeycombs”. The installation must be overlapped, similar to corrugated sheeting.

- Plexiglas. This variety has a high level of optical properties, is thicker than previous varieties, and is well suited for decorating buildings. Despite the thickness of the sheet, the material is quite light.

Some of the more popular brands of slate include:

- Yug-oil-plast , polycarbonate material, produced in the Russian Federation;

- Ondex , made of polycarbonate, made in the Russian Federation;

- Lariver , PVC material with fiberglass reinforcement, made in Italy;

- Suntuf , made of polycarbonate, made in Israel;

- Eliplast , fiberglass material, made in the Russian Federation.

Variety of types of transparent slate

Polyvinyl chloride

PVC slate sheets are available in both colorless and tinted versions; they may differ in size and thickness. PVC materials have become widespread due to their lightness, strength and high degree of fire safety.

Transparent PVC slate diffuses light well. This property allows the material to be used for roofing a winter garden, greenhouse or balcony.

As for the form of release of PVC sheets, there are two of them: trapezoidal and in the form of sine waves. Flat sheets of PVC slate are not available.

There is reinforced and regular PVC slate. Fiberglass is used as a reinforcing element. Reinforced sheets have greater mechanical strength, but an increase in strength somewhat reduces the ductility of the material.

Polyvinyl chloride is more resistant to aggressive chemical compounds than polycarbonate. It is for this reason that PVC slate is used to cover roofs, balconies, gazebos and canopies located in areas where industrial enterprises are concentrated. This is due to the high probability of dust settling with impurities of chemically aggressive compounds and sediments with an acidic component.

The standard size of PVC sheets is 2000×1090 and 2000×1080 mm with a thickness of 2 mm. The number of waves can be from 5 to 8 pcs. The weight of the sheet ranges from 2.5 to 3 kg, which is significantly less than that of other roofing materials.

On the Russian market, this material is presented in both colorless transparent and tinted versions. The color scheme consists of blue, blue, red, yellow and green shades. Opaque PVC slate is available in gray and blue.

Polycarbonate

Polycarbonate roofing materials can be divided into three main modifications: monolithic, honeycomb, and sine wave. Each of these materials can be used in roofing work.

One of the distinctive features of this material is that monolithic and cellular polycarbonate slates, like wave slates, have their own optimal area of use. Thus, monolithic material is most suitable for installing light-transmitting inserts in the roof. This is due to its mechanical strength and transparency. Transparent polycarbonate slate can easily replace conventional glazing.

For the construction of a greenhouse or greenhouse, installation of a canopy, canopy, or covering a gazebo, corrugated or cellular roofing material is more suitable.

According to the installation technology, cellular polycarbonate slates are connected to each other with a special profile. Wavy slate is laid with an overlap of one wave.

Polycarbonate roofing has a number of characteristic advantages:

- high mechanical strength. Polycarbonate-based roofing materials can withstand significant impact loads. A properly installed rafter system can support the weight of an adult. This allows you to significantly simplify installation and repair work;

- resistance to ultraviolet radiation. Roofing materials retain their original appearance for 8 to 10 years when directly exposed to ultraviolet radiation;

- light weight. Wave and cellular varieties of polycarbonate slate do not create a significant load on the foundation and load-bearing walls. A corrugated sheet with an area of 1 m2 can weigh from 1.15 to 1.2 kg, with a standard thickness of 0.9 to 1.0 mm.

Fiberglass

The raw material for the production of fiberglass is polyester resin, which ensures high resistance of the material to aggressive chemical compounds and atmospheric influences. Fiberglass is used to give the material extra strength.

Thanks to this composition, fiberglass is highly resistant to extreme temperatures and can operate in the temperature range from -40 to +140˚С.

Fiberglass roofing materials can be produced in both sheet and roll versions, which allows you to select the optimal material configuration for various installation works.

The low thermal conductivity of the material allows the use of fiberglass coating for warm roofs. Greenhouses, poultry houses, greenhouses and hotbeds are covered with this slate. The wide color palette of fiberglass slate makes it possible to use it for decorative roofing. Fiberglass slate will add uniqueness and style to any gazebo or terrace.

Standard roll sizes are 2.5×20, 2×20, 1.5×20 m. The coating thickness can be from 0.8 to 2 mm. The material has a low specific gravity. A standard sheet with dimensions of 3000×1000 mm weighs 3.5 kg, which greatly simplifies lifting the material to a height and carrying out installation work. The guaranteed service life of fiberglass roofing is at least 10 years.

Plexiglas

Acrylic plexiglass is available in monolithic and wave versions. The waveform can be sinusoidal or trapezoidal. Acrylic slate has a glossy surface, it diffuses sunlight well and has high sound insulation properties. It is advisable to use monolithic slate as inserts in the roof of an attic or residential building. Corrugated sheets are perfect for roofing various gazebos, terraces, canopies, canopies, etc.

The thickness of the corrugated material can vary from 1 to 1.2 mm, and of the monolithic material from 1 to 24 mm. The length of acrylic slate sheets can be 4000, 6000 and 12000 mm, however, to facilitate transportation, their standard sizes usually do not exceed 2050-3050 mm.

Acrylic plexiglass is resistant to deformation and bending moments. Even direct contact with ultraviolet radiation does not impair its performance characteristics. In addition, acrylic slate withstands the effects of inorganic chemical compounds well. The material is highly resistant to impact loads and does not lose its performance properties in the temperature range from -40 to +80˚С.

Even with strong heating, the material does not emit toxic compounds, and therefore does not pose a danger to humans and the environment. The main disadvantage of acrylic slate is its lack of resistance to various organic solvents.

Roofs made of silicate glass

Do not forget that ordinary transparent silicate glass has not lost its popularity. Today, thanks to innovative developments in the field of construction, it has become possible to construct transparent roofing structures. And this applies not only to awnings. Glass roofs are very popular today.

Manufacturers offer two varieties:

- based on plastic or aluminum window technology;

- based on thick sheet glass, the so-called panoramic glazing .

Roofs based on plastic or aluminum windows Source alkona.net

The first option is the simplest of the two and the most worked out to the smallest detail. Essentially, these are windows in double-glazed frames that are connected to each other to form a roof glazing structure. The main task of the work manufacturer is to accurately measure the future roof and accurately assemble all the elements together. A small discrepancy can lead to inconsistencies at the junctions of individual elements.

But this roofing structure also has its advantages. For example, the ability to construct roofs of any configuration and complexity. Presentable appearance, giving lightness and freshness to the architecture of the house. Even a small glass canopy near the house makes it stand out with its openwork and originality.

Sheet covering is thick glass laid in frames that form the roof. This technology came to suburban construction from the architecture of swimming pools and shopping centers. In fact, these are all the same windows, only larger in size. Aluminum and plastic profiles are also used here as materials for frames; some manufacturers offer steel profiles. The main requirement for such structures is the strength and reliability of the frame.

Panoramic roof glazing Source alutecno.com.ar

Forms of release of transparent roofing coverings

The fairly wide range of transparent material offered for sale can also be attributed to its positive qualities. You also need to get information about this in order to make the right choice.

- Variety of colors

Transparent slate has many colors, which allows you to choose the right option for a specific structure. It is produced in the following colors:

- transparent, colorless;

- white;

- colored - the color of the slate can be pure or mixed, such as turquoise, beige, milky, bronze, etc.

If colorless transparent slate is used for greenhouses, then for other buildings it is quite possible to use different color options.

Several color samples of transparent slate

The color of the selected slate for a canopy, veranda, terrace or fence should be organically combined with the design of the walls of the facade of the house. Therefore, if the ideal shade is not found, then you can choose a neutral one, for example, smoky or bronze.

- Light transmittance level

In addition to the color range, plastic slate is also divided according to the level of light transmission:

— Completely transparent, having 92÷95% light transmission. It may well be comparable to glass, so it is used for rooms that require increased lighting.

— Translucent material has 55÷75% light transmission. The contours of individual objects can be seen behind it, but it will not be possible to examine them properly.

— Matte slate has the lowest percentage of transparency, so it practically does not transmit light. But it is distinguished by the most intense coloring.

— Opaque material is completely lightproof.

- Sheet profile configuration

Plastic slate can look different, and its appearance largely depends on the cross section - it can have different shapes and sizes:

Transparent slate with “classic” sine waves

- wavy shape, in the form of smooth sinusoidal waves;

This slate is as close as possible to the configuration of corrugated sheets

— trapezoidal waves have clear wave boundaries, like most types of metal corrugated sheets;

Not quite “slate” - roofing sheets without wavy shapes

— flat sheets are divided into monolithic and cellular versions.

Table of wave types by size and color:

| Wave configuration | Wave (length, mm / height, mm) | Sheet length, mm | Sheet width, mm | Thickness, mm | Material color |

| 146/48 | 2000 | 1090 | 1,1÷1,3 | Transparent | |

| 94/34 | 2000 | 900 | 1 | Red Green Yellow Blue Brown Black | |

| 70/18 | 2000 | 1090 | 0.8 | Transparent Smoke Yellow Green Red Blue | |

| 76/18 | 2000 | 900 | 0.8 | Transparent Smoky | |

| 76/18 | 2000 | 1030 | 2.5 | Prism |

It should be noted here that slate, which has a wavy shape or trapezoidal profile, has much greater rigidity and strength compared to flat sheets, and therefore is more resistant to shock and static loads. Thanks to such configurations, water is drained from the roof more efficiently, leaving fewer drip marks.

Plastic slate can be sold in long rolls

Corrugated slate is produced in sheets and rolls. Their sizes are selected in accordance with the existing dimensions of the roof slopes. Standard sheet parameters: 2000×900; 2000×1086; 2200×1140 mm and others, depending on the type of material and manufacturer. Each slate sheet usually has 7÷12 waves, depending on their width and depth.

Slate, sold in rolls, can have a length of 10, 20, 30 m and a width of 1.5÷3 m. These dimensions allow the use of solid fragments of material to cover one roof slope in length or width. Thanks to these coating parameters, even on a large roof slope, the number of sheet joints is significantly reduced, and the installation process itself is simplified.

Let's sum it up

Polycarbonate is a material that has revolutionized the construction of transparent roofs. This is the only real alternative to glass not only for small buildings, but also for critical objects. Polycarbonate comes in three types:

- Monolithic is the most durable, even bulletproof, and durable, but expensive, heavy and difficult to install.

- Profiled - lightweight, very easy to install and quite durable, but it withstands impacts less well and practically does not prevent heat loss.

- Cellular is extremely cheap, very light and can withstand light impacts well, but transmits less light, is a short-lived and often unaesthetic material.

Polycarbonate is mainly used to make flat, single-pitched, gable and arched roofs of gazebos, terraces, galleries, verandas, greenhouses, and canopies.

To install monolithic polycarbonate, it is better to hire specialists, while profiled and honeycomb sheets can be installed on the roof yourself. How is written in detailed instructions in this article.

Positive and negative sides

Before you finally decide on transparent slate, you should familiarize yourself with its advantages and disadvantages.

Positive characteristics include:

- Light weight . The material is lightweight despite its durable structure. This allows you to use slate instead of glass.

- Aesthetic appearance. Thanks to the beauty of this material, it is possible to implement a variety of design ideas and ideas.

- Not exposed to ultraviolet radiation. This property is achieved due to the fact that the sun's rays pass through the material without stopping or disturbing its structure.

- Durable and safe. It has a high level of impact resistance compared to ordinary glass. This also guarantees safety if, for example, a solid object gets into the slate structure.

- Economical. In cases of construction of certain specific structures, such as a chicken coop, slate will help save money on additional lighting . It is also able to withstand temperatures reaching 60 degrees.

- Environmental friendliness. The material from which any type of transparent slate is made does not harm the human body in any way, because it does not emit harmful substances even when heated.

- Flexibility. Thanks to this property, transparent slate can be laid on rather complexly constructed roofs; it can be bent to the required angle without any damage.

IMPORTANT!

Transparent slate has a high level of light transmission. This characteristic will be useful for those who like more open and lighter designs. Sunlight passes through the transparent slate in large quantities.

Scope of application

Negative points to consider when choosing roofing material:

- Quite a complicated installation process. Due to the fact that it is not recommended to step on the material during its installation , it is necessary to use additional structures, such as scaffolding.

- Narrow range of applications. The impossibility of using the material to cover the entire roof area; in some cases, even making a transparent insert is not recommended.

- Low level of thermal protection. Given the small thickness of transparent slate, this material is not suitable for structures that require thermal insulation.

Style directions

There are many styles in which curtains for gazebos are decorated:

- country;

- Roman;

- roll;

- roller blinds;

- thread;

- sliding

The rustic country style will delight you with its bright patterns and cheerful mood.

A practical option is roller blinds for the terrace; they have another name – fabric roller blinds. The roll is opened automatically by remote control or manually. Acrylic fabric or blackout is often used. Roller blinds have the same design principle; they are mounted indoors, and roller blinds are mounted outside.

There are fans of thread curtains - fabric strands on a common basis. They can be made from natural jute threads, fishing line, plastic, wire. They often serve as an element of terrace decor; they do not absorb the sun's rays.

For verandas, sliding panels with a rigid frame in the Japanese style are often chosen; they are attached to the eaves.

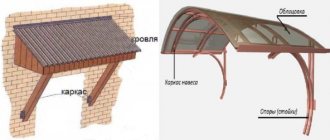

Areas of use of transparent slate

Transparent roofing material can be used in quite a variety of ways. And to make sure that it can be not only a functional coating, but also give a special aesthetics to any structure, it’s worth first considering several options for its use.

Transparent inserts on the roof of large objects allow you to achieve considerable savings on lighting large areas

- Transparent slate is often used to cover the roofs of individual premises of public buildings and agricultural structures. The material is installed completely on the entire roof or inserts are made from it, which are used to illuminate interior spaces that do not have windows, which helps to significantly save on energy.

Transparent insert on an arched roof structure

- It is used to cover arched structures in poultry farms, greenhouse complexes, as well as hangars and construction warehouses.

Original translucent polymer slate fence

- Increasingly, transparent slate in combination with other materials is used to construct fences. For example, this photo shows a structure made of transparent tinted material, protected on the outside by a chain-link mesh. This lightweight building looks quite aesthetically pleasing, but at the same time it is quite reliable, since it is not easy for an attacker to overcome it without the owners noticing.

Tinted transparent slate will create the desired shadow on the car area

- Transparent slate makes an excellent canopy over a parking lot - such a building will cost much less than a permanent garage. Moreover, if desired, it can be used as a gazebo by installing a table, chairs or a lounger under the roof.

Sun and shadow in moderation - translucent roof over the traditional resting place

- Covering gazebos, terraces and verandas with this material is increasingly becoming part of landscape design, as it adds exclusivity and aesthetics to it. In addition, a transparent roof helps to save on electricity, since it will be light under it all day long.

An excellent solution for reliable and durable greenhouses and greenhouses

- Home greenhouses and greenhouses built entirely from sheets of transparent slate or with a roof made of similar material function perfectly not only in the spring, but even in winter. This is because the material retains heat well inside the building and does not allow wind to pass through, and natural light flows inside throughout the day.

Functional, lightweight and at the same time a beautiful canopy over your home pool

- To protect the pool from wind, ultraviolet rays, dust and tree leaves, transparent slate is the best option. It looks harmonious with the surface of the water against the backdrop of natural landscapes, and most importantly - the pool - can be used in the summer in any weather.

Reliable protection from precipitation for terraces, porches, entrances, entrances to houses or outbuildings

- This material has become very popular for installing canopies over entrance doors, as well as for forming shaped roofs over terraces. All this thanks to its light weight, original appearance and the ability to create designs of various shapes.

The main areas of application of plastic transparent slate were listed above, but besides this, they cover winter gardens and balconies, make indoor partitions, canopies over the yard area and much more.

Advantages of a translucent roof

A transparent roof has the following significant advantages:

- visual expansion of the area indoors;

- intensive lighting without the use of artificial light; The room under the glass roof is so bright, as if light bulbs are turned on everywhere

- long service time;

- maximum protection from moisture;

- the ability to shelter people from bad weather and the scorching sun at a summer cottage or at the entrance to a room;

- maintaining performance characteristics under high temperature conditions;

- the ability to withstand ultraviolet radiation;

- invulnerability to corrosion;

- light weight;

The transparent roof weighs little, which is why it does not exert much pressure on the walls of the room - Suitable for both suburban and residential construction.

Tips for installing and correctly installing transparent slate

1. Recommended tilt angle is at least 10 degrees;

2. Carefully study the bending radius before installation (plastic manufacturer documentation), in order to avoid cracks and rapid wear, usually the bending radius should not be less than 2.5 meters;

3. The overlap of sheets is at least 15 cm;

4. Carefully consider the material consumption, add 10-15% for cutting and overlap;

5. If the sheathing is made of metal, it is recommended to paint it in light colors to avoid strong heating, or wrap it in foil. It is also possible to use wooden sheathing;

6. Lay the sheets from bottom to top, the wave perpendicular to the slats (rafters) of the sheathing - to avoid water retention on the roof;

7. Use only special rubberized thermal washers for fastening, with a diameter of at least 20 mm;

8. IMPORTANT! Before screwing in the screws, make a hole in the transparent slate with a diameter 3-4 mm larger than the diameter of the screw,

to avoid unpleasant sounds during temperature changes (since plastic has its own expansion coefficient)

9. For 1 sheet measuring 1.26 x 2 meters we use 15 thermal washers with self-tapping screws (for metal or wood)

10. Leave a gap of 3 mm when abutting transparent slate to the wall, or better yet, use special abutment strips;

These simple rules for installing transparent slate will help you avoid unpleasant moments and enjoy the open sky without leaving your home!

What to consider before starting construction

- When choosing, you need to rely on the available building material. Of course, brick columns look solid, but they are heavy; therefore, you will have to build a fairly strong foundation, and this is long, difficult and expensive, so I recommend excluding such options;

- If there is a body of water nearby, then you should not skimp on impregnations and protective compounds for the frame and rafter system. Otherwise, the service life of such a gazebo will be short;

- A barbecue is very often placed next to such structures or directly inside them, which means that the roofing material must be exclusively fireproof or the barbecue must be moved at least 5 m away from the gazebo;

A fireproof roof must be installed under a structure with a barbecue.

- The roof covering should at least partially coincide with the overall landscape. After all, for example, a metal frame covered with slate is clearly discordant with a wooden frame under a soft roof;

- When choosing the angle of inclination of the rafter system, take into account the wind rose and the amount of precipitation in the area. If the gazebo is closed from the wind, then it is better to make the angle larger so that the snow melts off on its own. In open areas, it is advisable to design a flat roof with low windage.

The gazebo should be in harmony with the overall landscape.

Preparatory work

Before proceeding directly to laying slate on the roof, it is necessary to carry out some preparatory measures. These include:

- calculation of the required material;

- preparing the base for attaching slate material.

Calculation of the amount of material will depend on the type of slate that was chosen. But the essence of the calculations is to divide the total area of the roof surface to be covered by the dimensions of the slate.

If these are sheets, then by calculating the sheet area you can determine their number. In the case of the rolled variety of best man, the principle is similar.

In addition, it is advisable to take into account the load on the roofing. It can be found out based on the region parameters, which are indicated in special documentation. In addition, the future load on the slate is influenced by such parameters as the degree of roof slope and the location of the structure.

NOTE!

The minimum permissible angle of inclination of plastic slate is not less than 10 degrees.

Preparing the base for later attaching slate to it consists of preparing the so-called cellular structure, which is otherwise called lathing.

There are some requirements for this design:

- Each sheet that will be attached to the sheathing must have at least three support points.

- The frame is assembled from wood beams or boards. You can use an unsanded and unedged board, which will exceed 15 mm in thickness. As an alternative, a metal frame is used.

- Laying is carried out in a checkerboard pattern, while maintaining an intermediate distance of 200 mm.

- You can use timber with dimensions of 50x50 mm ; the intermediate distance must be selected based on the parameters of the slate sheet.

- In areas of the roof where there is any equipment, for example, a service pipe, it is necessary to install an additional contour of wooden sheathing.

- To ensure the waterproofing properties of the roof , you should resort to the use of appropriate materials.

- After all measures to prepare the roof surface have been carried out, you can begin installing the roof covering.

Surface preparation

Design

The construction of a terrace or veranda allows you to connect the enclosed space of your home and nature into a single whole and opens up wide possibilities for the design of these buildings.

Fencing. They can be made protective or decorative, for example, in the form of a low, elegant fence or pergolas - canopies of several arches, decorated with vines or potted compositions of bright hanging plants. It is good to decorate the perimeter with ornamental shrubs and flowers.

- Instead of a standard roof, you can use a removable awning, retractable awnings, or a portable umbrella.

- When a terrace or veranda is not attached to the house, but is located separately in the yard, then a path is used as a connecting link between the buildings. To decorate the path, spotlights built into niches on the ground cover or LED lighting plus one or more openwork arches to create the effect of a luminous tunnel are suitable.

For a summer veranda or open terrace, it is advisable to choose plastic in muted dark colors - smoky, tobacco shade, bottle glass color with a grayish or bluish undertone. Being in red, blue or bright green on your porch can be irritating.

c36ac8488e67a8800292fa292c6acd5e.jpe

9f0b5e627f9f2bc2f0997f5d86cca0bd.jpeWhen the frame is made of wood, then after antiseptic treatment and varnishing the wood acquires a reddish color. In this case, brownish or orange polycarbonate is selected for the roof. Such tones help create a relaxing atmosphere and increase the color temperature of the veranda interior.

Installation process of transparent slate

The process of installing slate on the roof begins with arranging the sheathing. Taking into account the above requirements, the whole process can be divided into stages:

- The sheathing is constructed from timber with dimensions of 30x40 and 40x40 mm . You can use bars of larger sizes.

- First of all, you should secure the timber to the rafters using roofing screws . Each connection node requires the installation of two fastening elements.

- Before fastening parts of the sheathing, it is recommended to treat the wood with fire retardant and antiseptic agents. This will protect the material from being eaten by insects and molds, and will also reduce the flammability of the wood.

- The step for placing the beams should be 50-60 cm , although there is an option for a more frequent step, however, it is worth taking into account the reduction in lighting intensity in the future structure.

- Stepping back half a meter from the cornice, you need to attach the first beam to the rafters.

- If the proposed structure will be made with separate sheets of slate, they should be laid horizontally with an overlap of 1 wave, with a vertical overlap of no less than 20-25 cm.

- The installation of sheets is carried out in the direction from the eaves to the ridge , while maintaining a zigzag arrangement, namely, laying is carried out in such a way that the top sheet covers the bottom row of the coating to the middle.

- The fastening elements must be screwed in at the crest of the slate wave.

- To avoid the formation of cracks when screwing in the screws, it is best to first make holes in the required parts , which will be slightly larger in diameter than the element itself, up to 2.5 mm.

- In order to ensure the maximum level of rigidity in the connections between slate and sheathing, while preventing the material from deforming, it is necessary to install a special stand under the wave , which already has holes for screws.

- The supports are selected depending on the nature of the wave and can be sinusoidal or trapezoidal.

- In order to properly fasten the slate, it is best to use specialized self-tapping screws , which are equipped with a washer made of rubber and metal. This will additionally provide waterproofing properties and reliably protect the drilled holes.

- The screws must be screwed in, observing a step of 3-4 waves, in the area in the middle of the sheet . In the case of fastening on a cornice and ridge beam - 1 wave.

Fastening the covering with roofing screws

Covering installation

The sheathing structure can be made of metal. If this particular material was chosen for the base under the slate, then it is necessary to wrap each connection point with aluminum foil.

How to choose curtains: selection criteria

Usually, when choosing curtains for a veranda, they are guided by the following criteria:

- resistance to precipitation;

- air permeability;

- material strength;

- easy care;

- convenience when washing.

Protective curtains on the veranda or gazebo completely cover the openings, allowing you to spend time there before the onset of cold weather. They tightly cover the veranda, help retain heat when heating devices are turned on inside, and prevent insects from getting inside. Some summer residents consider transparent PVC curtains a worthy replacement for veranda glazing. They are also chosen because of their suitability for the winter season; they are not afraid of frost and dampness. There are fastening systems that can be opened in summer. Typically, transparent protective curtains are combined with fabric curtains inside; they protect from sunlight.

The choice of curtains made of moisture-resistant textile fabric or acrylic is good if they are needed only for the summer season. They are not afraid of rainy weather or wind. You can look at a convenient roller version of blackout curtains; they can be controlled using a lever. Another plus: they suit any interior style. Caring for them is simple, just wipe them with a damp cloth. They have to be removed for the winter.

If protection for a gazebo or veranda is needed only from the bright sun and heat, it is enough to choose curtains made of decorative fabric in a color that matches the interior. Fabric curtains can be beautifully decorated. The main requirement is that the fabric for them must be dense, durable, easy to wash and iron. After all, the open veranda is susceptible to dust. Most suitable are burlap, linen or cotton fabric, with or without a pattern - the hostess decides. Sometimes the gazebo is draped with tulle.

Having decided to cover the veranda with curtains, it is important to understand what function they will perform: to decorate the interior or to protect from rain, sun, and insects. This will help you choose the right option when purchasing.

Moreover, modern materials make it possible to combine aesthetic components and practical properties.

Owners of garden buildings usually need a moisture-resistant material that protects from bright rays, an attractive material that is easy to care for and durable, which will bring joy for many years.

Construction of a classic terrace

A terrace or veranda was an essential element of a house back in the century before last. One of the traditions was family dinners outdoors. And now many households like to spend time in an open extension to the house, fenced with low balusters and railings.

One of the elements of the terrace, like the gazebo, is the roof. It can be made separately or be a continuation of the home one. To support the roof, several supports in the form of square pillars or figured racks are installed at the corners of the site and along its sides.

There are options for open terraces, partially closed and completely closed.

For terrace roofing, all traditional materials are used, as well as a number of materials unusual for home roofs. They are what make the roof durable and original, and the terrace bright and undarkened.

Polycarbonate

If you need a transparent material for the roof of a gazebo, the best option would be to use polycarbonate. This material allows you to create very complex roof structures. It is possible to install a dome-type roof, an acute-angled one, and so on. A polycarbonate roof will decorate the gazebo and give it originality.

At the same time, plastic for the gazebo roof has many functional advantages, which should be indicated in more detail:

— This material is quite durable. It will not be damaged by impact or other impacts. This guarantees a long operational period; — Polycarbonate retains its beneficial properties unchanged for 20 years or more. Accordingly, such a roof will not have to be replaced or repaired; — A large selection of colors allows buyers to choose the best option that will match the color of the roof or facade of the house; — Polycarbonate does not lose strength and other qualities at low temperatures. It can easily withstand even strong heat; — The material is not of interest to rodents and will not become a breeding ground for fungal and mold bacteria.

Thickness

First of all, you need to look at the manufacturer, since a high-quality 6 mm sheet will be stronger than a cheap 8 mm sheet. It is not recommended to buy cheap 4 mm sheets, since the service life of such material will be a maximum of 2 years.

The thickness of a good polycarbonate for a gazebo is more than 6 mm, and the market price is average or higher.

People with experience recommend overpaying and buying thicker polycarbonate - more than 6 mm, that is, 8 mm and 10 mm. This will allow you to avoid holes from hail and damaged coating after the season changes.

If there is a sharp choice between a cheap thick one and an expensive thin one, then it makes sense to take a thinner one. But I can’t imagine which region currently lacks a large supply of this material. In my opinion, it is already being sold everywhere.

Terrace design options

The terrace is an architectural element that, if properly designed, can become a decoration for the entire household. In addition, if you make it comfortable enough, it will become an ideal place for relaxing in nature with a good view of the surrounding landscape.

Various terraces on the roofs of cottages:

Garage roof terrace

The best way to arrange an upper terrace is to place it above the garage attached to the house. A garage extension, or rather the space above it, often remains unused. Firstly, it is undesirable to locate living rooms above the garage. Secondly, if the garage is attached and stands on a separate lightweight foundation, it is impossible to build a full floor above it. But for a terrace, the area above the garage is ideal. The terrace on the roof of the garage attached to the house is convenient in that it can be accessed through the premises of the second floor, and there is no need to build a superstructure for the exit.

Garage roof terraceSource pinterest.com

Pitched terrace

If, if they want to have a serviceable roof, homeowners want to preserve the classic silhouette of the house, they can make a triangular-shaped canopy. In this case, it is a pergola canopy. This type of imitation of a gable roof can be used when decorating a terrace above a house, above a summer kitchen, above a bathhouse, etc.

Canopy over the terraceSource pinterest.com

Roof veranda

To use the upper platform constantly, regardless of the time of year and weather conditions, you can make a glazed veranda on the roof. The roof of the veranda can also be gable. There are technologies for constructing collapsible or sliding enclosing glazing structures.

Glazed veranda on the roof Source krov-torg.ru

High-tech house with roof terrace

Below is a video review of a high-tech style cottage. This architectural trend is characterized by cubic shapes. The buildings seem to consist of blocks of different sizes. A terrace built over one of these blocks increases the functionality of the entire structure and provides the house with a more attractive appearance.

This type of recreation area is protected on 4 sides. On the rear side it is closed by a neighboring block with access to the site. There are high partitions on the sides that harmoniously fit into the architecture of the building. If the front part is covered with plastic and glass, as in the example given, the terrace will always be a calm and cozy place to relax without wind and dust. But if you wish, you can make a fence from metal or wooden railings.

Overview of a house project with a roof terrace:

A terrace on the roof of a house or other building on a site is an original, comfortable and beautiful recreation area that does not take up space on the ground. It is not difficult to make such a terrace aesthetically pleasing and safe; for this there are various modern materials and technologies

But the design and construction of an operating site on a flat roof should be done with extreme caution, taking into account all technical rules and regulations

Life time

PE (Polyester)

If installed correctly, the service life of roofing sheeting with polyester coating will be 25 years or more. At the same time, the color qualities will remain unchanged throughout the service life. This applies to the glossy type of coating. And the matte version will last up to 40 years.

Plastisol

UV-resistant coating that hardly fades. Roofing and facades made of plastisol sheets will not change their color for 40 years. As a rule, PVC-coated profiles are preferred in northern regions, in harsh climates, as well as in industrial zones, especially for chemical enterprises. In addition, plastisol is indicated for use when the likelihood of external influence of a mechanical nature predominates, for example, if the area is characterized by precipitation in the form of hail, dust storms, etc.

PVDF

Preserves metal material even in aggressive conditions. This type of corrugated sheeting is optimal for roofing and finishing buildings in cold climates, industrial areas, coastal areas and near busy highways.

Pural

The service life of such corrugated sheets is 5 decades. It is resistant to mechanical stress, as can be judged by the thickness of the coating layer, corresponding to 50 microns. Therefore, this corrugated sheeting, in particular, is used in harsh natural conditions, in areas where many industrial enterprises are concentrated. Due to its high cost, it is usually used for covering roofs and finishing facades. The polymer coating made from pural can be glossy or matte. The matte protective layer becomes resistant to stains over time.

Peculiarities

Metal profiles with polymer processing are made from steel in rolls, pre-coated with a protective colored layer.

Typically, the front side of the profile sheet is coated with polymers, and the inside is treated with a special varnish.

Polymers are applied to a metal base using different methods, but essentially the process is the same. Galvanized steel is degreased and prepared for painting. The painted sheets are sent to the oven to polymerize and harden the applied protective layer. In addition to material with one-sided coating, factories produce sheets that are more decorative and durable, with double-sided processing.

Plastic or PVC

The most affordable budget option of material for making a transparent canopy over the terrace. PVC plastic is cheaper than other materials, has good ductility and flexibility, but ordinary sheet material is rarely used to form a smooth and durable surface.

A flat sheet of PVC, even with a high degree of transparency, when heated under scorching rays, becomes too soft and sags on an aluminum or wooden frame. Therefore, the best option for a translucent roof is a profiled wave or trapezoidal PVC sheet.