Chemical compositions

How to flush the heat exchanger of a gas boiler?

The safest option is citric acid. Industrial products for washing the heat exchanger of a gas boiler - Cillit, DETEX, Sanax. Hydrochloric acid is more effective. But its use is more dangerous for both the user and the system. Concentrated acid can destroy the internal protective layer of the heat exchanger and also increase the fragility of the metal.

External treatment of contaminated parts is carried out with special compounds to remove soot and carbon deposits. As a last resort, you can use household detergents.

Video about flushing the heat exchanger of a gas boiler.

Periodic flushing of the gas boiler heat exchanger is a basic requirement for the maintenance of heating equipment. Cleaning significantly affects the smooth operation of the entire system and greatly extends the life of the home heating device. When do you need to do flushing and can you do it yourself?

When a gas boiler operates, a layer of scale forms, which prevents the necessary cooling of the heat exchanger. In this case, the circulation pump takes on a greater load. Therefore, without flushing the heat exchange device, the heating unit may fail.

At home, cleaning should be done every two years. If the water in your home is quite hard, it is recommended to reduce the interval between flushes.

The first signs for the user of the need to flush the heat exchanger are:

- long-term heating of a gas boiler;

- reduction in thermal output;

- partial heating of the system;

- presence of extraneous sounds during operation of the heating device;

- significant increase in gas consumption.

When scale appears in double-circuit boilers, the water may not fully warm up or the pressure level may decrease.

It is advisable to avoid a combination of such symptoms. But if alarming signs appear, flushing should be done immediately.

In addition to internal cleaning of the heat exchanger, external cleaning of its body from soot is used. Socialized services are responsible for eliminating scale and contamination in the gas boiler system. The cost of their services is not cheap. Therefore, sometimes you can wash the heat exchanger yourself.

Burners for universal equipment

Gas burners intended for solid fuel heating boilers have a complex design. They are intended for converting heating appliances from one type of fuel to another. Thanks to the special design, after purchasing a universal unit that runs on wood, when a gas main appears in a populated area, it can be converted to operate using natural gas.

They produce automatic gas burners for solid fuel appliances in accordance with the fan circuit. After supply, the gas is mixed with air, and then the prepared fuel-air mixture is sent to the nozzle. Here it is ignited, and a flame of high temperature is formed.

An automation system, a powerful fan, a special filter and a gearbox are mounted on board the gas burner. For the unit to function, a power supply is required. The device itself has a modular (removable) design.

An example of such a device is a product for Cooper boilers. The device itself is pellet, but it can be converted to natural or liquefied gas if a replacement burner is connected to it.

Operating a gas boiler

Necessary tools: multimeter, pliers, flat-head screwdriver, alcohol, open-end wrenches - 9, 10, 12. Troubleshooting involves, first of all, inspecting the thermocouple and solenoid valve. Having previously found the draft sensor on the gas duct, it is necessary to remove the two terminals and connect them tightly with pliers to close each other, while simultaneously attempting to ignite.

If the ignition problem still remains, then the cause of the problem is probably in the traction sensor, which needs to be checked in this way - tight fixation of the contacts, integrity of the paronite gaskets, the presence of a gap between the hole in the gas pipeline and the plane of the sensor. It is necessary to examine the rating of the sensor; if there is a temperature discrepancy, it will not open. Oxidation on the contacts, even unnoticed, is not allowed. Then the traction sensor is checked for the degree of resistance using a tester. The sensor must be replaced if the resistance is deviating, that is, not minimal. You should find an identical, working sensor with similar temperature performance.

If no failures are detected with the sensor, then it’s time to wipe the contacts and terminals of the circuit using alcohol, then dry and tighten them. Then the traction sensor returns to its place and the ignition attempt is repeated again.

It is necessary to monitor the burner draft after each attempt to ignite, placing your palm on the sensor and noting the lack of heat flow. The problem must be corrected if there is a flow.

Igniter in a gas boiler

The next possible cause of failure could be the combination of the traction breaker and the sensor contacts. The manipulations with the terminals and resistance measurements are repeated again, the norm of which is up to 3 Ohms. Next, take the open-end wrench “9” and unscrew the nut that secures the thermocouple to the traction breaker. This breaker includes 2 components - a brass sleeve and a plastic insert, the removal of which allows you to completely unscrew the part.

If ignition is unsuccessful in the igniter, the problem may lie in the thermocouple, due to the fact that malfunctions of the solenoid valve rarely occur. Next, for diagnostic purposes, the thermocouple is connected to the solenoid valve and secured with a key. The thermocouple is not hopeless and can be corrected; for example, it is possible to solder a disconnected contact instead of irrationally replacing the part.

Do not forget to inspect the dielectric gasket and return the thermocouple to its place, paying attention to the location of the tip. Let us remind you that cleaning procedures are carried out with an alcohol-containing liquid and high-quality drying is carried out before assembly.

From this article you will learn what problems can arise in the automation of gas boilers, why it is impossible to ignite the igniter, which is why the boiler can turn off for no reason, and most importantly, we will figure out what actions need to be taken to diagnose and eliminate this malfunction.

Owners of non-volatile gas boilers are probably familiar with the situation when, for some reason, it is not possible to ignite the boiler, or a lot of time is spent on ignition. In this case, the problem lies in the boiler automation.

Today, the gas valve EUROSIT 630 is most often used in domestic and imported gas equipment. It is this valve that performs the function of maintaining the set coolant temperature and, in the event of an emergency, completely shuts off the gas supply to the burners. Further starting of boilers with such automation is only possible manually. However, the cause of a boiler emergency shutdown is not always a real accident.

Let's try to understand this using the example of the Zhitomir-3 boiler. Automatically, it provides protection against loss of flame on the igniter and loss of traction.

Note:

All gas-hazardous work must be carried out exclusively by representatives of specialized organizations that have the appropriate permits. Therefore, this article is provided for informational purposes only. This article will also help you monitor the work of the technician and, perhaps, save you from the need to purchase unnecessary spare parts.

Let's decide what we will call igniting the igniter. The EUROSIT 630 valve control knob allows you to switch the boiler to three main modes:

- disabled;

- ignition;

- temperature adjustment (1–7).

To ignite the pilot burner (igniter), you must move the control knob to the “ignition” (spark) position, press it and use the piezo ignition button to ignite the pilot burner. Next, the handle is held for several seconds (no more than 30) and released. The pilot light should continue to burn. This is what we will call igniting the igniter. If the pilot light goes out, you need to repeat the procedure several more times. If this does not help, you need to look for the problem.

At the moment the igniter is ignited, the flame heats the thermocouple, which in turn generates an EMF (approximately 25 mV for working SIT thermocouples), which is supplied through the automation sensor(s) circuit to the solenoid valve.

By pressing the gas valve handle, we manually open the solenoid valve, supplying gas to the igniter, which, if the equipment is operating correctly, is held by the EMF generated by the thermocouple and remains in the open position after the handle is released. The thermocouple itself performs the function of protecting against loss of flame on the igniter. The sensors located in the circuit are normally closed and, when triggered, open their contacts, ensuring complete shutdown of the boiler.

Types of valves

The gas valve is responsible for regulating the gas flow, its distribution and shutting off. The valve has a hole for the passage of gas (the so-called seat), closed by a piston or disk.

Depending on the number of inputs and operating positions, there are one-way, two-way and three-way valves, as well as modulating ones:

- a one-way valve is either open or closed;

- two-way is equipped with one input and two outputs. The start is smoother due to opening through an intermediate position;

- three-way valves are installed on boilers with two-stage power;

- With the help of modulating valves the power can be adjusted smoothly.

Accordingly, gas burners () with automation for heating boilers come with single-stage power control, two-stage or modulated.

Combustion products and the cause of their occurrence

- soot;

- resin;

- tar.

The reasons for the appearance of these substances are the following important points:

- Causes of soot:

- there is not enough oxygen for the combustion process;

- Fuel combustion temperature is too low.

- Factors influencing the appearance of resin:

- low-quality fuel is used;

- the fuel material has a high degree of humidity;

- the boiler operates at low temperature;

- Too much fuel is loaded into the firebox.

- Tar appears in the following cases:

- weak air flow into the combustion chamber of the pyrolysis boiler;

- incorrect design of the unit;

- low height chimney.

As we can see, the main reasons for the appearance of harmful substances are poor fuel and the technical aspects of organizing the combustion process.

Experts advise: use only high quality fuel - otherwise the wear and tear on the boiler will rapidly increase.

The situation with Zhytomyr

This brand is famous for its devices with piezo ignition. For an example of burner cleaning, the Zhytomyr 3 model, equipped with EURO SIT technology, is used.

The following list of tools is required for the operation:

- Screwdriver. A flat tip is required.

- Open-end wrenches.

- A regular brush and its analogues for cleaning metal products.

- Yorshik.

After blocking the gas with a key, remove the screw securing the boiler door. It is removed entirely. This way the core of the unit becomes open.

The main burner is concentrated in its lower zone. To remove it and subsequently clean it, you need:

- Disconnect the cable from which the piezoelectric element and electric ignition operate.

- Use a key to remove the thermocouple and its clamp from the valve.

- Mark with a marker the distance of immersion of the nozzle into the burner itself. This will make it easier to return it to the correct position.

- Unscrew the nut securing the valve to the burner. Communication goes through a copper tube.

- Carry out the same manipulations with the ignition electrode.

- Using a screwdriver, remove the two fixing nuts of the other burner (pilot). There is a gasket underneath. If it is damaged or deformed, replace it.

- Remove the nozzle from the burner. If the process is difficult, gently tap around this part with a key.

To dismantle the main burner, the screw connecting it to the boiler body is released. Then it is removed. To do this, you need to grab its lower part and the copper tube and sharply pull it out of the valve.

The screw that fixes the insertion distance of the nozzle part is loosened.

For the cleaning itself, a brush and a brush are used. Carbon deposits are carefully removed.

A vacuum cleaner is used to clean the holes. All work affects both external and internal components.

This algorithm is also suitable for the procedure with the burner of the Dani AOGV series devices, for example -11.5; 23.2 and 29.

You can do the same with many similar units: Aton AOGV 16-EM, ZhMZ-AOGV 17, etc.

The injectors also need to be cleaned. Carbon deposits from the top side are removed with a brush. A wire or thin needle is used to clean the holes.

After this, all the parts are assembled using the reverse algorithm.

Furniture items

A few examples of furnishing a kitchen combined with a living room:

- 1. Sofa. It becomes an object that zones space. The sofa is placed with its back facing the place where food is prepared. In small rooms (less than 20 sq m) a corner is placed, which is placed against a wall installed perpendicular or parallel to the kitchen.

- 2. Set. According to designers, minimalist models without elaborate details look modern. The service, vases or glasses are placed on an open shelf. You can buy a fashionable display case for them. Furniture is placed near the wall. If the space is large (20 sq. m, 25 sq. m or 30 sq. m), then in the central part you can install an island, which also has sections for kitchen appliances.

- 3. Furniture set. The style should be combined with the design of both rooms. In small rooms, a compact table and chairs made of transparent material or painted in light colors look good. You can add a table with a round top to your living room interior. In spacious rooms, the kit is installed near the wall or in the central part. An elongated rectangular dining table would look good here.

Rules for using a gas boiler

Let's look at how to properly use a gas boiler.

Ignition instructions

One of the design components of gas boilers that distinguishes them from each other is the ignition system. Therefore, when starting boilers of different types, there may be certain subtleties. Before putting the device into operation, you must study the operating instructions. The ignition sequence looks like this:

1. Visual inspection of the system for leaks. To do this, set the thermostat to maximum. In this case, automatic switching occurs.

2. When performing this operation, the boiler must be connected to the electrical network. After it starts working, a slight noise will be heard and after filling the coolant system, the automatic ignition of the system will work and the boiler will return to the set operating modes.

How to turn off the boiler correctly

If the boiler is not planned to be used for a certain period of time, then it makes sense to turn it off. First of all, close the gas supply valve. Installed control automation and pumps must be de-energized. Of course, we must not forget about shutting off the supply of coolant and water if it is used to heat it. If it is expected that the temperature may drop below zero during downtime, then the water will have to be drained.

Self-diagnosis

The operation of gas equipment will be significantly simplified if it has a self-diagnosis system. Most manufacturers have been installing similar systems on their products for quite some time. Error messages are displayed on the built-in monitor. For some manufacturers, error A7 indicates a malfunction of the temperature sensor. Self-diagnosis of gas equipment simplifies its operation. The decoding of the codes that are displayed on the monitor is usually given in the instruction manual.

Frost protection

One of the key rules for the safe operation of gas equipment is to guarantee the presence of a minimum temperature of the working environment, which will not allow it to freeze. If the water poured into the heating system freezes, this will lead to irreparable consequences, in particular, rupture of the radiator.

Most models in use today require constant monitoring of the condition of the coolant. They provide protection against freezing; one of the components is a circulation pump, which is turned on to ensure forced movement of water (coolant) through the system. As a rule, it turns on automatically when the water reaches a temperature of 10 degrees. If, for certain reasons, the temperature drops even lower, then in addition to the pump, an auxiliary heater is turned on, heating the water to a predetermined level, for example, 18 degrees.

What to do if problems occur

Even during proper operation of boiler equipment, certain problems may occur. The following interruptions may occur in some boilers:

- boiler overheating;

- temperature sensor failed;

- The boiler is too noisy during operation.

As a rule, some breakdowns can be caused by violations of operating conditions, manufacturing defects, a drop in pressure in the gas pipeline, a voltage drop in the supply network, or errors made during the installation of a gas boiler.

Some owners of gas devices try to solve the problems themselves, but it is more advisable to call specialists from a service organization.

General safety rules

Manufacturers of gas heating equipment pay a lot of attention to its safety, despite this, equipment of this class can be a source of danger

The Fire Department of the Ministry of Emergency Situations does not tire of constantly talking about precautionary measures, in particular, it is unacceptable to purchase gas boiler equipment from companies that do not have the appropriate license. The delivery package must include a manual or operating instructions

Installation of equipment and its commissioning can only be carried out by employees of relevant organizations. Such equipment must undergo a technical condition check. As a rule, this is done once a year.

In the boiler room it is unacceptable to store items that are not related to the operation or maintenance of the installed equipment. And yet, the upper limit of heating the coolant should not exceed 90 degrees.

Preventive recommendations

Each user manual supplied to the heating boiler by the manufacturer must contain a section describing the mandatory periodic maintenance of the device.

The owner can call service center employees for this, or can perform maintenance work independently.

Before starting work, be sure to turn off the gas supply and power supply to the device.

To carry out maintenance you will need:

- wire brush;

- a toothbrush with hard bristles;

- fine grain skin;

- air compressor or enema;

- thin awl or needle;

- vacuum cleaner;

- soap solution;

- rags.

To carry out maintenance, you will need to remove the device housing. On some boilers you will have to unscrew several screws to do this, while other models are equipped with quick-release fasteners.

For maintenance you will have to remove the body of the gas boiler

After removing the casing, you can begin to remove carbon deposits from various parts and components. These include:

- heat exchanger radiators;

- gas-burners;

- igniter;

- security sensors.

Using the tools listed above and without applying excessive force, you need to carefully clean off the carbon deposits. After this, you need to blow out dust and carbon deposits from the cavities and openings of the unit using compressed air.

The next stage is cleaning the holes of the burner nozzles and igniter. For this, a needle or thin awl is used. After cleaning, they also need to be blown with compressed air.

The sensor electrodes and contacts of the electric ignition system are cleaned with careful, gentle movements using sandpaper and wiped with a rag.

At the end of the service, the unit should be vacuumed and, where possible, wiped with damp wipes or rags.

After installing the housing in place, you should check the draft force of the chimney and the absence of gas leaks in the connections.

Despite the fact that a gas boiler is a rather complex device, in some cases it can be repaired with your own hands. It is enough to follow the above repair instructions, and in difficult cases contact a workshop. Regular maintenance extends the useful life of a gas boiler and several times reduces the likelihood of its unexpected failure.

Gas boiler systems are the most popular devices for heating and creating hot water supply in private and apartment buildings. This equipment is functional, reliable and, with proper care, can serve its owner for decades. But any technology has the unpleasant property of breaking down, and at the most inopportune moment.

According to safety rules, repairs of gas boilers must be carried out by personnel who have been trained and have a gas industry permit. There are times when a gas boiler repairman is not “at hand” or the breakdown of the boiler installation is not related to the “gas components” of the heating system (CO). Knowing the main causes of gas boiler breakdowns, you can always repair it yourself, without involving expensive specialists in this process.

Flushing

How to clean the heat exchanger of a gas boiler from scale with your own hands? If there is a small amount of plaque inside, you can get by with manual washing using a citric acid solution.

If there is a thick layer of scale, you will need a washing unit that will circulate the detergent for several hours. A 10-liter tank with a pump is suitable for this purpose (you can use a circulation pump from the circuit). Two hoses from the pump are connected to two heat exchanger pipes.

There are three cleaning methods:

- mechanical;

- chemical;

- hydrodynamic.

In the first case, you can use a brush, scraper, or vacuum cleaner to remove plaque. Heat exchanger parts are pre-soaked in cleaning solutions.

During chemical treatment, an acid wash solution is pumped into the system using a booster and driven through a heat exchanger for several hours. Acidic solutions are good at removing ferrous and carbonate sediment. At the end of cleaning, the product is drained and a neutralizing agent is added.

The hydrodynamic method is the injection of water with abrasives into the system under pressure. In this way, the internal surfaces are cleaned mechanically, but the cleaning efficiency is higher than when processed manually. Flushing can be done without dismantling the system, but it is quite expensive. When cleaning yourself, you need to monitor the pressure in the circuits to avoid rupture of the heat exchanger.

Settings failed

Settings are a “trouble” that can affect the owners of almost all energy-dependent boiler systems, regardless of the manufacturer and brand of equipment. The problem may be a voltage drop that caused the settings to fail. But, more often than not, the boiler begins to work inadequately after the intervention of the owner or “would-be repairmen” from the nearest workshop.

Advice: Repairing the control board of a gas boiler yourself is a thankless task: any problem related to electronics can lead to failure of the boiler installation or, worse, to an emergency. Entrust the competent adjustment of the boiler to professionals.

Connection nuances and verification

Connect the thermoelectric converter to the measuring device using a compensation cable. In order to minimize the measurement error as much as possible, the cores of this wire are made of the same material as the sensor itself.

Check the functionality of the thermocouple as follows:

- one end of the device is connected to a multimeter;

- the other end is manually heated using a lighter or gas torch.

To check the functionality of the thermocouple, connect one end of the device to a multimeter.

If the device is in good condition, this is indicated by the presence of a voltage in the region of 50 mV.

Working with AOGV

It begins when the gas supply is blocked - the corresponding valve closes. And this is a general principle for similar work with any boilers and columns.

How to clean the burner of an AOGV gas boiler? After shutting off the gas, this element is removed from its position. The burner has a nozzle

It is carefully unscrewed and carefully cleaned with a brush. The burner itself is cleaned by blowing using a special pump

Then the nozzle and burner are returned to their place.

These are general criteria. And the details are presented on the next two models.

First. AOGV 11.6-3. This is a reliable and practical device.

But after a certain period of operation, it is thoroughly cleaned. The process goes like this:

The burner block is removed

To do this, the pan of the apparatus is rotated, and three tubes are disconnected from the automation unit: contact, gas and thermocouples. Carefully unscrew the nuts located on the fittings of the automation mechanism. The paronite gasket on the main gas pipe is removed and its conditions are studied. If it is damaged, it needs to be replaced. The marked pallet is taken out through the groove, which is as close as possible to the tubes

The casing is also pulled out along with it. When fixing the lower part of the tray, point it towards you and remove the remaining holders (two pieces) from the engagement. This entire assembly falls to the floor. The main burner is examined and cleaned. The igniter nozzle is inspected. The wick and thermocouple are unscrewed. The box-shaped casing is separated from the pilot burner. This clears the way to the nozzle. If it is brass and there is plaque on it, it can be removed with fine-grained sandpaper. Cleaning the nozzle. To do this, thin copper wire and a blowing method under high pressure are used. The second action is carried out by a special pump on the side where the tube is connected to the tee. The same sandpaper is used to very carefully clean the bend of the thermocouple tube.

After this work, all the parts are assembled using the reverse algorithm. Smoothly, avoiding distortions, lift the entire block. The burner should be inside the housing, and the igniter and thermocouple should not touch the casing flange.

From the side of the tubes, the entire assembly should be tilted towards itself with a slight downward slope. The opposite side of the tray should rise.

Then feed it forward and simultaneously put on a pair of distant holds. They should be on the casing flange. The nearest hook goes to a cut groove. After it enters there, the entire pallet rotates in the opposite direction to the clockwise direction. The gas pipe should be positioned only under its branch pipe of the automation unit.

Next, it is tested how correctly the gaskets fit, and all the tubes are returned to their places. The wrench tightens the nuts on two tubes: the igniter and the gas tube.

Before reassembling the thermocouple tube, its contact areas are carefully but carefully cleaned. The nut here is tightened with your fingers.

The final stage is to check the tightness of all connections for potential leaks. If they are absent, the boiler turns on. If available, these places are covered with sealant, the nuts are tightened.

The second model is AOGV-23.2-1 Zhukovsky.

It works like this:

- The nut is unscrewed so that the gas pipe passes through.

- The angle, igniter and thermocouple are unscrewed.

- All burners in the set stretch outward and extend to the side towards the user. If there are difficulties with their movement, loosen and unscrew the studs with pliers. Clean all jets and other components.

- Disassembly of burners. To do this, unscrew 4 pins on both sides.

- The plates with slots are removed from the top of the burners, then the springs. All parts are thoroughly cleaned.

- Reassemble all elements in reverse order.

After reassembly, a leak test is carried out to examine how tightly the burners adhere to the body.

Other models

In practice, cleaning burners follows the same principles. The differences lie in their removal and reassembly.

The following examples are provided:

For example, the Helios AOGV 4 parapet apparatus is equipped with Eurosvit 360 automation and burners of the European brands Bray and Polidoro.

The burner set is removed following the example of the Zhitomir process. A pump is used to clean the nozzle, and hard brushes are used to clean the surfaces.

The Conord line stands out in particular.

The automation variations here are:

- AGU-T-M (Russia),

- "Eurosvit" (Italy),

- Honeywell (USA).

The most popular is the second variation:

It includes a sectional burner, Polidoro tubes, igniter, thermocouple, gas valve, temperature indicator and wires.

A similar system is available in the Lemax Premium 12.5 model.

Only the burner here is micro-flare. The mechanism is very easily removed by removing the top cover and lightly unscrewing the fixing bolts.

Its analogues are also found in the Siberia models.

Ecological burners "Vorgas" are used here.

Does not lag behind in this regard. Here its models Novella Maxima 108 N RAI and Mynute Boiler stand out.

Honeywell automation looks like this:

It has a similar operating principle to the Eurosvit system. The differences lie in the materials of some components.

It is often found in wall-mounted modifications, for example in Baksi Fortech 24

It also has an ecological burner that leaves no combustion products.

An equally popular device is the Ariston ALTEAS X 24 FF NG.

Many Daewoo models operate with similar automation. For example – DGB 200 MSC.

Whatever model or brand you have, strictly follow the suggested instructions for removing and reinstalling the burner block. Clean it thoroughly with the right products 1-2 times a year. Maintain other mechanisms as well. And then your boiler will work properly for a long period.

Causes and consequences of clogging

Energy-dependent ones are in turn divided into:

- gas processing;

- electrical installations;

- solid fuel and liquid fuel equipment;

- combined models.

Volatile boilers may turn off for a number of reasons:

- voltage drops and surges in power lines

- lack of electricity

- factory settings failure.

Often used in homes: AOGV, Zhukovsky boiler, gas “Ochag”, Lemax, Signal, Conord.

Do-it-yourself furnace: drawing, operation diagram. Read here.

Connection to the city water supply network: documents, prices:

Mechanical ones may work intermittently due to wind flow entering the chimney. In addition, due to insufficient oxygen, the flame may go out

You should pay attention to the hood (cheaper models do not always have it)

If the chimney becomes dirty, modern devices have a warning system that will notify you of problems and the need for cleaning.

Air turbine

Bearings are the most problematic part of any fan. Due to the increase in the coefficient of friction in the bearing, heating increases and the rotation speed of the rotor, and therefore the blades, significantly decreases. There is another reason for the heating of the housing associated with a decrease in the performance of the air turbine - interturn short circuit.

In the first case, you can carry out the repair yourself by unscrewing the device and lubricating the bearing with “graphite” or any other high-temperature-resistant lubricant. In case of problems with the motor winding, it is unlikely that it will be possible to solve this issue without the intervention of specialists.

How to check it

Keeping your home safe is a working thermocouple sensor. Several times a year, the thermocouple requires mandatory checks and adjustments. To do this, invite a specialist who will perform a safe and accurate analysis of the device.

When checking thermocouple readings, consider the measurement quality of the device itself by systematically checking its operation.

Reasons for incorrect operation of the thermocouple:

- incorrect soldering of two metal rods;

- presence of electrical noise;

- you smell gas, there is a leak;

- thermoelectricity is inhomogeneous.

To resolve these issues, during device installation you should:

- choose a thermocouple with thick and large wire;

- avoid temperature changes;

- do not allow tension and vibration of the metal wire;

- use a sensor that has a working temperature spread.

You need to check the serviceability of the thermocouple by following the step-by-step instructions.

- The thermocouple has two ends. When checking, one of them must be heated with a flame from the igniter, and the second must be secured to the thread of the valve (electromagnetic) using a nut.

- The next step is to separate it from the boiler. Then you need to ensure a stable flame. A gas burner is also used for this purpose. But experts advise using a candle flame.

- The tip of the device is immersed in the flame, it should be approximately 1 cm above the flame. Here you need to remember that the fire heats the device to almost half, so it is better to hold it by the tip.

- Next, a tester is used that determines millivolts. It is connected to the output contact and to the body of the thermocouple itself.

- If the thermocouple is working properly, then 30 seconds after heating the result will be from 17 to 25 mV. But if this indicator does not exceed the minimum threshold, then this means that it is faulty.

You can find out more about how to replace a thermocouple on a gas stove.

The thermocouple for a gas boiler is a thermoelectric converter for automatic control and monitoring systems of gas equipment. The device serves as the main element of gas control protection and is designed to ensure the fastest possible shutdown of the gas supply in the event the flame goes out.

Preventive recommendations

It’s not for nothing that they say: the best repair is prevention. Gas boilers require annual preventative maintenance, which must be carried out before the start of the heating season.

If possible, maintenance should be carried out twice a year: before the start of the heating season and after it ends.

Check all previously discussed boiler elements to ensure they are in good working order. Follow the prevention recommendations given by the manufacturer in the instructions specific to your boiler. Correct any problems that arise in a timely manner, if possible.

Remember! A gas boiler is a potentially dangerous piece of equipment. If it is used incorrectly and problems are not corrected in a timely manner, irreparable consequences may occur. Therefore, be careful and do not carry out any repair work if you doubt your abilities and the correctness of your actions. Otherwise, follow the instructions received.

Cleaning methods

Cleaning is carried out in two ways: mechanical and chemical

Mechanical cleaning

The cleaning method is imperfect and involves mechanical action. Soot should be carefully removed so as not to damage the internal surface of the boiler and parts, which can subsequently lead to metal corrosion. Often the tools come with the boiler - these are pipe cleaners, brushes and scrapers. It is also possible to use air cleaning, when warm air is supplied under pressure.

Dry cleaning

It is recommended to apply cleaning agents while wearing PPE (personal protective equipment); rubber-based gloves are usually used, this will protect the skin from interaction with harmful substances. Chemicals clean not only soot, but also metal, which can further lead to its destruction. This method is best used on minor dirt and small areas of contamination.

Hydrodynamic cleaning

Hydrodynamic cleaning or how to clean soot from a diesel boiler.

It is used in boilers with a small thickness of contamination, as well as when speed of execution is required. Equipment for such washing consists of:

- pump and

- containers with water supplied under high pressure.

Thanks to this cleaning, soot and soot are removed quite quickly, but this method can only be used by specialists and is not recommended at home.

Booster cleaning

The procedure for flushing the heat exchanger with a booster (using the example of cleaning a Zhukovsky boiler from soot):

- First you need to disconnect the pipes from the heating system.

- Next, connect a booster hose to one of them to supply the reagent.

- We connect the second pipe to the second end of the hose. The spent reagent will be removed through it. This closes the system and the reagent will circulate through the pipes.

- After cleaning, the solution must be drained from the tube.

- Rinse the heat exchanger itself with sufficient water.

Booster is a device for chemical cleaning. Thanks to it, the reagents circulate autonomously.

During such cleaning, it is recommended to change the reagent several times, since the old one gradually reduces its properties. This method is most often carried out by specialists.

An effective way to descale

To carry out the highest quality cleaning of equipment, you can use a modern device - a booster. It will effectively solve the problem of how to flush a gas boiler from limescale.

What does the booster include:

- circulation pump;

- container for loading reagents;

- electric heating part.

The booster functions as follows:

- the reagent is heated in a special container (in order to increase its cleaning properties);

- the circulation pump pumps the heated reagent into the coil;

- chemicals circulate through the heat exchanger and clean the walls;

- the spent reagent with dirt pours out.

The heat exchanger must be cleaned regularly, at least once a year. However, this procedure can be repeated more often if the quality of the coolant is very low. If ordinary tap water is poured into the system, then it is very simple to determine this: observe how quickly scale forms on the kettle. Hard water “suffers” from this deficiency.

Atmospheric burners

The presence of an atmospheric burner significantly simplifies the design of heating devices. Such devices operate as a result of the natural flow of oxygen, and chimneys are installed to remove combustion products. Since oxygen is taken from the room, it is necessary to provide high-quality ventilation.

The advantages of boilers with an atmospheric gas burner are as follows:

- A simple design device, which has a positive effect on the cost of the equipment.

- Low noise level. There are no additional fans in the device, only the roar of the flame is heard.

- High degree of reliability. Since the device consists of a minimum number of components, it rarely breaks down.

- Energy independence. Since the operation of the unit does not depend on the availability of electricity, it can be used in homes where the power supply is turned off.

There are also negative points:

- Low efficiency. Boilers with closed burners have a more advanced design, they are more efficient and economical.

- Mandatory installation of a chimney, which must be brought to the roof, which entails additional financial costs.

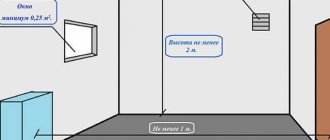

- The boiler should be installed under a gas burner in a room specially designed for this purpose, where there is a window and ventilation, and such requirements are sometimes problematic to fulfill.

The possibility of incomplete combustion of gaseous fuel cannot be ruled out either.

How to clean an AOGV boiler

For this operation you will need a regular plastic bottle cleaning brush. It can be purchased at a hardware store and is perfect for cleaning vertical channels. Tie it with electrical tape to a wooden stick so that you can easily go through the channels along their entire height. In order not to spread excess dirt in the boiler room, take everything that can be moved out into the yard for cleaning.

- Start cleaning from the top plane of the heat exchanger, clean off and sweep down all the soot.

- Then comes the turn of cleaning the channels. The soot will come off the walls quite easily if it has not yet hardened, otherwise you will have to make some effort.

- After completing the cleaning process of the boiler itself, proceed to the removed components and parts. Clean the top cover of the heat exchanger. After this, remove layers of soot on the top cover of the boiler itself and from the hood.

- Lastly, use a brush to brush away the soot that has accumulated from above from the burner block; the burner itself is already clean.

Immediately lightly clean the tube with fine sandpaper. This completes the process of cleaning the boiler and its parts. Proceed to reassembling the AOGV boiler.